lcd panel destroys t-con in stock

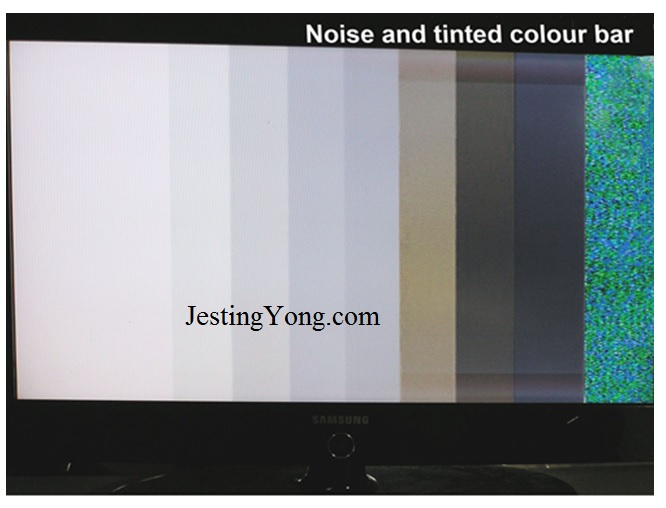

One of my business associate asked me whether I can analyse the Samsung LCD TV for him. The model is LA32A330JLX which is in the store room for quite some time as it is very dusty when I received it. He said it too expensive to repair so he just kept it for sentimental reason. When I switched it on, the LCD display has incorrect colour, noisy disturbances at black level and poor contrast picture as shown below.

This type of defects normally caused by the main or the T-Con board . From the TV channel display, it is unlikely that the main board failure as it is impossible for the video processing circuits in the main board to display a problem on a specific area of the screen. Failure of the main board or video circuit normally appear noisy or distortion of colours across the whole screen.

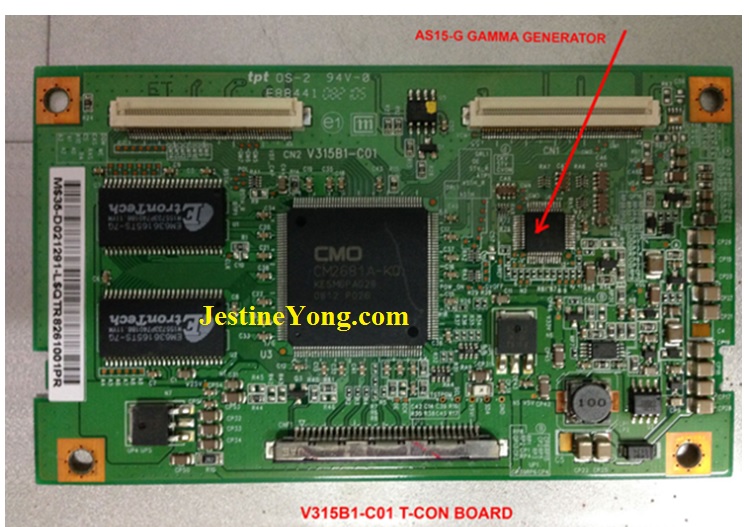

Most likely the T-con board BN81-01868A (V315B1) is creating the problem. It cost around US$60 including postage which is on the high side considering the age of this model. Changing the T-con board can be a very fast & easy repair job but it is not cost effective or may not worthwhile to repair it. A better solution will be to try to trouble shoot the T-con board, since it may not be big problem as the major function i.e the timing controller is working fine or else the TV channel will not be able to display normal picture except with the problems mentioned earlier.

The analogue grey scale signal is apply to the LCD TV AV input and the screen display turned out to be abnormal grey scale image (see photo 1). From the abnormality and discoloration of the grey scale display, it is confirmed that the gamma correction or generator IC is no longer operating normal and not performing gamma correction with the original characteristic. The gamma correction IC could be damaged or deteriorated which resulted in tinted colour and noise generated being superimposed on the dark or grey level.

Most LCD TV manufacturers do not provide schematics for T-con board and there are limited information on the internet. Spotting the gamma correction IC is not a problem as there are only a few IC’s on the board. The gamma correction or generator IC on this T-CON board is labelled as U6 with marking “ AS15-G” and it cost only around US$4.

I used to work for a laptop manufacturer doing support, and we were instructed that in the event that a customer ever called reporting a leaking LCD we were to IMMEDIATELY tell them to hang up the phone, call emergency services, and get a hazmat team onsite, while we escalated the call to our internal dedicated safety response team. That seems like a pretty harsh response (it"s more severe than what I would have been expected to do for anything short of "My laptop set my house on fire") so I"m inclined to think this stuff isn"t especially safe. It may be true that it"s only a hazard if ingested, though; based on my semi-limited knowledge of the chemistry involved that seems possible. If it were me, though, I"d take the extra cautious route just in case.

(In practice, this basically never happens short of a severe puncture like a blade would cause because of the way these things are manufactured. I"ve actually never personally heard of a situation where an LCD was leaking short of taking a bullet.) EDIT: Let me just make this stronger. This hardly ever happens, ever, anywhere, ever - it"s designed to prevent exactly this sort of problem. Unless you actually witness it in action there is probably no reason to worry about it. See further discussion in comments.

There are two ways to properly perform this task on any OEM adhered lcd assembly. One way is very costly to setup and the other is not but it is slightly more time consuming.

Following these steps you will have a reconditioned lcd assembly in under 30 minutes using common household items and a few you will need to hit the harware store to obtain.

While wearing leather gloves, wrap the ends of the wire around your index fingers on each hand enough times to give you a very sturdy grip. Keeping the assembly face down on the griddle apply slight pressure on the lcd with your thumbs while you gently work the wire between the glass and the digitizer/polarizer layers. You only want to get the wire in a few millimeters, just enough to get your playing card in behind it.

Take off the gloves, leave the wire in the glass and slide a playing card in right behind the wire. Make sure the card spans the ENTIRE width of the lcd and protrudes from both edges, left and right.

Have someone hold the hair dryer for you and point it at the glass, to the very bottom edge of the card. Moving together, slowly but steadily work the card down between the layers, separating the glue. Do not bend the card towards the lcd at this point or you may shatter it. Continue moving the card through as your friend follows the edge of the card down with the hair dryer. You will more than likely need to throw away the card and use another 3-4 times to get all the way through as the card will get mangled and lose its edge, becoming ineffective.

You will notice that your lcd is free of all the glass but is also covered in gooey gum. Much of this can be removed by simply grabbing some tightly and peeling it back with your fingers. If you run into any stubborn gum use the safe scrap plastic razors to remove it. Do not use any solvents to remove the gum unless you are proficient with a soldering iron and do not mind re applying the back light layer on the rear of the lcd.

Place your lcd face up in the LOCA mold. Apply a line of LOCA straight down the middle of the lcd from top to bottom. Excess will not hurt but it is messy, however you are better off using too much adhesive than not enough. Once the LOCA is applied, place ONLY the bottom edge of the glass into the mold but hold the top edge up and do not allow the glass to contact the glue yet. VERY SLOWLY begin to lower the top edge down to the lcd. ONLY move as fast as it takes for the glue to make it all the way to the left and right edges, it will like watching a horizon of glue rise to the top and outward to the sides.

Congratulation, you have rebuilt your lcd assembly. In our shop we often do have to perform this task in a similar fashion as the machines we use do not work when the glass is completely shattered, so this advice is based on my personal experience from owning one of only 3 facilities in the United States that is capable of this on a large scale.

Keep in mind that iPhone screens are so inexpensive comparatively speaking that there are probably many things you could be doing with your time other than attempting this. But if you are like me, and it always bothers you when someone tells you something cant be done, then enjoy. Remember, patience is the key. Frustration, shaky hands, being irritated or distracted often leads to a shattered lcd. If you are having trouble put it down and take a break for 5 minutes.

quick edit: I forgot about the Alcohol! using a q-tip NOT dripping in isopropyl alcohol gently clean excess glue form underneath your new glass. Unlike solvents, this only removes uncured LOCA and will not effect the bond you created. Be careful to use as little as possible or you may need to solder a new back light layer on the lcd, as even alcohol is not pure and contains some water which will stain the otherwise immaculate back light layer, giving you that bad whiteout splotchy look.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey