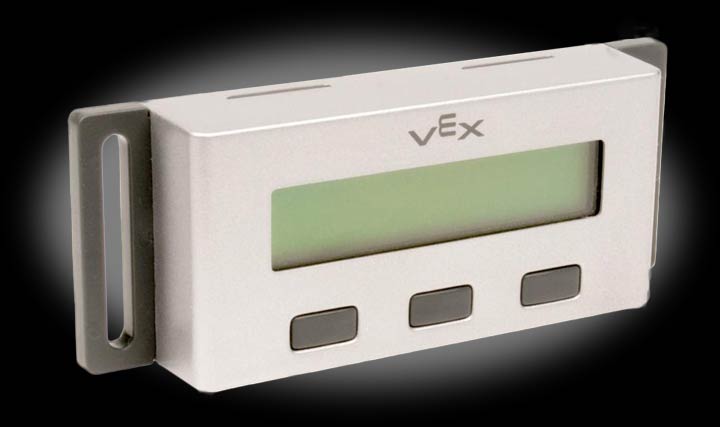

vex lcd module brands

VEX Robotics is educational robotics for everyone. VEX solutions span all levels of both formal and informal education with accessible, scalable, and affordable solutions. Beyond science and engineering principles, VEX encourages creativity, teamwork, leadership, and problem solving among groups. It allows educators of all types to engage and inspire the STEM problem solvers of tomorrow!

VEXcode allows students to get started coding quickly and easily. VEXcode is consistent across Blocks, Python, C++ and all VEX Brands. As students progress through elementary, middle, and high school, they never have to re-learn

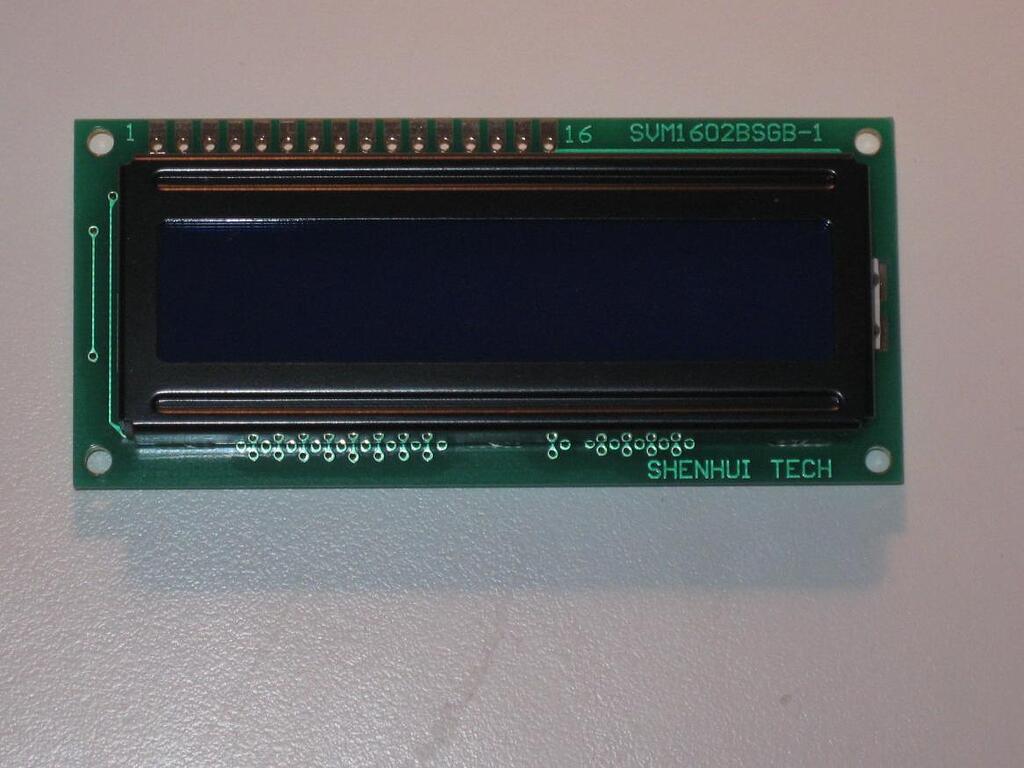

LCD & Display components are used to give visual feedback and display text, images and videos. There are simple LED bar gauges, 7-segment, and matrix displays and also LCD modules that interface with Microcontroller & FPGA Boards with serial, or with Single Board Computers with USB.

Your key phrase is “using school equipment” and asking “the schools IT folks” for items does not work for us. Downingtown Area Robotics is not an official school club, there are not any teachers involved in an official capacity in either the 105 roboteer VEX group, or the 35 roboteer FRC group. We are all parents of roboteers or in the case of Steve and I, deranged believers in competition robotics being good for students (we don’t have roboteers in the program) .

We rent the school, we rent the custodial services. So there isn’t school equipment to use. When the VEX year started we had 50 roboteers and 8 robots, with plans to buy netbooks. When the school year started we had an influx of 50 more roboteers (105 total) and decided to field 7 more robots than buy computers. If we had $2000 we would buy netbooks for the roboteers to program on.

Most things in VEX robotics need to be purchased from VEX directly or through one of their resellers; many products used in VEX are custom/only-to-be-found at VEX On High.

However, there *are* some items—identical to VEX parts—that can be purchased elsewhere, and are thus legal to use on a competition robot. And those other places are cheaper!

I’ll say it again: Items purchased from non-VEX suppliers must be *identical* to what you’d buy from VEX. Same material (with the exception of screws / nuts / washers), same size, same everything. For example, VEX makes aluminum standoffs in various lengths. The first parts section below lists McMaster-Carr as an alternate supplier. However, McMaster sells standoffs made from metals other than aluminum: not legal. McMaster also sells standoffs in sizes that are not in the VEX catalog: not legal for a competition bot. So when purchasing from other suppliers, be very careful to purchase products that are in every way, shape, and form identical.

I recommend that for any identical-but-not-purchased-from-VEX parts that your team is using, that you keep copies of the invoices/packing slips, and BRING THEM WITH YOU to each competition. Inspection volunteers have the right to ask for you to prove that the parts are otherwise identical to VEX. If you don’t have the documentation, your team may be in for a world of hurt.

For purchasing parts, one can order from VEX On High, or from one of several official resellers that offer the same thing—just through a middle-man. While the prices are the same as from the VEX Mother Ship, you may get a better deal on shipping or get products faster if you choose one of the resellers. (If you’re in the Western US — CO, UT, ID, WA, OR, CA, AK, HI — I recommend RobotMesh: $6 flat-rate shipping, free shipping over $50, and stuff arrives FAST.) You can locate the resellers that cover your state from VEX’s Find a Reseller page (scroll down the page past the map for countries outside the US).

The important part with pneumatics from alternate sources is that you MUST make sure that the parts are identical to VEX. You really, really don’t want your team building a robot that uses the wrong parts, and not even make it past robot inspection at a tournament. At that point there’s no way to remedy the problem.

One of the things I like about the reseller RobotMesh is that for pneumatics, they get kits from VEX, then take them apart and sell the individual components. Take a look at your region’s reseller, see if they offer anything interesting!

Many robots that use pneumatics use 2 air canisters/reservoirs so that they can get more “pops” from their system during a match. VEX On High does not sell individual air canisters, but (as mentioned above) the RobotMesh reseller does sell these types of parts individually (air reservior, $43). Check your state’s reseller to see if you can purchase *just* an air canister.

The first industrial supplier to try is Motion Industries, below are the parts available from them (you’ll pay shipping). If you luck is good, you can check out Radwell International (PLC center) for deals, as they work with surplus equipment. Their inventory and availability varies daily, but there are deals to be had. They also stock the special reservoir in both the US and UK. You can also try Zoro for deals. Be sure to check and double check the SMC part number, as there are variations available that will not work for VEX.

So where does one find these magical part numbers? On VexRobotics.com, if you navigate to the pneumatics page, down at the bottom of the screen click on the tab that says “Kit Contents” and there is a part number listed next to each one. (I find the RobotMesh website easier to navigate and see the individual part numbers that match the piece you need, FYI.)

* These part numbers are from the VEX website page linked above, as of November 9, 2017. Please double-check these numbers with the link above before ordering any pneumatics from a non-VEX source.

And finally a word of warning, from experience: You need to buy the solenoids from VEX, they are “specials” with a 6 volt coil. I tried buying them from Motion Industries using the SMC part number from the VEX page, and got industry-standard 24 volt coils with attached wires. VEX is reworking the solenoids with 6-volt coils and the special connector.

When you’re buying screws, note that you are not restricted to screws that LOOK exactly like VEX screws. The ones from VEX are “button head”; there is also “socket head,” for example. While steel & aluminum screws are mentioned below, there are also stainless steel, alloy steel, and so on. You can find most of these other material types at McMaster and Fastenal.

If you use the Torx screws (the star-shaped hole, instead of the hex-shaped hole), apparently VEX is the place to go for them. From another Facebook coach:

I only buy torx now, and VEX has the best price, because commercial torx seem to be all grade 8 (heat treated), which we don’t need for robot building. VEX is having specials made for them overseas.

#64 and #32 rubber bands are official VEX parts, so you are welcome to use #64 and #32 rubber bands that you purchase from anywhere (like your local office supply store). I find that the orange ones in the VEX catalog are nicer than the ones you can buy around town. They’re really soft and have a nice amount of stretch.

In our lab, we refer to this stuff as “bath mat”. What I’m referring to here is the thin and thick no-skid mat that’s in the VEX catalog. Apparently this stuff is just toolbox/tool drawer liner that you can buy by the roll (4 feet of mat, ~$6) instead of buying a small piece (15″ of mat, ~$2.50). I see that one can buy this stuff on Amazon as well as Home Depot, Lowes, Sears, and places like Harbor Freight. If you happen to already be in possession of a piece of this stuff, I’d recommend bringing it with you to a store to make sure you’re buying an identical item.

velcro – local fabric or crafts store, or Robosource.net. If you go to a local store, make sure you write down the exact specifications of the VEX product so you can make sure you’re buying an *identical* item.

VEX requires that you use the standard VEX battery on your robot for competition use; they will check it at inspection. HOWEVER, that doesn’t mean that you have to use them around your lab for testing and practice. VEX batteries are pricey: $30 for a single battery. And since most teams bring 8-10 batteries per robot to a competition, there’s $300 of your budget right there. You can make these pricey batteries last longer if you don’t use them around the lab, and use substitutes instead.

One very important thing: When you’re getting pins from elsewhere, make sure they are Gold Plated! The non-plated ones are more common, but they are not meant for constant (un)plugging and not identical to the VEX ones.

See my VEX Sensors: Introduction post for some important details about the plastic end pieces. Robosource.net has kindly created some video tutorials on how to repair the wires that make the whole thing a lot less scary.

Here’s a link to their VEX tools page: MIP (Moore’s Ideal Products). Their VEX page includes a multi-pack wrench set, and also individual items if you scroll all the way down the page.

The VEX ARM® Cortex®-based Microcontroller coordinates the flow of all information and power on the robot. It has built in bi-directional communication for wireless driving, debugging and downloading using the VEXnet wireless link. The Microcontroller is the brain of every VEX robot.

VEXnet devices contain internal processors and run on special software called Firmware (or Master Code). Firmware is updated periodically to provide additional functionality or fix bugs. To fully unlock the potential of VEX Robotics VEXnet devices, it"s important to ensure that all applicable drivers are installed and firmware is updated.

VEX IQ is an educational robotics system which is quite new. It was launched in October 2013, about at the same time as the EV3. The system includes plastic elements, metal axles, gears, wheels, treads, servo motors, sensors, and the VEX IQ brain, a microcomputer with 12 I/O ports and backlit display. The VEX IQ smart motors have a very precise PID loop controller on board. For a very good review of the VEX IQ system, check out this post at Bot Bench.

The VEX IQ brain is programmed using ROBOTC and controls the movements of the robot and reads the sensors, while the cube is scanned and solved by a custom Android app running on a Samsung Galaxy SL. I am using the same app for my latest LEGO MINDSTORMS Rubik’s cube solver robots as well.

The biggest challenge in realizing this project was making the VEX IQ system communicate with an Android app. The VEX IQ brain is not Bluetooth enabled, so I came up with the following work-around. The robot can just send acknowledgements to the app by waving a piece in front of the phone proximity sensor. The phone, in return, must send the sequence of the solving moves back to the robot. So I implemented a synchronous 2-bit base-6 parallel communication channel flashing colors on the screen of the smartphone and reading them using the VEX IQ color sensors. This way of communication is quite slow, estimated around 12 bauds: It takes 10 seconds (sped up in the video) to send a solution of 21 moves to the robot. I thought of many other ways to implement the communication (creating a custom Bluetooth adapter for example), but the current solution works out of the box, without modifying or creating any component. The communication channel is the bottleneck and the pitfall of the robot, though it is the novel feature that makes me pretty proud of it. Someone at the VEX World Championship, referring to the communication channel, told me “you made the impossible“. A bit over-the-top, but gives you the idea.

The VEX IQ brain has a slot for the radio module that allow you to make remote controlled robots. I hope VEX will enrich the IQ system with a Bluetooth module, or release the full SDK and HDK documentation to develop custom sensors using the I2C bus.

Asia has long dominated the display module TFT LCD manufacturers’ scene. After all, most major display module manufacturers can be found in countries like China, South Korea, Japan, and India.

However, the United States doesn’t fall short of its display module manufacturers. Most American module companies may not be as well-known as their Asian counterparts, but they still produce high-quality display products for both consumers and industrial clients.

In this post, we’ll list down 7 best display module TFT LCD manufacturers in the USA. We’ll see why these companies deserve recognition as top players in the American display module industry.

STONE Technologies is a leading display module TFT LCD manufacturer in the world. The company is based in Beijing, China, and has been in operations since 2010. STONE quickly grew to become one of the most trusted display module manufacturers in 14 years.

Now, let’s move on to the list of the best display module manufacturers in the USA. These companies are your best picks if you need to find a display module TFT LCD manufacturer based in the United States:

Planar Systems is a digital display company headquartered in Hillsboro, Oregon. It specializes in providing digital display solutions such as LCD video walls and large format LCD displays.

Microtips Technology is a global electronics manufacturer based in Orlando, Florida. The company was established in 1990 and has grown into a strong fixture in the LCD industry.

What makes Microtips a great display module TFT LCD manufacturer in the USA lies in its close ties with all its customers. It does so by establishing a good rapport with its clients starting from the initial product discussions. Microtips manages to keep this exceptional rapport throughout the entire client relationship by:

Displaytech is an American display module TFT LCD manufacturer headquartered in Carlsbad, California. It was founded in 1989 and is part of several companies under the Seacomp group. The company specializes in manufacturing small to medium-sized LCD modules for various devices across all possible industries.

The company also manufactures embedded TFT devices, interface boards, and LCD development boards. Also, Displaytech offers design services for embedded products, display-based PCB assemblies, and turnkey products.

Displaytech makes it easy for clients to create their own customized LCD modules. There is a feature called Design Your Custom LCD Panel found on their site. Clients simply need to input their specifications such as their desired dimensions, LCD configuration, attributes, connector type, operating and storage temperature, and other pertinent information. Clients can then submit this form to Displaytech to get feedback, suggestions, and quotes.

A vast product range, good customization options, and responsive customer service – all these factors make Displaytech among the leading LCD manufacturers in the USA.

Products that Phoenix Display offers include standard, semi-custom, and fully-customized LCD modules. Specifically, these products comprise Phoenix Display’s offerings:

Clients flock to Phoenix Display because of their decades-long experience in the display manufacturing field. The company also combines its technical expertise with its competitive manufacturing capabilities to produce the best possible LCD products for its clients.

True Vision Displays is an American display module TFT LCD manufacturing company located at Cerritos, California. It specializes in LCD display solutions for special applications in modern industries. Most of their clients come from highly-demanding fields such as aerospace, defense, medical, and financial industries.

The company produces several types of TFT LCD products. Most of them are industrial-grade and comes in various resolution types such as VGA, QVGA, XGA, and SXGA. Clients may also select product enclosures for these modules.

All products feature high-bright LCD systems that come from the company’s proprietary low-power LED backlight technology. The modules and screens also come in ruggedized forms perfect for highly-demanding outdoor industrial use.

LXD Incorporated is among the earliest LCD manufacturers in the world. The company was founded in 1968 by James Fergason under the name International Liquid Xtal Company (ILIXCO). Its first headquarters was in Kent, Ohio. At present, LXD is based in Raleigh, North Carolina.

All of their display modules can be customized to fit any kind of specifications their clients may require. Display modules also pass through a series of reliability tests before leaving the manufacturing line. As such, LXD’s products can withstand extreme outdoor environments and operates on a wide range of temperature conditions.

We’ve listed the top 7 display module TFT LCD manufacturers in the USA. All these companies may not be as well-known as other Asian manufacturers are, but they are equally competent and can deliver high-quality display products according to the client’s specifications. Contact any of them if you need a US-based manufacturer to service your display solutions needs.

We also briefly touched on STONE Technologies, another excellent LCD module manufacturer based in China. Consider partnering with STONE if you want top-of-the-line smart LCD products and you’re not necessarily looking for a US-based manufacturer. STONE will surely provide the right display solution for your needs anywhere you are on the globe.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey