printrbot lcd panel made in china

This was made to house a printrbot LCD screen with encoder wheel and mount to a laser-cut opening. I updated it by making slightly larger openings and now fits perfectly. This was designed in inches and will need to be scaled to 25.4 if you use mm. ...I...

I"ve moved my designs over to www.youmagine.com All updates will be posted on that site https://www.youmagine.com/designs/printrbot-lcd-housing-and-knob-for-simple-metal

I liked the Idea of the LCD screen mount for the reprap style LCD, however it was too large for a printrbot simple to print. So I split it into two pieces with a jigsaw puzzle style connector. The second addition was the inclusion of the wrap around...

An LCD mount for the printrbot play that sits underneath the print bed for space efficiency. Note: This does not work with the LCD provided by Printrbot as of yet. And it may not. As I don"t have one, it would be difficult to redesign for one. ...

Here is a little case I designed for the Printrbot LCDv1. Did not like the ones out there as they were too hard to print. This is very easy to print. I wanted something I could clip to my new Printrobot Metal Plus so I made holes on the back for...

This system does the following; Raises the printer on legs to help stability and give extra room for cabling (such as the extended ATX power supply jacks) Provides an interlocking, flush mounted LCD housing for standard RepRapDiscount 20x4 LCD...

Please note this is not for the printrbot LCD screen that used to on the printrbot"s website for purchase. Also, the .stl file needs to be scaled 10x times larger in order for it to be the correct scale. ...For a detailed explanation on how to install...

A simple tight fitting bracket that holds an easy to find ~$20 RepRap LCD 2004 Module to the upper tower spool holder of a Printrbot Simple with either the XL upgrade or the tower upgrade instead of the $65 addon lcd screen.

If you have the most recent Printrbot LCD kit (with the wooden enclosure) and a Printrbot Simple with a tower (standard or tall) this will allow you to mount your LCD on the outside of the tower; it retains the two wooden faceplates, but replaces the...

This is an ok version to hold the lcd panel. You still need to modify it a bit with a dremel tool. ... I will update this later with a better version.

This is a desk mount for a 20x4 generic lcd screen with seperate encoder used on a Printrbot maker"s kit (1405) The Knob is http://www.thingiverse.com/thing:517242 Instructions Printed in PLA with 20% infill The mount is my design, however i forgot...

THIS BEZEL WILL NOT FIT THE OFFICIAL PRINTRBOT LCD Instructions Manufacture the board as laid out. Build with all components on the back of the board except the rotary encoder and LCD. Attach Standard 20x4 LCD directly to the base board with...

Please note this is not for the printrbot LCD screen that used to on the printrbot"s website for purchase. Also, the .stl file needs to be scaled 10x times larger in order for it to be the correct scale. ... For a detailed explanation on how to...

This is a remixed version of https://www.youmagine.com/designs/printrbot-lcd-v2-case It is remixed to be used with http://www.thingiverse.com/thing:403555 I also cleaned up the inside for a better fit for the lcd assembly. I have also included my...

I can send you .stl file if you want stelmo@pyramidpower.co.za Instructions Measured out actual printrbot LCD panel then cut on laser. After few iterations the fit was excellent. ...Also made spacer frame to space LCD.

Printrbot LCD v2 mount with 3 auxiliary switch holes with diameter of 0.5 in or 12.7 mm.The case has an open back design for easy access of the cables and has for 4 mounting points for the LCD with an interference fit so that a 6-32 or 3 mm machine...

Printrbot Simple Metal stability feet and lcd mounting if you have the x axis upgrade you can print these flat if not you will need to turn them at a 45 degree angle on the z axis and they will print with supports. you need supports either way for...

Bracket for a cheap (Chinese) Geeetech Ramps 1.4 LCD controller to mount it on the Printrbot Play (http://www.geeetech.com/reprap-ramps-v14-smart-2004-lcd-controller-with-adapter-p-615.html) Please note there is also an official Printrbot LCD...

The many cases and mounts for the standard LCD display, are too big to be printed on the metal simples 150mm bed, which is not surprising since the physical size of the board (Sain Smart version) is 150mm wide. So I created this mount plate with four...

I actually got it! The LCD screen works great! Now I just need to design and 3D print a housing mount for it (that"s the easy part). The following website helped me out a bunch:

The site above had a pretty good walk through on how to install it, pins and all. However, for troubleshooting, I enjoy YouTube screen casts because of the visual aspects it provides; so, and I may decide to make a video that walks the user through the process step by step. You were right, thankfully I did not need to flash the firmware, the printrboard was good to go. You are also correct about he SD connector, they do wear out. The good news is that my school where I work is less than 15 minutes away from printrbot headquarters; so, if something serious breaks down I can drive on over there. They have a new option on their website called the "bot spa" treatment where they tune up and work on printers. To help with the SD card problem, I actually ordered these adapters below (see link) to help ease the wear and tear on them and just utilize a standard USB cable.

If printrbot does not create a wireless method to print, I will definitely be upgrading to octoprint here soon. I hear nothing but good things about it. I follow the printrbot forums and I notice you help out alot! That"s awesome, thanks again for your help!

Fork of the PrintrBot Firmware to work with RAMPS, it was tested with RAMPS 1.4 - Arduino Mega (Chinese, very much Chinese) - Drivers DRV 8825 - PrintrBot Power Supply . I haven"t test the LCD Smart display that you will find in the description Below, Work in Progress.

In the file "configuration.h" you will find between line 306 and 336 all settings for PrintBot Model available at the time of publish except the new PrintrBot Simple, AND by the way is not SIMPLE at all... Just saying...

It’s been a little over a week since I’ve had my Printrbot Simple Metal and I thought I would share my take on this great little printer. First my background in 3D printing…i.e. what gives me the right to voice my opinion on a 3D printer. I have been the Lead Dream Consultant (i.e. facilities tech) at TechShop Pittsburgh for just about 2 years. In those two years, I’ve had the chance to use/service/build from scratch a few different 3D printers. I’ve also learned a great deal in the matter from ZeGo Robotics in building one of their delta style robots (great robot/printer/cookie decorator by the way). I’ve also had a chance to really see a Makerbot Replicator 2 and 2x be put to hard use by members new and experienced to the 3D printing world. With all that said, in an effort to get a simple to use machine for home use, I sought out the Printrbot Simple Metal (Assembled).

Why assembled some may ask. Aren’t you a maker! Indeed I feel I am. However, having already experienced a full build of a ZeGo robot and countless repairs to our Makerbots, I felt I had done my due diligence and wanted to get down to 3D printing! I had kept my eye on the Printrbot Simple Metal since it’s first days being introduced in a video by Make: . Alas, I missed out on the limited red edition. The choice was easy to make as there are already countless reviews out there and a friend or two had already had great success with one.

After unboxing, always a favorite activity of mine, I immediately plugged it in and got down to business. I did the recommended test that Printrbot suggests. First the cube. They ask you to print the basic cube and adjust the Z height in the gcode terminal. Not too tough having come from the ZeGo bot and Prontrface (a program for controlling the printer). Once you get this dialed in you are ready to go. They recommend printing a fan shroud as well to help direct cooler air to the print. I did this and felt joy as I attached it to the fan mount. I was already making parts to improve what seemed to be an already awesome little printer.

The tool chain turned out to be more simple than I could have ever asked for, yet complex enough to satisfy a seasoned 3D printing veteran. Printrbot recommended to me to use Cura Slicer. Cura had a profile built in for the Printrbot Simple Metal so setup was extremely easy. With the prospect of potentially having a few of these printers for member use at TechShop Pittsburgh, the simple settings were very appealing. The advanced settings were great too and would potentially allow for teaching a deeper understanding of what the printer is doing and what can be changed in order to get better prints.

After the week with the printer. I’ve already gone through a half kg of filament (currently using Makerbot filament because I like the small spools). I will most likely be switching to Printrbot filament in the near future as it’s cheaper and sold by the same company as the bot. I recently acquired an LCD panel for controlling the bot with out a computer and after a quick test, I think I’m falling deeper in love with this printer.

The picture below is of a scan of my head done in Skanect software with a Kinect 360. The glasses and hat were added using Tinkercad. Support was added using Meshmixer from Autodesk and finally it was printed on the Printrbot Simple.

We’ve seen a lot of experimenting with 3D printers over the years, and that is a good thing. However, [Tyler] has had a bad experience with experimenting. He has a Printrbot Simple Metal and decided to try nylon weed wacker line. Since he wanted to get straight to printing, he skipped the apparently important step of drying the trimmer line before printing. This experimentation ended in several clogged nozzles. Removing and cleaning the nozzle several times put undo stress on the Ubis hot end wires and they broke. Things were not going well.

It looks like [Tyler] got back to printing with a little creative thinking. Unfortunately, the Ubis and J-Head hot ends are not interchangeable. A couple of other ex-Ubis users have made J-Head adapters for their Printrbots.

In order to print with the Printrbot Simple Metal you have to connect your computer with your printer via USB and make sure that the computer continuously sends data to the printer. If your computer crashes, your printer stops and your maybe long hour print is a piece of chunk. If your computer goes into stand by the result is the same. And there are various other reasons like energy consumption. The way to go is untethered printing.

The Printrbot Simple Metal is capable of that in two ways, both of them require a Mini-SD card inserted into the printer. The first way is to write the G-Codes generated by your Slicer, typically Repetier Host and Slicr to the SD-Card. Name it auto0.gcode, insert the card into the printer. Shut it down and on again. The printer should now start to print. But you will not know if it works for a couple of minutes as it’s first heating up. Nothing moves, etc. I tried that a couple of times and found the procedure to be very annoying.

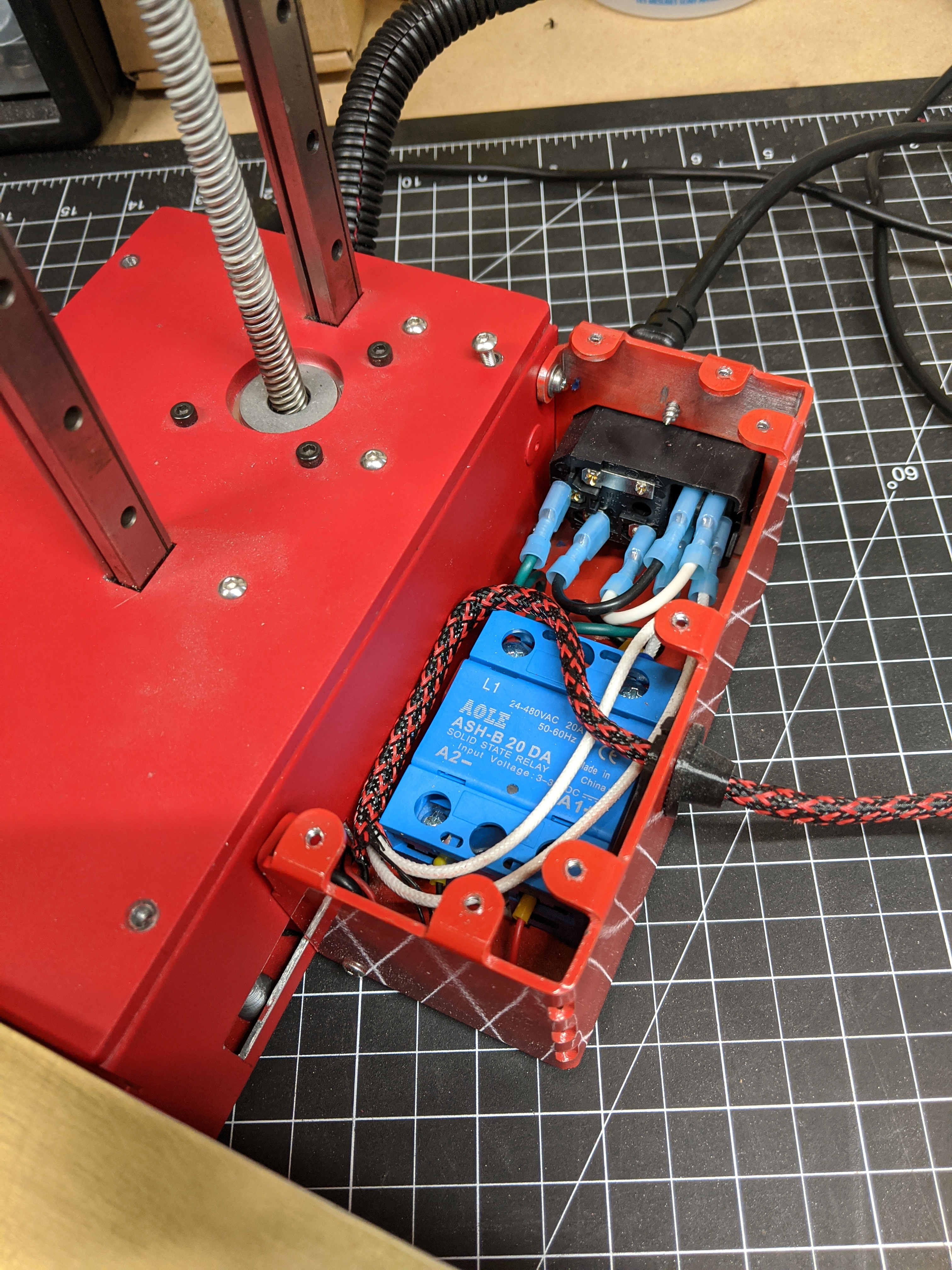

Your Printrbot is already capable of displaying a nice LCD-Menu with all kinds of options and the option to browse the SD-card and run any print from it untethered from your PC. All that is needed is a Standard 20×4 LCD Display and a rotary encoder. A rotary encoder is a special kind of input sensor that sends signals when it is rotated.

Printrbot sells these LCDs for $65 in their store. But they still have that wood look. It does not match the Metals Design. And, as I am living in Germany you will have to wait a few days for it to arrive and you will likely have some issues regarding customs. I did not found a german distributor a few weeks ago so I wanted to built my own. A few days ago I have found 3ddinge.de selling the LCD Controller in Germany for €70. That’s a lot of money and by doing it yourself you will end up with 30-40 Euros for the LCD Controller.

As said before the Printrbot has everything built in. There is an expansion slot (Exp2) with 14 pins that allows for connecting the PCB that hosts the LCD Display and the rotary encoder. I have found an excellent resource: Ricks Blog. Rick explains the pinout of the Expension slot and has created his own PCB. Instead of building my own PCB, I just used Ricks PCB Layout he provides and sent them to Smart Prototyping for manufacturing. I received the PCBs 3 weeks later. In the meantime I ordered the BOM. Rick provides everything in his blog but just a quick tip to resistor R1 which will depend on the LCD display you want to use: Adafruit has a very detailed explanation of how to calculate the correct value for the Resistor: Adafruits 20×4 LCD Character Tutorial.

Find a nice LCD 20×4 HD44780 Display. There are a lot of different colors available. Adafruit sells them for example. I opted for a nice White on Blue Display.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey