printrbot lcd panel quotation

The Printrbot Simple Metal is a very simple 3D printer with not much to offer. Despite its price tag, it’s still not fast enough to meet today’s standards.

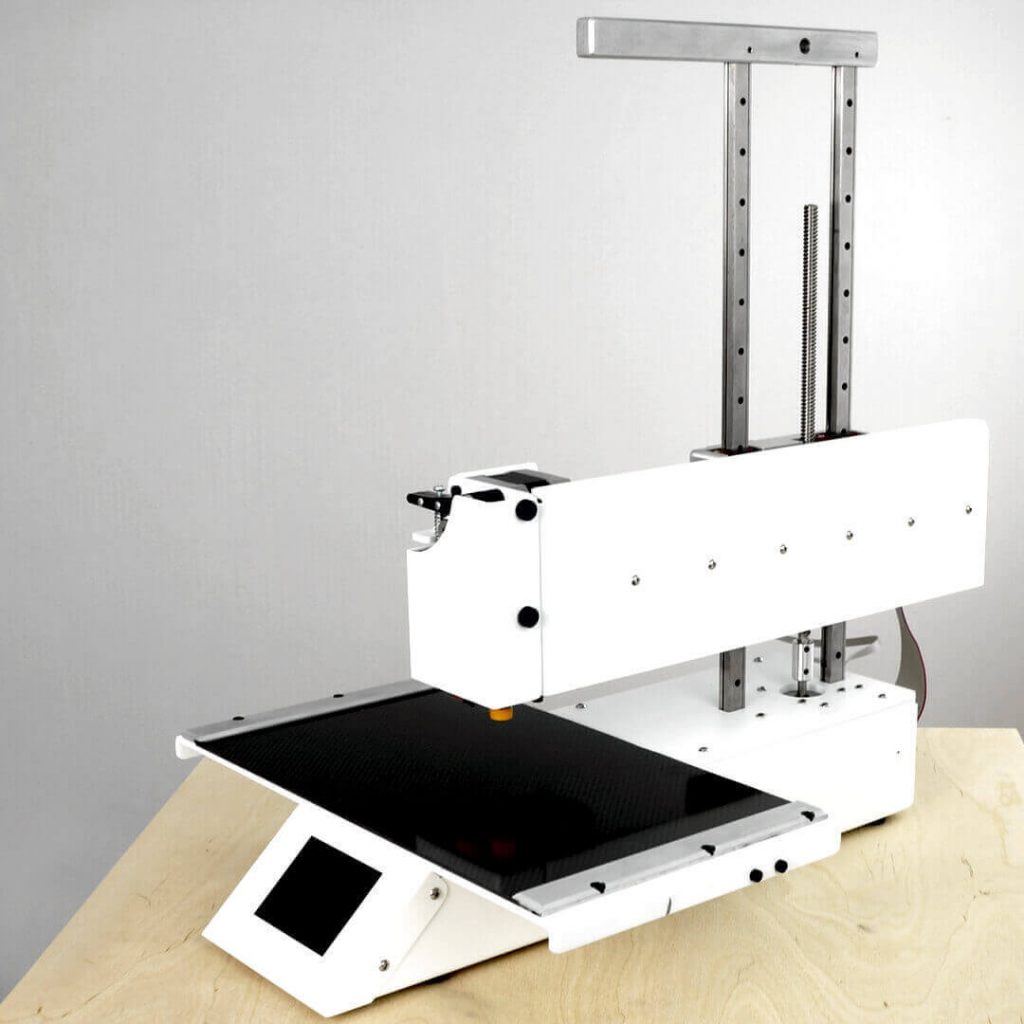

Today, we’re talking about the Printrbot Simple, sometimes called the Simple Metal. Despite being superseded by the Simple Pro, this remains an excellent way to get started. We’ll be looking for its strengths and weaknesses so you can decide if it’s the right printer for your needs.

It doesn’t actually come with any printing software, however, Printrbot recommends using Cura. As this is available for free online, it’s not a major issue. This software is compatible with Mac, Windows, and Linux, so there aren’t any limits on the computers you can print from.

This model performs admirably given its low price. That said, because the upgraded version costs about the same and includes an LCD screen, there’s really no reason to opt for the original. There’s even a heated bed variant of the Pro version, although it costs around $100 extra.

As Printrbot don’t offer phone support, you’re limited to either asking for help on the forums or sending them an email explaining your problem. This is a little underwhelming: even though the products don’t cost all that much, you’d still expect some assistance from the manufacturer if you run into trouble.

Printrbot is a 3D printer company created by Brook Drumm in 2011 and originally funded through Kickstarter. Printrbot printers use fused deposition modelling to manufacture 3-dimensional artifacts. Printrbot closed shop in 2018, noting "low sales".

Models are printed by depositing molten ABS or PLA plastic filament onto a hotbed from a print head which moves about the X and Z axes using stepper-motors, guided by metal threaded rods.USB interface using specialized software such Repetier-Host (recommended by the manufacturer for use with newer printers) or Pronterface (recommended by the manufacturer at the time of Printrbot"s initial launch).

Printrbot models can print in ABS or PLA plastic filament which can be purchased from the official store or other sources.Nylon, Ninjaflex, and Carbon fiber-reinforced PLA.

All Printrbots are controlled by nearly similar open source circuit boards called Printrboards. The Printrboard has experienced several revisions and is identified by revision letters printed on them. For example, the most recent official revision of the Printrboard is Rev F, which can be purchased separately. The Printrboard can have many types of firmware loaded on it, but they are sold with an open-source firmware from the RepRap Project called Marlin. The printer is controlled through a USB interface.

Printrbot does not come with any software and the official getting started guide recommends using the freeware program Cura 1.5 with Pronterface to interface with the printer. A freeware program with 3D visualization called Repetier-Host is also used.

The Printrbot interprets G-code produced by a computer program called a slicer, turning commands into outputs for four stepper motors, heated bed and extruder outputs, and a cooling fan port.

Import 3D models (oftentimes STL files from Thingiverse or user created in apps like Autodesk Fusion 360). The user can rotate and scale the 3D model to fit the virtual print bed. They can then convert the 3D model into G-Code that the printrbot can understand.

NOTE: This review was for the pre-assembled wooden version of the printer, which Printrbot no longer sells. For beginners, we recommend upgrading to the $599 pre-assembled Printrbot Metal. , which also has a larger 6 x 6 x 6 build area. If you feel up to the challenge, you can still buy the kit version of the wooden model for $349.

There is something of a race to the bottom in 3D printing: Who can make the cheapest 3D printer out there? Kickstarter is full of projects pursuing that goal, but they often fail to deliver. The least-expensive 3D printer you can actually buy right now is the Printrbot Simple Maker. And it"s one you might want to buy, too.

When I first unpacked the Printrbot Simple Maker, my wife declared, "That"s adorable! We have cats bigger than that!" She’s right: At just 11 x 10 x 8 inches and 9.3 pounds, this is a diminutive printer compared to models like the Lulzbot TAZ 3 (about 27 x 21 x 21 inches) or even the new MakerBot Replicator Mini (15 x 12 x 11 inches).

Printrbot kept costs down on the Simple Maker by using materials such as plywood rather than metal for the frame, and string instead of rubber for the drive belt. The electronics and motors are fully exposed, as well. The Simple Maker has a single extruder and, because it lacks a heated print bed, it prints in organic PLA plastic only.

We tested the pre-built version of the Printrbot Simple Maker, but it is also available as a cheaper ($349) kit version. The kit takes a little time to assemble, but it isn"t complex. Anyone who has used Legos and knows one end of a screwdriver from the other should have the skills to complete the assembly with the building instructions.

There are no controls on the Printrbot Simple itself. Instead, you operate the device through a computer connected over USB. Printrbot does not supply any software of its own, instead recommending the free Repetier Host open-source software, which is available for PC, Mac and Linux systems. Repetier Host is quite easy to use, but does require some configuration to work with the Printrbot Simple. This process is covered in the well-written and illustrated setup guide.

The Printrbot Simple Maker can print directly from a micro SD Card (it will print from a file called auto0.g when turned on). But with no controls on the device itself, that"s not a very practical option, as there is no way to stop the print except by pulling the plug.

The Printrbot Simple Maker is a fairly fast printer: Building a test print of The Thinker statue (which is just over 3 inches high) took about 3 hours and 50 minutes. Printing the star sculpture that we also use in our tests took just under 2:28, which is also quite fast for a 3D printer.

The Printrbot struggled with a sculpture of a star, producing a print with several edges missing and several spots where the filament didn"t stick together. To be fair, this is a very difficult print that we use to test the limits of a printer"s capabilities. The sharp edges and overhangs of this model challenge the printer to keep a very tight control over the flow of the printing material, and the Printrbot Simple failed occasionally, producing rough edges and loose fringes of filament on parts of the print. .

The Printrbot Simple did a better job printing our third test model, a small set of gears. The cogs came out fairly clean, though we did have to lightly sand them in areas to remove some excess plastic before they would fit together. However, the PLA material the printer uses proved to be too brittle for the gears to work well. The small supports that hold the gears in place broke under moderate pressure.

The Printrbot Simple shows how much 3D printing has advanced over the past few years. Until recently, the idea of a 3D printer that costs $350 producing anything decent would have been laughable. Now it is a reality, though you"ll have to live with compromises — such as the lack of a display or controls on the device, the small build area, the limitation of only one printing material, and the device"s tendency to jam. But the Printrbot Simple achieves its goal of providing respectable performance and an introduction to the world of 3D printing without costing a fortune.

Printrbot is a 3D printer company created by Brook Drumm in 2011 and originally funded through Kickstarter. Printrbot printers use fused deposition modelling to manufacture 3-dimensional artifacts. Printrbot closed shop in 2018, noting "low sales".

Models are printed by depositing molten ABS or PLA plastic filament onto a hotbed from a print head which moves about the X and Z axes using stepper-motors, guided by metal threaded rods.USB interface using specialized software such Repetier-Host (recommended by the manufacturer for use with newer printers) or Pronterface (recommended by the manufacturer at the time of Printrbot"s initial launch).

Printrbot models can print in ABS or PLA plastic filament which can be purchased from the official store or other sources.Nylon, Ninjaflex, and Carbon fiber-reinforced PLA.

All Printrbots are controlled by nearly similar open source circuit boards called Printrboards. The Printrboard has experienced several revisions and is identified by revision letters printed on them. For example, the most recent official revision of the Printrboard is Rev F, which can be purchased separately. The Printrboard can have many types of firmware loaded on it, but they are sold with an open-source firmware from the RepRap Project called Marlin. The printer is controlled through a USB interface.

Printrbot does not come with any software and the official getting started guide recommends using the freeware program Cura 1.5 with Pronterface to interface with the printer. A freeware program with 3D visualization called Repetier-Host is also used.

The Printrbot interprets G-code produced by a computer program called a slicer, turning commands into outputs for four stepper motors, heated bed and extruder outputs, and a cooling fan port.

Import 3D models (oftentimes STL files from Thingiverse or user created in apps like Autodesk Fusion 360). The user can rotate and scale the 3D model to fit the virtual print bed. They can then convert the 3D model into G-Code that the printrbot can understand.

You may ask: What the hell is the point here? So, let’s get started: The other day I noticed in a Copper sales report that someone with a @printrbot.com email address bought Copper. Being a fan of them I sent them an email thanking them for purchasing Copper and telling them I loved their Simple Metal. This changed everything! We got in contact and Mick told me he learned about Copper by reading my blog post about Little Helper (http://www.appfruits.com/2015/12/little- helper/), which he noticed in a blog post on hackaday.com (http://hackaday.com/2015/12/25/little- helper-open-source-hardware-hacker-multitool/). He also told me he uses Copper to quickly checkout pin numbers and signals when working on the firmware for their printers.

A few days later I had a Skype chat together with Mick and Brook Drumm (founder and CEO of printrbot) and they asked me if it would be possible to use Little Helper as a display and input system for their printers. A year ago most 3D printers used a tiny LCD screen with a rotating input wheel (rotary encoder) and a SD card slot for printer control. Little Helper seemed like a good fit and a step forward.

So, after one Skype chat we started the project to create a LCD display for the next generation of printrbot products. This is awesome. I don’t think a lot of CEOs in Germany would start things like that. This is visionary and full of risks. They are in the US, I am in Germany. We have a time difference of 8-9 hours. There are so many things that could go wrong. In Germany you would rather want to hire someone around you. You want to be able to control what he/she is doing. Brook just has been confident that it will work out. I am running a German internet company full time (4players.de (http://www.4players.de)). These projects and Copper are filling my spare time that I need to fill with creativity and product development to be healthy and happy ;-). This has been a great chance for me to do something with a little more impact than working in my lab for myself or the open source community.

The Display system (http://www.appfruits.com/2016/11/printrbot-simple-2016-display-system- explained/) built upon the amazing and very fast display driver developed by Paul J. Stoffregen (Teensy creator). Although it uses SPI (which is not the fastest method to connect to a display) it’s very fast and just works great. We have written our own driver for the FT6206 touch controller we use, although it’s been heavily influenced by the driver from Adafruit.

We had to develop a whole new way of handling the pixels of a small display. And we managed to do that. Our display system is versatile, fast, easy to use and very flexible. It permits very large scrollable areas without eating a lot of memory and while keeping very fast refresh rates and responsiveness. It’s an amazing system and you should learn how it works (http://www.appfruits.com/2016/11/printrbot-simple-2016-display-system-explained/) and how you can use it yourself in your next project.

Time difference has been good and bad at the same time. Due to 8-9 hours time difference we only had a short window for chatting each day. It forced us to organize our work but modern tools like Github and Skype allowed us to do that very easily. For me time difference has been great as this project never collided with my full time job. While I have been working my daily job the printrbot guys have been sleeping, and once they started their day I already had finished my daily job and were able to work on this project. Time difference had been an issue in the last weeks of polishing the product. It required us to package all that little pieces we developed in the past months and it’s been frustrating as the team testing the printers sometimes had to wait a day until I have been able to fix the issue.

If you ever have the chance to work with Printrbot: Do it! You will not regret it. You will learn a ton, you will have a lot of fun and you will have new friends after that. This sounds like a final conclusion, but think about that like a season 1 final: We just got started!

With the Printrbot Simple Pro, Brook Drumm and team are trying to deliver what he believes is his easiest to use machine yet. While we didn’t have a totally smooth experience with it, you will find the machine quality that one expects from Printrbot, and a whole new way of printing to go alongside the old standards.

The Simple Pro combines a color touchscreen with the new Printrboard G2, a 32-bit controller running G2 Core (the ARM port/successor to TinyG). These tie it into Printrbot’s new cloud software and ideally allow one of the easiest printing experiences yet: a true scroll, click, and print process that lets you, with as few settings as possible, send your STLs to the machine and have them print. This means no more separate slicing software hassles.

Through the shootout weekend the team had issues getting Printrbot’s cloud software to work smoothly, so we used Cura, tethered via USB, to generate our test prints. Assessing the quality of these probes, the testing team found that the machine was capable of producing great results. Once I got the Wi-Fi and cloud set up and running I had small hiccups, like machine freezes during preheating and buttons missing on the LCD. These were usually remedied with a good old fashioned reboot. But overall my experience went fine, and to be able to load designs as I found them, from anywhere, and print them when I get home was refreshing, and certainly kept my downloads folder cleaner.

The all-metal construction of the Printrbot Simple Metal feels more like a professional power tool than an entry-level 3D printer. The weight of this small, portable printer gives it a real sense of quality, and the inclusion of a now-standard auto-leveling bed makes it a real step up from its wooden predecessors. This printer is packed with features and rivals machines costing much more.

With the healthy-sized bed you can print many substantially sized items in PLA and nylon on the unheated surface. ABS is supported if you add the optional heated bed upgrade. In fact, the heated bed upgrade ($99) and the interchangeable tips (ranging from 0.25 to 0.75mm for $8 each) allow you to experiment with just about any material. You can print tethered via Repetier-Host, untethered via onboard microSD card, or add onboard controls with the Printrbot LCD control kit accessory ($65). Don’t forget to print the fan shroud upgrade, it enabled our test unit to attain perfect scores on the Bridging and Overhang tests.

The Simple’s setup documentation is professional and thorough. Due to the amount of information presented, it can feel a bit overwhelming, but it’s a fantastic reference when needed. Printrbot also has a robust help site () and community forum (), and it’s common to the see the Printrbot’s founder, Brook Drumm, answering questions directly. That’s a nice customer service touch. There’s also a great education section for teachers and students ().

The Simple Metal is pretty great, but it’s not perfect. The initial adjustment of the auto-level probe is a tad cumbersome. It takes a bit of double-hand holding to adjust the probe while fighting the tension on the wiring in the close quarters around the adjustment nuts. The inclusion of a laser-cut wrench helps, and is a nice, sentimental reminder of Printrbot’s beginnings. In addition, it can be hard to tell if the printer is turned on until you notice the glow from underneath the machine. This was not immediately apparent in a well-lit room. We also had a serious nozzle clog issue during an 8-hour overnight print that resulted in the filament forcing its way out of the extruder in a bizarrely perfect, spring-like coil.

Although it’s a common open-source toolchain issue not directly related to Printrbot, it can be a frustrating experience for a first-time user to walk through Slic3r’s multiple setup screens and dialog boxes. I’d like to see Cura formally recommended as another open-source option, as the Printrbot community already recommends it. I also was not impressed with the “write to SD” function of Repetier-Host; I took the microSD card out and loaded it into the computer to transfer the file manually, although it’s a bit hard to access.

Almost finished with my version of the LCD screen support. Happy with how it turned out so far. Printrbot Support gave me the ref at digikey for a longer SD cable.

The SD backplate hole is too small to connect the SD cable on the 1412 at the moment unfortunately (due to the 90° plug). BUT, Printrbot Support promised to send me a retrofit this month. You can see the new iteration of the Metal+ (1504) is already modified to tackle all that.

Printrbot founder and CEO, Brook Drumm apparently foresaw the demand for these larger-than-normal 3D printers begin to gain traction over a year ago. Back in June, we reported that he had been working on creating a larger than normal 3D printer. He had built it for a company called 11dy as a trade for photography work that they did for him. While we had a feeling that Drumm had something up his sleeve, more so than just creating a one-off design for a client, Drumm never mentioned anything about mass manufacturing these machines at that time. Things changed yesterday though, when the Printrbot Pro was officially unveiled.

“I have wrestled with this monster for over a year,” explained Drumm. “I buil[t] 5 prototypes from scratch and hated them all. The last one was too ambitious with servos and ballscrews… That last one printed beautifully after, oh, SO much work, but I tore it down the next day and went back to the drawing board, hacking together a totally new design in a couple days from spare parts lying around. The Printrbot Pro is aimed at those who want a very large build volume but don’t want to pay the big bucks for other options out there. “

Drumm also made two more announcements. He unveiled a Printrbot CNC router called the “Crawlbot”, which will have the ability to cut objects 4’x 8′ in dimensions, and announced that the Printrbot Play has gone on sale today for just $399, completely assembled. Orders for the Play can be placed now, and shipping will commence on June 1st.

The Printrbot Play is constructed of metal and features the all new Alu Extruder v2 as well. It is targeted toward beginners, kids and “enthusiasts”, and it has the following specifications:

Without a doubt, these two new printers and the CNC router will all bring Printrbot even more satisfied customers. Drumm has quickly built his company up from a Kickstarter baby into one of the more popular desktop 3D printer manufacturers in the world. His customers are usually extremely happy because his machines are built with such high quality.

Printrbot has released the latest version of their popular Printrbot Simple 3D printer, that can now be pre-orderedonline through their website, with shipping to starte in late July (U.S. only).

The Printrbot Simple v2 is an updated version of their former 3D printer, including features such as WiFi, removable built plate, LCD touch screen, enhanced electronics (Printrboard G2 and Powrboard) and dual power plugs. Additionally, the new printer comes with an updated handle and spool rack design, rubber feet, on/off power switch, led indicator lights, linear rails and bearing carts as well as an Ubis 13S hot end. The build volume of 203 x 150 x 203 mm is also bigger than the one of its predecessor.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey