tft display interface microcontroller factory

The display is a critical component in every project, impacting the case, firmware, electrical design, user interface, and even battery life. For these reasons, and because it is the most visible component of your product, it must be approved by the mechanical design team, management and marketing.Before these teams can approve, they need to see it in action. But it can take days or weeks to connect a display to your platform, initialize it and build a code library able to create believable demonstrations. Meanwhile, the whole project is on hold.Our 8051 development kit / demonstration board can solve this problem. Use it to get the display seen, demonstrated and approved for your project.

ER-DBTM080-2 is a microcontroller 8051(80C51) demonstration and development kit for ER-TFTM080-2 product that is 8 inch tft lcd display with RA8875 controller board.The kit includes MCU board controlled by STC12LE5A60S2,ISP(In System Programming) with USB port and cable to customize the demonstration that includes your own bitmap images,personalized fonts,symbols,icons and burn sketches,microSD card that is written graphic and text into it,the power adaptor,the adaptor board with various pitch dimension used to connect MCU board and display.Optional for 8080 8/16-bit,6800 8/16-bit parallel interface and I2C,3-wire,4-wire serial interface.

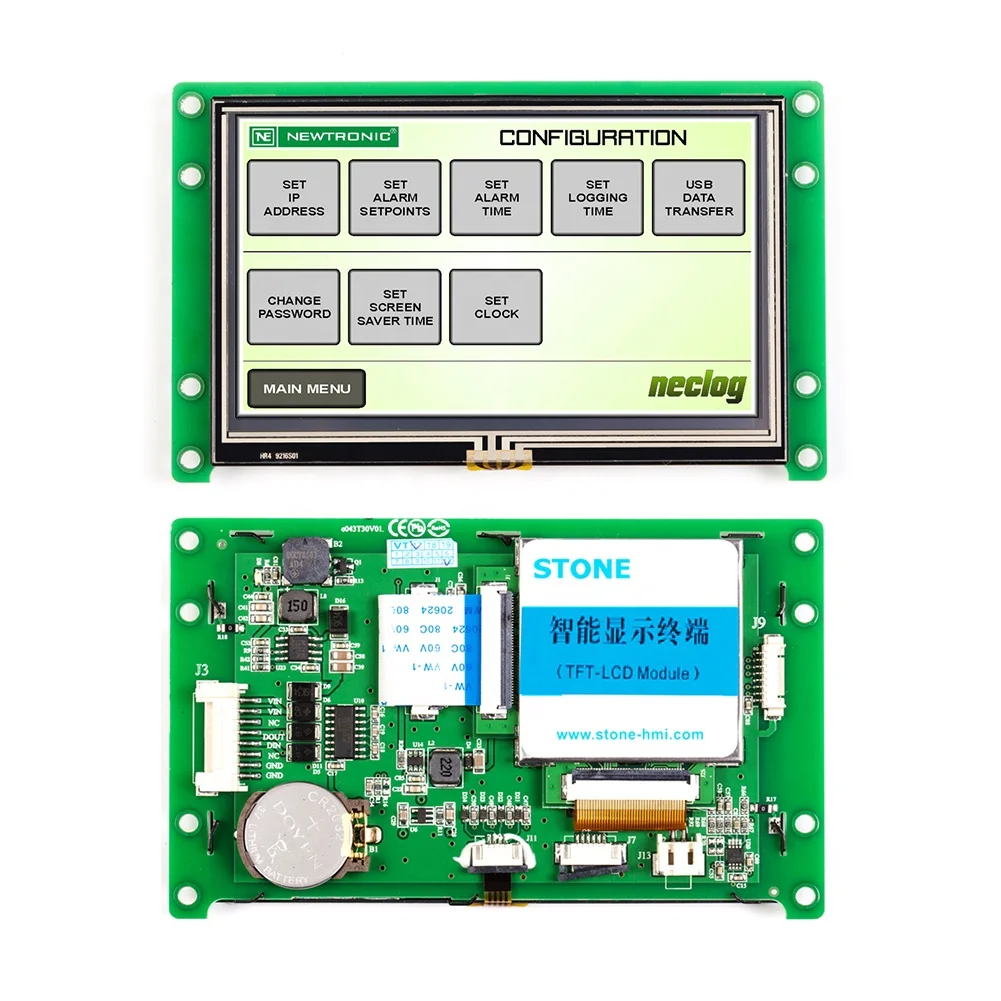

This guide is about DWIN HMI Touch Screen TFT LCD Display. HMI Means Human-Machine Interface. DWIN is specialized in making HMI Touch screen displays that are compatible with all microcontrollers like Arduino, STM32, PIC, and 8051 families of Microcontrollers.

This is a Getting Started tutorial with 7-inch DWIN HMI TFT LCD Display. We will see the architecture, features, board design, components, and specifications. We will also learn about the TTL & RS232 interfaces. Using the DGUS software you can create UI and with SD Card you can load the firmware on display memory.

You can change the TTL Interface mode or RS232 mode from here. Just solder these two terminals as shown here to enable TTL Interface. By default, the module is in RS232 Interface.

One of the method to load the firmware to the T5L DWIN LCD Display is by using the SD Card. An SD Card of up to 16GB can be used to download the firmware files. We can easily insert the Micro SD card into the SD Card slot on the backside.

After copying the file, remove the SD Card from your computer and insert it into the SD Card slot of DWIN LCD Display. Then power the display using the USB Cable. The firmware downloading process will start automatically.

The next part of this tutorial includes creating UI and interfacing DWIN LCD Display with Arduino. For that you can follow the DWIN LCD Arduino Interfacing Guide.

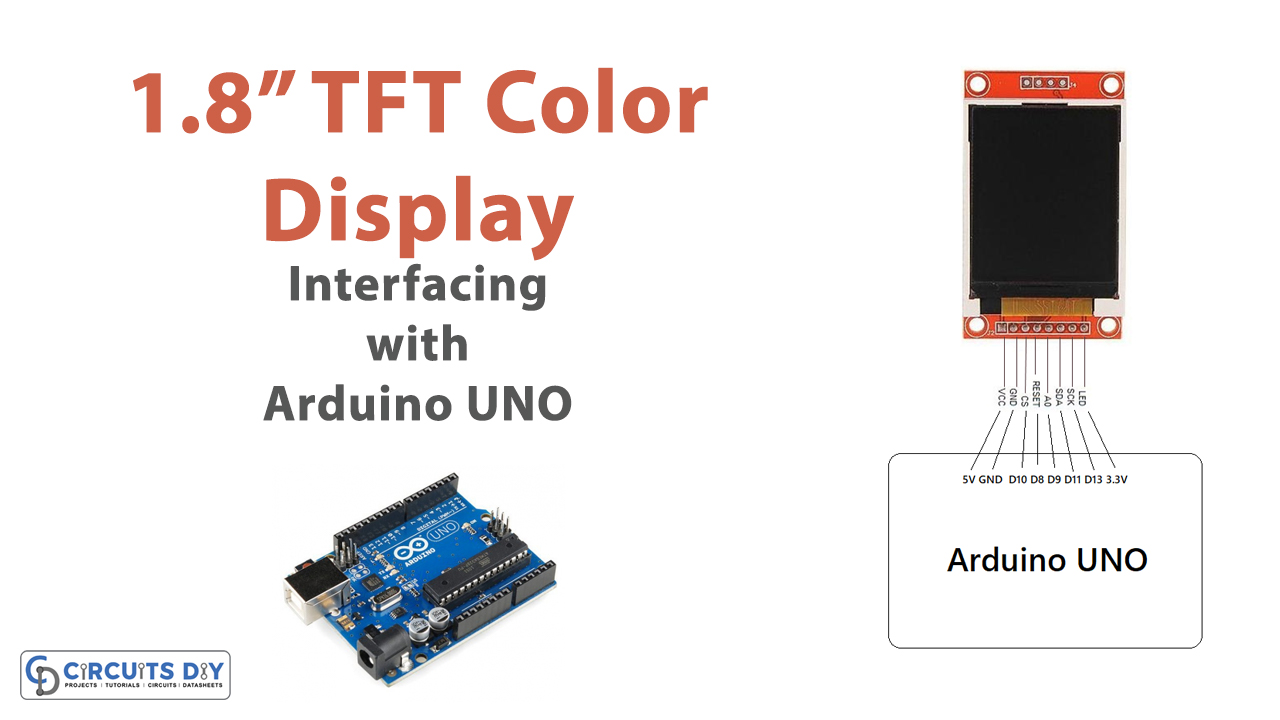

In electronics world today, Arduino is an open-source hardware and software company, project and user community that designs and manufactures single-board microcontrollers and microcontroller kits for building digital devices. Arduino board designs use a variety of microprocessors and controllers. The boards are equipped with sets of digital and analog input/output (I/O) pins that may be interfaced to various expansion boards (‘shields’) or breadboards (for prototyping) and other circuits.

The boards feature serial communications interfaces, including Universal Serial Bus (USB) on some models, which are also used for loading programs. The microcontrollers can be programmed using the C and C++ programming languages, using a standard API which is also known as the “Arduino language”. In addition to using traditional compiler toolchains, the Arduino project provides an integrated development environment (IDE) and a command line tool developed in Go. It aims to provide a low-cost and easy way for hobbyist and professionals to create devices that interact with their environment using sensors and actuators. Common examples of such devices intended for beginner hobbyists include simple robots, thermostats and motion detectors.

In order to follow the market tread, Orient Display engineers have developed several Arduino TFT LCD displays and Arduino OLED displays which are favored by hobbyists and professionals.

Although Orient Display provides many standard small size OLED, TN and IPS Arduino TFT displays, custom made solutions are provided with larger size displays or even with capacitive touch panel.

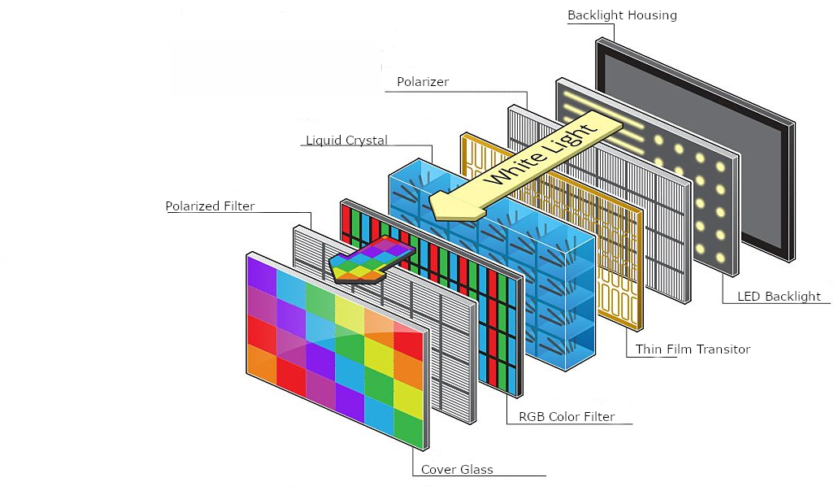

A TFT LCD display module consists of a TFT LCD panel, one or more COG (chip-on-glass) or COB (chip-on-board) driver ICs, a backlight, and an interface. Several TFT display interface technologies exist today. Picking the right interface depends on specific end-product concerns. There are several types of TFT display interfaces which have been designed in the last number of years for various screen sizes, including LVDS, (Low-Voltage Differential Signaling) parallel, SPI (Serial Peripheral Interface) RGB and so on. Here is an overview of these display interfaces to give you a better idea of the variety of TFT LCD displays that are taking center stage.

SPI LCD Interface: Serial Peripheral Interface allows serial (one bit at a time) exchange of data between two devices. It has an advantage over parallel ones, that of simpler wiring. SPI also can have longer cables, since there is much less interaction or crosstalk in the cable. The downside of SPI is that you can"t read from the TFT LCD display, you can only write on it and it is slow. That"s why you normally see smaller TFT LCD screens use SPI.

MCU Parallel Interface: Many modern MCUs have built-in LCD controller function. There are two types that are commonly used, 6800 and 8080. Generally, MCU/Parallel interface consist of data signal(4/8/9/16 bits) and control signal. MCU interface is simple, but requires display RAM.

RGB Interface: RGB interface is a special kind of parallel interface. It requires no display RAM. MCU directly updates the TFT screen, sending Red Green & Blue sub-pixel data (16/18/24 bits) and timing signals. RGB interface provides high speed communication to TFT LCD, but it needs more data wires and controlling is more complex.

LVDS Interface: Low-voltage differential signaling is an electrical digital signaling standard. Devices with LVDS interface can communicate at very high speeds over inexpensive twisted-pair copper cables. It is much less susceptible to EMI and crosstalk issues, allowing the transmitting device to be located farther from TFT LCD display.

UART/RS232/RS485: These serial interfaces are used in Topway"s Smart TFT LCD display module. Universal Asynchronous Receiver/Transmitter (UART) is a block of circuitry responsible for implementing serial communication. Essentially, the UART acts as an intermediary between parallel and serial interfaces. On one end of UART is a bus of eight-or-so data lines (plus some control pins), on the other is the two serial wires – RX and TX.

HDMI Interface: High Definition Multimedia Interface is a connector and cable definition that supports high-quality and high-bandwidth streams of video and audio between devices.

MIPI DSI: MIPI Display Serial Interface defines a high-speed serial interface bewteen host processor and display module. The interface facilitates a high performance, low power and low EMI way to render brilliant color for the most dempanding image and video scenes.

To choose your product"s TFT LCD interface, besides above technical considerations, target use environment and bandwidth are two main factors as well. You can read more about how to choose LCD interfaces here, or consult with us. Topway has been manufacturing TFT LCD in the past 20s years. Our TFT LCD modules cover full spectrum of interfaces. And we surely can suggest a TFT LCD display that suits your use case.

The traditional mechanical instrument lacks the ability to satisfy the market with characters of favorable compatibility, easy upgrading, and fashion. Thus the design of a TFT-LCD (thin film transistor-liquid crystal display) based automobile instrument is carried out. With a 7-inch TFT-LCD and the 32-bit microcontroller MB91F599, the instrument could process various information generated by other electronic control units (ECUs) of a vehicle and display valuable driving parameters on the 7-inch TFT-LCD. The function of aided parking is also provided by the instrument. Basic principles to be obeyed in circuits designing under on-board environment are first pointed out. Then the paper analyzes the signals processed in the automobile

instrument and gives an introduction to the sampling circuits and interfaces related to these signals. Following this is the functional categorizing of the circuit modules, such as video buffer circuit, CAN bus interface circuit, and TFT-LCD drive circuit. Additionally, the external EEPROM stores information of the vehicle for history data query, and the external FLASH enables the display of high quality figures. On the whole, the accomplished automobile instrument meets the requirements of automobile instrument markets with its characters of low cost, favorable compatibility, friendly interfaces, and easy upgrading.

As an essential human-machine interface, the automobile instrument provides the drivers with important information of the vehicle. It is supposed to process various information generated by other ECUs and display important driving parameters in time, only in which way can driving safety be secured. However, the traditional mechanical automobile instrument is incompetent to provide all important information of the vehicle. Besides, the traditional instrument meets great challenge with the development of microelectronic technology, advanced materials, and the transformation of drivers’ aesthetics [1, 2]. Moreover, the parking of the vehicle is also a problem puzzling many new drivers. Given this, traditional instruments should be upgraded in terms of driving safety, cost, and fashion.

The digital instrument has functions of vehicle information displaying, chord alarming, rear video aided parking, LED indicating, step-motor based pointing, and data storage. The instrument adopts dedicated microcontroller MB91F599, a 7-inch LCD, and two step-motors to substitute for the traditional instrument. All the information generated by other ECUs can be acquired via not only the sample circuits but also the CAN bus.

The instrument provides interfaces for different types of signals and the CAN bus. All types of signals (such as square wave signal, switching signal, resistance signal, analog voltage signal, etc.) coming from other ECUs can be acquired either from different types of sampling circuits or from the CAN bus. This makes it suitable for both the outdated application where the information from other ECUs can only be acquired via the sampling circuits and the modern application where the information from other ECUs are transmitted via the CAN bus.

The CAN bus interface and the 7-inch TFT-LCD make it more convenient to upgrade the instrument without changing the hardware. If the software needs to be upgraded, we need not bother to take the instrument down and program the MCU. Instead, we can upgrade the instrument via the vehicle’s CAN network without taking the instrument down, which makes the upgrading more convenient. Most of the information from other ECUs can be transmitted via the CAN bus; so, we do not have to change the hardware circuits if some of the ECUs’ signals are changed in different applications. Besides, since most of the driving parameters are displayed on the TFT-LCD, and the graphical user interface can be designed with great flexibility by programming, only the software needs to be revised to meet different requirements of what kind of driving parameters to display and so forth. These characters, together with the reserved interfaces, enhance the instrument’s compatibility in different applications.

It is a trend to incorporate the instrument into the vehicle information system via the CAN bus. The CAN bus interface gives the instrument access to the vehicle CAN network which enables easier fault diagnosing [3, 4] and information sharing. The fault diagnosing could be realized by accomplishing the fault diagnosing protocol above the low-speed CAN bus.

On the one hand, there are some automobile instruments which adopt 8-bit MCUs or 16-bit MCUs which have limited peripherals, so it is difficult for them to meet some requirements such as rearview video and high real-time data processing performance. And many extra components are needed if the designer wants to accomplish some functions such as video input. On the other hand, there are some advanced automobile instruments which adopt high performance MCUs (such as i.MX 53, MPC5121e, and MPC5123) and run Linux on them. They even use larger TFT-LCDs (such as the 12.3-inch TFT-LCD with a resolution of 1280 × 480 pixels) to display driving parameters. These automobile instruments show higher performances than the instrument in this paper. However, they are more expensive than this automobile. This instrument is able to provide almost all the functions of the advanced automobile instrument with a lower cost.

The instrument receives signals from other ECUs via the sampling circuits or the CAN bus interface. It can also receive commands from the driver via the button interface. The signals are then processed by the MCU, after which the MCU may send the vehicle information to the LCD or light the LEDs and so forth, according to the results. Therefore, the automobile instrument can be viewed as a carrier of the information flow. And the design of the system can be viewed from two aspects: the hardware system and the information flow based on it.

Overvoltage protection circuits should be placed at the interfaces of power supply and important signals (such as the CAN bus interface) in case of voltage overshoots.3.1.3. Generality

Reserved interfaces should be taken into consideration to shorten the development cycle of subsequent similar instruments and optimize the instrument for general use.3.1.4. Inventories

The automobile instrument receives and processes information from other ECUs such as the tachometer, the speedometer, the cooling water temperature gauge, the oil pressure gauge, and the fuel gauge. The signals coming from these ECUs are of different types, according to which different kinds of sampling circuits and interfaces should be designed. Accordingly, a classification of the input signals is first carried out, as shown in Table 1.

The microcontroller is essential to the performance of the instrument cluster. Therefore, the microcontroller that suits the system should have rich peripherals to reduce extra components, thus saving the space of the cluster and enhancing the stability of the system. Meanwhile, the operating frequency should be high and the memory size should be large for the demand of speed and accuracy in real-time processing. Besides, various operation modes are needed to lower down the power consumption.

Respecting the above mentioned factors, we finally chose the MB91F599 produced by Fujitsu as the microcontroller. The MB91F599 is particularly well-suited for use in automotive instrument clusters using color displays to generate flexible driver interfaces. It integrates a high performance FR81S CPU core which offers the highest CPU performance level in the industry. Besides, it has a graphics display controller with strong sprite functionality, rendering engine, and external video capture capabilities. These greatly reduce the need for extra components and enhance the stability of the system. The rendering engine can operate in combination with the video capture to enable image manipulation. Overlaid graphics such as needles or parking guidelines can be rendered in conjunction with captured video, which helps to accomplish the aided parking. What is more, multiple built-in regulators and a flexible standby mode enable the MB91F599 to operate with low power consumption.

Square wave signal is the signal that comes from the tachometer. The engine speed, the velocity of the vehicle, and the mileage are proportional to the frequency of the square wave signal. However, the square wave is not “standard” because it is often corrupted by interferences. Besides, the peak voltage of the square wave is +12 V while the I/O voltage of the microcontroller is . The main task for the circuits is to remove the interferences and convert the +12 V voltage to . As shown in Figure 3, the square wave signal is input from node ②; node ① is connected to one pin of the microcontroller.

After the preprocessing of the square wave, the microcontroller detects the positive edge of the “standard” square wave and calculates its frequency. The engine speed, the velocity of the vehicle, and the mileage can be calculated based on the frequency.

The switching signal acts as a trigger signal to trigger some events such as lighting up the backlight and waking up the MCU. It can be categorized into active high and active low according to the ECUs that generate it. Figure 4 offers a complete picture of the sampling circuit of active high signal. The switching signal is input from node ②; node ① is connected to one pin of the microcontroller. Diode clamps the peak voltage of the switching signal (usually +12 V) to the standard I/O voltage of the microcontroller () after resistive subdivision. The sampling circuit of active low signal is similar to Figure 4.

The resistance signal is generated by the fuel gauge and the air volume gauge. As shown in Figure 5, the resistance signal is input from node ①; node ② is connected to one pin of the microcontroller. , , , and have the same value of and they form a series-parallel network to cut down the power consumption of each resistor to one forth that of a one-resistor solution.

The analog voltage signal reflects the battery voltage and the air pressure. The corresponding circuit adopts the resistive subdivision so as to adjust the ratio of the resistors for putting voltage of the signal below the microcontroller’s maximum I/O voltage. The value of the resistors should be a little larger to lower down the static power consumption of the resistors. It is unnecessary to go into detail of the circuit.

The rearview video contributes a lot to vehicle backing and parking. The signal coming from the rear camera must be regulated before being processed by the microcontroller. The rear camera outputs NTSC video. The MB91F599 integrates a video decoder which supports NTSC/PAL video input, which makes the design of the regulatory circuit simple.

The video buffer circuit consists of a clamping circuit (, , ) and an emitter follower (, , ), as shown in Figure 7. Node ① is connected to the NTSC input pin of the microcontroller; node ② is connected to the clamp level output pin of the microcontroller; node ③ is connected to the camera’s signal output. is the coupling capacitor; is the matching resistor to realize the 75 Ω back termination.

Here, the sync signal is not present, so the clamp level is controlled by the clamp level output pin of the microcontroller, which is called “keyed clamp” [5]. The graphics display controller of the microcontroller let the clamp level output occur in coincidence with the sync pulse; that is, the clamp level output occurs during the sync tip in Figure 6, thus we get the “sync tip clamp” [5].

Since the FLASH size of the microcontroller is only 1 MB which is limited for the storage of pictures displayed on the LCD, external FLASH is needed to store different kinds of meaningful pictures such as the background of the dial. Two S29GL256N chips with a memory capacity of 256 Mb are chosen for picture data storage for their high performance and low power consumption. The application circuits of the chips are provided in their datasheets, so it is unnecessary to go into the details of them here.

Controller Area Network (CAN) is widely deployed in automobile, industry, and aerospace domains. As a major trend of the technological development of in the automation industry, CAN is now reputed as a local area network in automation [6]. Its low cost and ability to integrate with most microcontroller silicon families have made it a standard for automobile applications [7–9].

The 7-inch TFT-LCD has a resolution of pixels and supports the 24-bit for three RGB colors. The interface of the 60-pin TFT-LCD can be categorized into data interface, control interface, bias voltage interface, and gamma correction interface.

The data interface supports the parallel data transmitting of 18-bit (6 bits per channel) for three RGB colors. Thus, a range of colors can be generated. The control interface consists of a “horizontal synchronization” which indicates the start of every scan line, a “vertical synchronization” which indicates the start of a new field, and a “pixel clock.” This part is controlled by the graphics display controller which is integrated in the MB91F599. We just need to connect the pins of the LCD to those of the microcontroller correspondingly.

Bias voltages are used to drive the liquid crystal molecules in an alternating form. The compact LCD bias IC TPS65150 provides all bias voltages required by the 7-inch TFT-LCD. The detailed circuit is also provided in the datasheet of TPS65150.

The greatest effect of gamma on the representations of colors is a change in overall brightness. Almost every LCD monitor has an intensity to voltage response curve which is not a linear function. So if the LCD receives a message that a certain pixel should have certain intensity, it will actually display a pixel which has intensity not equal to the certain one. Then the brightness of the picture will be affected. Therefore, gamma correction is needed. Several approaches to gamma correction are discussed in [20–22]. For this specific 7-inch LCD, only the producer knows the relationship between the voltage sent to the LCD and the intensity it produces. The signal can be corrected according to the datasheet of the LCD before it gets to the monitor. According to the datasheet, ten gamma correction voltages are needed. These voltages can be got from a resistive subdivision circuit.

For this instrument, the LED indicators, the backlight, and the chord alarm need to be supplied with a voltage of +12 V; the CAN transceiver, the EEPROM, and the buttons need to be supplied with a voltage of +5 V; the video buffer circuit, the external FLASH, and the data interface of the LCD need to be supplied with a voltage of +3.3 V. Besides, the microcontroller needs to be supplied with voltages of +5 V and +3.3 V simultaneously. Figure 8 offers a detailed block diagram of the power supply for the automobile instrument.

The main task for the program is to calculate the driving parameters of the vehicle and display them on the TFT-LCD. The calculation is triggered by the input signals via the sampling circuits or the CAN bus. The main program flow chart of the system is shown in Figure 10.

The design scheme of a TFT-LCD based automobile instrument is carried out form aspects of both the hardware and the main program flow chart. The MB91F599 simplifies the peripheral circuits with its rich on-chip resources and shows high performance in real-time data processing. The automobile instrument is capable of displaying the velocity of the vehicle, the engine speed, the cooling water temperature, the oil pressure, the fuel volume, the air pressure, and other information on the TFT-LCD, which contributes a lot to driving safety and satisfies drivers’ aesthetics. Besides, the rearview video makes the parking and backing easier and safer for the driver. Moreover, the CAN bus interface and TFT-LCD make it easier for the upgrading of the instrument without changing the hardware, thus saving the cost.

Have you ever asked yourself what LCD is? No worries, we are here for you. Therefore, like in any display gadget, liquid crystal display coordinates with a microprocessor or microcontroller. The MCPU and MCU send the brightness that every pixel should produce. It creates the required color of the pixel for your LCD screen.

However, the mode of communication between the MPU/MCU and an LCD segment is known as the interface. We shall discuss more of the LCD interface in this guide.

The LCD interface is a link between the flat panel display module and the multimedia processor. Therefore, the interface can be separated or incorporated as part of the structure on the chip. Additionally, the application produces an image, and then the screen displays it using an LCD interface for the user.

The Serial Peripheral Interface is a data bus with several lines for the data. It accurately harmonizes the two ends of the data transmission. Therefore, the signal clock rotates, indicating when to sample the data bits on the line.

Besides, the serial peripheral interface has another component known as the slave select (SS) or chip select. The function of the SS is to wake the peripheral to receive or send data. For instance, since the SPI can support several peripherals, the SS can wake particular peripherals instead of all. Finally, you can use the SPI in graphic, character, digit, and small TFT LCDs. It allows simple interfacing, affordable hardware, and faster speeds than in the SCI.

It is another serial interface in LCDs that resembles the SPI with slave, clock functions, and master. The I²C does not integrate the SS line as in SPI. Therefore, a process known as addressing is essential in selecting a slave to communicate. A frame of the signal is sent on the data bus to address a specific slave after the first bit. Nevertheless, the output signal gets to every slave connected with, although only the slave with the corresponding address to the signal will receive the message.

The MCU interface is essential because it can write and read data stored in the internal frame bugger or the gadget"s storage. Therefore, if you want to store images for future use, MCU is the best match for you.

Additionally, in MCU parallel interface for Liquid Crystal Displays, data signals are sent through data lanes on either 18-bit, 16-bit, 9-bit, or 8-bit data channels. Besides, the MCU interface is simple, although it requires a display RAM for its memory functionality. Also, you can use it in graphic LCDs, character LCDs, and small TFT LCDs.

LVDS is an acronym for Low-Voltage Differential Signaling. This type of interface is essential as a complement for large LCDs and peripherals that require high bandwidth, such as HD graphics and fast frame rates. Therefore, it is a good choice due to its fast data transmission while consuming low voltage. One of the LVDS interface wires carries the precise inverse of its companion. Additionally, the electric charge from one wire is correctly masked by the other wire, reducing the interference to the wireless system nearby. Finally, at the recipient end, a circuit checks the variation in voltage between the two wires.

Red Green and Blue (RGB) interface functions are to link with color displays. It transmits 8 bits of data for each of the colors in every clock oscillation. Therefore, this means there are 24 bits of data sent for every clock oscillation.

Currently, you must have seen an improvement in terms of performance as electronic devices become smaller and easy to use. Therefore, this has led to the introduction of an embedded display port. The interface connects a video device to a display device and carries USB, audio, and other data forms. Moreover, this display port offers a high-performance external A/V interface hence high display resolutions of 4K. Additionally, the motive behind the development of this interface is due to several computing requirements. First of all, the main requirement is hardware integration.

This is a new technology development from the MIPI alliance. Mobile Industry Processor Interface has become a preferred option for mobile developers. This interface uses the same signaling as in LVDS. It uses a clock pair and 1-8 data lanes. Mobile Industry Processor Interface supports complex rules that allow low power and high-speed modes. Additionally, it reads data coming from the display at low rates.

When choosing the correct display interface for your device, you need to consider several factors. Therefore, it requires you to know how to connect the display to your electronic system. Nevertheless, it would be best if you choose the correct interface for your display. Additionally, consider the amount of data transferred and the refresh rate your system requires.

Finally, we have made it easier as we have given you all the details on each display interface, including the pros and cons. Therefore, having gone through our guide, you will never have issues when making your choice.

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

There is also a downloadable design software called STONE Designer. This is a completely free GUI design software you can use to create responsive digital module-ready user interfaces.

STONE TFT LCD modules come with a microcontroller unit that has a 1GHz Cortex-A8 CPU. Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to them.

You can also use a peripheral MCU to serially connect STONE’s HMI display via TTL. This way, your HMI display can supply event notifications and the peripheral MCU can then execute them. Moreover, this TTL-connected HMI display can further be linked to microcontrollers such as:

Becoming a reputable TFT LCD manufacturer is no piece of cake. It requires a company to pay attention to detail, have excellent manufacturing processes, the right TFT display technology, and have a consumer mindset.

Now, we list down 10 of the best famous LCD manufacturers globally. We’ll also explore why they became among the top 10 LCD display Manufacturers in the world.

BOE Technology Group Co., Ltd., founded in April 1993, is an IoT company providing intelligent interface products and professional services for information interaction and human health. BOE’s three core businesses are Interface Devices, Smart IoT Systems, and Smart Medicine & Engineering Integration.

Interface Devises Business includes Display and Senor, Sensor, and Application Solutions. As a leading company in the global semiconductor display industry, BOE has made the Chinese display industry develop from scratch to maturity and prosperity. Now, more than one-quarter of the global display panels are made by BOE, with its UHD, flexible display, microdisplay, and other solutions broadly applied to well-known worldwide brands.

LG Display is a leading manufacturer of thin-film transistor liquid crystal displays (TFT-LCD) panels, OLED, and flexible displays.LG Display began developing TFT-LCD in 1987 and currently offers Display panels in a variety of sizes and specifications using different cutting-edge technologies (IPS, OLED, and flexible technology).

LG Display now operates back-end assembly plants in South Korea, China, and Vietnam. In addition, LG Display operates a sales subsidiary with a global network to effectively serve overseas markets.

With innovative and differentiated technologies, QINNOOptoelectronics provides advanced display integration solutions, including 4K2K ultra-high resolution, 3D naked eye, IGZO, LTPS, AMOLED, OLED, and touch solutions. Qinnooptoelectronics sets specifications and leads the market. A wide range of product line is across all kinds of TFT LCD panel modules, touch modules, for example, TV panel, desktop and laptop computer monitor with panels, small and medium scale “panels, medical, automotive, etc., the supply of cutting-edge information and consumer electronics customers around the world, for the world TFT – LCD (thin-film transistor liquid crystal display) leading manufacturers.

AU Optronics Co., LTD., formerly AU Optronics Corporation, was founded in August 1996. It changed its name to AU Optronics after its merger with UNIOPtronics in 2001. Through two mergers, AU has been able to have a full range of generations of production lines for panels of all sizes.Au Optronics is a TFT-LCD design, manufacturing, and r&d company. Since 2008, au Optronics has entered the green energy industry, providing customers with high-efficiency solar energy solutions.

Sharp has been called the “father of LCD panels”.Since its founding in 1912, Sharp developed the world’s first calculator and LIQUID crystal display, represented by the living pencil, which was invented as the company name. At the same time, Sharp is actively expanding into new areas to improve people’s living standards and social progress. Made a contribution.

From the introduction of Japan’s original washing machines, refrigerators, and other household appliances, to the world’s first laptop, the first 16MB flash memory, the world’s smallest 0.85-inch HDDs; Create advanced HDDVD technology; Toshiba created many “world firsts” in the research and manufacture of new SED displays and contributed to changing people’s lives through constant technological innovation.

Tianma microelectronics co., LTD., founded in 1983, the company focus on smartphones, tablets, represented by high order laptop display market of consumer goods and automotive, medical, POS, HMI, etc., represented by professional display market, and actively layout smart home, intelligent wear, AR/VR, unmanned aerial vehicles (UAVs) and other emerging markets, to provide customers with the best product experience.IN terms of technology, the company has independently mastered leading technologies such as LTPS-TFT, AMOLED, flexible display, Oxide-TFT, 3D display, transparent display, and in-cell/on-cell integrated touch control. TFT-LCD key Materials and Technologies National Engineering Laboratory, national enterprise Technology Center, post-doctoral mobile workstation, and undertake national Development and Reform Commission, The Ministry of Science and Technology, the Ministry of Industry and Information Technology, and other major national thematic projects. The company’s long-term accumulation and continuous investment in advanced technology lay the foundation for innovation and development in the field of application.

Wide viewing angle performance, consistent color performance, and brightness are key features of the P0650VGF1MA00 with Tianma’s implementation of SFT technology. Wide viewing angles of 85 degrees are supported in all directions (up/down, left/right). The white LED backlight has a 100K hour half-brightness lifetime and provides a 1200cd/m² brightness specification. A contrast ratio of 900:1 ensures that display images are bright, concise, and uniform.

The P0650VGF1MA00 features a single-channel 20-pin LVDS data interface that supports a configurable 6-bit or 8-bit RGB data which enables a color palette of up to 262Kor 16.7M colors. The 6.5-inch display module has mechanical outline dimensions of 154.0mm (w) x 121.0mm (h) x 7.1mm (d) and an active display area of 132.5mm (w) x 99.4mm (h).

The Tianma 6.5″ TFT has been designed to function reliably under rigorous operating conditions found in many industrial, marine, aerospace, and medical applications yet still provide exceptional optical performance. Support for operation in harsh environments is aided with an extended temperature range of -30°C to +80°C.

Typical applications for the new 6.5-inch Rugged+ display include medical devices, marine instrumentation, industrial process control, factory automation, and in-vehicle systems. The Tianma 6.5-inch P-series P0650VGF1MA00 TFT display module is now available for value-add and non-distribution sales only from Review Display Systems.

The TFT Display Shield Board (CY8CKIT-028-TFT) has been designed such that a TFT display, audio devices, and sensors can interface with Infineon"s PSoC 6™ MCUs.

The TFT Display Shield Board is compatible with the PSoC 6™ WiFi-BT Pioneer Kit CY8CKIT-062-WiFi-BT and the PSoC 6™ BLE Pioneer Kit CY8CKIT-062-BLE. Refer to the respective kit guides for more details.

The graphic display coordinates and the text display coordinates of the 2.2”screen are two different coordinates systems. The origin of the graphic display coordinates begin from the centre point of the screen while that of the later one begins from the top left hand side of the screen.

The following codes are just one part of the API funciotn description. For more information, please refer to ST7687S Library Introduction and Display Library Introduction.

* @The formal parameter size refers to the text size based on the font(6×8). Size is rounded to the integer greater than 0; if size is 1, the pixel points the font occupied will be 6×8. if it is 2, that will be 12×16. The text out of the screen cannot be displayed;

The function of the program: taking the centre point of the 2.2”screen as the starting point(note: the graphic display coordinates and the text display coordinates are two different coordinates, the centre point of the graphic display coordinates is (64, 64) while that of the later one is (0, 0)), display a character string ”fire” with red text background box, white font and the size of the font 2 on the screen. The formal parameter size of the function to set font size tft.setTextSize (uint8_t size) should be greater than 0 and the text out of the screen cannot be displayed.

The function of the program: use the software image2lcd.exe to extract the bitmap of one image and display it on the centre part of the 2.2”screen(note: for the reason of UNO’s internal memory, the following demo cannot be accepted on UNO since the image file is too large, but it can be displayed on ESP32. So you’d better choose small image file if you want to display it on UNO. ) The parameter selection of the software is provided below.

A few weeks ago, I wrote this article about using a text variable as an array, either an array of strings or an array of numbers, using the covx conversion function in addition for the latter, to extract single elements with the help of the spstr function. It"s a convenient and almost a "one fits all" solution for most use cases and many of the demo projects or the sample code attached to the Nextion Sunday Blog articles made use of it, sometimes even without mentioning it explicitly since it"s almost self-explaining. Then, I got a message from a reader, writing: "... Why then didn"t you use it for the combined sine / cosine lookup table in the flicker free turbo gauge project?"105 editions of the Nextion Sunday blog in a little over two years - time to look back and forth at the same time. Was all the stuff I wrote about interesting for my readers? Is it possible at all to satisfy everybody - hobbyists, makers, and professionals - at the same time? Are people (re-)using the many many HMI demo projects and code snippets? Is anybody interested in the explanation of all the underlying basics like the algorithms for calculating square roots and trigonometric functions with Nextion"s purely integer based language? Are optimized code snippets which allow to save a few milliseconds here and there helpful to other developers?Looking through the different Nextion user groups on social networks, the Nextion user forum and a few not so official but Nextion related forums can be surprising. Sometimes, Nextion newbies ask questions or have issues although the required function is well (in a condensed manner for the experienced developer, I admit) documented on the Nextion Instruction Set page, accessible through the menu of this website. On top of that, there is for sure one of my more than 100 Sunday blog articles which deals not only with that function, but goes often even beyond the usual usage of it. Apparently, I should sometimes move away from always trying to push the limits and listen to the "back to the roots!" calls by my potential readers...Do you remember the (almost) full screen sized flicker free and ultra rapid gauge we designed in June? And this without using the built-in Gauge component? If not, it"s time to read this article first, to understand today"s improvements. The June 2022 version does its job perfectly, the needle movement is quick and smooth, and other components can be added close to the outer circle without flickering since there is no background which needs constantly to be redrawn. But there was a minor and only esthetic weak point: The needle was a 1px thin line, sometimes difficult to see. Thus, already a short time after publishing, some readers contacted me and asked if there were a way to make the needle thicker, at least 2 pixels.Recently, when playing with a ESP32 based NodeMCU 32S and especially with its WiFi configuration, I did as (I guess) everybody does: I loaded an example sketch to learn more about the Wifi library. When you set up the ESP32 as an access point, creating its own wireless network, everything is pretty straightforward. You can easily hard code the Wifi name (SSID) and the password. But what about the client mode ? Perhaps one needs to use it in different environments. And then, a hard coded network name and password are definitively not the best solution. Thus, I thought, why not use a Nextion HMI for a dynamic WiFi setup functionality?Although the Nextion MIDI I/O interface has been primarily designed as an add-on for Nextion HMI screens to transform these in fully autonomous MIDI devices as shown in previous blog posts here, it is also of great use for any Arduino based electronic music project! Many MIDI projects for Arduino suffer from a lack good hardware support. There are sophisticated code, excellent libraries and an infinity of use cases, but afterwards, things tend not to work in a rather rough environment in the studio or on stage. That"s because two resistors and a few Dupont wires on a breadboard besides the Arduino are not really an interface which could drive your Synth, Sequencer, or Drum machine over a 5m long MIDI cable.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey