tft lcd fingerprint on display quotation

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The NEMEH Multi-Biometric Face and Fingerprint Access Control Reader from TURNSTILES.us is the first access control terminal to apply the most advanced fingerprint and facial recognition technology together. This biometric reader not only has an outstandingly high identification rate towards dry, wet, and rough fingers, but also provides the utmost security with live finger detection. It can operate under strong light and activates automatically with a motion sensor to save power.

Using a high-speed face recognition algorithm, it has extremely high verification speed and low error rate, in addition to being able to effectively prevent duplicated registration. In addition, the new hardware platform has a clock rate of 1.2 GHz, greatly enhancing the speed of fingerprint and facial verification.

1.2GHz High Speed CPU, Memory 128MB RAM / 256MB Flash, SilkID Fingerprint Sensor, 2,8 Inches TFT-LCD Touch Screen, 125KHz EM Reader / Mifare (Optional), Hi-Fi Voice & Indicator, Tamper Switch Alarm, Dual IR Camera

**Programming is performed by www.TURNSTILES.us, Inc. technicians and includes integrating access control devices and selected options purchased from www.TURNSTILES.us and www.EntraPass.us.

In the fierce market competition of different biometric methods in smartphones, where consumers are pursuing a high screen ratio, optical fingerprint recognition under OLED screen is a well-established approach. However, using thin-film transistor (TFT) technology to make large-area optical sensors generally has the issue of low sensitivity, which will make the signal difficult to be read out. In this paper, we propose to use gap-type TFT with high photosensitivity current and process compatible with display panels as the sensing device to build the sensing array. The pixel circuit can be simplified to structure containing only of two thin-film transistors (TFTs). Using this gap-type TFT sensing array under OLED panel for fingerprint recognition is proven to be effective by the clear images captured with the readout system.

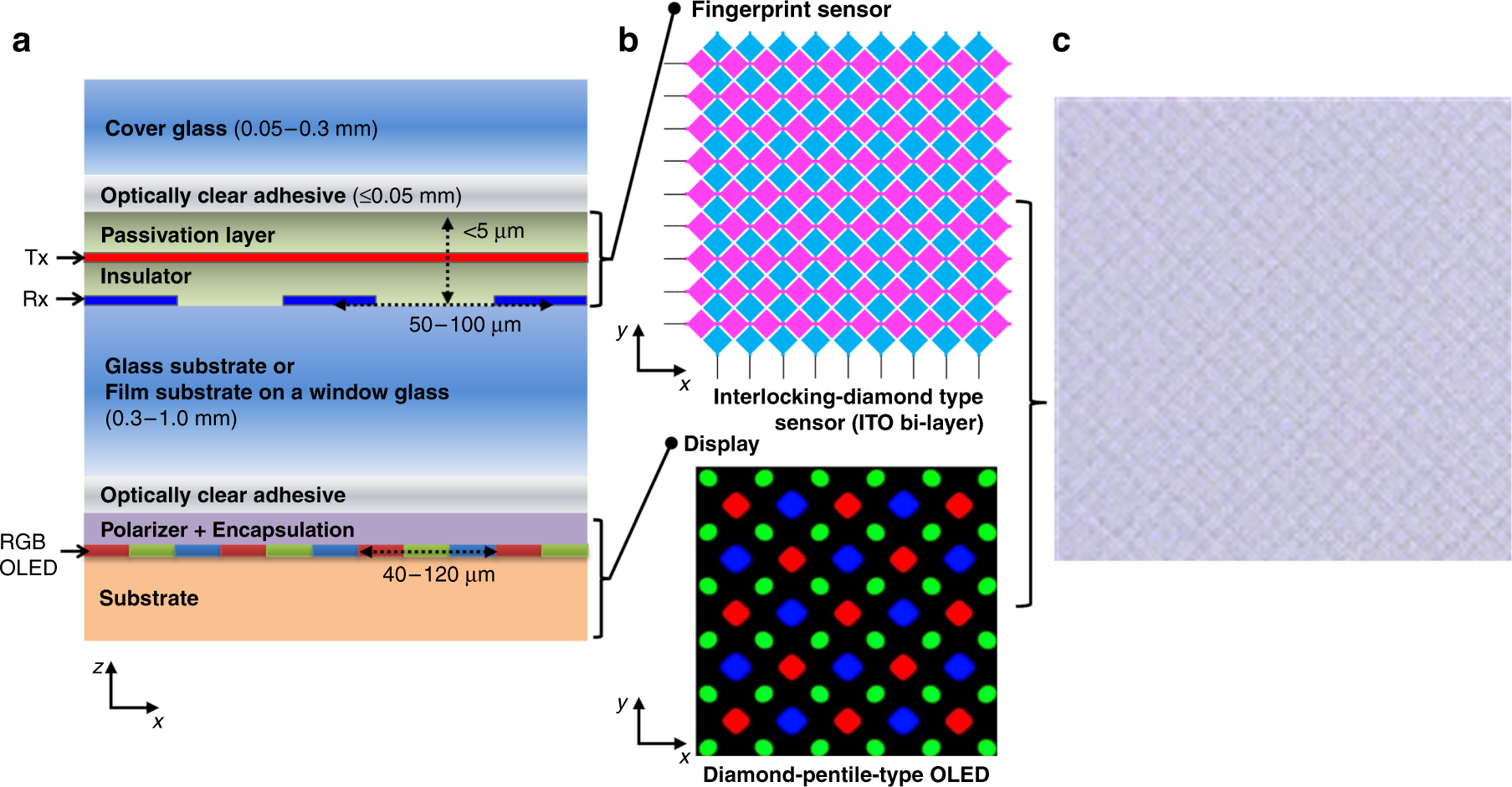

Considering the nature of the on-screen fingerprint sensor, which must acquire signals at regular intervals on a digital display device, Moiré patterns cannot be avoided. Therefore, the Moiré pattern should be made imperceptible through a proper combination of sensor geometrical parameters. A spectral analysis of overlapped display–sensor pattern pairs in the frequency domain can be carried out by Fourier transform to predict the Moiré pattern periods, directions, and strengths, i.e., perceptual contrastN × N pixel images of various overlapped patterns were prepared, and the discrete Fourier transform (DFT) was applied to the image matrices to perform spectral analysis. When the image is expressed as the gray-level intensity distribution function f(x,y), where x = 0, 1, 2, …, N − 1 and y = 0, 1, 2, …, N − 1, it can be Fourier transformed into

where u and v are the horizontal and vertical components of the frequency vector, respectively. F(u,v) provides the amplitude, which corresponds to the perceptual contrast of the Moiré pattern, at the spatial frequency represented by u and v, and can be plotted as in Fig. 2a (ref. 2a–1, a–2 and clearly shown around the origin in Fig. 2 a–3, denote the spatial frequency vector of the patterns in the overlapped images. The amplitude is represented by the brightness of the dots. The yellow circle in Fig. 2a represents the visibility circle beyond that fine details of the pattern cannot be detected by the human eye at a viewing distance of 40 cm. The viewing distance was assumed to be ~40 cm, as the mean eye–screen distance is ~33–40 cm for mobile devices

where fS is the spatial frequency of the visual stimuli in cycles per degree. The function is normalized to a maximum value of 1, as shown in Fig. 2d (ref.

a DFT calculation results, b approximate real-space pattern extraction images, and c observed Moiré patterns for the sensors with 1 a pattern pitch of 20 μm and a rotation angle of 0°, 2 a pattern pitch of 25 μm and a rotation angle of 38°, and 3 a pattern pitch of 45 μm and a rotation angle of 0° on a 570 ppi smartphone display. d Human CSFe Binary Moiré pattern extraction scheme

In addition, approximate Moiré patterns were obtained by extracting bright and dark areas of overlapped two-dimensional (2D) images directly in the image domain as a complementary approach to the spectrum analysis. We extracted the expected Moiré patterns by converting the overlapped grayscale images and their inversions into binary images, as simply described in Fig. 2e. As the binarization simplifies the pattern and enhances the contrast, patterns can be easily recognized from at least one of the two binary images, either the original or the inverse, and compared with the observed results.

These analysis methods were used to predict Moiré patterns for the selected smartphone display (diamond-pentile-type OLED, 570 ppi), and diamond-type ITO sensors with electrode pitches of 20–100 μm at an interval of 1 μm and rotation angles of 0–45° every 1°. Owing to the fourfold symmetry (Fig. 1b), the angle was varied from 0 to 45°. DFT calculations and pattern extraction were performed with overlap of a fixed display pattern image and rotated sensor pattern images in grayscale. Some of the analysis results are shown in Fig. 2a, b. Figure 2a–1 shows the DFT calculation result for the sensor pattern with a pitch of 20 μm without rotation. Inside the visibility circle, four manifest white dots are observed, which denote the frequency vectors of the main Moiré pattern. The directions and periods of the Moiré patterns in real space can be obtained by using the frequency vectors. The directions and periods coincide with those of the extracted real-space pattern in Fig. 2b–1, and the pattern in Fig. 2c–1 obtained by the experimental evaluation presented in the next section. Notably, Fig. 2a–2 predicts more than one pattern period. However, the peaks just outside the visibility circle are considerably higher than those inside the circle, and the pattern corresponding to the outside peaks is dominant, as shown in Fig. 2b–2, c–2. In Fig. 2a–3, the expected Moiré pattern frequency vectors are very close to the origin, thereby suggesting a very noticeable Moiré pattern with a period of several millimeters, as shown in Fig. 2b–3, c–3.

Considering the large number of different pitch and rotation angle combinations, a criterion that can quantify the visibility of the Moiré pattern is required. Therefore, in this study, approximate Moiré visibility (MV) values for each pitch and rotation angle were calculated for comparison and selection of the patterns,

This value quantitatively reflects the perceptual contrast of the pattern filtered with the CSF in the frequency domain. However, this value needs to be used carefully to narrow the search range, instead of finding the minimum and selecting the optimal pattern, as the simple summation can be misleading. For example, the values can be similar in the cases of one very bright dot in the spectral analysis plot and of many less bright dots, although the Moiré pattern can be more manifest in the former case. Nevertheless, the MV values significantly vary with changes in the sensor pattern and can be effectively used to narrow our selection of patterns for the next step. The pattern contrast in the image domain can be quantified after inverse Fourier transform of the MV, although the inverse Fourier transform results have limitations similar to those of the MV values3a. The results show that the smallest MV values can be found in the 30 µm pitch case around the rotation angles of 7–12 degrees, 15–20 degrees, and 35–40 degrees. Therefore, most of the candidates were selected from the cases, where the sensor pattern pitch is 30 µm or smaller.

a MV plots calculated for various sensor pitch and rotation angle combinations. b High-resolution camera images showing the Moiré patterns from the 20 candidate sensor patterns. Smartphone screens (c-1) without a fingerprint sensor pattern and (c-2, c-3) with fingerprint sensor patterns on them (c-2: a pattern with a pitch of 25 μm and a rotation angle of 38°, c-3: a pattern with a pitch of 20 μm and a rotation angle of 8°)

After the analysis described above, 55 patterns were fabricated on a glass wafer to obtain an area of 10 mm × 10 mm for each pattern. The other 35 test patterns in addition to the 20 candidate patterns mostly had sensor pitches of ~60–70 µm, which are commonly used in conventional mutual-capacitive fingerprint sensors, and have been verified for sensing capability. The goal was to determine whether a certain angle of rotation could make the sensors with these pitch ranges unexpectedly have minimized Moiré patterns, but the results were negative. The patterns were created using the same process used to fabricate the sensor, except that the electrical connections and pads were omitted. Therefore, the patterns consisted of lower ITO, organic insulator, upper ITO, and organic passivation layers. After fabrication, the glass wafer was diced to obtain the same size as that of the Samsung Galaxy S8 display panel. The diced glass substrate was placed on the smartphone’s full-white-mode OLED with glycerine in between. The generated patterns were carefully observed and evaluated. In addition, grayscale photographic images were acquired in a dark environment with a high-resolution industrial camera used for display panel inspection, as shown in Fig. 3b. The images were carefully acquired to avoid additional Moiré or other artifacts owing to the camera and for consistency with the naked eye observations. Although no standard method has been reported for the quantification of a Moiré pattern, the contrasts of different images of Moiré patterns can be compared with the standard deviations of the image pixels’ gray-level values, and the number of sensor pattern candidates can be reduced. In addition, mean opinion scores, popular indicators of the perceived medium quality3b), and a pattern with a pitch of 25 μm and a rotation angle of 38° (in a dashed square in Fig. 3b) were selected. Larger evaluation samples of these two patterns were generated to cover the whole front side of the smartphone display and compared to the case without the sensor pattern, as shown in Fig. 3c. Except for slight changes in color and brightness, no noticeable Moiré pattern was observed. In addition, no significant difference was observed between the display without a sensor pattern and the display with a sensor on it.

The dimensions of the selected electrode pattern based on the Moiré evaluation are considerably smaller than those of commercial capacitive fingerprint sensor patterns (in the range of 50–100 μm). Thus, the signal-to-noise ratio of the sensor could be significantly decreased, and the sensor might not operate properly. Therefore, a method that can provide a sensor with a pitch sufficiently small optically, but sufficiently large electrically to recognize a fingerprint is required. This can be achieved by connecting several electrode patterns as one unit block and driving the sensor by each block, as shown in Fig. 4b. In this manner, for example, an array of a pattern with a pitch of 25 μm will have a sensing pitch of 75 μm by connecting and controlling three electrodes together on both the signal transmitter (Tx) and receiver (Rx) sides. In other words, a 3 × 3 array of a diamond pattern with a pitch of 25 μm can form a unit sensing block.

a–1 Conventional electrode patterns and sensor driving configuration. a–2 Conceptual rotated electrode patterns with a small pitch, and corresponding sensor driving configuration used in this study. b–1 Mutual capacitance (CM0) without a finger on the cover glass. b–2 Change in capacitance upon finger contact, and mutual capacitance values at the finger ridge and valley areas

The validity of this idea was analyzed by calculating the electrical characteristics, such as the capacitance and resistance, for different sensor patterns by COMSOL Multiphysics® simulations. The Tx and Rx electrode structures in the simulations were interlocking diamond patterns of ITO with a sheet resistance of 11 Ω/sq. In addition, the thickness of the insulating layer between the Tx and Rx layers was assumed to be 1 μm, while the gap between diamonds was set to 8 μm, regardless of the pattern pitch owing to our fabrication capability. First, the mutual capacitances, which are the capacitances between the Tx and Rx electrodes forming each sensing node, were calculated for different cases. When no finger touches the cover surface, the mutual capacitance has the baseline value CM0, as shown in Fig. 4b–1. Once a finger is placed on the cover surface, the mutual capacitance values under the ridge and valley regions of the finger are reduced to CM–R (=CM0 – ΔCRIDGE) and CM–V (=CM0 – ΔCVALLEY), respectively. This occurs as the capacitors under the finger lose charge and the capacitance decreases, but the capacitance changes differ between the finger ridge and valley regions owing to the difference in the distance from the electrodes to the finger surface, as illustrated in Fig. 4b–2. In addition, the Tx and Rx electrode linear resistances (RTx and RRx) were obtained by the simulations.

Table 1 shows the calculation results for several different cases where the sensor patterns are composed of different numbers of arrays, while the fingerprint sensing pixel pitches are in the reasonable range of 70–85 μm, which correspond to resolutions of 300–363 dpi. Fingerprint images in this resolution range can be effectively used in commercial devices employing a pattern-based matching algorithmCM–R and CM–V, denoted ΔCM, is shown in the table instead of the capacitance values because the amplitude of the sensor output signal is determined by ΔCM. The rotation angles of the sensor patterns are not indicated because they do not considerably affect the electrical characteristics. The baseline mutual capacitances, CM0, of the unit sensing patterns composed of n × n arrays increase almost linearly with n if the sensing pixel pitches do not significantly differ. The ΔCM values do not substantially change with the pattern pitch for the analyzed sensor patterns, which implies that the signal levels of the selected sensor patterns with pitches of 20 or 25 μm are approximately the same as that of the standard sensor with a pitch of 70 μm, which is used for a conventional fingerprint sensor under the home button of smartphones. Although larger CM0 values can increase the noise level, all of the values in Table 1 are within the range covered by our integrated chip (IC) for fingerprint sensing. The IC for sensor driving and readout was revised from the commercial touch sensing IC to detect a considerably smaller mutual capacitance difference, while maintaining most of the scheme to filter various noise signals

Our final sensor pattern selection was carried out based on the resistance–capacitance (RC) time constants of the patterns, as they affect the signal acquisition time. The RC time constant can be estimated by using CM0 and RTx in Table 1. Although the resistance of the trace also needs to be considered to obtain the overall resistance (R) from the IC to each sensing node, the traces consist of metal with a very low resistivity and thus do not significantly affect the overall trend of R. The RC constants are expected to increase with decreasing pitch. Accordingly, the array size n in a unit sensing block increases, so CM0 rapidly increases. Although the line resistance of the electrodes per 10 μm, RTx, decreases with decreasing pitch owing to the more electrode lines in the unit sensing block, the decrease in RTx is relatively gradual and cannot change the trend of the RC increase. The time for fingerprint image capture in the 4 × 4 array of the pattern with a pitch of 20 μm with the largest RC time constant can be longer than 200 ms, the conventional limit for fingerprint sensors, at a typical driving frequency of 1 MHz with repetitive signal integration to obtain a sufficiently good fingerprint image. Therefore, the 20 μm 4 × 4 array pattern was excluded to finally select the 25 μm 3 × 3 array with a rotation angle of 38° as our sensor pattern.

Using the selected sensor pattern design, fingerprint sensors were fabricated on glass wafers, and their electrical and optical properties were characterized. The sensors can also be fabricated on the large glass substrates used for the manufacturing of display panels and can be transferred to plastic film substrates if needed. A schematic of the sensor design and optical microscopy images of the fabricated sensor are shown in Fig. 5a, b. The electrodes have smaller diamond shapes with thick and long necks between them compared to conventional touch sensors or fingerprint sensors, as the width of the necks and spacing between adjacent upper and lower diamonds cannot be reduced in proportion to the pitch of the diamond pattern. The width of the necks was maintained at 7 μm to ensure proper resistance levels of the electrodes, while the spacing was maintained at 4 μm to secure the alignment margins. The right image in Fig. 5b shows that three electrode lines are connected to one via, and that one interconnect line exits from the via, as mentioned above.

a (Left) Transparent fingerprint sensor fabricated on a glass substrate, and (right) schematic of sensing and dummy pattern areas and metal interconnects (i.e., traces) connecting the sensor electrodes to the pads for bonding to the FPCB. b Optical microscopy images of (left) part of the sensor pattern area, and (right) a lower section of the sensor pattern and vias connected to the traces. White squares drawn with solid lines and dotted lines indicate lower and upper ITO diamond patterns, respectively. The upper ITO electrodes appear bright in the left image, but are relatively dark in the right image owing to the different lighting and organic coating conditions. c Transmittance and reflectance in the visible wavelength range measured on the sensing area of the fabricated sensor. d Fingerprint images obtained by the sensor

Considering the literature results and preliminary experiments, we targeted an ITO electrode thickness of 200 nm to obtain proper combinations of sheet resistance and transmittance5c. The transmittance is slightly higher than that of the unpatterned ITO layer, as the sensors have gaps between the ITO diamond patterns, as shown in the optical microscopy image in Fig. 5b. The use of proper index-matching layers and coating on the cover glass is expected to improve the transmittance and haze close to the desired values (>90% and <1%, respectively). The transmittance of the electrode material is an important factor with respect to the Moiré issue, as well as the brightness of the display and battery life of the smart device. A higher transmittance implies a lower contrast when the patterns overlap, and thus, a pattern having the same period would be less noticeable according to the CSF. Therefore, the Moiré pattern may not be visible when the transmittance of the electrode is very high, even if the electrode pattern is not rotated or the electrode pitch is not adjusted, as suggested in a previous report

The fabricated sensor with 64 Tx and 128 Rx channels was connected to an IC controller through a flexible printed circuit board (FPCB). Fingerprint images were obtained on a cover glass attached to the sensor with an optically clear adhesive (OCA). The fingerprint sensor authentication rate was evaluated by using our pattern-based matching algorithm and over 10,000 fingerprint images5d. A high contrast is observed between the ridges and valleys of the fingerprint. In addition, features such as ridge endings and bifurcations are clearly visible. Approximately four to five sites of features are obtained in the fingerprint images from the 9.6 mm × 4.8 mm sensing area.

Finally, the sensor modules were assembled into smartphone prototypes. The Samsung Galaxy S8 Active’s window glass was replaced with the sensor wafer, which was diced to have the same dimensions as those of the original window glass and laminated with a cover glass. After the assembly, the sensing area is located at the bottom center of the front surface, where the soft home button is displayed. The remaining area is covered with dummy patterns to make the sensing area indistinguishable. Figure 6a shows a functioning smartphone display with the fingerprint sensor laminated on it. Notably, no reduction in image quality in the whole display area is observed. In addition, the location or size of the fingerprint sensor cannot be identified if they are not clearly indicated, such as by the red dashed slanted rectangle in Fig. 6a. A simple android app for fingerprint sensing demonstration was developed and installed on the prototype device to show enlarged images of the recognized fingerprints on the smartphone display. Clear fingerprint images can be obtained from the sensor on the fully functioning display screen of the smartphone, as shown in Fig. 6b, c. The fingerprint image in Fig. 6c is brighter and has a better contrast compared to the images in Fig. 5d, as real-time image enhancement was applied for demonstration purposes. To the best of our knowledge, this is the first study demonstrating a capacitive-type on-screen fingerprint sensor functioning, while integrated in a smartphone display, not just separately.

a The sensing area is outlined by the red dashed slanted rectangle in the soft home button area, while the display shows the normal home screen. The fingerprint sensing demonstration app shows the b white noise in the absence of objects on the sensor and c fingerprint image when a finger is placed on the sensor

The cost of this project is around $30. If you take in consideration the technology that this project uses, this cost is very low. 10 years ago, projects like this would cost a few hundred dolars!

This display is very fast. It uses the ILI9163C driver. It has a resolution of 128x128 pixels and it can display up to 260.000 colors. It is very easy to use with Arduino and it costs around 4$.

The display uses the SPI protocol in order to communicate with the Arduino board. We only need to connect 8 wires in order to make it work. Let’s start.

As you can see this display is very easy to use with Arduino. It is very cheap, very fast, it is small in size and it only draws around 30mA of current. I think it is a nice display to use in projects that don’t require a big display but color would be nice.

The sensor works like this. It is an optical sensor, which means it analyzes the photo of a finger. It then renders the image, makes some calculations, finds the features of that finger and then searches in its memory for a fingerprint with the same characteristics. It can achieve all that in less than a second!

This module can store up to 1000 fingerprints in its memory and its false acceptance rate is less than 0.001% which makes it pretty secure! Great! We get all that in a very easy to use module and with very low cost! It is a really impressive technology!

We need to download some libraries. First of all we need the Adafruit Fingerprint library, the Adafruit GFX library and the Sumotoy’s library for the display.

First of all we have to upload the enroll example to our Arduino board. We go to File -> Examples -> Adafruit Fingerprint Sensor Library -> Enroll. With this example program we can store fingerprints in the FLASH memory of the module. We upload the sketch and we open the Serial Monitor. The program ask us to enter the ID to enroll. Then we place the finger on the sensor twice as we are instructed and the fingerprint is stored! You can store as many as 1000 fingerprints this way!

We start the sensor and the display, and we check for a finger on the sensor every 50ms. If there is a finger on the sensor we request the module to search if that finger is enrolled in it’s memory. If it finds the fingerprint in the memory it returns that fingerprints’ ID. Next it displays a welcome message and locks the screen again after a few seconds.

As always you can find the code of the project attached in this tutorial. Since I update the code from time to time, for the latest version of the code please visit the project"s website: http://educ8s.tv/arduino-fingerprint-sensor-module...

I am really impressed by the performance and the ease of use of this fingerprint sensor module. With very low cost we can add biometric security features to our projects. That’s amazing. Projects like this would have been impossible for a maker even a few years back. That’s the beauty and power of open source hardware and software. After this first test I am going to use the fingerprint sensor module along with an electric lock in order to see if we can use this sensor in a real life situation, so stay tuned. Please let me know your thoughts about this sensor, in the comments section below. Thanks!

Tianma Microelectronicshas announced a multi-point in-display biometric fingerprint recognition sensor for LCD screens to unlock smartphones by touching different points on the display, writes Gizmochina.

Tianma claims the technology is proprietary, developed with its own team. The image processing element is integrated in a TFT display layer for concurrent touch, display and fingerprint sensing. The company allegedly used optical path design to make the module 50 percent slimmer. Until Tianma’s release, under-display fingerprint sensors were only available for OLED panels.

TCL’s China Star Optoelectronics Technology has also developed in-display fingerprint technology for LCD screens that allegedly operates on 92 percent of the display screen, allowing multiple touchpoints anywhere on the surface.

The latest sensor developments are not yet available on the market, but Gizmochina says mass manufacturing of the biometric technology is expected to start this year.

BTS-TA200W is a high performance fingerprint scanner. It requires employees to clock in and out using their unique fingerprint for precise authentication for Time & Attendance. It can read dry, wet or rough fingerprint very quickly and upload the fingerprint template via the internet to Benat USA’s secure servers.

The BTS-TA200W HID fingerprint reader eliminates buddy punching, a practice commonly used in the workplace. Each employee can enroll 10 fingerprints. This biometric fingerprint reader has three different verification modes: fingerprint, proximity card/keychain FOB, and pin/password.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The POS i600 brings performance and design to a new level. With an Intel Core i3 processor and die-cast aluminum body, the POS i600 can run even the most demanding software in harsh temperature environments to help every business owner excel their business. The POS i600 can be optionally integrated with a MSR & iButton, Smart Card Reader, Fingerprint Reader, VFD Customer Display, or 10.4" 2nd Display.

Module via a serial communication interface, directly with 3.3V or 5V power microcontroller communication: Module data transmission feet (2Foot TD) connected to the data bit machine receiving end (RXD), data receiver module feet (3 feet RD) connected to the data sender bit machine (TXD). For the RS-232 level (for example: PCread more...

It is a multi-biometric reader capable of capturing and processing finger vein and fingerprint biometric data at the same time. The new hardware platform uses ZMM220 core-board with 1.2Ghz CPU. With optimization of both hardware platform and algorithm, It is one of high recognition rate, high security & high speed terminal.read more...

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey