2 line 16 character lcd display datasheet brands

You are the BEST!!! Thank you. It was worth registering just to post this message to you. I hope to participate further. There are a LOT of bugs in the Arduino sketches (Projects 1-23). Thanks again.

Working OK with Picaxe 20x2 but uses pins I would like to have free for i2c. So, I am getting bigger picaxe to go with it. Used 2 rectifier diodes in series for the voltage drop to 4.2v on the backlight and two 1k ohm resisters in series for the contrast. Looks good.

Thanks loophole! I got the display working fine using this link that link that was mentioned, http://arduino.cc/en/Tutorial/LiquidCrystal, but it was dim since the backlight was not working. After reading loophole"s comment and looking at datafile I applied 4.2V pin 15 and grounded pin 16, and all was GREAT!

The post that KHartley posted with regards to all the pin connections and using an Aduino mini pro, who then also got a reply from member 468163, that the code and everything worked.

I am using the exact components and have followed the exact pin configurations for the past 2 weeks, connecting then reconnecting, I have also tried different FTDI cables for uploading onto the Arduino pro mini. BUT have had no success, PLEASE help me as it is a basic issue I am sure but cannot find the solution, My 16*2 LCD lights up and also when I upload a program the arduino page reads that it has successfully uploaded (Done Uploading).

We"ve had customers order face plates through Ponoko for these LCDs and be pretty happy with it. Check around on the comments on other products and on the forum. You"ll probably find a lot of different examples of mounting solutions.

can this run in 8bit mode? I"m trying so hard to just wire up the 8 data lines and manually send the bits required for certain symbols. But it"s either stuck in 4bit mode, or I"m completely lost. My program is simple and I KNOW that it is sending the 1"s and 0"s down the appropriate lines but I can"t get a response at all. And I can succesfully apply the example code for liquid crystal. In class we just banged some bits into those old lcd"s and got the expected response... Is this one more advanced or something? Thanks, I really appreciate any help.

No matter what line I set the cursor at using lcd.setCursor(0,0), or lcd.setCursor(0,1), it will print everything on line 0. I"ve used the same LCD, different size before and never had this issue.

You should make the LCD"s connection pins on the bottom, like on the RGB backlit LCD"s (https://www.sparkfun.com/products/10862). I like standing them straight up and down on breadboards. If I tried that with this one, it would be upside down.

I"m having a problem with this lcd, I can"d print custom caracters, I tried the code that this site http://icontexto.com/charactercreator/ gives you when you create a custom char, tried some other examples, but nothing, I always get just two vertical bars on the second and fourth columns.

I love this little LCD! It works great. However, I"m having a wicked hard time finding hardware (i.e. self-clinching PEM stud) that I can use to mount this. The 2.5mm mounting holes are pretty small. I"m trying hard not to use glues.

I"m having problems with my contrast - it"s always either too high (washed out characters) or too low (can"t see the character) on separate spaces at the same time. No matter how I adjust it, each character seems to require a different contrast level. Help, please?

I"m also having trouble with LCD. I hooked up at 10kOhm pot, but when I upload the code it just gives me random pixels and characters. Is my Atmega on my Arduino Uno shot?

Like others have said, works well with liquidcrystal library and I also like to pwm the backlight with a fet on the low side. Looks really cool to have it fade out to 1 or 2% duty cycle standby mode when there has been no button presses/input in a while and then fade back in when you press a button.

Also no external resistor is needed for the backlight; just like almost all other 5v character LCDs this one has a series resistor right on the board. Mine is 130 ohms.

I was able to achieve much better contrast by applying a slightly negative voltage on the Vo pin (3). Minus 200 mV did the trick. I seem to remember that LCD"s used to have a negative output for just this reason. I don"t know what the rating of this pin is, so proceed with caution.

3) If you hook it to an Arduino, powering the LED backlight from a digital I/O pin will only source 40mA max. (PIC micros are even less), any more and you are overloading your output. Tie pin K (or 16) to ground, and A (or 15) will be the high side. If you design for 40mA, calculate the current limiting resistor to put between the I/O pin and pin A (or 15) of the LED backlight as follows: 5V-4.2V=0.8V and 0.8V/0.040A=20ohms however, be sure to measure the voltage across your current limiting resistor and calculate the actual current flowing to the LED just in case... don"t overload your Arduino I/O!

4) If you want to really drive it properly, you need more POWER! So grab an NPN transistor such as a 2N4401 or 2N2222 or 2N3904, and amplify your I/O. Hook a 220 to 330 ohm resistor between your I/O and the base of the NPN, hook the emitter of the NPN to ground, and the collector to the K pin (or 16) of the LED backlight. Hook a 5 to 10 ohm 1/4W resistor between the A pin (or 15) of the LED backlight and the 5V rail (make sure your 5V regulator can handle the extra 120-160mA of current you are going to be consuming)

Thanks to the guy who first pointed that for that bcklight to work one needs pin 15 on +4.2V and pin 16 on ground. Without that I was getting a pretty dim job.

I made it work by using the same schematic featured in the LiquidCrystal Arduino library page, except LCD pin 6 is hooked to a digital PWM instead of a potentiometer for controlling contrast.

Pretty cool little LCD. I had some problems initially with the 4bit LCD library, but after finding that the standard LiquidCrystal library supports 4-bit data lines it worked great.

The one thing that threw me off was that the standard (not extended) datasheet mentions that the backlight (BKL) can be driven by pins 1,2 or 15,16 -- however I found that I needed to apply 4.2v to pins 15,16 before the backlight would work. Easy fix, just misleading on the datasheet.

I"m very impressed. I followed the connections from the data sheet and set them up the same way the LiquidCrystal "Hello World" example sketch calls for, and the display worked perfectly with my Arduino Duemilanove. It does take some playing with the contrast potentiometer, but I quickly found the perfect setting. The display is sharp, clear, and cool white letters on a black background.

Ordered mine a week ago and finally got around to playing with it. I used the included LiquidCrystal.h for Arduino to run this thing. Very easy to use once you get it up and running. To get the contrast working I used a 3.3Kohm resistor going to ground, looks amazing. Not quite as bright as picture but I think I"m close. 2.2Kohm is too washed out and 6.8 Kohm nothing shows up. I can"t believe how much easier this is compared to the 68HC12. Uhhh, I"m going to have nightmares for the rest of my life.

Have you wired in the backlight? That tutorial doesn"t include wiring pins 15 and 16 on the lcd. I have hooked the backlight up to a pwm output so that I can turn it on and off via sketch.

I am also ahving this same problem. The LCD was great and easy to set up, but the brightness is really really poor. I installed a pot and all, but no dice.

Has anyone got this working with the LiquidCrystal or LCD4bit library? I am having quite a bit of trouble getting it to work reliably and am at the point where I am going to try and code my own library for it.

I"m also having heaps of trouble. I can sometimes get it to display text, maybe once out of every 30 attempts. And IF it decides to display anything it ends up garbling the message and locking up, not displaying the other strings in the sequence. Is this the LCD, my Arduino or the library? I tried using LCD4bit and a modified LiquidCrystal and they all yield the same, frustrating results.

Late reply, but I have trouble with this if I forget to add decoupling capacitors on the V+ line. Especialy using multiple serial to parallel converters at high data rates.

Great little lcd, for basic output, debugging etc. Very easy to interface, and looks very slick! If you need a basic no frills LCD, this is a good buy.

The easiest way would be to stick a transistor inline with the power lead of the lcd and turn it off just before the cpu goes into the low power state.

This product worked great. I wrote a tutorial about manually writing data to the display using dips switches and push buttons. http://volatileinterface.com/2015/05/30/using-a-hd44780-lcd-display-in-4-bit-mode/

Completely useless, I have no idea what happened but when I wire it up according to the tutorial on arduinos site for the Hello World! LCD program, nothing but the backlight comes on. Also the pins are flipped from where they are in the schematic. Total cluster fuck of a product.

So apparently the product works fine, and I apologize to all those at sparkfun. I should be on the arduino forums tell them that the tutorial is a cluster F**k and not this item. for those who had the same problem, you have to connect pin 15 Vin and pin 16 to GND, everything on the tutorial is correct.

I just realized I forgot the bridge connections over the cnter of the breadboard to actually connect the data lines to the LCD. It works now I think I need to adjust the contrast or something. The text on the display is more visible when looking at the display from an angle.

I just bought this and thought it had the HD44780 chipset but now I started looking at the datasheet for the pin interface descriptions and I realize that it has the KS006U chipset? Is the datasheet wrong or is the sparkfun description wrong? Or maybe they are basically the same chipset? I"m confused right now. Do I need to buy a different LCD?

HD44780 is more a standard that a chipset at this point. there are tons of different chipsets that use the same protocols. like how people say "allen wrench" instend of saying hex key. HD44780 is the LCD equivilent of X86 instruction set. the cool think is you can lean how to use the 16x2, and then use the same code on everything from 8x1 to 40x4 displays.

You can simulate data on each pin of the HD44780 compatible LCD and see how it works, or if you are more advanced you can write directly your own scripts in the web browser to control the LCD, same as you would use them in the MCU code

Is there a flat cable assembly available for these? I"m OK using the 0.1" headers, but the electronics I need to hook up requires a cable interconnect. And I"d like it so that I can replace the LCD without desoldering it.

I?m considering using this in a battery powered device that will experience long periods of inactivity. During the inactive periods all system components will enter a low power stand-by or sleep state. This display does not appear to have a low power (uA) state.

This is a very late response, but anybody in this situation can simply connect the LCD in series with a MOSFET. YOu can then switch the LCD on and off from a microcontroller. Remember to leave all the microcontroller outputs floating because power can still flow into the LCD if you keep these in certain states.

This is a basic 16 character by 2 line display. Black text on Green background. Interface code is freely available. You will need ~11 general I/O pins to interface to this LCD screen. Using the very common Sumsang KS0066 parallel interface chipset which is equivalent of Hitachi HD44780. Includes LED backlight.

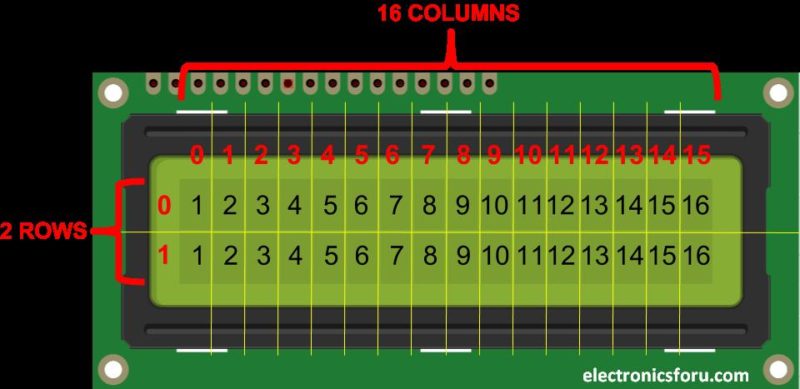

16×2 LCD is named so because; it has 16 Columns and 2 Rows. There are a lot of combinations available like, 8×1, 8×2, 10×2, 16×1, etc. But the most used one is the 16*2 LCD, hence we are using it here.

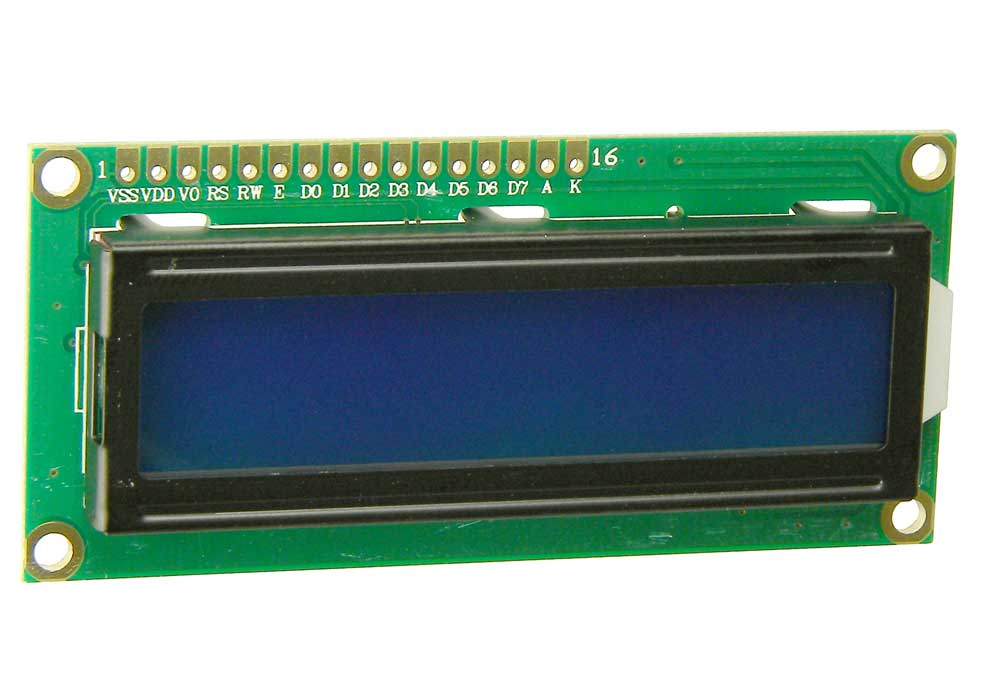

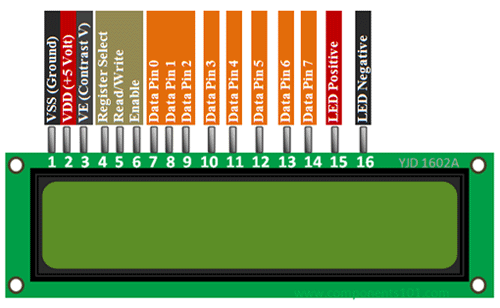

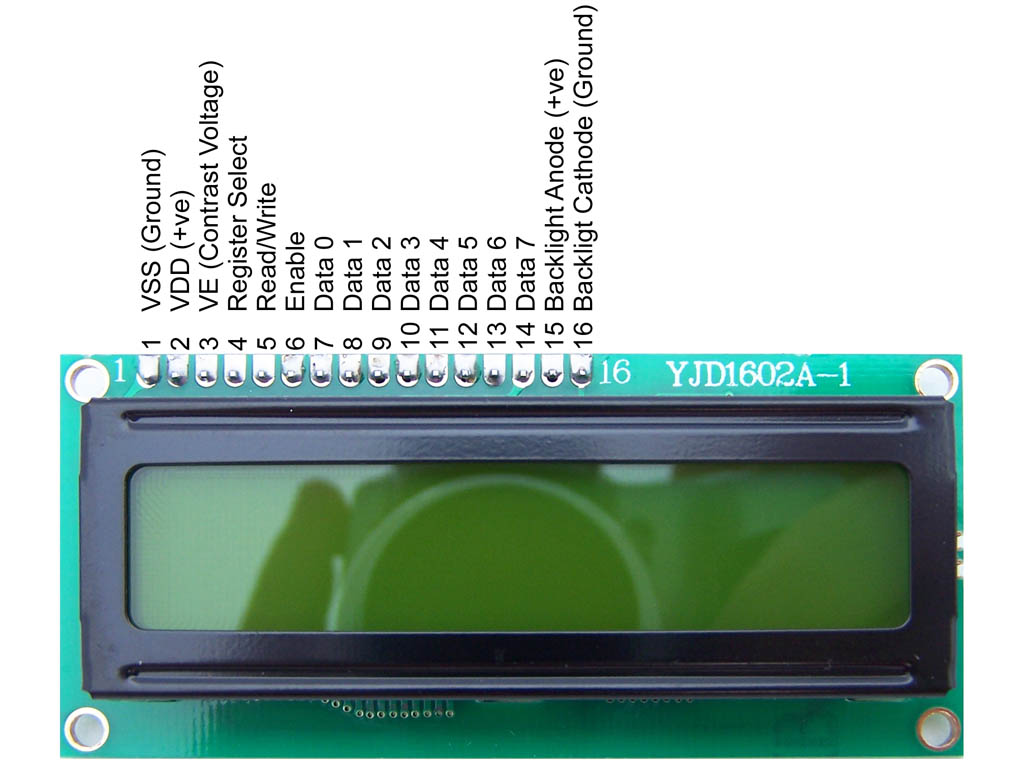

All the above mentioned LCD display will have 16 Pins and the programming approach is also the same and hence the choice is left to you. Below is the Pinout and Pin Description of 16x2 LCD Module:

These black circles consist of an interface IC and its associated components to help us use this LCD with the MCU. Because our LCD is a 16*2 Dot matrix LCD and so it will have (16*2=32) 32 characters in total and each character will be made of 5*8 Pixel Dots. A Single character with all its Pixels enabled is shown in the below picture.

So Now, we know that each character has (5*8=40) 40 Pixels and for 32 Characters we will have (32*40) 1280 Pixels. Further, the LCD should also be instructed about the Position of the Pixels.

It will be a hectic task to handle everything with the help of MCU, hence an Interface IC like HD44780 is used, which is mounted on LCD Module itself. The function of this IC is to get the Commands and Data from the MCU and process them to display meaningful information onto our LCD Screen.

The LCD can work in two different modes, namely the 4-bit mode and the 8-bit mode. In 4 bit mode we send the data nibble by nibble, first upper nibble and then lower nibble. For those of you who don’t know what a nibble is: a nibble is a group of four bits, so the lower four bits (D0-D3) of a byte form the lower nibble while the upper four bits (D4-D7) of a byte form the higher nibble. This enables us to send 8 bit data.

Now you must have guessed it, Yes 8-bit mode is faster and flawless than 4-bit mode. But the major drawback is that it needs 8 data lines connected to the microcontroller. This will make us run out of I/O pins on our MCU, so 4-bit mode is widely used. No control pins are used to set these modes. It"s just the way of programming that change.

As said, the LCD itself consists of an Interface IC. The MCU can either read or write to this interface IC. Most of the times we will be just writing to the IC, since reading will make it more complex and such scenarios are very rare. Information like position of cursor, status completion interrupts etc. can be read if required, but it is out of the scope of this tutorial.

The Interface IC present in most of the LCD is HD44780U,in order to program our LCD we should learn the complete datasheet of the IC. The datasheet is given here.

There are some preset commands instructions in LCD, which we need to send to LCD through some microcontroller. Some important command instructions are given below:

Very quick delivery, and well-packed. All LCD displays work okay, with minor ghosting (which might be normal) and subpar viewing angle (for any fixed VL level I tried). These don"t seem to be the model listed due to discrepancies from the datasheet, but they are very close: the mounting hole X pitch is 75 mm (non-E version), but the pinout has the anode at pin 16 (E version).

Character LCD Displays (aka Alphanumeric) are one of the most common display technologies available and for that reason we hold inventory for samples and prototypes in our Chandler, Arizona location.

These displays have been in use for many years, and in some ways the technology has become a commodity, but it is important to select the best options to fit your design. There are many details concerning this technology, including: fluid type, operating voltage, controller/drivers and other key details that can make your design excel or under-perform.

Our team of LCD specialists can assist you in selecting the best options so that your design is able to meet your needs and at a cost that is within your budget. Call today with any questions.

These displays are used in applications such as change machines, measurement devices, and data loggers. The module has the ability to display letters, numbers and punctuation marks.

One reason for the popularity of Character LCD displays is that they are equipped with a controller/driver chip containing a built in character (or font) table.

The table holds preloaded letters, numbers, and punctuation for each language. The font table allows the designer to request any character by addressing (selecting) the number of that character. In other words, the letter capital ‘T’ may be assigned the number 31 and the “&” symbol could be assigned number 141. This eliminates the work required to create each charter from scratch and reduces the amount of time necessary to program the LCD module.

The LCD you choose for your new design sets the perceived value of your product. Think about it: The first thing your customer looks at when they are deciding whether to purchase your product, is the LCD display. If it looks good, then your product looks good.

Negative mode displays are popular for new designs since they stand out. Negative mode means the background is a darker color, like black or blue and the characters/icons/segments are a lighter color such as: White, Red or Green.

The opposite of a negative mode is positive mode where the background is a lighter color such as yellow/green or grey and the characters/icons/segments are a darker color like black or dark blue.

Negative mode displays must have a backlight on all the time to be readable. The challenge is that the LED backlight will draw/drain 10 times more power than the LCD without a backlight. So, if this is a battery application, it is best to stick with a positive mode.

Positive mode displays are readable without a backlight if there is enough ambient light. The LCD without a backlight will draw around 1uA. LED backlights can draw as little as 15mA up to 75mA or more depending on the number and brightness of the LEDs.

The first question to answer is ‘what size of LCD?’ The larger the display the more information that can be displayed and the larger the characters can be. We recommend you choose one of the standard sizes on this page to reduce cost and lead time. Focus Display Solutions (aka FocusLCDs) carries many of the industry standard sizes in inventory and may be able to ship the same day.

Character LCD Displays are built in standard configurations such as 8×1, 20×2 and 40×4. The two numbers identify the number of characters in each row and then the number of rows. An example of this is a 20×2 which means there are 20 characters in each row and there are two rows. This will provide you a total of 40 characters. The more characters there are on the display, the more drivers are required to drive the LCD. The controller and drivers are included with the LCD.

Note: It is possible to program the software to scroll your letters and numbers across the screen, allowing you to choose a smaller sized LCD and still display all your information.

The cost of character displays is driven more by the size of the glass, then by the number of characters. A larger 8×1 can be more expensive than a small 16×2.

It is possible to custom build a unique combination such as a 12×2 or a 16×8. This would be considered a custom LCD and would require a one-time tooling cost and possibly a higher MOQ. Go to our

Character LCD modules are available in two temperature ranges, Normal (for indoor use) and Extended (for outdoor use). The outdoor version will continue to operate down to -30C. The cost difference between normal and wide (extended) temperature range is 5% to 7% higher for the extended versions. In most cases, if cost is not critical, we recommend that you incorporate the wider temperature version.

There are three types of backlights available for a character LCD module: No backlight; LED; or EL backlight. Before introducing the various backlight options, it is helpful to cover two terms that are common for backlights: NITs and half-life.

Backlight Half-life- The half-life of a backlight is the amount of time, in hours, that the backlight will burn before it is half as bright as when it was first turned on. So if its rated half-life is 50K hours, then the backlight will be half as bright at 50K hours as when it was first turned on. The same backlight will be 25% as bright at 100K hours as when it was first turned on.

Engineers designing a battery powered product may request a character module with no backlight since the backlight draws more than ten times (10x) the power required for the LCD alone. The goal with a battery powered product is to conserve power and extend the life-time of the battery.

If the product needs to be readable in the dark or low light conditions, then it will be necessary to attach a backlight of one type or another. The best way to conserve power is to keep the amount of time the backlight is on to a minimum. Turn off the backlight as soon as the user no longer needs it. This is a common practice in cell phones. The backlight turns off a few seconds after the number is dialed or the phone is answered. The person using the phone will continue to talk, but the display will be dark.

DC Current – LEDs are driven by DC (Direct Current), which is the same type of power required for the character LCD logic voltage. Also, batteries supply DC which makes it easy to integrate the LED backlight with a battery. EL backlights require an AC (Alternating Current) to operate. The AC signal needs to be generated by an inverter. The added inverter increases the cost of the display and produces electrical noise that can interfere with neighboring circuits.

Character LCDs that include an EL (ElectroLuminescent) backlight are not as common and their popularity is decreasing. EL backlights are AC driven which requires an inverter to be supplied by the customer or attached to the LCD. Their half-life is rated at 3K hours which makes this a poor choice for products where the backlight will be on all the time. Their MOQ (Minimum Order Quantities) have increased in the last few years. At this time there is a 500 piece MOQ.

There are some key advantages to EL backlights. They are very thin, around one to two millimeters in thickness. And they provide a very even flow of light. We carry inventory on a few EL character displays, but the majority of the character displays we sell are LED.

A character LCD is constructed by placing the nematic fluid between two layers of ITO (Indium tin oxide) glass. The function of the fluid is to either block or allow light to pass through.

A TN (Twisted Nematic) monochrome LCDs is the lowest cost option. TN does not provide a very sharp contrast and has a smaller viewing angle then STN or FSTN. A smaller viewing angle means the display is readable if you look directly at it, but if you rotate it more than 40 degrees in either direction, the characters will be difficult to read.

STN (Super Twisted Nematic) fluid is the most popular option. It provides a sharper contrast and a wider viewing angle than TN. Below is a photo of a STN 16 x2 character display.

FSTN monochrome character LCD displays are assembled by taking the STN fluid and adding a film or retardation coating to the glass. This produces a sharper contrast than STN. FSTN is more popular on higher end products such as medical applications. Below is a photo of a FSTN 16×2 monochrome LCD

There are three types of polarizers: Reflective; Transflective; and Transmissive. The correct polarizer is determined by the various lighting conditions your character LCD display will operate in.

The job of the polarizer is to allow some light to pass through and some of the light to be reflected. Depending on where your display will be operating, will decide which polarizer to choose. There is no cost difference between the three polarizers. Below is a quick summary:

The reflective polarizer is basically a mirror. It will reflect 100% of the ambient light and is ideal for displays operating in direct sunlight or in situations with very bright indoor lights.

A reflective polarizer cannot be used with a LED backlight or EL backlight since it will not allow any of the light to pass through, but it is possible to use with a LED edge-lit or side-lit display. An advantage of an edge-lit display is that it is thinner than a LED backlight, but not as thin as a display equipped with an EL backlight.

A Transflective polarizer is the most popular of the three options and works best with a display that requires the backlight to be on some of the time and off some of the time. It does not perform as well in direct sunlight as a reflective polarizer, but is sufficient in most cases.

The Transmissive polarizer is used when the backlight is on all the time. This is not the best option for battery powered products, but provides a brighter backlight. This polarizer must be used for displays that run in negative mode. Negative mode is when the characters are light colored and the background is a dark.

V Logic is the voltage used to drive an LCD and draws very little current, somewhere around 1mA or less. Character displays can be driven with a VL at 3.3V or 5V.

V LED is the voltage used to drive the LED backlight only. This can be 3.3V or 5V. LED backlights can draw up to ten times (10X) the amount of current of just the LCD alone (VLCD). If your product is a battery application, the backlight should be turned off when not in use. Or build in a sensor that only turns it on in the dark.

Is it possible to drive the LCD and the LED backlight from the same connection, but not recommended since interference from the LED backlight could affect the performance of the LCD.

A key advantage of character LCDs over multicolor technology such as TFT (Thin Film Transistor) and OLED (Organic Light Emitting Diodes) it their low thirst for current.

TFTS and OLEDs require power to generate light to be readable. In many cases, their backlight needs to be even brighter in direct sunlight. This could draw 50mA or more depending on the size and brightness of the display.

When the ambient temperature of the display drops too low, the display’s performance suffers. The colder the fluid in the display, the slower the response. At some point, the display freezes up and the characters no longer change.

As long as the temperature doesn’t drop too low, there will be no damage to the display, and it will return to normal operation when the temperature rises.

This is a much more affordable solution. A small PCB (Printed Circuit Board) is attached to the back of the LCD. The board is populated with several quarter watt resistors in series that generate heat. This option draws a great deal of power. In fact, it draws more than most LED backlights.

Believe it or not, LEDs do generate heat, but nothing close to resistors or heater film. In some cases, it is enough to give the display a little extra warmth to keep it operating when the temperature drops below its threshold.

Nothing saves heat and power like insulation. Putting your LCD into something that breaks the wind and holds in the heat, will save your batteries. Many times, a protected display will continue to operate even when the temperature drops far below the threshold. This should always be the first step taken when worrying about display functionality at low temperatures. Once your product is insulated, the heat producing options noted above can be implemented.

There are three fluid types used in character LCDs: TN, STN and FSTN. TN operates the best at colder temperatures and offers a faster response time. TN does not provide the wide viewing range found in STN and FSTN, but is sufficient for most industrial uses.

The five most common types of LCD technology are: Segment, Character, Graphic, TFT and OLED. Character and Segment are the least likely options to be discontinued. They have been around for many years and are still very popular.

The displays are made up of small squares that contain a 5x8, 7x10 or 16x16 dot matrix configurations. That means there are 5 dots across and 8 dots up for a total of 40 dots. Each dot is individuality addressed on or off to produce any letter or number.

Contrast adjust. Used to lighten or darken the character with respect to the background color. This is done by adjusting the voltage (through a potentiometer or software) between max logic voltage and ground

Used to read or write the data being transferred between the LCD and the microprocessor. Tie this to ground if you only plan to write data for one-way communications.

DB 0. Most character LCDs have eight (8) data bits for faster transfer. But can operate on just four (4) data bits if you are running low on I/O (In/Outs) pins.

Positive connection of the LED backlight or side lit. The voltage could range from 5V or 3.3V. Not all character LCDs contain a LED backlight. In this case, the two pins are no connect.

Polarity is an issue with LED backlights, since they are DC (Direct Current). That means positive must connect to positive. Half of the character LCDs have pin 15 as positive and 16 as ground. The other half are reversed. If you need the polarity reversed, there is a jumper on the back of the PCB to switch polarity.

This page contains a partial list of our standard displays. Simply choose the number of characters, the size of the display and the color combination that will meet your needs. If you need a size not listed on this page, please call us. We can still supply it to you.

Our lead time on standard Character LCD displays – that are not in stock – range from five to seven weeks. This rapid lead time is due to the fact that we do not ship LCD’s via boat, but FedEx Air. By shipping via FedEx Air, we receive the LCD glass within four to five days after it is completed, compared to shipping by boat which can add several additional weeks to your lead time.

Don’t see the exact display you want on this page? Focus Display Solutions can supply you a display to match the exact configuration you want, even if it is not in our current inventory.

The cost to design and tool up a custom replacement LCD is much less than the cost associated with retooling a case or having to redesign the customer’s PCB to accept a different LCD. The customer may also need the exact display to repair units that are in the field.

This custom character design allows the customer to avoid any redesign cost or delays in the manufacturing of their product and to offer replacement displays for products that had been in the field for over ten years.

Character LCD displays are built in standard sizes and configurations. This makes the process of locating an equivalent LCD a simple process, but it is critical to make sure that the replacement display is a drop -in equivalent to your current display. It may not be possible to build a 100% equivalent product without some modifications.

We are able to match and replace these discontinued Liquid Crystal Displays. There may be a one-time NRE (Non-Recurring Engineering) fee required to modify the ITO glass, PCB (Printed Circuit Board) and bezel to match the dimensions and characteristics necessary for your production.

If your current LCD supplier has discontinued your display, Focus Display Solutions (aka Focus LCDs) has the ability to cross it over to an equivalent display and in many cases Fed Ex/UPS a sample to you the same day.

Call one of our US-based Technical Support people at 480-503-4295 or email us by using theContact form. We respond to all business inquiries within one business day and in many cases can offer you a quote the same day.

Note: when you begin ordering LCD displays from Focus, we will supply you with the data sheet. If you purchase the display, you should own the data sheet.

Providing us the full part number of the LCD allows us to determine not only the size of the display, but also the type of construction such as COB (Chip on Board) or COG (Chip on Glass), number of characters, backlight option, operating temperature range, background and backlight colors, viewing angle, backlight and LCD logic voltage, and in most cases the controller driver used.

With the part number, we will attempt to locate a full data sheet with enough details allowing us to quote a replacement for your discontinued display. If we cannot locate a data sheet, we will ask if your previous supplier had provided one to you.

If we are unable to locate the data sheet of your current LCD, we will request a data sheet. If possible, please forward over the data sheet or a link to the data sheet. If your LCD supplier is no longer in business or they will not provide you the data sheet, the next option is a photo of the display.

If you decided to move forward with us and order samples of your replacement display based on the estimated cost, we will require two of your discontinued samples. They do not need to be working displays, but need to be in good condition. Please note: We will not be able to return the two displays.

Note: when you begin ordering LCD displays from Focus, we will supply you with the data sheet. If you purchase the display, you should own the data sheet.

This 16 × 2 LCD packs 32 characters into an outline smaller than that of most two-line displays. An LED backlight enables optimal viewing in all lighting conditions. This unit uses the HD44780 interface found on most parallel character displays.

RC1602D is a 2 Line x 16 Character LCD display with module dimension 85.0 x 30.0 mm. Default interface of RC1602D Two Line 16 Character LCD Display module is 6800 with built-in IC ST7066; if you require interface such as SPI or I2C, they’re available as well, but the IC will be replaced with RW1063. Power supply of RC1602D LCD display 16x2 is 5V. Negative voltage version is available for 3V power supply.

Raystar provides various LED backlight combinations for RC1602D 16 character x 2 lines LCD display module, such as yellow-green and white. You can choose module with LED backlight or without it. This RC1602D display LCD 16x2 offers a selection of fonts, including English/Japanese, Europe and Cyrillic (Russian), etc. Feel free to contact us if you need full datasheet or more info of this display LCD 16x2.

We come across Liquid Crystal Display (LCD) displays everywhere around us. Computers, calculators, television sets, mobile phones, and digital watches use some kind of display to display the time.

An LCD screen is an electronic display module that uses liquid crystal to produce a visible image. The 16×2 LCD display is a very basic module commonly used in DIYs and circuits. The 16×2 translates a display of 16 characters per line in 2 such lines. In this LCD, each character is displayed in a 5×7 pixel matrix.

Contrast adjustment; the best way is to use a variable resistor such as a potentiometer. The output of the potentiometer is connected to this pin. Rotate the potentiometer knob forward and backward to adjust the LCD contrast.

A 16X2 LCD has two registers, namely, command and data. The register select is used to switch from one register to other. RS=0 for the command register, whereas RS=1 for the data register.

Command Register: The command register stores the command instructions given to the LCD. A command is an instruction given to an LCD to do a predefined task. Examples like:

Data Register: The data register stores the data to be displayed on the LCD. The data is the ASCII value of the character to be displayed on the LCD. When we send data to LCD, it goes to the data register and is processed there. When RS=1, the data register is selected.

Generating custom characters on LCD is not very hard. It requires knowledge about the custom-generated random access memory (CG-RAM) of the LCD and the LCD chip controller. Most LCDs contain a Hitachi HD4478 controller.

CG-RAM is the main component in making custom characters. It stores the custom characters once declared in the code. CG-RAM size is 64 bytes providing the option of creating eight characters at a time. Each character is eight bytes in size.

CG-RAM address starts from 0x40 (Hexadecimal) or 64 in decimal. We can generate custom characters at these addresses. Once we generate our characters at these addresses, we can print them by just sending commands to the LCD. Character addresses and printing commands are below.

LCD modules are very important in many Arduino-based embedded system designs to improve the user interface of the system. Interfacing with Arduino gives the programmer more freedom to customize the code easily. Any cost-effective Arduino board, a 16X2 character LCD display, jumper wires, and a breadboard are sufficient enough to build the circuit. The interfacing of Arduino to LCD display is below.

The combination of an LCD and Arduino yields several projects, the most simple one being LCD to display the LED brightness. All we need for this circuit is an LCD, Arduino, breadboard, a resistor, potentiometer, LED, and some jumper cables. The circuit connections are below.

If you’ve ever tried to connect an LCD display to an Arduino, you might have noticed that it consumes a lot of pins on the Arduino. Even in 4-bit mode, the Arduino still requires a total of seven connections – which is half of the Arduino’s available digital I/O pins.

The solution is to use an I2C LCD display. It consumes only two I/O pins that are not even part of the set of digital I/O pins and can be shared with other I2C devices as well.

True to their name, these LCDs are ideal for displaying only text/characters. A 16×2 character LCD, for example, has an LED backlight and can display 32 ASCII characters in two rows of 16 characters each.

If you look closely you can see tiny rectangles for each character on the display and the pixels that make up a character. Each of these rectangles is a grid of 5×8 pixels.

At the heart of the adapter is an 8-bit I/O expander chip – PCF8574. This chip converts the I2C data from an Arduino into the parallel data required for an LCD display.

If you are using multiple devices on the same I2C bus, you may need to set a different I2C address for the LCD adapter so that it does not conflict with another I2C device.

An important point here is that several companies manufacture the same PCF8574 chip, Texas Instruments and NXP Semiconductors, to name a few. And the I2C address of your LCD depends on the chip manufacturer.

According to the Texas Instruments’ datasheet, the three address selection bits (A0, A1 and A2) are placed at the end of the 7-bit I2C address register.

By shorting the solder jumpers, the address inputs are puled LOW. If you were to short all three jumpers, the address would be 0x20. The range of all possible addresses spans from 0x20 to 0x27. Please see the illustration below.

According to the NXP Semiconductors’ datasheet, the three address selection bits (A0, A1 and A2) are also placed at the end of the 7-bit I2C address register. But the other bits in the address register are different.

So your LCD probably has a default I2C address 0x27Hex or 0x3FHex. However it is recommended that you find out the actual I2C address of the LCD before using it.

Connecting an I2C LCD is much easier than connecting a standard LCD. You only need to connect 4 pins instead of 12. Start by connecting the VCC pin to the 5V output on the Arduino and GND to ground.

Now we are left with the pins which are used for I2C communication. Note that each Arduino board has different I2C pins that must be connected accordingly. On Arduino boards with the R3 layout, the SDA (data line) and SCL (clock line) are on the pin headers close to the AREF pin. They are also known as A5 (SCL) and A4 (SDA).

After wiring up the LCD you’ll need to adjust the contrast of the display. On the I2C module you will find a potentiometer that you can rotate with a small screwdriver.

Plug in the Arduino’s USB connector to power the LCD. You will see the backlight lit up. Now as you turn the knob on the potentiometer, you will start to see the first row of rectangles. If that happens, Congratulations! Your LCD is working fine.

To drive an I2C LCD you must first install a library called LiquidCrystal_I2C. This library is an enhanced version of the LiquidCrystal library that comes with your Arduino IDE.

Filter your search by typing ‘liquidcrystal‘. There should be some entries. Look for the LiquidCrystal I2C library by Frank de Brabander. Click on that entry, and then select Install.

The I2C address of your LCD depends on the manufacturer, as mentioned earlier. If your LCD has a Texas Instruments’ PCF8574 chip, its default I2C address is 0x27Hex. If your LCD has NXP Semiconductors’ PCF8574 chip, its default I2C address is 0x3FHex.

So your LCD probably has I2C address 0x27Hex or 0x3FHex. However it is recommended that you find out the actual I2C address of the LCD before using it. Luckily there’s an easy way to do this, thanks to the Nick Gammon.

But, before you proceed to upload the sketch, you need to make a small change to make it work for you. You must pass the I2C address of your LCD and the dimensions of the display to the constructor of the LiquidCrystal_I2C class. If you are using a 16×2 character LCD, pass the 16 and 2; If you’re using a 20×4 LCD, pass 20 and 4. You got the point!

First of all an object of LiquidCrystal_I2C class is created. This object takes three parameters LiquidCrystal_I2C(address, columns, rows). This is where you need to enter the address you found earlier, and the dimensions of the display.

In ‘setup’ we call three functions. The first function is init(). It initializes the LCD object. The second function is clear(). This clears the LCD screen and moves the cursor to the top left corner. And third, the backlight() function turns on the LCD backlight.

After that we set the cursor position to the third column of the first row by calling the function lcd.setCursor(2, 0). The cursor position specifies the location where you want the new text to be displayed on the LCD. The upper left corner is assumed to be col=0, row=0.

There are some useful functions you can use with LiquidCrystal_I2C objects. Some of them are listed below:lcd.home() function is used to position the cursor in the upper-left of the LCD without clearing the display.

lcd.scrollDisplayRight() function scrolls the contents of the display one space to the right. If you want the text to scroll continuously, you have to use this function inside a for loop.

lcd.scrollDisplayLeft() function scrolls the contents of the display one space to the left. Similar to above function, use this inside a for loop for continuous scrolling.

If you find the characters on the display dull and boring, you can create your own custom characters (glyphs) and symbols for your LCD. They are extremely useful when you want to display a character that is not part of the standard ASCII character set.

As discussed earlier in this tutorial a character is made up of a 5×8 pixel matrix, so you need to define your custom character within that matrix. You can use the createChar() function to define a character.

To use createChar() you first set up an array of 8 bytes. Each byte in the array represents a row of characters in a 5×8 matrix. Whereas, 0 and 1 in a byte indicate which pixel in the row should be ON and which should be OFF.

CGROM is used to store all permanent fonts that are displayed using their ASCII codes. For example, if we send 0x41 to the LCD, the letter ‘A’ will be printed on the display.

CGRAM is another memory used to store user defined characters. This RAM is limited to 64 bytes. For a 5×8 pixel based LCD, only 8 user-defined characters can be stored in CGRAM. And for 5×10 pixel based LCD only 4 user-defined characters can be stored.

Creating custom characters has never been easier! We have created a small application called Custom Character Generator. Can you see the blue grid below? You can click on any 5×8 pixel to set/clear that particular pixel. And as you click, the code for the character is generated next to the grid. This code can be used directly in your Arduino sketch.

Your imagination is limitless. The only limitation is that the LiquidCrystal library only supports eight custom characters. But don’t be discouraged, look at the bright side, at least we have eight characters.

After the library is included and the LCD object is created, custom character arrays are defined. The array consists of 8 bytes, each byte representing a row of a 5×8 LED matrix. In this sketch, eight custom characters have been created.

In setup, a custom character is created using the createChar() function. This function takes two parameters. The first parameter is a number between 0 and 7 to reserve one of the 8 supported custom characters. The second is the name of the array.

A 16 x 2 line alphanumeric character display. This LCD features a parallel interface supporting both 4 bit and 8 bit modes, a yellow LED back-light, and a black trans-reflective font. This means LCD text is visible in direct sunlight and with the back light off.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey