tft lcd burn in factory

TFT LCD image retention we also call it "Burn-in". In CRT displays, this caused the phosphorus to be worn and the patterns to be burnt in to the display. But the term "burn in" is a bit misleading in LCD screen. There is no actual burning or heat involved. When you meet TFT LCD burn in problem, how do you solve it?

Burn in is a noticeable discoloration of ghosting of a previous image on a display. It is caused by the continuons drive of certain pixels more than other pixels. Do you know how does burn in happen?

When driving the TFT LCD display pixels Continously, the slightly unbalanced AC will attract free ions to the pixels internal surface. Those ions act like an addition DC with the AC driving voltage.

Those burn-in fixers, screen fixer software may help. Once the Image Retention happened on a TFT, it may easy to appear again. So we need to take preventive actions to avoid burn in reappearing.

For normal white TFT LCD, white area presenting minimal drive, black area presenting maximum drive. Free ions inside the TFT may are attracted towards the black area (maximum drive area)

When the display content changed to full screen of 128(50%) gray color, all the area are driving at the same level. Those ions are free again after a short time;

In my application, the same data will/can be kept on the TFT LCD display for a long time e.g couple of days or even for months and I can"t run any screen saver. I have read that this causes pixel burn or damage.

Does your Company offer any solution in terms of Industrial Grade Displays for Panel Monitoring with long long life ( Back-light as well as pixel safety)?.

If you"ve ever left your LCD monitor on a single static screen for an extended period, say 24 hours or more, and then changed the on-screen image and seen a "ghost" of the previous screen, you"ve experienced Image Persistence. You can also sometimes see this phenomenon while traveling through an airport and seeing the flight status monitors. The good news is that the persistence is not permanent, unlike previous technologies such as plasma displays or CRTs.

The previous technologies of plasma displays and CRTs are phosphor-based, and extended static images create a "burn-in" that affects the properties of the phosphor material and create permanent damage. The damage is called burn-in, whereas static image "ghosts" on an LCD are Image Persistence. Image Persistence is not permanent damage and is reversible. Modern LCDs include design, driver ICs and chemical improvements that minimize these effects.

Image persistence can happen with any LCD panel, and almost all specifications will have some reference to image persistence. Many will have a specific criterion of acceptable levels of it.

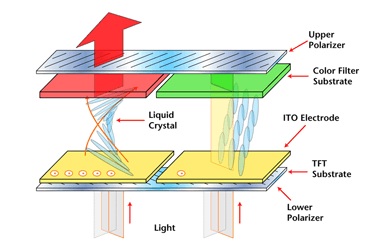

To understand why image persistence happens, we must first understand the basic structure of an LCD TFT. Within the TFT, a voltage is applied to the liquid crystal material to align or twist the crystals in each pixel to allow light to pass through or block light, thus creating the on-screen image. By allowing a static image to remain on screen for an extended duration, the polarity of that voltage on the crystals remains. During this time, ions within the liquid crystal fluid will migrate to either the + or – electrode of the transistor (source or drain). As these ions accumulate on the electrodes, the voltage applied to the crystals to align or twist is no longer sufficient to completely change the image on-screen, resulting in a "ghost effect" from the previous image.

The best method for preventing Image Persistence is to avoid having any static images on the screen for an extended time. If the image changes periodically, the ion flow will never have an opportunity to accumulate on any internal electrode. However, depending upon the use of the display, it is not always possible to avoid static images on the screen. In cases such as these, there are steps that you can do to reduce the chance of persistence.

Switching off the displayduring periods of inactivity (sleeping mode) and arousing at necessary image changes would also be reflected as a positive side effect providing lower power consumption.

Panel manufacturers specifically test for the phenomenon and have designed the TFT cell and improved the purity of the liquid crystal fluid to minimize any effect of image persistence.

If you have a project that is considering taking advantage of any display technology, US Micro Products can provide a solution designed for your application. Send us an email at sales@usmicroproducts.com.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

N2 - This paper describes a thorough investigation to identify the root cause of an LCD panel burn-in failure induced by an LCD source driver, which is observed in a large-scale LCD factory producing more than one million LCD panels per month. The investigation demonstrates the effectiveness of the circuit simulation to precisely locate the defective spot which is caused by a metal slice originated from outer rings of an LCD COG (chip-on-glass) source driver. With the aid of emission microscope (EMMI), Energy Dispersive Analysis X-Ray (EDAX), and Chip Probing (CP) tester, the root cause of the failure is well explained. The formation mechanism of metal slice from the outer rings is thoroughly studied. A solution to completely eliminate the source of metal slices from the outer rings during wafer processing is also proposed.

AB - This paper describes a thorough investigation to identify the root cause of an LCD panel burn-in failure induced by an LCD source driver, which is observed in a large-scale LCD factory producing more than one million LCD panels per month. The investigation demonstrates the effectiveness of the circuit simulation to precisely locate the defective spot which is caused by a metal slice originated from outer rings of an LCD COG (chip-on-glass) source driver. With the aid of emission microscope (EMMI), Energy Dispersive Analysis X-Ray (EDAX), and Chip Probing (CP) tester, the root cause of the failure is well explained. The formation mechanism of metal slice from the outer rings is thoroughly studied. A solution to completely eliminate the source of metal slices from the outer rings during wafer processing is also proposed.

DGBELL"s burn-in chamber is widely applied to electronic and electric products, components and materials by constant high low temperature, temperature shock and rapid temperature change reliability test.

With high precision perfect external design, external with double sides cold rolled plate electrostatic powder coated material, internal with SUS#304 high temperature resistant stainless steel. Insulation material adopts fire resistant high strength glass fiber thermal insulating material. The Control system and control circuit all introduced with the famous brand.

DGBELL"s burn-in chamber is widely applied to electronic and electric products, components and materials by constant high low temperature, temperature shock and rapid temperature change reliability test.

With high precision perfect external design, external with double sides cold rolled plate electrostatic powder coated material, internal with SUS#304 high temperature resistant stainless steel. Insulation material adopts fire resistant high strength glass fiber thermal insulating material. The Control system and control circuit all introduced with the famous brand.

Liquid Crystal monomers don’t have protein. Their chemical structures look like below. The effect of these chemicals shows in MSDS (Material Safety Data Sheet).

– In Proceedings of the National Academy of Sciences, Giesy’s research team assembled and analyzed a comprehensive list of 362 commonly used liquid crystal monomers gathered from 10 different industries and examined each chemical for its potential toxicity. When inhaled or ingested, these toxic chemicals can build up in the body over time with toxic effects, potentially causing digestive problems and other health issues.

-“These chemicals are semi-liquid and can get into the environment at any time during manufacturing and recycling, and they are vaporized during burning,” said University of Saskatchewan environmental toxicologist and lead author John Giesy in a press release. “Now we also know that these chemicals are being released by products just by using them.”

-The researchers found the specific monomers isolated from the smartphones were potentially hazardous to animals and the environment. In lab testing, the chemicals were found to have properties known to inhibit animals’ ability to digest nutrients and to disrupt the proper functioning of the gallbladder and thyroid–similar to dioxins and flame retardants which are known to cause toxic effects in humans and wildlife.

-To be clear, the researchers didn’t observe any adverse health effects from the accumulation of liquid crystals in the human body; they only found that these crystals do in fact leak from devices, and that they have the potential to be toxic. “We don’t know yet whether this a problem, but we do know that people are being exposed, and these chemicals have the potential to cause adverse effects,” said Giesy.

-Any artificial chemicals have potential hazard to human health. If you read the notes of your prescription drug, the statement is likely more alarming than above.

-If you crack LCD screens and find the liquid crystal leakage, don’t panic. Just remember that the liquid crystal materials might not be more toxic than your detergents for stove or washroom. Just wash your hands with soup throughout. Never try to play with it or even worse to taste it. The liquid of the cracked computer screen will not evaporate, no emissions worries.

-Any electronics has environment impact and can’t be used landfills. If you want to get rid of old LCD monitors or LCD TVs, give them to electronic collection stations. Let’s the professionals to handle them. They will extract some precious metals/parts and make them into something useful or at least not hazard. FYI, liquid crystal materials are retrievable.

:max_bytes(150000):strip_icc()/screenburnin01-5bdc37e9c9e77c00269c4545.jpg)

Note: this is an excerpt from a six-part series from Focus Display Solutions of Chandler, Ariz. The series will provide non-technical insights into why products such as cell phones use a color display, and other instruments, such as a blood pressure monitor, use 20-year-old non-color monochrome technology. This series will cover terms such as half-life, power budget, NRE, transflective, and others, and address the different LCD module options available when selecting a display for your product by being broken down into the following parts:Which color LCD technology is best for your application?

When choosing between a color LCD display and a monochrome display, there are several variables to consider. These include cost, EOL (end-of-life), power consumption, ability to customize, and appearance or perception of your product.

End of life is when the product is no longer manufactured. Once a product is discontinued it then becomes Legacy. The world is in color so why don"t all new products use color displays? After all, nobody watches black and white TV anymore. Users have come to expect color displays in all of the products they purchase because the appearance of a color display sets certain products apart from those which use the old monochrome technology.

Three of the mainstream color LCD technologies currently in use are TFT, OLED and FSC. My goal is to help the OEMs understand and decide which display is best for their product and will appeal the most to their end customer.

The best way to introduce these two types of displays is to compare them side-by-side and discuss their advantages and disadvantages. Please keep in mind that what is cutting edge today may be obsolete tomorrow, some of the comparisons below are guaranteed to change in the next few years.

TFTs (thin-film transistor) have been around for several years and control a large percentage of the color LCD market. Although this is the most popular color technology in use today, OLEDs (organic light-emitting diodes) looks like they will surpass TFT technology in the next few years.

TFTs and OLEDs can be seen in applications such as cell phones, laptop computers, and digital cameras. Video and high-resolution photos are also possible on both types.

Winner: OLEDs. OLEDs operate at temperatures as low as -40ºC (-40ºF) and as high as 85ºC (185ºF). TFTs perform poorly below -20ºC (-4ºF) and above +70ºC (158ºF).

Winner: TFT. The current size of TFTs range from 0.9 inches up to, and exceeding 19.2 inches, whereas OLEDs range from 0.5 inches to 7.7 inches (Samsung Galaxy Tab 7.7). It is important to note that these sizes are not absolute. There are TFT and OLED displays that are larger than the sizes listed above, but they are not in mass production at this time.

When choosing the size of your display, keep in mind two major factors: the popularity of the size and the number of suppliers that manufacture that size. Popular displays are LCDs that are manufactured in large quantities. The greater the popularity of the display, the less likely it will be discontinued in the near future, thus the lower the cost. The greater the number of manufactures for a particular size, the lower the cost, an the easier to second source.

Winner: TFTs. Half-life is a measurement of how many hours of use before a display becomes half-as-bright as when it was first turned on. The blue in the OLED has a half-life of 14,000 hours. This does not mean the display will burn out at that point, but will only be half-as-bright as when it was first turned on. There is much research in progress to increase the number of hours.

Keep in mind that not all products require the display to be on 24/7. Many products that require batteries, such as cell phones and digital cameras, only make use of the LCD for one to two hours a day. Many of these devices will be obsolete before the display reaches 14,000 hours.

Winner: OLEDs. OLEDs are estimated to be less than 0.01 mS (milliseconds). TFT is in the neighborhood of 15 mS. That"s milliseconds. The human eye blinks every 300 to 400 milliseconds. There are 86,400,000 milliseconds in one day. The eye can barely consciously detect a difference of 15 mS but the brain can tell there"s something up.

TFTs have been around longer then OLEDs. This head start has allowed TFT manufacturers more time to dominate the market, offer more sizes and lower the cost. The OLED has a few technical set backs at this time, but as technology improves, many or all of these issues may go away.

Expressly designed and tested for security and surveillance environments, AG Neovo’s patented Anti-Burn-in™ technology tackles the LCD monitor burn-in effect, otherwise known as a ghost image on the screen. Burn-in images result in the polarisation of the liquid crystal material contained within the TFT LCD panel. The Anti-Burn-in technology prolongs the lifetime of all AG Neovo monitors and displays featuring this technology to secure users’ investment.

LCD Burn-In, known as image sticking, image retention, image persistence, or ghost images, is the phenomenon where fixed images displayed on the monitor screen for extended periods cause the polarisation of the liquid crystal material contained within the LCD panel, making the image to be “burnt” on screen.

Burn-in on an LCD screen occurs because pixels permanently cannot return to their relaxed state after a static image is displayed on the screen over a long period of time. When a screen keeps displaying a single image, the crystals at those pixels will get a permanent memory, and thus the image on the screen will be imprinted onto them permanently. Once it causes screen burn-in, there is no recovery in most cases. Because of this, choosing a display or monitor allowing for pixel shift, like AG Neovo’s monitors with Anti-Burn-in, can help prevent LCD computer monitor burn-in.

“Image retention” and “Burn-in” are sometimes used interchangeably, but they are not precisely the same thing. Image retention, in most cases, is temporary and fixable. It appears when an image is temporarily “stuck” on the screen even if the content changes, but reversible by taking particular measures. Burn-in on the LCD screen is a form of image retention but is permanent and virtually impossible to fix. The prolonged use of static images would cause screen burn-in.

AG Neovo’s patented Anti-Burn-in™ technology tackles the LCD monitor burn-in effect, otherwise known as a ghost image on the screen. Burn-in images result in the polarization of the liquid crystal material contained within the TFT LCD panel. This technology prolongs the life of all AG Neovo monitors and displays to secure the user’s investment.

Anti-Burn-in technology is to activate the pixels to move by the designed time interval and protect panels from being seen the vaguely visible “residual image” under the static charge conditions so as to help prolong the lifetime of TFT LCD panels.

The patent on the Anti-Burn-in technology shows that AG Neovo places importance on its display quality to prevent image burn-in. To best fit the requirement of the security environment, Anti-Burn-in Technology is invented with high-level flexibility and effectiveness. There are three types of mode:

Execute faster than the Line and Dot Intervals. Frame Movement is to move the entire video frame horizontally and vertically (right/left/up/down) for a preset time interval.

Slower but more precise than the Frame Movement. Line Movement is to scan the screen starting from top to bottom and left to right with horizontal and vertical moving lines for a preset time interval.

The slowest but the most precise Anti-Burn-in mode. Dot Movement is to scan the screen with a set of “black & white” dots or pixels in left-to-right and top-to-bottom directions.

Unlike conventional displays, AG Neovo’s security and surveillance displays are built-in with Anti-Burn-in function to reduce the possibility of LCD burn-in for continuous security monitoring applications. It is not needed to create any screen saver, playback youtube video, or install additional tools to prevent burn-in effect.

Compared to the traditional LCD screen burn-in reduction tools which may cause evident interruption to the displayed images, AG Neovo’s patented Anti-Burn-in function is almost unnoticeable when applied. The specially designed three modes of Anti-Burn-in selection provide users with flexibility in choosing the optimal approach that best fits with their non-stop security monitoring.

Video surveillance is commonly used for monitoring of selected images to determine if an improper activity is occurring, such as theft, vandalism, and abnormal situations in daily operation, and any intervention is not allowed during the process. To ensure there are not any interruptions to the video monitoring, turning on a screen saver, reducing contrast/brightness or playing white static image for a particular while is not an option. Instead, selecting a security monitor with built-in Anti-Burn-in function is an efficient solution.

Burn-in on the screen is technically hard to fix. Instead, here are some tips on how to remove image persistence on LCD screens and prevent permanent effects:

Enable the “Pixel Shifting” function on your monitor or display. Most of AG Neovo monitors have a built-in Anti-Burn-in, which allows varying pixel usage by activating the pixel to move at regular intervals. If not enabled automatically, you can manually turn it on and try to alleviate any image retention problems.

Reduce screen contrast and brightness. Lower contrast allows even lighting levels across the LCD screen and thus has less strain on a specific area of the screen. Then, try to watch some different contents, and the effect of Image retention might go away on its own.

Turn on white static image for approximately as long as the persistent image was displayed; this is to use a completely white screen to overwrite the burn-in image. Or, create a screen saver that alternates between black and white images. The continuous changing of white/black across your screen can help alleviate the ghost image from the screen. The solid colour background might reset the image burn but is more likely to deal with image retention than image burn-in.

Ensuring that your Dell monitor is set up properly. Assembling the monitor stand and setting up the monitor ergonomically. Connecting the cables and organizing them. These will only help make the viewing experience the best it possibly can be.

The standard monitor stand is detached when the monitor is shipped from the factory. To learn more about attaching the standard monitor stand. Refer to the Setting Up the Monitor section in the User"s Guide of your Dell P3421W monitor.

Where you put your monitor is almost as important as what model you buy. The monitor should be directly in front of you, at an arm’s length away (between 20-40 inches from your eyes). The top edge of the screen at eye level when you are sitting comfortably. You may need to adjust your chair height or the height of the monitor to achieve this.

It’s important to have accurate and reliable information. Our learning hub is built for you and provides the content that helps you understand how to improve your operations and the lives of the firefighters on your crew.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey