sparkfun lcd displays made in china

If you have this screen (or any other serial device) connected to the same UART that is being used to program the board (ie: any Arduino with one UART and using that UART with the screen (Rx and Tx pins)), you run the risk of inadvertently sending commands during the programming process to the LCD that reconfigure it and cause it to not behave as expected!

Think about it. When you program an Arduino, both Rx and Tx LEDs show activity, meaning that the Arduino IDE is sending data to the board, and the board is responding. If the LCD screen is ALSO connected to the Arduino via the Rx and Tx pins, it too will be reading the bytes that is being send back to the IDE. If there is a byte sequence that includes the command to change the LCD baud rate, defined screen size, or whatever, then your screen will most likely not work correctly unless you send the appropriate commands to reconfigure it.

I am current considering use of this display but have not ordered it yet. I am a little hesitant due to the number of users reporting problems with these displays.

I would say use your best judgement. I have only looked at the reviews under the review page and they all seem fine; unfortunately, I don"t have time to comb through all +200 comments. That being said, you can check out our Technical Assistance page linked in the banner above and our returns policy. Another resource for you is the [forum]https://forum.sparkfun.com/], where you can check for what issues users had and if there was a resolution to the issue.

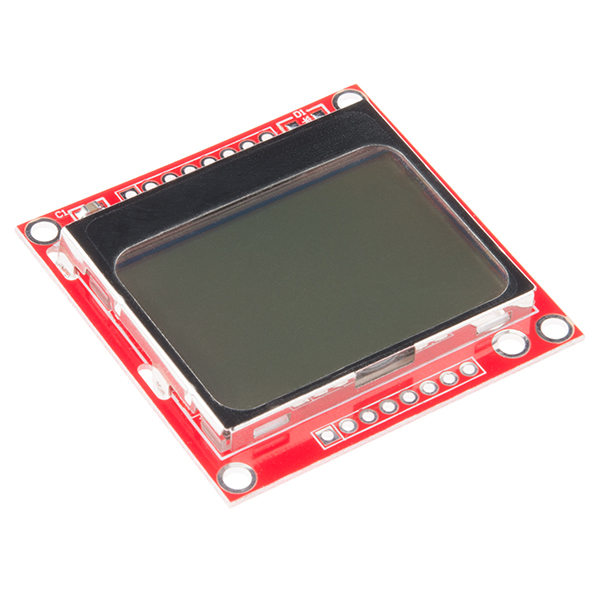

I had a project that needed some live data display, and looking for the cheapest low-power solution for our loggers lead me to the Nokia 5110 LCD. Once you get the backlight current under control, you can power the entire display from a digital pin, and if you use shiftout for soft SPI you can then get rid of the Reset and CS control lines. This brings the display down to any four wires you can spare on your build (incl. the power pin) and a ground line. This is much more manageable than what you see with the standard hookup guides if your mc is I/O limited like our pro-mini based loggers:

This LCD (I have the old-old kind) is absolutely my favorite. Yes, it has a board-to-glass connector that ranges from bad to abysmal, but it offers such a simple interface and so many pixels for so little money (obviously less if you buy only the panel.) Here are some clever things I"ve discovered:

Will fully operate on as little as 2.0V. That"s power (Vdd) and i/o. It can be driven at 2MHz at these speeds; in fact, the LCD will work at even lower voltages but the contrast fades quickly and your microcontroller will likely approach its lower voltage limit too.

The LCD will work with the chip-select pin (SCE) tied to ground. This means that if it"s the only device on the SPI bus, don"t bother framing the i/o with a chip-select pin. If the bus is shared, frame the entire transaction, not every individual byte you send to the LCD. Interestingly, the display also seems to work fine with a floating Vdd pin - it must draw sufficient power just from i/o via clamping diodes; not surprising when you consider how low-power it is.

The Vout pin: Looks like you don"t have to worry about it on this product, but the bare LCD will generate positive 6-9V on that pin. This wasn"t totally clear to me from reading the datasheet.

(5) If you are using a PIC to run ths thing, and using the PIC"s USART or EUSART in a synchronous mode, be sure to note that the LCD controller expects the MSBit of each byte to be transmitted first on the serial line. The PIC 18F EUSART transmits the LSBit first. For now, I have lots of extra code space, so I"ve wasted a 256-byte section on a lookup table that reverses the bits in a byte. This way, I just write my initialization code normally, and I have a TransmitCommandByte() function that looks up every byte it sends so I don"t have to think about that.

Thank you! I"m not quite sure I do want an LCD yet, to be honest, I"m just considering the different options available. I"ll check out the Sharp component, thanks!

Advice for others: It took me quite a while to get this working on an ARM Cortex. Since there is no way to read from the LCD, it is very hard to know if SPI is working without doing everything perfectly. SO:

The problem with these displays, and it seems to be common to all the manufacturers, is that the PCB material is too thin. After a month or two, the board slowly bows away from the glass display panel under pressure from the conductive rubber connector strip. Pressing on the top centre of the metal part of the display makes it work again, but only temporarily.

If the LCD module is soldered to another board and the two top screws installed and tightened carefully to pull the bow out of the module it seems to prevent (or solve) the problem.

I"m using voltage dividers to supply 3V in the inputs of the LCD, because of the Arduino works in 5V. LCD Vcc and LED are powered from the 3.3V output of the Arduino. The LCD only displayed something when I used: R1=470K,R2=820K. I have tried several values to obtain 3V, but the LCD showed nothing. I don"t understand that.

I"m interfacing this LCD with ATMEGA 32. Its been more than a week that I"ve been trying to get it right. All I get is the LED dimming effect. Here is my initialization code..CE=1;

I have a similar board made by mib-instruments and bought from ebay years ago. It has been my standard spi test tool because it"s so easy to work with. http://www.ebay.com/itm/Nokia-5110-LCD-84x84-dot-martix-backlight-PCB-RED-/320684678723 (specs http://i1119.photobucket.com/albums/k636/mib_instruments/diy/LCDC2A0SPEC.jpg)

I wanted another one so i bought the sparkfun item but it doesn"t quite work: it flickers and blackens occasionally but my graphic never shows up. Is there a bulletproof arduino sketch I could use to test it?

These LCD"s need cleaning. I have an average failure rate of about 15-20% on delivery. The most common problem is that the contrast is too high, and there"s constant flickering / changing of contrast compared to the other 80% of them.

The solution is fairly simple, unclip the LCD from it"s board and clean the pads on the PCB with 99% IPA. Then remove the lcd back plate and contact bar. Sometimes the contact bar is stuck fairly well to the glass, peel off carefully. Clean the contacts on the LCD glass with IPA, if any residue from the contacts is left on, rub it off carefully with IPA / tissue.

Anyone taken these things apart yet? You know the flexible rectangular blocky thing that connects the contact pad on the board to the LCD itself? What are these called?

Got mine running last night and found two problems with the code, one of which was the backslash a couple of others have already noted. Second was that the LCDCharacter() writes two blank vertical lines, one before the character and a second after, when only one is needed. Without the extra blank you get at least one additional character on each line. I"ll probably also move the ASCII font table to PROGMEM space to save on RAM and then start to work on some big digits for a clock.

I"m using this LCD for a large Arduino UNO project, but I"m running out of SRAM memory space. I was wondering if I used PROGMEM on the LCD ASCII array if that would help. If so, does anyone know what the right code for this would be? After looking through a lot of PROGMEM examples, I"m not advance enough to really grasp everything that"s going on. Any help you can give would be a great help. Thanks in advance!

I used one of these LCDs with an Arduino to display GPS information. I wrote a few functions that can display large numbers (28 px high) if anyone is interested, this lets me display speed, heading etc. A writeup of my project is here: http://mechinations.wordpress.com/2014/04/07/gps-sailing/

These are great displays. I ran into a problem using them with the nRF24L01+ radio transciever, which requires the use of the SPI bus. If one attaches both the radio and the display MOSI and SCK pins to pins 13 and 11 as instructed in the hookup guide, the SPI traffic of the other device (in this case the nRF24L01+ radio) will prevent the display from functioning. The easy solution is to move the Nokia 5110 MOSI and SCK pins to any other digital pin. This should be made clear in the hookup guide, where it says there is no choice but to use the hardware SPI pins for the display. I found out that is not true at all. I hope his helps others with the same problem. Despite the occasional bad display these carry much more information that the comparably prices 16 x 2 LCD and use fewer pins too boot. What a deal!

Hello people, is there anyone that can tell me the height of this display. I mean the displays height 45x45 mm is the size but i wonder the thickness of it. Only the display not the pcb. I couldn"t find this info on the datasheet. Best Regards..

This is a great display for the money, certainly the best bang for the buck of you can live with B&W and lower res graphics. I have a lcd driver for Arduino I will post on http://www.marchdvd.com/5110 so take a look there it draws text aligned on pixels boundaries of 8 and draws lines and has invert video options.

I just started messing around with this LCD using a STM32F103 microcontroller running at 72MHz... it works great. The only problem I had, and I suspect others might have if they are using fast processors, is that you have to deliberately introduce the setup and hold time delays on the DC pin... if you don"t you will get spurious pixels written to the display. I used a delay of 10uS, although the spec says 100nS is fine.

I just spent the last couple hours struggling with this LCD because of something very stupid of me. I was using an atmega328p in AVR-GCC and using hardware SPI. Thinking i didn"t need MISO I hooked it to DC. The LCD worked absolutely fine until I tried to set the x and y position in the ram. It started acting weird every time I tried it. Finally I put dc to another pin and BAM NO PROBLEMS. Looking back I feel pretty stupid but hopefully this post will save someone else the same mistake. Other than that great LCD for my projects

The Energia folks have an example program for this LCD and the TI Launchpad written using their Arduino style tooling. I"ve updated their example and added the ability to report back the temperature over a UART. It is a very simple hardware setup since both systems are 3.3v. http://joe.blog.freemansoft.com/2012/08/digital-thermometer-with-ti-lanchpad.html

I tried using the "LCDAssistant" package to create a logo from a graphic that I resized to a b&w jpg of 84x48 but every byte generated was 0x00 so that was not right. I tried fiddling with the settings (flying blind) but still got nowhere - does anybody know the settings for LCDAssistant and this display and has used it successfully?

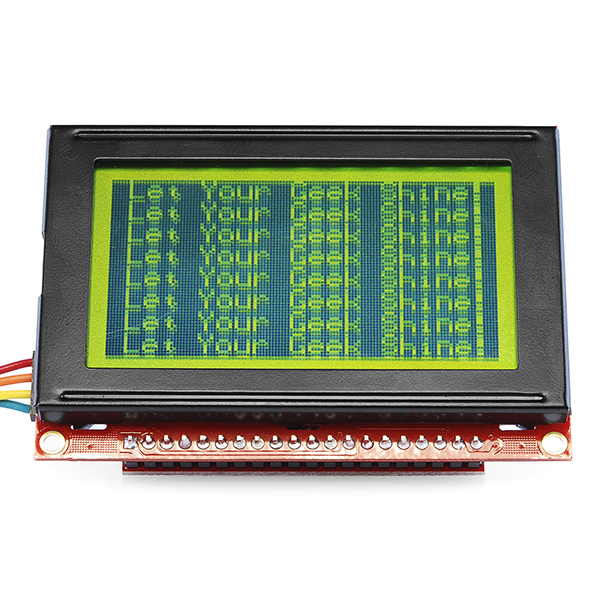

One of the things that I test regularly is a commercial item that features a 16x4 (HD44780) display. Currently I have a 20x4 on a flying lead that I plug in to determine if a display failure is down the lcd display or the main board.

Make sure your power is regulated correctly, and that all of your soldering points and connections are good. It may simply be a bad screen. If you still run into problems, shoot us an email at techsupport@sparkfun.com

I see that this item is Out of Stock (back-order allowed). I have a embedded system I have been documenting / publishing the design for over the last month, so I would like to know if Sparkfun Plans on keeping this part and if so for how long? Is there a part you would recommend for replacement if this one is going away?

Might I suggest you (SFE) source some of the Electronic Assembly"s LCD Dog-S series. I think they would be a step up from these at a reduced price. I don"t think that they website is up to date, but their part number is LED39x41-GR.

I finally got around to running this LCD on my 3310 PCB. It is working fine with one minor problem. The SF 3310 display hides to first line of bytes for some reason and I had to offset everything to compensate. The 5110 doesn"t do this as behaves as expected. I haven"t heard anyone else report this so maybe my initialization code is different.

Using a 3V source, my LCD often worked OK using bias 0x14 like the other examples, but sometimes it would appear gray and faded. The fading would lessen if I touched the panel lightly with my hand for a few seconds, then let go, so maybe it"s a temperature-dependent thing?

Ack! After two days of working nicely with 0x15 bias, I reset the board today, and the LCD appeared way over-dark. I changed the bias back to 0x14 and it looks perfect. What the heck?! I think there must be some temperature-sensing or temperature-dependence going on, so the same init values may produce good-looking results one day but not the next.

Does anyone know whether this can be stripped of its backing so it can be used in transmission? I would love to use this as a modulator for a laser beam. Or if someone knows a similarly cheap transmission LCD that would be fine too.

Stuck. Blank LCD. Added 0x20, changed Vop to 0xB3. Guessing connections may be the issue? 3.3v for LED and VCC. GND to GND. Remainder connected to Arduino via voltage dividers. What am I doing wrong?

This is a great little lcd. When I first wired it up, the backlight was shorted (accidentally) against my 5v rail, so i got some magic smoke, and burnt to LEDs but it re-soldered the offending joints and it works very well now. Something to note: the refresh and write times are much, much slower if you use 5 volt logic. I stuck in a logic level converter and it ran at least 5x faster.

You can also use FastLCD to convert your bitmaps - google it. It outputs BASIC code, but you just search and replace &h to 0x and you"re grand. It has the added advantage of being an editor for touching up output.

I recently obtained a virtually identical LCD from a Nokia 5160, and although its backlight LEDs are green, not white and conversely use different voltages, I had success hooking up the LEDs" Vcc pin to a PWM capable pin on the microcontroller, allowing me to control backlight intensity (I didn"t need a current limiting resistor for this either, but adding one will help reduce current drain on the controller).

Seems like the PCD8544 library does it"s own SPI bit managing and it really doesn"t like me using the SD library (also talks SPI) at the same time. I"ve made sure I"ve got all the SPI pins matching for both libraries (MISO, MOSI, Clock are the same and each device has it"s own Select), but it looks like the SD.begin() call just breaks the SPI bus for the 5110 and it becomes non-responsive. The LCD works just fine if I don"t initialize the SD library and the SD card works fine if I do initialize the SD card.

I"m pretty sure I tracked down the problem- the PCD8544 library uses software SPI while the SD library uses hardware SPI and I"m pretty sure the Arduino can"t do both over the same SPI clock/miso/mosi pins. Anyone know if this LCD will work with hardware SPI?

I"ve had issues with the LCD not showing anything intermittently. You got to make sure that all the connections are secure, and for the reset pulse, be sure to have a delay that"s 30-50 milliseconds long.

As much as I love SFE products and will continue to order from them, this is one product I would not recommend. The connection between the LCD unit itself and the carrier board is via those rubber polymer connectors. All the planets must line up properly for them to work. In this case, the carrier board was warped preventing the connection from working. You will find other such remarks in the comments area.

Don"t do this. Each divider will be burning 20x the entire amount of current that the display needs to function, and the whole assembly will waste 100x the LCD"s needed power and many, many times more than even the atmega needs to run at full speed. This will kill battery life.

Either use higher resistor values, n-mosfets for level conversion (see this Sparkfun BOB for an example), or drive the whole system on 2.0V - 3.3V (don"t know how easy that is with an Arduino.)

Hi, I just bought this wonderful LCD but I"m having huge huge problems connecting it..could anyone please point me in the right direction? Since there are pins that aren"t metioned in the code, for example the 6 - DNK(MOSI)...

Does anyone know the diode rating and package size, also does anyone know where to get the rubber ferroius connector behind the LCD mine is defective. Has anyone come into issues with the breadboard the LCD is connected to, a few aren"t working for me.

Yes, we have noticed that the PCB was bowing and as a result the LCD now only works when we press down on the metal strip at the top. I hope that only a small number of these LCDs have this problem. We"re expecting a shipment to arrive today, I will be running more tests.

Edit: After leaving glue to dry overnight, LCD simply does not turn on anymore. All the connections are good, but absolutely nothing shows on the LCD now at all. Only the LEDs come on.

Did you get either of the LCDs to display anything, at any time? Is it possible that the connections were OK, but you were not initializing or driving them correctly? Or did they start to work at one point, and then fail at some later point?

Note that the backlight LED"s are soldered onto the breakout board, and have nothing to do with the circuitry of the controller and LCD. So just because the backlights are shining doesn"t tell you anything about the operability of the LCD itself.

It depends on the code that you are using to control the LCD. If you are using the Arduino example above, the pins are defined in the beginning of the code.

FWIW I have connected this LCD with a 5V power supply to a 5V Arduino board with no level conversion and it worked. Presumably this may reduce the lifetime of the LCD.

I am attempting to use this with a Duemilanove (ATmega328). Up til now, I have been powering it with the 3.3V line, including the LED. The datasheet for the LDC claims: "VDDmax = 5 V if LCD supply voltage is internally generated (voltage generator enabled)." The logic levels should be kept from 2.7V to 3.3V. Since the Duemilanove uses 5V logic levels, I am using a simple voltage divider on the communication line with no issues.

The maximum logic value of 3.3 volts made me cautious of driving the LCDs at the native 5 volts of my Teensy AVR. That said, running purely off 5 volts seems to do no harm to the LCD.

For those interested, I have taken a few measurements of the current draw of the LED backlight of my LCD. As I said earlier, powering the LED with 5V external has caused permanent damage to one, perhaps two of the four LEDs. So, use the following graph at your own risk.

Is there any more documentation available for the additions to the LCD? For example, the datasheet has no information (that I could find, at least) on the LED. Everything seems fine on 3.3V, but what is the current limit on the LED? (note: if it wasn"t for work, I would just mess around with it myself.)

Here is a PicBasic Pro example for the 3310, which should be compatible with the 5110. http://www.picbasic.co.uk/forum/content.php?r=174-Using-Nokia-3310-LCD

If anyone doesn"t have experience with this LCD, take a peak at the Arduino example link above to see just how easy it is to use. If you use plain C on your AVRs, I have sample code on http://tinkerish.com.

The 4Duino is an Arduino compatible display module with built in 240x320 resolution TFT LCD Display with Resistive Touch, and Wi-Fi capabilities, perfect for IoT (Internet of Things) Applications.

At the heart of 4Duino is an ATmega32U4 8-bit micro controller from Atmel. The same microcontroller is found on popular Arduino Leonardo. 4Duino features a 2.4” colour TFT LCD display, with resistive touch. It is powered by the feature-rich 4D Systems Picaso Graphics Processor, which offers an array of display functionality and options for any Designer/ Maker. In addition, the 4Duino features the popularESP8266 Wi-Fi module which is pre-programmed with the AT command set firmware, enabling the 4Duino to have many Wi-Fi capabilities right out of the box.

The 4Duino design has incorporated a TFT LCD Touchscreen Display and Wi-Fi solution with the intention of providing a flexible and hugely capable hardware platform. This will enable Markers and Designer to significantly improve the quality and the scope of their projects, and do so rapidly with the aid of the 4D Systems Workshop4 IDE.

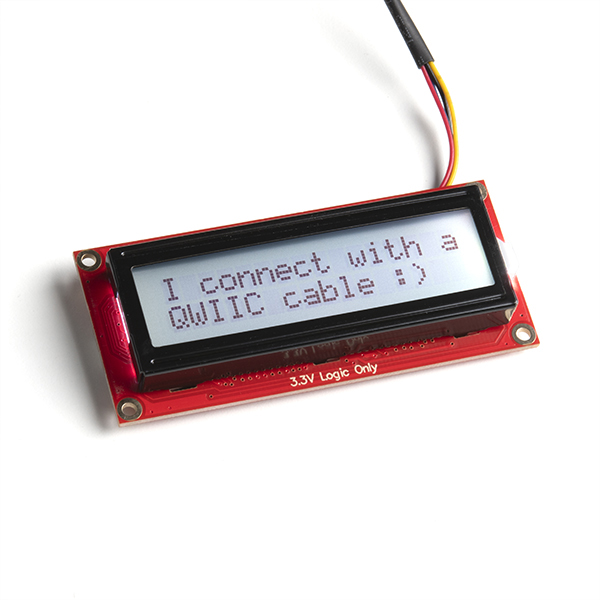

The SparkFun SerLCD is an AVR-based, serial enabled LCD that provides a simple and cost effective solution for adding a 16x2 RGB on Black Liquid Crystal Display into your project. We"ve seriously overhauled the PCB design on the back of the screen by including an ATmega328P that handles all of the screen control, meaning a backpack is no longer needed! This display can now communicate in three different ways: serial, I2C, and SPI. This comes equipped with a Qwiic connector, bringing serial LCDs into the Qwiic ecosystem. This simplifies the number of wires needed and allows your project to display all kinds of text and numbers.

The on-board ATmega328P AVR microcontroller utilizes 11.0592 MHz crystal for greater communication accuracy with adjustable baud rates of 1200 through 1000000 but is default set at 9600. The firmware for this SerLCD is fully opensource and allows for any customizations you may need.

Note: Since the SerLCD is a 3.3V device, please make sure you convert to 3.3V logic depending on your chosen microcontroller or single board computer. Otherwise, you may risk damaging your board.

The SparkFun Qwiic Connect System is an ecosystem of I2C sensors, actuators, shields and cables that make prototyping faster and less prone to error. All Qwiic-enabled boards use a common 1mm pitch, 4-pin JST connector. This reduces the amount of required PCB space, and polarized connections mean you can’t hook it up wrong.

Need a custom board? This component can be found in SparkFun"s À La Carte board builder. You can have a custom design fabricated with this component - and your choice of hundreds of other sensors, actuators and wireless devices - delivered to you in just a few weeks.

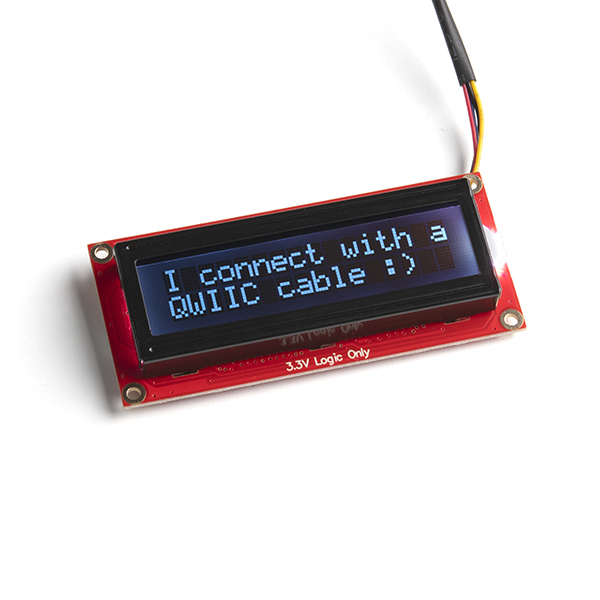

The SparkFun 16x2 Character LCD Display RBG on Black 3.3V is an AVR-based, serial enabled LCD that provides a simple and cost-effective solution for adding a 16x2 RGB on Black Liquid Crystal Display into your project. This module features a new PCB design on the back of the screen by including an ATmega328P that handles all of the screen control, meaning a backpack is no longer needed!

The on-board ATmega328P AVR microcontroller utilizes 11.0592 MHz crystal for greater communication accuracy with adjustable baud rates of 1,200 through 1,000,000 but is default set at 9,600. The firmware for this SerLCD is fully opensource and allows for any customizations you may need.

We are the world 1st produced and shipped over hundred million pieces of e-paper displays for electronic shelf labels (ESL) and industrial markets since 2011 focusing on design and manufacturing of ultra-low power display providing proprietary technologies (key components, driving waveform…), tailor-made service, open design and technical field support to ensure the best quality and reliability.

In recent time, China domestic companies like BOE have overtaken LCD manufacturers from Korea and Japan. For the first three quarters of 2020, China LCD companies shipped 97.01 million square meters TFT LCD. And China"s LCD display manufacturers expect to grab 70% global LCD panel shipments very soon.

BOE started LCD manufacturing in 1994, and has grown into the largest LCD manufacturers in the world. Who has the 1st generation 10.5 TFT LCD production line. BOE"s LCD products are widely used in areas like TV, monitor, mobile phone, laptop computer etc.

TianMa Microelectronics is a professional LCD and LCM manufacturer. The company owns generation 4.5 TFT LCD production lines, mainly focuses on making medium to small size LCD product. TianMa works on consult, design and manufacturing of LCD display. Its LCDs are used in medical, instrument, telecommunication and auto industries.

TCL CSOT (TCL China Star Optoelectronics Technology Co., Ltd), established in November, 2009. TCL has six LCD panel production lines commissioned, providing panels and modules for TV and mobile products. The products range from large, small & medium display panel and touch modules.

Established in 1996, Topway is a high-tech enterprise specializing in the design and manufacturing of industrial LCD module. Topway"s TFT LCD displays are known worldwide for their flexible use, reliable quality and reliable support. More than 20 years expertise coupled with longevity of LCD modules make Topway a trustworthy partner for decades. CMRC (market research institution belonged to Statistics China before) named Topway one of the top 10 LCD manufactures in China.

The Company engages in the R&D, manufacturing, and sale of LCD panels. It offers LCD panels for notebook computers, desktop computer monitors, LCD TV sets, vehicle-mounted IPC, consumer electronics products, mobile devices, tablet PCs, desktop PCs, and industrial displays.

Founded in 2008,Yunnan OLiGHTEK Opto-Electronic Technology Co.,Ltd. dedicated themselves to developing high definition AMOLED (Active Matrix-Organic Light Emitting Diode) technology and micro-displays.

Nokia manufactures a wide variety of cell phones and many of their cheaper phones contain simple LCD"s which may be used in microcontroller projects. There is one particular LCD model that is used in a wide variety of their phones and is often referred to as simply a "Nokia LCD", or "Nokia 6100 LCD". I used to use a Nokia 2600 phone and whenever I upgraded I took the Nokia apart to remove its LCD. This LCD appears to be the same one that is sold as "Nokia 6100 LCD" and I was able to get it up and running with a bit of work using an AVR.

You will need some sort of breakout board in order to connect the display. Sparkfun sells several (a standard breakout, an Arduino shield, an Olimex module, etc) as well as the bare surface-mount connector. Since all of SparkFun"s boards include the LCD, I just bought the connector and made my own breakout board since I already had the LCD.

If you don"t have a breakout board, you need to first make some sort of connector for the LCD. My first attempt was to solder thin magnet wire to each leg of the connector with a fine-tip soldering iron. This took several tries but eventually I got it connected. I then applied generous amounts of super glue to make sure it wouldn"t come apart and soldered on some thicker wires to connect to the microcontroller.

After you have a breakout board for the LCD connector, you must connect it to your circuit. There are 10 pins on the connector, one is unused. The LCD has four control signals (Clock, Data, Reset, Chip Select), two 3.3V inputs, two grounds, and a backlight input. The LCD driver circuitry runs on 3.3V as do the control signals. However, the backlight requires a higher voltage around 7V. Using a 1K ohm resistor between the backlight power and a 12V power supply seems to work well, the voltage is around 6-6.5V which makes it bright enough to use.

Since the LCD protocol is 9-bit SPI, you cannot use the hardware SPI interface found on many microcontrollers (including the AVR series microcontrollers) as they often only support 8-bit mode. This means that you will probably have to implement a software SPI output. Electrically, this means you can connect the four control lines to any unused I/O pins on your microcontroller. Your microcontroller must be running at 3.3V to connect the lines directly, otherwise add 10K ohm resistors on each line to limit the current going into the LCD.

The LCD has many functions that are available by sending commands over the SPI interface. The important ones are explained here and will allow you to get your LCD up and running. A full set of commands is listed in the PCF8833 datasheet here:

Before you can write to the LCD, it must be initialized. First, the Reset line must be pulled low for around 100ms and then raised high again. The Reset line must remain high during operation. Then, a sequence of commands must be sent, in the following order:

Continuing with the protocol, once the LCD is initialized it is ready to draw. Drawing works by first defining a region to draw and then streaming pixel data to fill that region. It is confusing at first, but if done properly is more efficient than pixel-by-pixel drawing. A region is simply a rectangular area on the screen. We"ll say it begins at point (X1,Y1) and ends at point (X2, Y2). Once defined, the LCD controller will fill in pixels from left to right starting at (X1, Y1). When it reaches the edge of the region, it will jump to the next line [in my example, (X1, Y1+1) ]. It does this until it reaches (X2, Y2) at which it stops accepting data. If you only want to draw one pixel, you simply set (X1, Y1) and (X2, Y2) to the pixel you want to draw. This defines the region as a single pixel. Any data sent after the first pixel"s worth of data is discarded.

To implement the 9-bit protocol using an AVR, I found a nice ASM function in the SparkFun example code. I modified the code some to clean it up and adapt it for the Phillips controller. This ASM code is more efficient than using regular C and allows faster LCD writes.

Rectangles are incredibly useful. You can draw one big rectangle to clear the screen, use them for menu elements, indicators, check boxes, frames, text backgrounds, and much more. Thankfully they are easy to draw on the Nokia LCD"s. All you need to do is define a region the size of the rectangle and fill it in with a solid color. The following AVR C code (using the functions described in the last section) will do this.

Although this is a graphical LCD, it is still useful to be able to print text to it. Unlike character-based LCD"s, graphical LCD"s do not contain a character map or font table or anything. To print text to a graphical LCD, you must define your own font table in your code and then print it character-by-character using the table. In my code, I have provided a font table (one that I converted by hand because I couldn"t find a good program to do it for me). The font is 6x8 which should allow you to fit plenty of text on the screen. I have provided functions for printing characters as well as strings.

With rectangles and text down, we can begin making truly useful stuff. Menus allow users to select from a large number of options with only a few buttons (Up, Down, and Select are common). To make a menu that looks good, you need to format your screen and text properly. I wanted a single title line and the rest to be menu entries. The LCD is 130x130 (usable) pixels in resolution. This means that I have 130 vertical pixels to divide up into menu lines. Since my font is 8 pixels tall, I decided that using 10-pixel-tall menu lines would be good. This gives a 1 pixel border around the text on top and bottom, 13 total menu lines (1 title + 12 entries), and up to 21 characters per menu line.

When drawing moving objects on the LCD, you can greatly speed up the frame rate and eliminate screen glitches by only redrawing the moving parts of an object rather than redrawing the entire screen or entire object. For instance, if a ball is moving across the screen, rather than redrawing the entire ball you can just draw the pixels along the edge that has moved and clear the pixels on the edge that has moved away. Techniques such as frame buffering and double buffering can be used, where a new frame buffer is compared against an old frame buffer and only differing pixels are written to the display. However, given the limitations of AVR and similar 8-bit microcontrollers, these techniques are probably out of range. If you are using an ARM or other 32-bit microcontroller with a higher performance CPU, more RAM, etc. then you can take advantage of double buffering for a much more efficient screen drawing system.

It is actually very easy to draw full color photos on the LCD! I simply used the serial port to transfer the image from the PC to the AVR which displays it on the LCD. To convert the image into the correct format, I wrote a small application in Visual Basic (VS 2010) that takes a 130x130 .bmp formatted image and transforms it into the 12 bit per pixel color format needed to display on the LCD. The Visual Basic VS2010 project is included with the code package at the end of this Instructable.

I have posted example code for both AVR and 8051 microcontrollers as I have used the LCD with both. The code was originally written for ATMega168 based on the SparkFun examples for both the LCD and Arduino LCD Shield. I added text and menus then ported it to 8051 for use on my 8051 project board. I then revised many systems which have been backported into the AVR code.

Thank you for this instructable. I"m an accomplished mechanic with custom fabrication for various component and systems for race cars. I"d like to tackle a screen / illumination project on an 02 GM Tahoe. Specifically the GM message center and prnd321 / odometer screen / display. All other regularly running interior / dash lights have been switched to blue led. I"m wondering how difficult it would be to change the colors of these 2 displays also to blue to match as best as possible to the blue led color. I have a spare dash cluster to use while this project is underway. Thanks in advance for any light :) you can shed on this

Have you had luck with your project? I am not familiar, but it appears the display in such vehicles is usually not an LCD of any kind, but a vacuum fluorescent discharge tube display, VFD. It"s a collection of thin shaped glass vacuum tubes that are coated with a Luminophore on the inside that determines their colour; correspondingly, while they can be manufactured in various colour, their colour can not be changed afterwards. I am not aware of any possibility to get a custom one-off VFD made for you.

It"s possible to reverse engineer the signals driving the display, and then create a drop in replacement, based on a microcontroller interpreting the signal and driving a graphic display of some kind, an LCD or OLED. With OLED, there is the question of suitability to vehicle use. The displays aren"t intended to run for hours on end, they degrade with use. Also their brightness is typically 10 times weaker than VFD. Also very few colours are available, you may be stuck with a colour that is more similar to that of VFD blue than your chosen LED blue. With LCD, there is an aesthetic issue with lowered contrast and potentially bad viewing angles. Monochromatic LCDs usually allow replacement of LEDs lighting them, and also LCDs with adjustable RGB backlight are available. An advantage of using a graphic display on a microcontroller is that you are not stuck with static symbols, you can adorn them with effect graphics, such as the frame of PRNDL gliding across the display or magnifying the currently active mode, beautiful, easily legible font for your odometer, etc.

Do you have a photograph of your display at hand so i know whether i"m thinking in the right direction? I am thinking of a display which has PRND321, a set of 7-segments for odometer, a couple of extra symbols around, but no text capability. If you have text dot matrix display which has distinct single-pixel spaces between the characters, it"s likely an HD44780 signal-compatible VFD, and you can get HD44780 LCD replacements. They come with width of 8, 16, 20 and 40 characters and height of 1, 2 and 4 lines.0

The "Message Center" appears to be an LCD it illuminates 2 colors, orange for some advisements, red for others i.e. low battery. I would like to change the color to blue or maybe green when it lights up as part of normal starting and vehicle going thru its checks. Any thoughts you have on this would be greatly appreciated.

The other project revolves around installing an aftermarket car stereo. It has (1) auxiliary 3.5mm input audio source option on the back. I have more than 1 aux audio source I would like to use. The stereo also has an audio video 3.5mm jack. (4 contact points vs 3 on the stereo aux input. I"ve pinned out the correct wires and can use the audio video source for audio only and the audio plays just fine when I select audio video input from the source selector on the front of the radio... However the screen displays "No Signal" even though the audio source plays thru it just fine. I realize this is because it is receiving no video signal. What I am wondering is if there is a manner in which I could provide a static image of my choosing or creation to put on a thumb drive or other media, power it and feed it to the video side of the audio video input. So that when I select audio video input it will not display "No Signal" and would display an image while utilizing the other audio source to play music from. Thank you if you have any insight into this area.

Message center is a monochrome graphics LCD. You shall probably find some SMD LEDs on the board beneath it, that can be replaced. I am not familiar with specific display model employed, nor are there any data sheets - it has apparently been manufactured by Optrex Corporation, Japan, specifically for use by a division of General Motors, and has not been available generally or used anywhere else. Most companies wouldn"t be caught dead ordering or a 45x28 LCD. For reference, the display model designation is DMF-50796H. If it"s anything like i imagine it to be, there should be a metal shield retained by twisted tabs on a PCB, and merely removing the shield should give you access to the LEDs.

An interesting hack, with possibility of grand destruction, is inverting the LCD. On top of the glass is usually a polarization film that can be peeled off and replaced with one mounted 90° off-angle. Tough luck if the filter is instead sandwiched between glass layers.

Dear friends,i have nokia 2600c2 and nokia 2700c mobile. I need lcd datasheet used in these mobile. Do any budy have any idea where can i find it. I tried google but no use.2

I read that it can be easily controlled via any 3 wire interface (which I am planning to software implement with a sort of loop till get a kind of 9-bit serial with enable/disable) in the datasheet, but as it"s the driver datasheet it only shows the whole driver IC pinout instead of the 10 pin nokia LCD connector. I don"t know how to connect it, I am afraid of damaging it. The display is currently working (with the phone) so if I could connect it, then it should work or show anything more than a black background.

i am doing a project on high speed photography controller. in which i have to interface nokia 6100 lcd with the ATMEGA 32 IC for setting parameters. i have the nokia 6100 LCD, but have few questions

I posted the pinout as well as the commands. The circuit is described above as well, it"s pretty simple if you take the time to look at the documentation of the LCD and read through the code. Note that Instructables is not in any way a professional help organization for your immediate needs, and no, I will not contact you in dire emergency because you didn"t read the code or pinout all the way through, because you would"ve learned all 3 of those things by doing so. Plus, no two setups are exactly the same, you can"t expect me to spit out your particular circuit...you have to do some of the work yourself!0

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey