advantages and disadvantages of touch screen monitors quotation

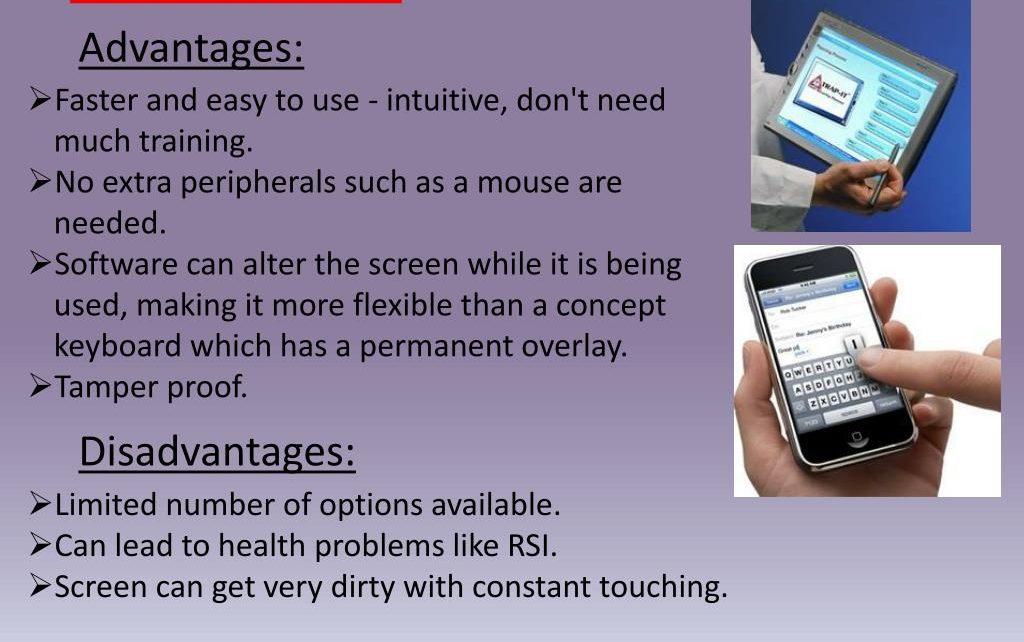

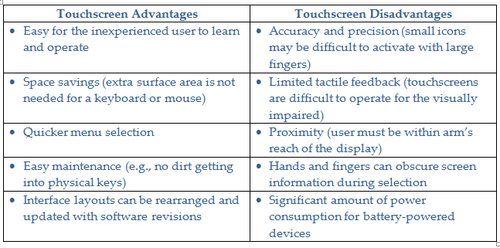

Touch screens are the latest addition in the world of technology. It has become a new trend to work using a touching device. These light emitting diode (LED) screens considered an ideal tool for the business and for personal use. Monitors with touch screens are valuable for various reasons. However, there are few shortcomings as well that a touch screen possesses. There is a dire need to be aware of pros and cons of a monitor with a touch screen before making any investment over it.

The user needs to be very close to a monitor’s screen because he has to touch the screen for work. It would be difficult for a user to work with such monitor placed on a large desk. On the other hand, a monitor without a touch screen will allow the user to work from a distance that is bearable for the keyboard and a mouse.

The user cannot work with accuracy on a monitor with a touch screen by using his finger. There is always the need of Stylus pen for a perfect effect. It is difficult to touch the small objects with a finger but the use of a mouse and a keyboard can make it easy.

The user can promptly click anything with the use of his finger and a stylus pen instead of using a mouse and a keyboard. Speed is the most important element for a user whether he is playing a game or placing an order in a business. The use of a mouse and a keyboard do affect the speed of the work.

There will be enough space on the desk of the user because a monitor with a touch screen does not want any keyboard or a mouse with it. The user can easily place his food, popcorns, tea or drink on a desk without any fear of spilling anything on a keyboard or on a mouse. There is no need to replace a keyboard or a mouse because of the sloppy customers and employees.

The screen of monitors gets dirty due to the continuous touching with the greasy and moist fingers. Luckily, touch screens consist of a glass or a similar material that is the reason it is very easy to clean the monitor having a touch screen as compared to a traditional monitor.

The users can easily work with a monitor that possesses a touch screen. There is no need for any prior training. Even a beginner can use it without any hurdle. It is user-friendly. There is a need for less concentration while using a touch screen as compared to a keyboard and a mouse. On the contrary, the user of a regular monitor has to go for prior training for a better understanding of the system.

Touch screens are handy for the users having some physical impairment while it is difficult for them to work with a mouse and a keyboard. For instance, a person with arthritis can face difficulty in operating a mouse and typing with a keyboard.

Touch screen devices are portable since input devices like mouse and keyboards are inbuilt in the devices. You can also manage space with touch screen devices since many components can be incorporated into it.

Simple UI, the use of graphics as buttons, and other features make it easy for seniors to use, therefore, touch screen technologies can be used by a wide age range.

Speed is one of the advantages of touch screens since users can easily send commands on the visual display. You can easily scale your business easily if you provide touch screen devices for customers to pay bills, make inquiries or to just server themselves.

Touch screen devices are more accessible for people that are physically or mentally challenged. Since there are no buttons, even people with physical disabilities can still use it. Most touch screens can also be adjusted to suit different preferences, especially for vision and others.

A touch screen works as both an input and an output device. You view the options available to you on the screen (output) and use your finger to touch the option you want (input).

Touch screens are used in many products like computers, mobile phones, tablets and in touch screen kiosk solutions. As you press with your finger on the display it sends a signal to the inputs.

Touch screen solutions make interaction with these devices seamless by using just a finger or stylus. A touch screen kiosk can display important communications, applications, software and general information. They are manufactured in a wide range of sizes to meet your preferences and business needs.

Atouch screen kiosk can be used for many professional tasks such as managing QSR orders effectively, saving the employees time and effort. Touch screen interfaces have changed the way people engage with products, businesses and human interactions.

Making It is easier to operate as users do not need to understand any complicated process. Children, adults and elderly can operate the touch screen with ease.

Intuitive interface: Navigate the touch screen interface with the tap of a finger via the onscreen keyboard without having to use arrows or cursors directly. Pinch, zoom, swipe etc just like you do on your mobile phone. It’s intuitive and fast.

Less mess and cords:A touch screen does not require an extra keyboard or mouse to operate it, so with minimal peripheral requirements the workplace is tidier.

User Satisfaction:The benefits oftouch screen solutions will be seen as visitors and customers engage with the screens. They are fast, intuitive, and even fun.

A touch screen works best when the areas being clicked are at least 8mm wide and high. Smaller items may require additional touches to get the click in just the right point.

Touch screen keyboards work well for small amounts of text. But they can feel a bit clunky if you need to type large paragraphs. In this case some of our customers add a stainless steel keyboard to their kiosk.

A touch screen costs more than a monitor with no touch capabilities. In some cases consumer grade touch screens don’t cost much more, but if you want a reliable, accurate touch screen that will last, the cost is definitely more.

It is crucial to know where you will be using your device – some touch screens and kiosks are not built for outdoor use for example. Knowing this will help determine the best touch screen product to use.

It is important to know your budget before investing in a touch screen device. Weigh up what features and functionalities are important to your business.

Consider the location of where you want to place your kiosk or touch screen before making your purchase. Some kiosks for example are higher than other, or take up more floor area, making them more suitable for certain retail locations. Select a touch screen or kiosk option that fits your space perfectly and provides you with ease of accessibility.

Consider the features you require from the touch screen. For example do you need it to display information, accept EFTPOS payments, display wayfinding information, engage in a software application or stream videos. Make your choice after considering all the elements of using a touch screen device.

Digital Wayfinding Directory:Help your visitors locate a place or person with minimal stress and time. Free up staff. Very popular in hospitals and shopping centres.

Payment Terminals:This allows the users to pay their bills or place orders through the touch screen kiosk. Thesetouch screen solutions are efficient and help process payments easily.

Document Management:Store all work-related documentation in one place. A document management kiosk allows users to access documents in seconds. Search, browse, print and validate documents at the touch of a finger.

Product Promotion:These kiosks can be used in retail, libraries, airports or museums. Develop engaging experiences for customers and allow them to learn about your products.

Visitor and Contractor Management:Visitors can self-register and badge themselves when they attend your site in a matter of seconds. This frees up reception staff to perform other important tasks.

Finding the right manufacturer and besttouch screen kiosk solution for your requirement can sometimes be a laborious job. There are lots of cheap touch screens and touch screen kiosks out there with dubious quality, and poor support. Speak to our team of experts and we will guide you through the process of finding the best solution to your unique requirements.

Touch screen monitors are one of the best inventions for computers. They are lightweight, easy to use, and provide a lot of convenience for the users. Even though touch screens are prevalent devices nowadays, many people are still confused about how they work. Touch screen monitors can confuse people who rarely use computers and only want a primary computer to use once in a while. Given the advancement of touch screen technology, many people are looking to buy these types of monitors. But what are their advantages and disadvantages compared to standard computer monitors? Let’s get started.

A touchscreen monitor is an electronic visual display that features a touch-sensitive screen for user interaction. The screen allows the user to interact with the computer by touching icons or links on the screen, rather than using a keyboard and mouse. Touchscreen monitors are available in many different sizes and specifications, ranging from small hand-held devices to large wall-mounted screens. They are most used in public kiosks, ATM machines, and point of sale (POS) systems.

You can’t beat a touchscreen monitor for convenience, and it’s easy to see why they’re becoming popular. If you’re considering buying one, here are some specific benefits you’ll enjoy.

One of the most significant advantages of a touchscreen monitor is that it’s compact. It takes up less room than an all-in-one computer, with its separate tower unit. It’s also more organized than a desktop, with many wires running from the screen to the keyboard and mouse. You don’t have to worry about finding space for all those trailing cables or accidentally pulling the wrong cord.

A touchscreen monitor also puts less strain on your eyes: since you’re sitting closer to the screen, you won’t have as far to look to read what’s on it. And without having to rely on a mouse and keyboard, you can use your arms and hands in better ways for your posture and your overall health.

A 4k touch screen monitor lets you use your computer directly with your fingers. This is convenient and keeps your hands from transferring dirt onto the keyboard and mouse. Keeping those devices clean is possible with effort, but it’s much easier to keep your fingers clean than a keyboard clean.

You might think that the downside to this would be that the screen would become dirty faster than usual. Yet, with many models of touch screen monitors, you can wipe them down with a soft cloth without affecting their performance.

A touch screen monitor for PC replaces a keyboard, mouse, or trackpad. It can also be operated with the same hand-on approach people use with other devices, such as smartphones and tablets. This means less hardware reducing production costs for manufacturers who offer touchscreen options in their products. It’s also more convenient for users who don’t have to worry about communicating with the monitor through a peripheral device.

Touch screens are more accessible for people who have difficulty using traditional computer equipment. For example, individuals who experience fine motor difficulties or mobility issues often find touch screens more straightforward than other kinds of computer equipment. This increased accessibility means that more people can effectively use computers, making all their functions more convenient for everyone involved.

Another advantage of a large touch screen monitor is that it’s highly durable. While it’s easy for keyboards and a mouse to stop working due to spills, dust, or wear and tear, touch screen monitors can withstand anything. They’re designed so that nothing will happen to them, even if something gets spilled on them. Since they’re also made of very sturdy material, they won’t break easily if you accidentally drop them.

Finally, another significant advantage of a touch screen monitor for Mac is that it increases efficiency in the workplace. With these monitors, employees can easily navigate documents and programs without using a mouse or keyboard. They also eliminate the need for separate keyboards and a mouse for each computer in the office.

You can create typing errors with a touchscreen monitor. Your hands could have oil or residue that leaves smudges on the screen, which can cause the cursor to move around erratically. It can be frustrating if you use your computer for business purposes and need to type quickly and accurately. If you are using a USB touch screen monitor for these reasons, you must keep your hands as clean as possible so you do not leave any residue behind.

Cleaning is more complicated. You could be used to wiping down your monitor, keyboard, and mouse with the same cloth and some water or window cleaner. But, this method can do more harm than good for touch screens. Instead, use a dry microfiber cloth or an anti-static cloth designed especially for cleaning monitors.

One of the significant disadvantages is fragility. A simple scratch can damage a touch screen, so many people place a screen protector on their devices. Repairing a touch screen is often more expensive than other types of repair. Some devices might be unrepairable after significant damage. But, you can use an anti-glare protective film for the monitor.

Touch screen monitors cost a lot more than similar non-touchscreen models. The technology inside them is more complex, meaning the initial cost of production is higher for a manufacturer. If you want to use touch screen monitors in your business, you’ll need to make sure that you’re getting enough value out of them to justify their higher price tag.

Touch screen monitors are more common nowadays, especially on home computers. They are also slowly being used in the office. These screens allow you to draw on your computer using a stylus, which is quite fun and practical sometimes. Yet, they have some disadvantages that you should be aware of before deciding whether to buy a touch screen monitor. Touch screen monitors can be a handy choice if you know what to expect from them.

Responsible for performing installations and repairs (motors, starters, fuses, electrical power to machine etc.) for industrial equipment and machines in order to support the achievement of Nelson-Miller’s business goals and objectives:

• Perform highly diversified duties to install and maintain electrical apparatus on production machines and any other facility equipment (Screen Print, Punch Press, Steel Rule Die, Automated Machines, Turret, Laser Cutting Machines, etc.).

• Provide electrical emergency/unscheduled diagnostics, repairs of production equipment during production and performs scheduled electrical maintenance repairs of production equipment during machine service.

When you use touch phones and POS devices, have you ever wondered why you could control them by touch? Yes, capacitive touch screen technology can achieve these functions. Now let"s read the following article to learn about capacitive touch screen technology.

Capacitive touchscreen devices are typically handheld and connect to networks or computers via an architecture that supports various components, including satellite navigation devices, personal digital assistants and mobile phones.

A capacitive touchscreen glass is activated by human touch, which serves as an electrical conductor used to stimulate the electrostatic field of the touch screen. However, special gloves that produce static electricity or specialized stylus pens may be used.

In capacitive touchscreen display, glass panel of a particular device is covered with a capacitive layer with a static charge when we touch a finger on the screen some of the charge shifts from the device to the finger.

Capacitive touch screen panel glass types are as follows:•Projected Capacitive Touch (PCT): Uses etched conductive layers with electrode grid patterns. It has robust architecture and is commonly used in point-of-sale transactions.

•PCT Self Capacitance: Columns and rows operate individually via current meters. It has stronger signal than PCT mutual capacitance and functions optimally with one finger.

Choosing the right button or menu item on the screen has never been easier. You just need to point it out. The on-screen buttons can be as big as necessary. Make sure that all users have a clear view of the button and know where to touch to select a feature or feature. capacitive touchscreen stylus requires little coordination by the user. The final benefit of the touch screen is to help users protect system content from unauthorized access. Always ensure that the right users can interact with the right content and information.

Of course, the main advantages of capacitive touch screen technology are its strength and durability. Touch screen devices have seen many uses over the years, especially in commercial applications.

When your application or the environment of the application can be described as harsh a capacitive touch screen is the way to go. Capacitive touch screens are typically more robust than resistive touch screens.

They can better withstand demanding use in difficult environments. When the touch solution is frequently used resistive touch screens tend to show some wear. MMake them not respond in the heavy use area. Capacitive touch panel does not have this problem.

Cracked touch screen glass continue to function. TFT capacitive touchscreen are more likely to continue to work when damaged. Cracked screens are among the most common type of damage sustained by touchscreen devices.

Anyway, minor cracks should not interfere with the function of the capacitive touch panel device. It will continue to measure the charge generated by the operator controller and use this information to determine the exact location where the touch occurred.

One of the biggest benefits of capacitive touch screens is the fact they are usually all-in-one solutions. The factory can customize different sizes of a capacitive touch screen according to customer needs.

Capacitive touch panel controller / touch monitors save space on desks as a mouse or keyboard is not needed. Integrating everything into the display helps save us valuable space. Integrating data entry with the display saves space in the final device

The big difference between resistive and capacitive touch screens is the top layer. Capacitive touch screen devices have extraordinary picture quality thanks to their use of a glass layer.

Resistive touch screens have a flexible plastic layer. Glass is more clear than plastic, greatly improving the image quality of a capacitive touch screen compared to a resistive touch screen.

If you’re planning to use the touchscreen device to watch movies, TV shows or videos, you’ll probably want to choose a capacitive model for this reason.

Because capacitive touchscreens register touch via the human body’s electrical current, they require less operating pressure than resistive touch panel glass.

You can usually operate a capacitive touch screen simply by dragging your finger across the surface. This is in stark contrast to resistive touchscreens, which typically require a firm, medium-pressure press.

Projected capacitive touch screens are very similar to conventional capacitive touch screens. Projected capacitive touch screens make multi-touch possible, which is a big advantage for these types of touchscreen capacitive.

One of the greatest benefits of touchscreens is the intuitive interaction between user and device. We uses a touchscreen interface in life that is usually capacitive,such as tablets, smartphones, Microsoft Surface, etc. Therefore manufacturers around the world are committing to touchscreen technology.

We believe capacitive touch screens will become the technology of choice for many different industries. This means advancements will most likely be designed to fit capacitive touch. They are making the technology future proof and compatible with developments.

The top glass layer makes the capacitive touch panel extremely durable and reliable. They are not susceptible to scratches and other damage as well as external influences.

But glass is easier to break than plastic and even though breakage doesn"t affect the touch screens a lot. We can add a protective layer like thermally hardened glass in the future

Where human touch makes work easy and quick on small and standard sized appliances there, it becomes problem on a wide screen or if it is placed at higher place.

Like it is not suitable for projectors because you cannot use hand everywhere and it becomes difficult to explain a higher point on the projector where your hand is not able to reach.

You interact with a touch screen monitor constantly throughout your daily life. You will see them in cell phones, ATM’s, kiosks, ticket vending machines, manufacturing plants and more. All of these use touch panels to enable the user to interact with a computer or device without the use of a keyboard or mouse. But did you know there are several uniquely different types of Touch Screens? The five most common types of touch screen are: 5-Wire Resistive, Surface Capacitive touch, Projected Capacitive (P-Cap), SAW (Surface Acoustic Wave), and IR (Infrared).

We are often asked “How does a touch screen monitor work?” A touch screen basically replaces the functionality of a keyboard and mouse. Below is a basic description of 5 types of touch screen monitor technology. The advantages and disadvantages of type of touch screen will help you decide which type touchscreen is most appropriate for your needs:

5-Wire Resistive Touch is the most widely touch technology in use today. A resistive touch screen monitor is composed of a glass panel and a film screen, each covered with a thin metallic layer, separated by a narrow gap. When a user touches the screen, the two metallic layers make contact, resulting in electrical flow. The point of contact is detected by this change in voltage.

Surface Capacitive touch screen is the second most popular type of touch screens on the market. In a surface capacitive touch screen monitor, a transparent electrode layer is placed on top of a glass panel. This is then covered by a protective cover. When an exposed finger touches the monitor screen, it reacts to the static electrical capacity of the human body. Some of the electrical charge transfers from the screen to the user. This decrease in capacitance is detected by sensors located at the four corners of the screen, allowing the controller to determine the touch point. Surface capacitive touch screens can only be activated by the touch of human skin or a stylus holding an electrical charge.

Projected Capacitive (P-Cap) is similar to Surface Capacitive, but it offers two primary advantages. First, in addition to a bare finger, it can also be activated with surgical gloves or thin cotton gloves. Secondly, P-Cap enables multi-touch activation (simultaneous input from two or more fingers). A projected capacitive touch screen is composed of a sheet of glass with embedded transparent electrode films and an IC chip. This creates a three dimensional electrostatic field. When a finger comes into contact with the screen, the ratios of the electrical currents change and the computer is able to detect the touch points. All our P-Cap touch screens feature a Zero-Bezel enclosure.

SAW (Surface Acoustic Wave) touch screen monitors utilize a series of piezoelectric transducers and receivers. These are positioned along the sides of the monitor’s glass plate to create an invisible grid of ultrasonic waves on the surface. When the panel is touched, a portion of the wave is absorbed. This allows the receiving transducer to locate the touch point and send this data to the computer. SAW monitors can be activated by a finger, gloved hand, or soft-tip stylus. SAW monitors offer easy use and high visibility.

IR (Infrared) type touch screen monitors do not overlay the display with an additional screen or screen sandwich. Instead, infrared monitors use IR emitters and receivers to create an invisible grid of light beams across the screen. This ensures the best possible image quality. When an object interrupts the invisible infrared light beam, the sensors are able to locate the touch point. The X and Y coordinates are then sent to the controller.

We hope you found these touch screen basics useful. TRU-Vu provides industrial touch screen monitors in a wide range of sizes and configurations. This includes UL60601-1 Medical touch screens, Sunlight Readable touch screens,Open Frame touch screens, Waterproof touch screens and many custom touch screen designs. You can learn more HERE or call us at 847-259-2344. To address safety and hygiene concerns, see our article on “Touch Screen Cleaning and Disinfecting“.

Because a user operates an electronic device by directly touching the images on the display he is seeing, the operation will be intuitive, thus anyone can operate it from first use.

Unlike keyboard or physical switch, there will be no dirt, dust, and moisture getting into the spaces between buttons. Thus, it is easy for maintenance.

Because a user operates an electronic device by directly touching the images on the display he is seeing, the operation will be intuitive, thus anyone can operate it from first use.

Unlike keyboard or physical switch, there will be no dirt, dust, and moisture getting into the spaces between buttons. Thus, it is easy for maintenance.

LCDs are capable of displaying either arbitrary images, such as a computer monitor, or fixes images like the numbers on a digital clock. Regardless of which type of images are being displayed, the underlying technology remains the same: a source of light (backlight) emits light through liquid crystals, causing them to form visible colors; thus, producing the image.

Very minimal power consumption. To put the efficiency of LCD into perspective, a typical CCFT backlit display uses 30-50% of the power of a CRT monitor, but an LCD display uses just 10-25%.

As you can see, there are both advantages and disadvantages to LCD technology. However, most people will agree that the pros outweigh the cons. What do you think?

Due to increasing global competition and demand for innovative new products on a more frequent basis than ever before, industry is being forced to move at a faster pace than ever before. In addition, customers, whether in a B2B or B2C market, demand customized products, short lead times, and higher quality. For several years during the transition, companies relied on cost-cutting to stay competitive with low-wage regions, but cost-cutting is not a sustainable long-term strategy.

As a result, companies in most industries are searching for ways to retain and grow market share while staying profitable. With margins at the breaking point, companies are looking at alternatives. Technology and ingenuity are both necessary to navigate the changing industrial landscape. Touch screens are one of the technology tools that can help by increasing worker productivity, improving product quality, and making operations more efficient.

Most companies today sell to customers all over the world, which means competition is no longer confined to just the company across town or in the next state. New competition arises daily in every corner of the world. These competitors start with a clean sheet of paper—no old equipment, outdated processes, or expensive wage and benefits structures. As a result, these companies can focus on creating lean, streamlined processes that enable them to meet customer expectations for price, delivery, and quality easily, even for customized products.

As established companies work to hone their competitiveness, the aging workforce becomes a complicating factor in this endeavor. Pew Research reports that 10,000 baby boomers turn 65 each day, and that pace will continue through 2030. While this helps to relieve some of the wage pressures from the higher salaries that experienced workers command, it also means that industries are facing a constant drain of critical knowledge and skills. They need to capture and disseminate this knowledge before it is lost.

Long-established companies have countered these forces by adopting business process modeling and lean or Six Sigma to help them level the quality and delivery time playing field. Most companies today focus on a few core metrics to help them monitor process performance and quality in near-real time. They use continuous improvement techniques such as Kaizen and DMAIC (Define, Measure, Analyze, Improve, Control) to ensure they make products of consistent quality at a predictable and repeatable pace.

In certain industries, particularly those heavily process dependent such as chemicals, pharmaceuticals and oil and gas, PLCs or sensors have been used to provide information directly from equipment to Supervisory Control and Data Acquisition (SCADA) or manufacturing execution systems (MES) for later analysis. However, despite collecting data in real time, the technology for analysis frequently couldn’t keep up, so data didn’t become actionable information until it was too late to take meaningful action.

The Internet of Things, or IoT, is the term used to refer to the new generation of connected devices and equipment. More devices than ever before are connected and collecting data in real time. In fact, Gartner estimates that 26 billion devices will be connected by 2020. Connected devices range from home heating and cooling equipment and thermostats (think Nest or Lyric) to nuclear reactors, high-voltage power plants, and a vast array of industrial machinery and equipment. With all those devices monitoring multiple parameters in real time, the volume of data is staggering.

Fortunately, analytics technology has advanced as well. Big Data analytics engines such as Hadoop or SAP’s Hana in-memory database can analyze vast quantities of data very quick. Unlike traditional business intelligence and analytics solutions, this new generation does not require information to be in a specific format, nor do they require predefined queries and reports to be useful.

Big Data functions with a vast array of data, including traditional structured or formatted data, as well as unstructured data such as documents, newsfeeds, or data streamed from sensors. Big Data tools sift through disparate data from multiple sources at a high speed, looking for trends and anomalies and presenting their findings in a visual format that is easy for users to quickly grasp. Thus, Big Data is an ideal solution for industrial companies looking for a better way to monitor process quality and performance.

As industry becomes even more data driven, companies need to find ways to make data more accessible to workers in every area, including the plant floor. Touch screens are the ideal solution because they are inexpensive, easy to operate, rugged, and mobile. The large screen sizes available mean that a touch screen can display more information than traditional methods, such as bar code readers. The use of dashboards enables users to see process status at a glance without having to check a mechanical cockpit with multiple dials and gauges.

The data visualization makes it easy for people to see and act on exception information, even allowing for the diminished vision of older workers. Data visualization on industrial touch screens overcomes language barriers, skill sets, and environmental conditions such as low light.

Touch screens can be mounted directly on the equipment they are monitoring, in any nearby area, or even in another location altogether in the case of dangerous or unhealthy industrial environments, making them ideal for any industrial facility.

Touch screens are versatile as well. By selecting a resistive touch screen, users will be able to interact with the device using a stylus or while wearing gloves, which may be an important consideration in certain conditions. In low-light situations, you may prefer an infrared touch panel. If graphics are a top priority, a high-quality surface capacitive screen may be the best choice.

If the screen must be visible at a distance, the large sizes available in infrared screens may be very important. The lifecycle of the screen also varies by touch type, as does its resistance to environmental conditions such as grit, solvents, or water. You can find out more information about the characteristics of the various types of touch screens by reading our technical article, and of course, our engineering team will be happy to work with you to identify the best option for your situation.

Touch screens have so many applications in the industry that it’s hard to understand how companies functioned without them in the past. Here are a few examples:

CNC machine setup: Production lines and manufacturing equipment are often controlled by computers (CNC). Rather than use tooling or manual settings, these units use computer programs to define operating specifications. Using a touch screen to load the instructions speeds up changeovers and reduces downtime. A touch screen provides an easier interface than a traditional screen and often shields the user from the operating system complexities.

Production reporting: Industrial companies need to monitor production throughput on a regular basis to ensure they stay on schedule, but to date there hasn’t been an easy and accurate way to capture the required information. RFID sensors are expensive and unreliable. Bar codes are cumbersome and complex. Entering production status on a touch screen at the point of the operation is easy, fast and accurate. It transcends language barriers and is simpler than any other available method. The increased accuracy helps ensure efficient production scheduling and can help improve customer satisfaction by providing more accurate delivery information.

Recording quality results: When transcribing complex measurements or other quality standards, accuracy is paramount. Using a touchscreen helps improve accuracy because it is easier to enter information on the screen than on a keyboard, especially in low-light situations or while wearing gloves.

Mechanical controls: Industrial equipment often has several mechanical controls and switches, but many companies are replacing the complex array with a simple touch screen. This helps to eliminate operator errors, and the on-screen steps help walk workers through the process without the need for extensive training or process aids. In addition, the screens provide immediate feedback about process issues, and if the process changes, the change shows up right away on the screen.

There is little doubt that touch screens are changing the face of industry. In fact, IHS Research predicts that shipments of industrial touch panels and sensors will reach 2.5 billion by 2019, a compound annual growth rate of more than 4 percent. Touch screens are adaptable to almost any industrial environment, including wet, low light, dirty, or dangerous locations that require workers to wear protective gear such as gloves and goggles.

Using a touch screen interface enables vision-impaired or older workers to continue to perform effectively because screens are large, bright, easy to read, and they present data in a simple-to-use format. Workers who are comfortable in the digital world enjoy working with touch screens more than with paper reporting or mechanical controls, which makes touch screens the perfect medium to help companies retain older workers longer, helping to bridge the potential skills gap they might otherwise face.

Touch screens adapt easily to multiple languages, so workers can interact in their native language, increasing accuracy and compliance. This helps companies with a diverse or global workforce meet the needs of every worker.

With their easy-to-understand data visualization, touch screens help companies react quickly to potential production or quality problems. Workers can see immediately when a problem occurs and stop the line or take the appropriate corrective action. This helps ensure efficient production, reduces quality problems, increases throughput, and helps with job satisfaction because workers feel more empowered and knowledgeable.

Companies can monitor performance toward goals and ensure that quality and costs are on target, helping to ensure healthy margins and enabling them to compete better in global markets. Touch screens are an essential part of the industrial future. They provide important benefits to every industry. Touch screens increase efficiency, help ensure compliance, make it easier to monitor performance, adapt quickly to changes, are rugged and are versatile for a variety of conditions and use cases, are highly visible and cost-effective. Consider incorporating touch screens in your industrial processes so your company can begin enjoying these benefits.

All of a sudden, it seems like there are touch screen PCs everywhere. I"ve even seen monitors and all-in-one desktops touting their "built for touch" features. While I like the touch screen on my tablet, I"m not sure what the point is on a laptop or desktop. What advantages do these new touch screen PCs really offer?

Depending on whom you talk to, touch screen computers are either the natural evolution of the PC or the dumbest idea ever. (On one side you have Microsoft and Intel touting the latest Windows 8 touch screen PCs and on the other you have people quoting Apple"s Steve Jobs and Tim Cook about

Well, no one, really. As with deciding on any other computer feature—for example, display size or processor—choosing to have a touch screen or not is a matter of preference and your needs.

This bestselling bidet has ... pretty much everything you want from a toilet seat. It’s got a heated seat, a deodorizer. A remote control (yeah!), and a design that allows for no splash-back when in use.

Tapping and swiping on a touch screen, on the other hand, is more intuitive, since you"re interacting directly and immediately with the elements on the screen. If you use trackpad multi-touch gestures or have used a tablet or smartphone, working with a PC touch screen feels just as natural and fluid. Photo by

One of the earliest criticisms about touch screen PCs is that programs and desktop windows are hard to use with touch. The close button, scrollbars, and other navigational elements are small and hard to accurately hit. Windows 8 has changed that to a big extent, with things like the Explorer ribbon creating a more touch-optimized interface in desktop mode and, of course, its new full screen apps. Desktop programs like Microsoft Office are even pretty touch-friendly. And with those that aren"t, you can easily zoom in and use gestures to make working with a Windows 8 touch screen PC at least as easy as using a tablet (or you could use a stylus and tap very accurately on the screen).

More smears on your screen: Greasy, scummy smears are the bane of every smartphone and tablet user. It"s no different when you"re constantly touching a PC screen. Getting out the microfiber cloth more often is a hassle, but for most of us this alone isn"t a deal-breaker.

If you"re continually holding up your arm to point at a vertical display, sure that"s going to hurt. However, the truth is you"re probably not going to be perpetually holding up your arm. If you"re using a touch screen desktop PC or monitor, you might tap and swipe, then switch to the keyboard and mouse, and back. Touch screen laptops and hybrid tablet/laptops (with screens that can detach from the keyboard or swivel into tablet mode) can be positioned closer and at angles that are more comfortable, which makes this whole "Gorilla arm" argument moot, as

Added thickness: Touch screen panels are usually thicker than non-touch ones—especially if the touch panel has an active digitizer for pen support. two pounds and is a bit over a half an inch thick.)

Cost: Finally, the biggest disadvantage of touch screen PCs is the added cost. Touch screen PCs cost more than their non-touch counterparts. The difference can be between $100 to $200, with pen-enabled touch screens costing the most.

There"s been a lot of backlash in the media about these newer touch screen PCs and how they"re doomed to failure. However, most of that really isn"t about touch as a user interface at all, but rather Windows 8

Keep in mind that the touch screen is really just another way to interact with your PC. You still have your keyboard and your mouse (or trackpad) when you want them and can use the touch screen as little or as much as you want. (After using a touch screen for a while, though, you may find yourself attempting to tap and swipe any non-touch displays you come into contact with.)

If the added cost of the touch screen and the possible battery life hit don"t matter much to you, you don"t have anything to lose—and you might very well enjoy that touch screen as much as you do the one on your tablet.

Not all touchscreens are created equally—and if you’ll be investing hundreds of dollars into a tablet or smartphone, you’ll want to know the difference. In the touchscreen world, there are two main types of technology: capacitive touchscreens and resistive touchscreens. Each has its own advantages and disadvantages.

Capacitive touchscreens register a touch whenever it comes in contact with a conductive object—such as human fingers. As such, capacitive touchscreens are highly responsive, as they do not require any pressure to register a touch. Even the slightest touch will activate the screen. Capacitive touchscreens can use glass as the front panel, which makes them highly durable, easy to clean and resistant to scratches. Capacitive touchscreens can also implement multi-touch gestures. In general, capacitive touchscreens are considered to be capable of faster typing speeds. However, given the sensitivity of a touchscreen, you may have difficulty with typos. The size of the keyboard and the amount of space between keys will deeply affected typing accuracy as well. Capacitive touchscreens can be used with a screen protector to keep them clean and scratch-free.

The disadvantages of capactive touchscreen come with accuracy. Most capacitive touchscreens do not respond to objects other than naked human fingers, and thus do not work with a stylus or a fingernail or a gloved hand. Because fingers are far wider than a stylus, this makes handwriting and other precise actions rather difficult. Capacitive screens are also more expensive.

Resistive touchscreens are constructed from two layers of material with a space between them. When you push on the outer screen, the two layers are pressed into contact, thus registering a touch. Because the system works on pressure, it can be activated using inanimate objects such as a stylus, fingernail or a gloved finger. This makes resistive touchscreens useful for handwriting and other high precision functions. Resistive touchscreens are also preferable in colder climates, where smartphone and tablet users often wear gloves. Resistive touchscreens are considerably less expensive than capacitive screens.

The drawbacks of resistive touchscreens include its inability to support multi-touch gestures, its poor visibility in direct sunlight and its lesser durability. The top layer on a resistive touchscreen is made of soft, flexible material which can be damaged much more easily than glass. It also may need recalibrating from time to time.

It’s difficult to say whether resistive or capacitive touchscreens are better. Capacitive touchscreen technology is newer, and is thus more expensive. While many state-of-the-art devices tout the multi-touch gestures and glass screen as must-have features on their high-end tablets with capacitive touchscreens, if you prefer to use a stylus or wear gloves, a capacitive touchscreen won’t provide as many benefits over the resistive screen. Consider your needs before deciding on a capacitive or resistive touchscreen.

PS: They say the classics never go out of style—but that doesn’t stop them from going out of production. From the original Atari gaming system to the Nintendo Entertainment System (NES), many of the video gaming systems of yore have stood the test of time in terms of fun factor and replayability. But as technology progresses, it seems that many games from the 20th century have been left behind. Today’s PCs and next generation consoles are simply incompatible with the clunky, yet endearing cartridges and floppy disks of yesterday.

A surface capacitive touchscreen uses a transparent layer of conductive film overlaid onto a glass sublayer. A protective layer is then applied to the conductive film. Voltage is applied to the electrodes on the four corners of the glass sublayer to generate a uniform electric field. When a conductor touches the screen, current flows from the electrodes to the conductor. The location of the conductor is then calculated based on the activity of the currents. Surface capacitive touchscreens are often used for large screen panels.

Projected capacitive touchscreens are extremely precise and quick responding and are typically found on smaller devices such as iPhones, iPod touches or iPads. Unlike the surface capacitive touchscreens, which use four electrodes and a transparent conductive film, the projected capacitive touchscreens use a vast amount of transparent electrodes arranged in a specific pattern and on two separate layers. When a conductor moves near the screen, the electrical field between the electrodes change and sensors can instantly identify the location on the screen. Projected capacitive touchscreens can accurately register multi-touch events.

Capacitive touch panels are the more modern and advanced touchscreen option because of their advanced capabilities. They are commonly found in consumer products like smartphones, tablets, appliances, and monitors.

A capacitive touchscreen detects and responds to changes in capacitance caused by the screen"s electrostatic field when the screen"s surface is touched.

Capacitive touchscreen displays allow for touch gestures and respond to multi-touch inputs. You’ll typically be able to enter one to five touch inputs simultaneously, but some capacitive touchscreens can process even more.

Capacitive touchscreens deliver brighter, higher contrast images due to the makeup of their panels. Displays with capacitive touch screens are more durable than resistive touch screens because they are designed with cover glass on their top layer. In fact, all of our capacitive TFT displays have standard 0.7mm thick built-in cover glass and can be further

While the cost is currently higher than resistive touchscreens, capacitive touchscreens are quickly becoming the industry standard in touchscreen technology.

The enhanced responsiveness can be a downside depending on how and where the display is used. For example, a capacitive touchscreen would not easily respond to the user while wearing certain types of gloves. Although capacitive touchscreens don’t respond to inorganic inputs, they can still be accidentally activated by other conductive elements. One of the the most common elements that causes interruptions is water.

Rain, humidity, and condensation on the surface of capacitive touchscreens will often cause accidental inputs and reduced accuracy until the water is removed. This is one of the main reasons why a resistive touchscreen would be chosen over a capacitive touchscreen in certain situations.

Any device that utilizes touch gestures like swiping, pinching, or multi-touch will require a capacitive touchscreen. These features often help make capacitive touchscreen displays more intuitive and user-friendly than resistive touchscreens. Capacitive touchscreens are best suited for applications requiring improved touch responsiveness with better image brightness and contrast.

sense pressure on the display"s top layer and send a signal to the circuit layer to activate the touchscreen functionality. Because they use pressure to activate the touch inputs, resistive touchscreen displays can be used with a stylus, gloves, and other items. Resistive touchscreens are built without cover glass and made of plastic, making them more susceptible to dents and scratches.

"touch event" occurs when these two layers make contact with each other (closing the circuit) by the user"s action of pressing into the soft, semi-flexible top layer. Each layer consists of horizontal and vertical lines (x,y matrix) that detects the exact location of the touch.

The gap or space layer typically consists of air or inert gas and some spacers whose only purpose is to separate the soft top layer from the bottom layer.

Resistive touchscreens are often seen as the less advanced variety of touch panel compared to capacitive touch panels. However, being able to interact with non-organic inputs keeps these touchscreens relevant in specific industries.

Resistive touchscreen displays are less sensitive than capacitive touchscreen displays. This is considered an advantage in some cases and is why they’re chosen for specific applications. Resistive touchscreens will not respond to accidental inputs from the environment, so they won’t be interrupted by things like water spills or lightweight debris landing on the screen.

This type of touchscreen requires more intentional inputs from the user, making them more reliable in rugged and unstable environments. For example, a resistive touchscreen is the perfect solution on a construction site where water or debris might land on the screen. They’re also the best touchscreen display option for situations where the user is wearing gloves.

Resistive touchscreen panels are unfortunately more susceptible to dents and scratches. Their poor visibility in direct sunlight does not make them ideal for outdoor applications. Their inability to respond to multi-touch inputs can be a disadvantage in fast-paced applications requiring such. Because resistive touchscreens rely on the pressure applied to the top layer, they tend to be abused and mishandled, which makes them less durable over time than capacitive touchscreens.

Resistive touchscreen technology is ideal for low-cost applications involving rugged environments, indirect sunlight, and simple touch features. Fewer accidental touch inputs, better resistance to heat and moisture, and the ability to be operated with pretty much anything (stylus, pen, gloves, fingers, etc.) make this touchscreen technology a more reliable solution when user input is crucial.

While it’s clear that capacitive touchscreens are dominating the consumer electronics market, resistive touchscreens still have an advantage in some ways.

If you’re looking for a cost-effective touchscreen that can operate with simple tap inputs in rugged environments, resistive is the way to go. For more advanced and intuitive touchscreen technology with higher quality applications, choose capacitive touchscreens.

Interactive industrial touchscreen monitors and displays are becoming a commonplace staple technological feature of many commercial business settings and projects. Features are becoming increasingly advanced with each new generation of commercial-grade monitors. Yet, user interfaces are easier to navigate and use than ever before. Plus, industrial and commercial displays are a lot more affordable and easier to maintain than they were in the past. Accessibility and consistency are key factors when it comes to designing modern-day industrial and commercial touchscreen monitors.

If you’re wondering if this is a worthwhile investment for your business, then keep reading to learn more about the benefits of commercial and industrial touchscreen monitors.

Interactive displays in public settings automatically draw people in and engage them in the content that’s being displayed. They go from being passive presentation viewers to active participants. Increased customer engagement leads to greater brand awareness, education, and eventually loyalty. Creating an inviting and fun customer experience through engaging activations effectively cements the customer-brand relationship.

Whether you’re doing a product demonstration or displaying your brand catalogue on a self-serve kiosk, interactive monitors are a great way to create a personalized and more memorable customer experience.

Industrial and commercial touchscreen displays are incredibly easy to clean and maintain. Fingerprint smudges and marks can be wiped off using a soft microfiber cloth. Modern touchscreen displays also come with durable enclosures that prevent dust, water, and other debris from penetrating the surface and causing internal damages.

Since these displays are designed for industrial and commercial use, they contain certain protective features that ensure excellent long-term performance. Industrial and commercial touchscreens are built to last a long time and withstand all kinds of harsh environmental conditions and rough usage. Perfect for grocery stores, restaurants, retail stores, warehouses, distribution centers, medical facilities, and even military and marines operations, industrial and commercial monitors can be custom-tailored according to the specific parameters that are called for by various applications.

Touchscreens are operated by capacitive or resistive touch. That means you can use your fingers or a stylus pen to perform various functions with ultimate precision, speed, and efficiency. The intuitive design of these machines allows them to automatically detect accidental touches such as grazing against the screen versus actual performative functions to prevent system errors. Functions are performed more quickly through direct touch without the need of peripheral devices such as mouses.

Commercial and industrial touchscreen devices offer excellent security and reliability as long as you provide them with the proper protection. Touchscreen enclosures in public settings effectively prevent system damages and theft from occurring by securing the displays in place. Protect your investment from potential damages by installing appropriately fitted touchscreen enclosures.

Self-service is the future of many different industries. It’s a great money-saving feature that allows you to cross-train your staff in different departments so that they can be of greater use to your business by performing back-end operations or assisting customers. Moreover, customers love the convenience and expediency of using self-service kiosks in grocery and retail stores.

Nauticomp Inc.provides world-class fully customizable touchscreen displays for commercial and industrial settings. With features like sunlight readability, brightness adjustability, infrared lighting, full backlighting, all-weather capabilities, etc., our displays are second to none. Contact us today to learn more.

You do not need to calibrate the image projector before lecturing; with LED lighting technology, IFPDs provide a clear image all the way; and thanks to the IR touchscreen, you can annotate your presentation with almost anything, a dry/wet finger, pen, or stylus.

Commonly, the overlay is a piece of protective glass hemmed in by the IR touch frame, in which Infrared LEDs and photodetectors are embedded. A kind of optical bezel will be inserted between the glass and the frame to fix the frame and transmit infrared light emitted by those LEDs.

Through the optical bezel, IR LEDs emit invisible infrared beams forming grids on the surface of the overlay, Photodetectors are installed across from the LEDs to detect interruptions of beams if touch events on the overlay happen.

There are two rows of IR LEDs, which generate horizontal and vertical invisible IR beams. They form a large beam grid that covers the surface of the overlay. In the meantime, two rows of photoreceptors are installed on the opposite side of the LEDs.

As long as an opaque object touches the surface, it will blot out the light beams. Photoreceptors in both directions (vertical and horizontal) can detect this interruption by that object, finally localize the x and y coordinates, and then send the signal to the processor to respond with relevant action.

To know more details of its structure and workings, you’d better walk into a workshop to learn its assemble process. Most of the time, we do not have that chance, however, regular maintenance work offers you the opportunity to check its components inside.

Better display – without other substance between the LCD and overlay, IR touch screens offer the best light transmission, so they can render more vivid images without color and brightness loss.

Supports multi-touch – with windows and android 9.0 double OS, it can support as many as 40 touchpoints simultaneously. That means it can support up to 4 students interacting together on an IFPD.

Short response time – commonly less than 8ms, IR touch screens localized touch events by detecting light interruption, so they are accurate and quick to respond with actions.

More flexible in customizing screen sizes – by adjusting the numbers of LEDs and photodetectors embedded in the overlay frame, you can fit any custom-made monitor with an infrared touch interface

Maintenance– there is no adhesive substance between the monitor and overlay, so you can disassemble the two parts freely by releasing a few screws when doing regular maintenance, such as cleaning the surface, and wiping dust.

Clear images – compared with many camera or projector-based systems, equipment with IR touch screens often adopts backlight LED. So, wherever lighting environment they perform in, they can provide clear images to the audience.

No loss of screen display– Since LEDs and sensors are designed to be fixed in the frame that is around the monitor, the screen can display an unrestricted view.

Write with any object – you can write on an IR touch screen with anything, a bare finger, a gloved finger, wet hands, or a pen, as long as it is not transparent.

No calibration – a traditional smart projector board may require regular calibration to display correct pictures, however, devices with IR touchscreen do not need to calibrate the IR LEDs and sensors to guarantee a normal function.

No pressure is required to write – Resistive touch screen technology perceives the writing track by pressure, which can damage the screen after a long time of usage, while IR touch screen technology by detecting light interruption, so you can write freely without having to push hard on the screen.

Of touch screen technologies, infrared and projected capacitive are the top two types that are mostly utilized. However, they are applied to different applications due to the differences between them.

For PCAP touch screens, There is a layer of transparent electrode film that is fixed between the LCD panel and the cover glass, when the human finger touches the screen, the current through that film changes, and the signal of x and y position will be transferred to the computer.

For IR touch screens, the equipment detects the finger’s position by detecting the block of invisible lights from the infrared LEDs that are embedded in the touchscreen frames.

So you will often see a bezel in the IR touchscreen, which is used to transfer the infrared light to the surface of the overlay, while the PCAP touchscreen does not require the bezels.

IR touchscreen can be activated by anything that is not transparent, whereas PCAP types only accept bare fingers, thin surgical gloves, or cotton gloves.

The electrode film in PCAP touchscreens is expensive, especially when it comes to large screens, but for IR ones, when it is applied to large-scale screens, you only need to add a few LEDs and correspondent detectors, apparently, the IR touchscreen solution is more cost-effective in large interactive displays, such as the interactive digital board, which are used for presentation in business meetings.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey