tft lcd fingerprint on display free sample

This month, I planned to develop a fingerprint door lock project. When I selected the fingerprint identification module, the project was suspended. However, I thought that since the fingerprint identification module had been purchased, I would simply test it.

This fingerprint module can be easily purchased online, connected over UART to an MCU board. It supports fingerprint scanning, fingerprint entry, fingerprint comparison, and fingerprint deletion.

Since the fingerprint module manufacturer provides a demo program for STM32F103 series microcontrollers, I bought a small development board based on STM32F103C8T6.

The demo program of the fingerprint module uses LED lights to prompt the user to enter the fingerprint and compare the status (success or failure). But I want to use an LCD display, so I chose a 480×272 resolution serial LCD display. The specific model of this display is STONE STVC050WT-01, which communicates with MCU through UART, and will be covered in later chapters.

The UART fingerprint reader module is powered by STM32F205 high-speed digital processor from STMicro and integrates a fingerprint algorithm (TFS-9), as well as a high-precision optical sensor (TFS-d400). It supports fingerprint entry, image processing, feature value extraction, template generation, template storage, fingerprint comparison, and search. It exposes a UART interface to be driven from a host microcontroller or processor.

Sensitive fingerprint sensing and fast identification speed: the fingerprint module adopts high-precision optical path and imaging components, so only hands are needed when using it.

Easy development: serial port UART operation (directly connect to any single-chip microcomputer with serial port), extremely simple operation. The company provides demo software, learning software, MCU routines, and related tools.

Typical applications include fingerprint locks, fingerprint safes, fingerprint access control, fingerprint attendance, intercoms, personnel identification, permission management, etc…

In this project, I would like to use STONE STVC050WT-01 TFT LCD to display the status of the fingerprint module (entry status, comparison status and deletion of fingerprint data). This display comes with a driver chip, and development software is provided for user interface development. The user simply needs to add the designed UI picture through the software as well as any button or text box as needed, and then generate the configuration file to flash into the display.

In theory, the STONE display and fingerprint module can communicate directly. However, due to the different communication data protocols, it is impossible to establish communication. Therefore, an MCU is still needed to handle serial communication.

Keil vision is an integrated development environment developed by Keil. Currently, there are several versions of Vision2, Vision3, Vision4, and Vision5. In 2005, Keil was acquired by Arm. In March 2011, the latest integrated development environment Realview MDK development tool released by Arm integrated the latest version of Keil uvision4, and its compiler and debugging tool were optimized for Arm devices.

The STM32F103C8T6 development board and STVC050WT-01 TFT-LCD display are connected through UART, and then the STM32F103C8T6 development board and fingerprint module are also connected through UART.

First of all, we need to design a UI display image, which can be designed with PhotoShop software or other image design tools. After designing the UI display image, save the image as JPG format. Here’s the UI I designed in Photoshop.

The UI includes a status bar that shows fingerprint verification in real-time, so you need to add a font, as well as text display components and buttons.

Once the UI design above is complete, you can generate the configuration file and download it to the STVC050WT-01 display, which is described in the STONE development materials.

Perform step 1 to generate the configuration file, then insert the USB flash drive into the computer. The flash drive will display. Then click “Download to u-disk” to download the configuration file to the USB flash drive, and then insert the USB flash drive into STVC050WT-01 to complete the upgrade.

The core part is the driver circuit, which is integrated with an STM32F2 series chip. The fingerprint algorithm and scanning algorithm are embedded into the chip, and UART communication is used to get the results making it very convenient for application developers.

The first time, you can use a Windows PC to communicate with the fingerprint module through the serial port to do testing. You can find more details on Waveshare Wiki (in Chinese).

Visit the official website of the fingerprint module supplier, download the fingerprint module demo program (示例程序), and then open the program with KEIL software.

If you ended up on this page doing normal allowed operations, please contact our support at support@mdpi.com. Please include what you were doing when this page came up and the Ray ID & Your IP found at the

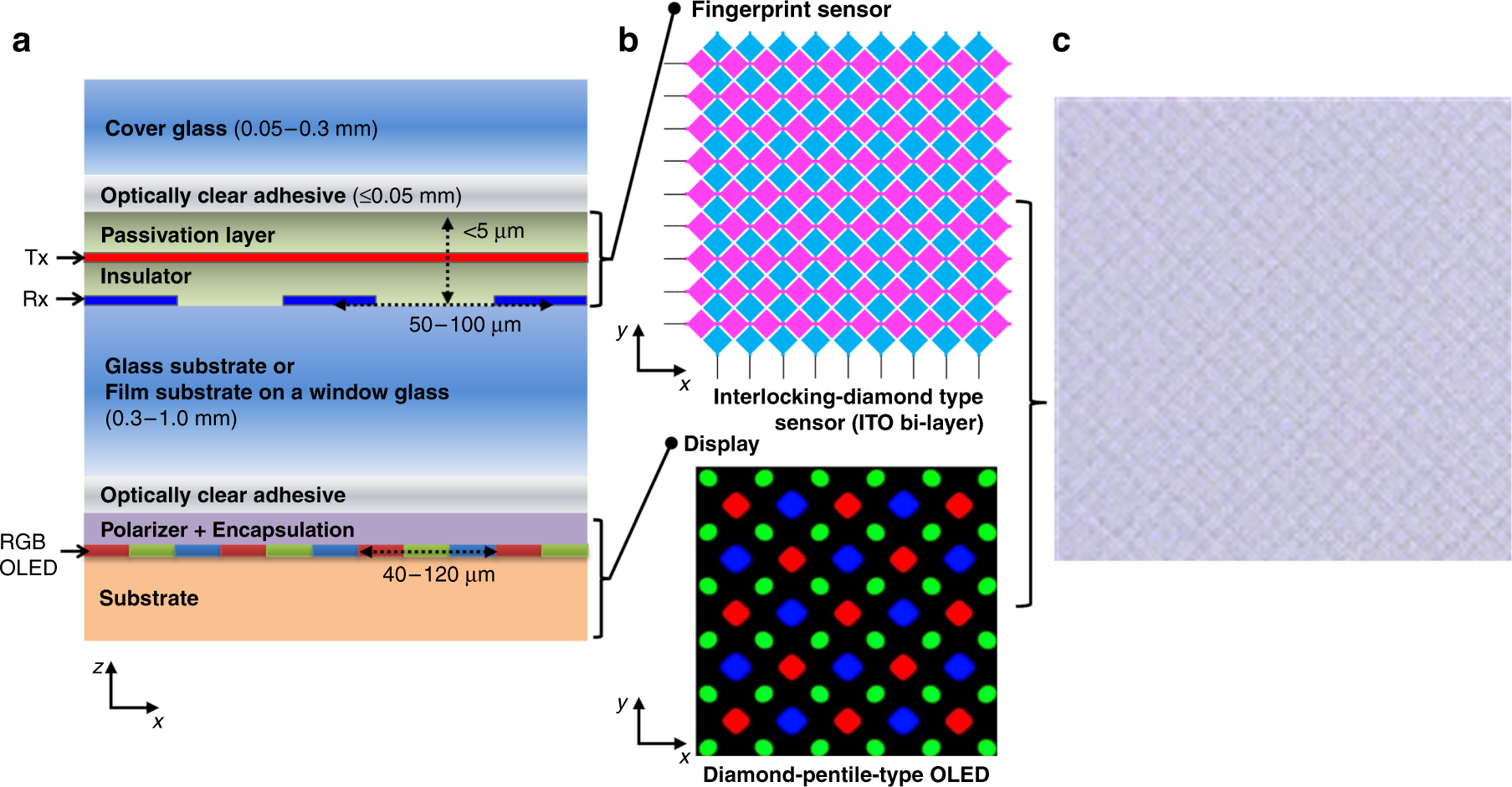

Considering the nature of the on-screen fingerprint sensor, which must acquire signals at regular intervals on a digital display device, Moiré patterns cannot be avoided. Therefore, the Moiré pattern should be made imperceptible through a proper combination of sensor geometrical parameters. A spectral analysis of overlapped display–sensor pattern pairs in the frequency domain can be carried out by Fourier transform to predict the Moiré pattern periods, directions, and strengths, i.e., perceptual contrastN × N pixel images of various overlapped patterns were prepared, and the discrete Fourier transform (DFT) was applied to the image matrices to perform spectral analysis. When the image is expressed as the gray-level intensity distribution function f(x,y), where x = 0, 1, 2, …, N − 1 and y = 0, 1, 2, …, N − 1, it can be Fourier transformed into

where u and v are the horizontal and vertical components of the frequency vector, respectively. F(u,v) provides the amplitude, which corresponds to the perceptual contrast of the Moiré pattern, at the spatial frequency represented by u and v, and can be plotted as in Fig. 2a (ref. 2a–1, a–2 and clearly shown around the origin in Fig. 2 a–3, denote the spatial frequency vector of the patterns in the overlapped images. The amplitude is represented by the brightness of the dots. The yellow circle in Fig. 2a represents the visibility circle beyond that fine details of the pattern cannot be detected by the human eye at a viewing distance of 40 cm. The viewing distance was assumed to be ~40 cm, as the mean eye–screen distance is ~33–40 cm for mobile devices

where fS is the spatial frequency of the visual stimuli in cycles per degree. The function is normalized to a maximum value of 1, as shown in Fig. 2d (ref.

a DFT calculation results, b approximate real-space pattern extraction images, and c observed Moiré patterns for the sensors with 1 a pattern pitch of 20 μm and a rotation angle of 0°, 2 a pattern pitch of 25 μm and a rotation angle of 38°, and 3 a pattern pitch of 45 μm and a rotation angle of 0° on a 570 ppi smartphone display. d Human CSFe Binary Moiré pattern extraction scheme

In addition, approximate Moiré patterns were obtained by extracting bright and dark areas of overlapped two-dimensional (2D) images directly in the image domain as a complementary approach to the spectrum analysis. We extracted the expected Moiré patterns by converting the overlapped grayscale images and their inversions into binary images, as simply described in Fig. 2e. As the binarization simplifies the pattern and enhances the contrast, patterns can be easily recognized from at least one of the two binary images, either the original or the inverse, and compared with the observed results.

These analysis methods were used to predict Moiré patterns for the selected smartphone display (diamond-pentile-type OLED, 570 ppi), and diamond-type ITO sensors with electrode pitches of 20–100 μm at an interval of 1 μm and rotation angles of 0–45° every 1°. Owing to the fourfold symmetry (Fig. 1b), the angle was varied from 0 to 45°. DFT calculations and pattern extraction were performed with overlap of a fixed display pattern image and rotated sensor pattern images in grayscale. Some of the analysis results are shown in Fig. 2a, b. Figure 2a–1 shows the DFT calculation result for the sensor pattern with a pitch of 20 μm without rotation. Inside the visibility circle, four manifest white dots are observed, which denote the frequency vectors of the main Moiré pattern. The directions and periods of the Moiré patterns in real space can be obtained by using the frequency vectors. The directions and periods coincide with those of the extracted real-space pattern in Fig. 2b–1, and the pattern in Fig. 2c–1 obtained by the experimental evaluation presented in the next section. Notably, Fig. 2a–2 predicts more than one pattern period. However, the peaks just outside the visibility circle are considerably higher than those inside the circle, and the pattern corresponding to the outside peaks is dominant, as shown in Fig. 2b–2, c–2. In Fig. 2a–3, the expected Moiré pattern frequency vectors are very close to the origin, thereby suggesting a very noticeable Moiré pattern with a period of several millimeters, as shown in Fig. 2b–3, c–3.

Considering the large number of different pitch and rotation angle combinations, a criterion that can quantify the visibility of the Moiré pattern is required. Therefore, in this study, approximate Moiré visibility (MV) values for each pitch and rotation angle were calculated for comparison and selection of the patterns,

This value quantitatively reflects the perceptual contrast of the pattern filtered with the CSF in the frequency domain. However, this value needs to be used carefully to narrow the search range, instead of finding the minimum and selecting the optimal pattern, as the simple summation can be misleading. For example, the values can be similar in the cases of one very bright dot in the spectral analysis plot and of many less bright dots, although the Moiré pattern can be more manifest in the former case. Nevertheless, the MV values significantly vary with changes in the sensor pattern and can be effectively used to narrow our selection of patterns for the next step. The pattern contrast in the image domain can be quantified after inverse Fourier transform of the MV, although the inverse Fourier transform results have limitations similar to those of the MV values3a. The results show that the smallest MV values can be found in the 30 µm pitch case around the rotation angles of 7–12 degrees, 15–20 degrees, and 35–40 degrees. Therefore, most of the candidates were selected from the cases, where the sensor pattern pitch is 30 µm or smaller.

a MV plots calculated for various sensor pitch and rotation angle combinations. b High-resolution camera images showing the Moiré patterns from the 20 candidate sensor patterns. Smartphone screens (c-1) without a fingerprint sensor pattern and (c-2, c-3) with fingerprint sensor patterns on them (c-2: a pattern with a pitch of 25 μm and a rotation angle of 38°, c-3: a pattern with a pitch of 20 μm and a rotation angle of 8°)

After the analysis described above, 55 patterns were fabricated on a glass wafer to obtain an area of 10 mm × 10 mm for each pattern. The other 35 test patterns in addition to the 20 candidate patterns mostly had sensor pitches of ~60–70 µm, which are commonly used in conventional mutual-capacitive fingerprint sensors, and have been verified for sensing capability. The goal was to determine whether a certain angle of rotation could make the sensors with these pitch ranges unexpectedly have minimized Moiré patterns, but the results were negative. The patterns were created using the same process used to fabricate the sensor, except that the electrical connections and pads were omitted. Therefore, the patterns consisted of lower ITO, organic insulator, upper ITO, and organic passivation layers. After fabrication, the glass wafer was diced to obtain the same size as that of the Samsung Galaxy S8 display panel. The diced glass substrate was placed on the smartphone’s full-white-mode OLED with glycerine in between. The generated patterns were carefully observed and evaluated. In addition, grayscale photographic images were acquired in a dark environment with a high-resolution industrial camera used for display panel inspection, as shown in Fig. 3b. The images were carefully acquired to avoid additional Moiré or other artifacts owing to the camera and for consistency with the naked eye observations. Although no standard method has been reported for the quantification of a Moiré pattern, the contrasts of different images of Moiré patterns can be compared with the standard deviations of the image pixels’ gray-level values, and the number of sensor pattern candidates can be reduced. In addition, mean opinion scores, popular indicators of the perceived medium quality3b), and a pattern with a pitch of 25 μm and a rotation angle of 38° (in a dashed square in Fig. 3b) were selected. Larger evaluation samples of these two patterns were generated to cover the whole front side of the smartphone display and compared to the case without the sensor pattern, as shown in Fig. 3c. Except for slight changes in color and brightness, no noticeable Moiré pattern was observed. In addition, no significant difference was observed between the display without a sensor pattern and the display with a sensor on it.

The dimensions of the selected electrode pattern based on the Moiré evaluation are considerably smaller than those of commercial capacitive fingerprint sensor patterns (in the range of 50–100 μm). Thus, the signal-to-noise ratio of the sensor could be significantly decreased, and the sensor might not operate properly. Therefore, a method that can provide a sensor with a pitch sufficiently small optically, but sufficiently large electrically to recognize a fingerprint is required. This can be achieved by connecting several electrode patterns as one unit block and driving the sensor by each block, as shown in Fig. 4b. In this manner, for example, an array of a pattern with a pitch of 25 μm will have a sensing pitch of 75 μm by connecting and controlling three electrodes together on both the signal transmitter (Tx) and receiver (Rx) sides. In other words, a 3 × 3 array of a diamond pattern with a pitch of 25 μm can form a unit sensing block.

a–1 Conventional electrode patterns and sensor driving configuration. a–2 Conceptual rotated electrode patterns with a small pitch, and corresponding sensor driving configuration used in this study. b–1 Mutual capacitance (CM0) without a finger on the cover glass. b–2 Change in capacitance upon finger contact, and mutual capacitance values at the finger ridge and valley areas

The validity of this idea was analyzed by calculating the electrical characteristics, such as the capacitance and resistance, for different sensor patterns by COMSOL Multiphysics® simulations. The Tx and Rx electrode structures in the simulations were interlocking diamond patterns of ITO with a sheet resistance of 11 Ω/sq. In addition, the thickness of the insulating layer between the Tx and Rx layers was assumed to be 1 μm, while the gap between diamonds was set to 8 μm, regardless of the pattern pitch owing to our fabrication capability. First, the mutual capacitances, which are the capacitances between the Tx and Rx electrodes forming each sensing node, were calculated for different cases. When no finger touches the cover surface, the mutual capacitance has the baseline value CM0, as shown in Fig. 4b–1. Once a finger is placed on the cover surface, the mutual capacitance values under the ridge and valley regions of the finger are reduced to CM–R (=CM0 – ΔCRIDGE) and CM–V (=CM0 – ΔCVALLEY), respectively. This occurs as the capacitors under the finger lose charge and the capacitance decreases, but the capacitance changes differ between the finger ridge and valley regions owing to the difference in the distance from the electrodes to the finger surface, as illustrated in Fig. 4b–2. In addition, the Tx and Rx electrode linear resistances (RTx and RRx) were obtained by the simulations.

Table 1 shows the calculation results for several different cases where the sensor patterns are composed of different numbers of arrays, while the fingerprint sensing pixel pitches are in the reasonable range of 70–85 μm, which correspond to resolutions of 300–363 dpi. Fingerprint images in this resolution range can be effectively used in commercial devices employing a pattern-based matching algorithmCM–R and CM–V, denoted ΔCM, is shown in the table instead of the capacitance values because the amplitude of the sensor output signal is determined by ΔCM. The rotation angles of the sensor patterns are not indicated because they do not considerably affect the electrical characteristics. The baseline mutual capacitances, CM0, of the unit sensing patterns composed of n × n arrays increase almost linearly with n if the sensing pixel pitches do not significantly differ. The ΔCM values do not substantially change with the pattern pitch for the analyzed sensor patterns, which implies that the signal levels of the selected sensor patterns with pitches of 20 or 25 μm are approximately the same as that of the standard sensor with a pitch of 70 μm, which is used for a conventional fingerprint sensor under the home button of smartphones. Although larger CM0 values can increase the noise level, all of the values in Table 1 are within the range covered by our integrated chip (IC) for fingerprint sensing. The IC for sensor driving and readout was revised from the commercial touch sensing IC to detect a considerably smaller mutual capacitance difference, while maintaining most of the scheme to filter various noise signals

Our final sensor pattern selection was carried out based on the resistance–capacitance (RC) time constants of the patterns, as they affect the signal acquisition time. The RC time constant can be estimated by using CM0 and RTx in Table 1. Although the resistance of the trace also needs to be considered to obtain the overall resistance (R) from the IC to each sensing node, the traces consist of metal with a very low resistivity and thus do not significantly affect the overall trend of R. The RC constants are expected to increase with decreasing pitch. Accordingly, the array size n in a unit sensing block increases, so CM0 rapidly increases. Although the line resistance of the electrodes per 10 μm, RTx, decreases with decreasing pitch owing to the more electrode lines in the unit sensing block, the decrease in RTx is relatively gradual and cannot change the trend of the RC increase. The time for fingerprint image capture in the 4 × 4 array of the pattern with a pitch of 20 μm with the largest RC time constant can be longer than 200 ms, the conventional limit for fingerprint sensors, at a typical driving frequency of 1 MHz with repetitive signal integration to obtain a sufficiently good fingerprint image. Therefore, the 20 μm 4 × 4 array pattern was excluded to finally select the 25 μm 3 × 3 array with a rotation angle of 38° as our sensor pattern.

Using the selected sensor pattern design, fingerprint sensors were fabricated on glass wafers, and their electrical and optical properties were characterized. The sensors can also be fabricated on the large glass substrates used for the manufacturing of display panels and can be transferred to plastic film substrates if needed. A schematic of the sensor design and optical microscopy images of the fabricated sensor are shown in Fig. 5a, b. The electrodes have smaller diamond shapes with thick and long necks between them compared to conventional touch sensors or fingerprint sensors, as the width of the necks and spacing between adjacent upper and lower diamonds cannot be reduced in proportion to the pitch of the diamond pattern. The width of the necks was maintained at 7 μm to ensure proper resistance levels of the electrodes, while the spacing was maintained at 4 μm to secure the alignment margins. The right image in Fig. 5b shows that three electrode lines are connected to one via, and that one interconnect line exits from the via, as mentioned above.

a (Left) Transparent fingerprint sensor fabricated on a glass substrate, and (right) schematic of sensing and dummy pattern areas and metal interconnects (i.e., traces) connecting the sensor electrodes to the pads for bonding to the FPCB. b Optical microscopy images of (left) part of the sensor pattern area, and (right) a lower section of the sensor pattern and vias connected to the traces. White squares drawn with solid lines and dotted lines indicate lower and upper ITO diamond patterns, respectively. The upper ITO electrodes appear bright in the left image, but are relatively dark in the right image owing to the different lighting and organic coating conditions. c Transmittance and reflectance in the visible wavelength range measured on the sensing area of the fabricated sensor. d Fingerprint images obtained by the sensor

Considering the literature results and preliminary experiments, we targeted an ITO electrode thickness of 200 nm to obtain proper combinations of sheet resistance and transmittance5c. The transmittance is slightly higher than that of the unpatterned ITO layer, as the sensors have gaps between the ITO diamond patterns, as shown in the optical microscopy image in Fig. 5b. The use of proper index-matching layers and coating on the cover glass is expected to improve the transmittance and haze close to the desired values (>90% and <1%, respectively). The transmittance of the electrode material is an important factor with respect to the Moiré issue, as well as the brightness of the display and battery life of the smart device. A higher transmittance implies a lower contrast when the patterns overlap, and thus, a pattern having the same period would be less noticeable according to the CSF. Therefore, the Moiré pattern may not be visible when the transmittance of the electrode is very high, even if the electrode pattern is not rotated or the electrode pitch is not adjusted, as suggested in a previous report

The fabricated sensor with 64 Tx and 128 Rx channels was connected to an IC controller through a flexible printed circuit board (FPCB). Fingerprint images were obtained on a cover glass attached to the sensor with an optically clear adhesive (OCA). The fingerprint sensor authentication rate was evaluated by using our pattern-based matching algorithm and over 10,000 fingerprint images5d. A high contrast is observed between the ridges and valleys of the fingerprint. In addition, features such as ridge endings and bifurcations are clearly visible. Approximately four to five sites of features are obtained in the fingerprint images from the 9.6 mm × 4.8 mm sensing area.

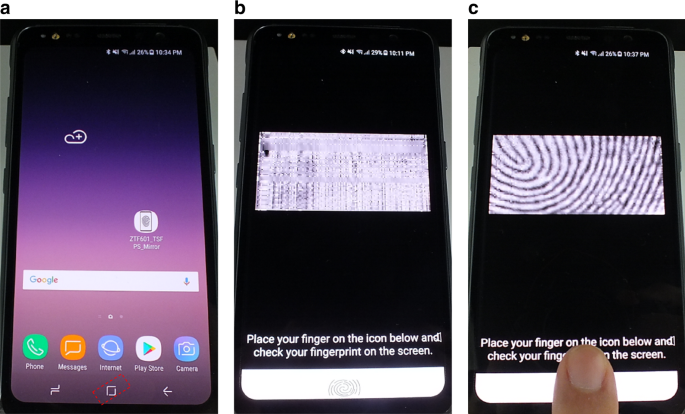

Finally, the sensor modules were assembled into smartphone prototypes. The Samsung Galaxy S8 Active’s window glass was replaced with the sensor wafer, which was diced to have the same dimensions as those of the original window glass and laminated with a cover glass. After the assembly, the sensing area is located at the bottom center of the front surface, where the soft home button is displayed. The remaining area is covered with dummy patterns to make the sensing area indistinguishable. Figure 6a shows a functioning smartphone display with the fingerprint sensor laminated on it. Notably, no reduction in image quality in the whole display area is observed. In addition, the location or size of the fingerprint sensor cannot be identified if they are not clearly indicated, such as by the red dashed slanted rectangle in Fig. 6a. A simple android app for fingerprint sensing demonstration was developed and installed on the prototype device to show enlarged images of the recognized fingerprints on the smartphone display. Clear fingerprint images can be obtained from the sensor on the fully functioning display screen of the smartphone, as shown in Fig. 6b, c. The fingerprint image in Fig. 6c is brighter and has a better contrast compared to the images in Fig. 5d, as real-time image enhancement was applied for demonstration purposes. To the best of our knowledge, this is the first study demonstrating a capacitive-type on-screen fingerprint sensor functioning, while integrated in a smartphone display, not just separately.

a The sensing area is outlined by the red dashed slanted rectangle in the soft home button area, while the display shows the normal home screen. The fingerprint sensing demonstration app shows the b white noise in the absence of objects on the sensor and c fingerprint image when a finger is placed on the sensor

>> Step 1: Connect Anviz device to PC via TCP/ IP or Wi-Fi. (Step 2: Run a browser (Google Chrome is recommended). In this example, the device is set in the server mode and IP address as 192.168.0.218.

>> Step 2: Run the CrossChex and click the "Device" menu on the top. You will be able to see a small blue icon if the device has connected to the CrossChex successfully.

(****** Sometimes devices are not allowed to be updated, this is because of device protection policy. You can use force update mode when this situation occurs. *****)

Jingda®0100-21083A1 is a 1 inch TFT Lcd display module, with 128*96 resolution and ST7735S-G4-1 control IC interface. 1 inch TFT Lcd display can be applied in Fingerprint lock, watch, recorder air purifiers and other smart wearable and Internet intelligent electronic devices make life more intelligent and convenient.

Hot Tags: 1 Inch TFT LCD Display, Manufacturers, Suppliers, Factory, Customized, In Stock, Free Sample, China, Nice Price, Buy Discount, Quality, Latest Selling, Two Years Warranty

All products are 100% tested before shipment. We will do reliability tests, including high & low terperature tests, heat impact test and vibration test as per customer"s special requirements.

We are not only manufacture products,but also provide display solution.We can realize your project from your product concept to real product,to help you save sourcing cost.In the mean time.we provide competitive price,on-time delivery and efficeint work with customers.

HiTech Part is a leading wholesale supplier of cell phone repair parts for over 12 years in consumer electronics business. We offer high-quality repairing parts including LCD assembly, battery, camera and flex cable, etc. for many brands such as Apple, Samsung, Huawei, Sony, LG, and many other brands. Besides, repair & refurbish tools and other mobile accessories are also available in HiTech Part. Having formed a long-term stable and friendly cooperative relationship with 50+ factories, we provide wholesale service for our customers. In HiTech Part, you can enjoy quality products at competitive prices, excellent customer service and one-year warranty with free return labels. Feel free to contact us !

switch (USART_RX_BUF[5]) { case ADDUSER_BTN_ADDR: //printf("User:%d\r\n",GetUserCount()); switch(AddUser(i)) { case ACK_SUCCESS: i++; //printf("finger add success\r\n"); data_send[5]=TEXT_STATUS_ADDR; data_send[7]=USER_SUCESS; UART1_Send_Array(data_send,8); LED2_ON; delay(); LED2_OFF; break; case ACK_FAIL: //printf("fail\r\n"); data_send[5]=TEXT_STATUS_ADDR; data_send[7]=USER_FAIL; UART1_Send_Array(data_send,8); LED3_ON; delay(); LED3_OFF; break; case ACK_FULL: //printf("full\r\n"); data_send[5]=TEXT_STATUS_ADDR;

case VERIFY_BTN_ADDR: switch(VerifyUser()) { case ACK_SUCCESS: //printf("Verify sucess\r\n"); data_send[5]=TEXT_STATUS_ADDR; data_send[7]=USER_SUCESS; UART1_Send_Array(data_send,8); LED2_ON;

The Google Pixel 7 features a beautiful, almost bezel-free 6.3-inch display. Unfortunately, even though Google has plastered it with Corning’s Gorilla Glass Victus, the display remains the most fragile part of the smartphone. An accidental bump or drop is bound to leave it bruised. So if you want the screen to keep looking as pretty as it was out of the box, a screen protector is a wise investment.

Fortunately for you, there are plenty of excellent options on the market. You can either go for the tempered glass protectors or choose PET/ TPU films. But we must note that tempered glass has several advantages over PET/ TPU films. For example, you get better scratch resistance, and the glass has a superior look and feel.

amFilm has a solid track record of producing high-quality tempered glass screen protectors at affordable rates. So it"s hard to go wrong with the company"s offering for your brand-new Pixel 7. It promises to protect the phone"s beautiful 6.3-inch OLED screen from scratches, scrapes, and other blemishes. Moreover, as the glass is only 0.26mm thick, it doesn"t impact touch sensitivity or the fingerprint sensor performance. That said, follow the company"s instructions to ensure the in-display fingerprint sensor continues to work even after the screen protector installation.

Speaking of the installation, amFilm bundles an alignment frame in the box that makes the whole process super smooth. Plus, you get three tempered glass protectors in the box. If you mess one up while installing, you"ll have two spares on hand.

The Whitestone Dome Glass is one of the more expensive screen protectors for the Pixel 7, but there is a reason for that. Its UV-curing system results in a better seal than traditional glass protectors and helps with the performance of the in-display fingerprint sensor.

Sure, the slightly unusual installation freaks out most first-time buyers. Still, there are plenty of helpful installation tutorials online to guide you all the way, like the one from Whitestone. As long as you apply it correctly, it won’t disappoint you. The $40 Whitestone Dome Glass kit for the Pixel 7 includes two screen protectors, so even if you mess up the installation for the first time, you have a spare to get it right the second go-round.

Apart from being great for the in-display fingerprint sensor, the glass protector is equally good at keeping the screen safe from anything that may scar it.

Another highlight of the Dome Glass protector is the included camera guard that will keep the rear camera bar safe from scratches, scrapes, and other scars that may hamper the look of the phone.

Supershieldz has made a name for itself by consistently producing high-quality screen protectors for phones, and this tempered glass protector for the Pixel 7 is no exception. Rated for 9H hardness, it’ll protect the screen from any blemishes, including scratches and scrapes.

While the company doesn’t include an alignment tray like some other popular protectors, you get alignment stickers that will help you install the tempered glass without much fuss. Plus, the pack has three screen protectors, so even if you mess one up, you have spare to try again.

The Made-in-the-USA ArmorSuit MilitaryShield is one of the most popular TPU-based screen protectors on the market. So if you want TPU film for the Pixel 7, there is no better option. Its two-pack includes two case-friendly TPU films that offer a perfect fit with the phone. The film is also scratch-resistant and includes anti-yellowing material to ensure it continues to provide exceptional clarity even after months of usage.

One of the other major highlights of the MilitaryShield is its self-healing property, which helps the screen protector recover from minor blemishes over time. The company also promises a lifetime replacement warranty, so you can get free replacements if you have any issues with it.

ZAGG is one of the few brands whose screen protectors Google recommends if you are having trouble with the fingerprint sensor. So given the hit-or-miss track record of in-display fingerprint sensors with tempered glass protectors, it"s a good idea to pick the one that Google itself endorses.

The Glass Elite for the Pixel 7 promises better shatter protection than other tempered glass options and features reinforced edges to stop chipping or cracks. In other features, the company has treated the Glass Elite with its ClearPrint technology, which ensures it doesn"t attract fingerprint smudges.

In addition to its tempered glass protector, AACL offers a screen guard made with PET material. It works well with Pixel 7’s fingerprint sensor while protecting the screen from scratches and other minor blemishes. As you can expect, it’s not as protective as tempered glass, but that’s a sacrifice you’ll have to make for fingerprint sensor support.

Unlike some TPU-based protectors that require a wet install, applying the AACL Hybrid Film is super easy. And the supplied alignment frame helps in lining up the film. You’ll also be happy to know that AACL bundles four screen protectors in each pack, which is more than enough to last the phone’s lifetime.

If you are having a tough time with tempered glass protectors and Pixel 7’s in-display fingerprint sensor, this IQ Shield screen protector is a good alternative. This clear film protector is made of TPU material, which typically doesn’t impact the fingerprint sensor performance.

The one major caveat with this screen guard is its wet install method. You may find it tricky if this is the first time you are trying the wet install. Moreover, you don’t get an alignment tray. Fortunately, you can reposition the IQ Shield screen protector for several minutes after you put it on the screen, giving you sufficient time to get it right. You also get two screen protectors in each pack, so even if you mess up the installation the first time, you have a spare to try again.

You’ll love this Skinomi screen protector if you’re into TPU films. It’ll protect the front of your phone from scratches, punctures, and minor dents. And thanks to the self-healing nature of TPU, Skinomi TechSkin can recover from minor abrasions over time.

The screen protector uses a wet installation method that allows you to adjust until you get the perfect alignment. It’s also less susceptible to bubbles during the application process. In other features, the TechSkin has superb clarity and doesn’t impact the touch response of Pixel 7’s display.

Tempered glass films make the best screen protectors, and this one from AACL is an excellent option for the Pixel 7. Even though it costs just $10, it delivers a fantastic performance. In addition, its 9H hardness-rated glass can protect the phone’s display from cracks, scratches, scrapes, dents, and other blemishes.

The AACL protector also shines on the installation front thanks to the bundled alignment frame that makes installation seamless, and you’ll be ready to use your phone in a matter of minutes.

Like most high-quality screen protectors, it has exceptional clarity, and there won’t be any interference with the display’s touch response. The company has also included hydrophobic and oleophobic coating to reduce sweat and fingerprint marks.

Keep in mind that as the tempered glass is case-friendly, it doesn’t offer the maximum coverage to avoid obstructing case usage. Lastly, you get three screen protectors in one pack, enough to last your phone’s lifetime.

JETech’s tempered glass protectors are typically a great value for money, and its Pixel 7 offering is no different. It’s a good option for your phone if you aren’t too dependent on the fingerprint sensor. Like other tempered glass protectors, it doesn’t have an excellent track record when it comes to the in-display fingerprint sensor. But otherwise, it has no issues. It will keep the screen safe without interfering with clarity or touch sensitivity. In addition, you get free camera lens protectors to safeguard the rear camera module from scratches and other minor damage. The JETech protector is easy to install thanks to the bundled tool.

Although primarily known for its smartphone cases, Caseology also produces solid screen protectors, like this Snap Fit tempered glass protector for the Pixel 7. It"s designed to offer a perfect fit and protect your display from any scars.

In other features, the screen protector maintains the display"s touch sensitivity. However, the company recommends enabling the "Increase touch sensitivity" option in Settings to ensure there are no issues. This option will also help with the performance of the in-screen fingerprint sensor.

The in-display fingerprint sensors included in the Pixel-series phones don"t have a great track record of working with tempered glass protectors. And unfortunately, the trend continues with the new Pixel 7. Be ready for trouble if you plan to invest in a tempered glass protector for your Pixel 7.

Google blames these issues on the screen protector manufacturers and suggests picking one made by a Made for Google certified brand, like ZAGG, OtterBox, Case-Mate, and PanzerGlass. While you are less likely to have trouble with these brands, there is no foolproof option because Google doesn"t test these products for compatibility. Instead, the manufacturers conduct the tests to meet Google"s compatibility standards.

Alternatively, you can go for TPU or PET screen protectors. While they are not as great at scratch resistance as tempered glass protectors, they are better at working with in-display fingerprint sensors. Or, you can simply ditch the fingerprint sensor and rely on the newly re-introduced Face Unlock, but it"s only useful for unlocking the phone, nothing else.

Accidents are a sad reality of life, and you don"t know when your Pixel 7 will inevitably fall or when you will bump its screen into a table"s corner. So it"s a good idea to make a screen protector one of the first purchases after ordering the phone, followed by one of the best Pixel 7 cases. Both of these purchases will help to keep the phone in good condition.

We really like amFilm"s tempered glass protector for the Pixel 7. It"s reasonably priced and will safeguard the display from any mishaps. The company also bundles a nifty alignment tool to ensure your installation goes smoothly.

Our premium pick, the Whitestone Dome Glass, is perfect for people looking for the absolute best. The company has a reputation for producing some of the best tempered glass protectors on the market, and its Dome Glass screen protector for the Pixel 7 is no exception. It comes with the company"s liquid dispersion technology and UV-curing to help you get a perfect seal without bubbles.

SuperShieldz"s screen protector is another solid option if you want bang for the buck. Its $10 three-pack includes three solid tempered glass protectors rated for 9H hardness and comes with everything to facilitate an easy installation.

New sensor technologies are being developed specifically for the integration of fingerprint scanning functionalities with OLED displays. The recent announcements indicate that the industry is moving away from capacitive sensors to focus their efforts on optical or ultrasonic detection. For display manufacturers, this could even present opportunities to innovate and offer their own solutions.

Once a premium feature, fingerprint sensors have become almost standard on smartphones. However, the latest design trend is to remove the bezels around the display, leaving no room for the fingerprint sensor. Some OEMs made the choice to move the sensor to the back of the device, which is not always convenient (for instance when mounted on a car dash).

The more ambitious option is to integrate the fingerprint sensor with the display. For the iPhone X, Apple considered this option but decided in the end to rely only on their new FaceID technology which uses an infrared camera for face recognition. The exact reasons are unclear, but it is safe to say that introducing a fingerprint sensor would have pushed the manufacturing cost of the phone even higher. It is also possible that the technology was simply not up to the standard of Apple at the time.

The industry is progressing fast however. At CES this year, Vivo introduced the first smartphone with an under-display fingerprint scanner. The sensor inside is the new Clear ID FS9500 by Synaptics. What makes it so different? It is an optical sensor.

Although Synaptics had built a strong expertise in capacitive sensors, they had to switch to an optical system for the FS9500. You can think of it like the image sensor inside a camera but without a lens. Conventional capacitive fingerprint sensors are difficult to integrate with a display because the distance between the sensor and the finger must be very short (300 microns). With optical sensing, it is possible for the sensor to be further away from the surface and still produce a high resolution scan.

There is however another challenge: an optical sensor is not transparent so it has to sit behind the display. This solution does not work well with LCD panels which are transmissive displays with a backlight. Fortunately, many new smartphones now use OLED displays instead of LCD, making it much easier to integrate an optical fingerprint sensor. With OLED, the display is used as the illumination light and the sensor captures the reflected light that travels back through the display. According to the presentations from Synaptics the distance between the finger and the optical sensor can be as high as 1.5 mm. This is well within the thickness range of an OLED panel with a standard cover glass.

Image sensors like the one used by Synaptics are usually made with CMOS technology. CMOS sensors can achieve resolutions over 2,000 dpi and can be mass produced in existing semiconductor foundries. Synaptics is not the only one taking advantage of this mature industry. For example, Vkansee is another company that has developed a CMOS optical sensor for fingerprint scanning. However, large CMOS sensors are expensive and the cost increase exponentially when scaling up to even larger sensing areas. In other words, it is not an economically viable option to turn the whole display into a fingerprint scanner. You are more likely to get a scanning area the same size of a small button.

For the display industry, there is an opportunity to offer an alternative to CMOS sensors. Some companies are now trying to leverage their expertise in manufacturing thin-film transistors (TFT) to make their own fingerprint sensors. For example, Japan Display Inc. (JDI) are now developing a sensor on glass that is based on the same polysilicon TFTs used in their LCD panels. The sensor is capacitive so is not designed to be placed behind a display. Since TFTs are used to make the active matrix in LCD or OLED displays they are ideal for making large sensor arrays.

The most interesting new development was shown by BOE at the Display Week exhibition this year. The Chinese manufacturer demonstrated the first under-display fingerprint sensor made in-house with TFTs. The optical sensor had a resolution of 500 dpi and was placed directly under an OLED display. They said they could make the sensor on conventional glass substrates or on plastic to match the sensor with flexible OLED displays.

BOE was also showing another prototype featuring an 800 dpi CMOS fingerprint scanner manufactured by Vkansee. This clearly demonstrated the strengths of each approach: higher imaging resolution with CMOS, larger sensing area with TFT. Although the sensor in the TFT demo was smaller than the display, it will be possible in the future to make larger ones to cover the whole. BOE also said they use new materials which will make it cheaper to scale up.

Making fingerprint sensors with TFT is not completely new. Already back in 2016, FlexEnable and Isorg demonstrated a flexible fingerprint and vein sensors with an 86 Ã 86 mm active area. The device combined FlexEnable’s organic TFT backplane with Isorg’s organic photodetector. Since then, they have been able to achieve a resolution of 500 dpi, which is the level usually required for secure biometric applications. It would be fascinating to see this sensor integrated with an OLED display, as it would result in a Trinity of organic electronics (OLED, OTFT, OPD) combined into a single device.

The Holst Centrehas also been developing organic photodetector arrays, but they used metal-oxide TFT for the backplane. The prototype they demonstrated at Display Week is relatively large (60 Ã 80 mm) but can only produce images at 200 dpi [update: they also made a smaller sensor with a 500 dpi resolution]. The Holst Centre says the technology will be transferred to industry for commercialisation.

Is optical detection going to be the dominant technology for fingerprint sensors? It seems that most of the industry is betting on it. However, one big player wants to offer an alternative. Qualcomm has been developing an ultrasonic sensor for several years and the company says it can also be placed behind a display. There are limitations though. Unlike optical sensors, ultrasonic sensors do not see through air gaps, so they will be better suited for flexible OLED displays that are bonded to the front glass of the device.

The rapid adoption of OLED displays in smartphones has enabled new possibilities. First it was the transition to flexible displays and now the integration of fingerprint sensors. It is going to be a very exciting time for the sensor and display community and I believe we are going to see a lot of innovations in the coming years.

Dr Guillaume Chansin is the founder and principal consultant at Irimitech Consulting. He has been following emerging materials and devices since 2012 and has been a speaker at major industry events on flexible electronics, displays, and sensors.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

PO Box, APO/FPO, Afghanistan, Africa, Alaska/Hawaii, Albania, American Samoa, Andorra, Anguilla, Antigua and Barbuda, Argentina, Armenia, Aruba, Azerbaijan Republic, Bahamas, Bahrain, Bangladesh, Barbados, Belize, Bermuda, Bhutan, Bolivia, Bosnia and Herzegovina, Brazil, British Virgin Islands, Brunei Darussalam, Cambodia, Cayman Islands, Chile, China, Cook Islands, Costa Rica, Dominica, Dominican Republic, Ecuador, El Salvador, Falkland Islands (Islas Malvinas), Fiji, French Guiana, French Polynesia, Georgia, Germany, Gibraltar, Greenland, Grenada, Guadeloupe, Guam, Guatemala, Guernsey, Guyana, Haiti, Honduras, Iceland, India, Indonesia, Iraq, Jamaica, Jersey, Jordan, Kazakhstan, Kiribati, Kyrgyzstan, Lebanon, Liechtenstein, Macau, Macedonia, Marshall Islands, Martinique, Micronesia, Monaco, Mongolia, Montenegro, Montserrat, Nauru, Nepal, Netherlands Antilles, New Caledonia, Nicaragua, Niue, Oman, Pakistan, Palau, Panama, Papua New Guinea, Paraguay, Peru, Russian Federation, Saint Kitts-Nevis, Saint Lucia, Saint Pierre and Miquelon, Saint Vincent and the Grenadines, San Marino, Serbia, Solomon Islands, Sri Lanka, Suriname, Svalbard and Jan Mayen, Taiwan, Tajikistan, Tonga, Trinidad and Tobago, Turkmenistan, Turks and Caicos Islands, Tuvalu, US Protectorates, Ukraine, Uzbekistan, Vanuatu, Vatican City State, Venezuela, Virgin Islands (U.S.), Wallis and Futuna, Western Samoa, Yemen

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey