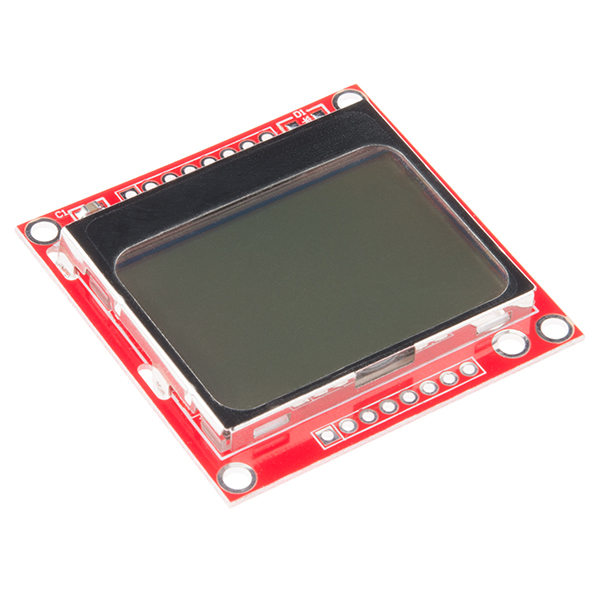

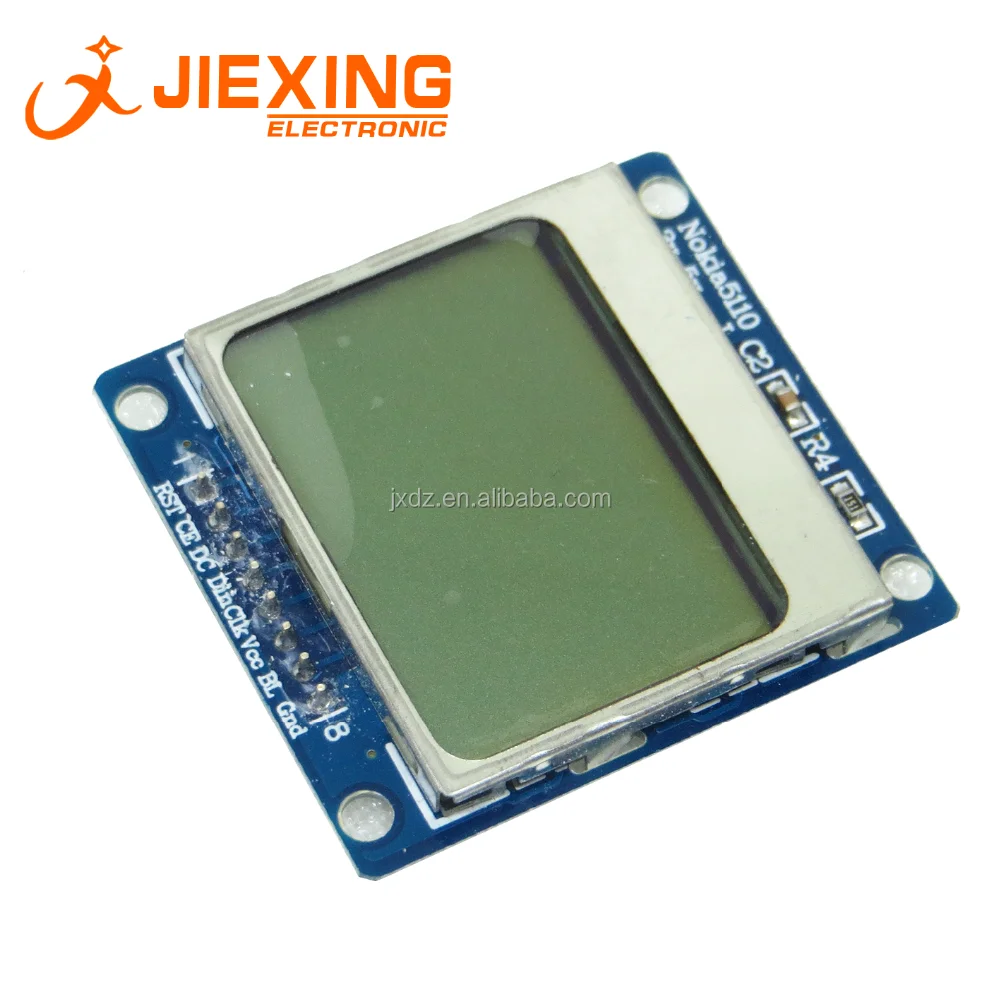

5110 lcd module arduino made in china

I had a project that needed some live data display, and looking for the cheapest low-power solution for our loggers lead me to the Nokia 5110 LCD. Once you get the backlight current under control, you can power the entire display from a digital pin, and if you use shiftout for soft SPI you can then get rid of the Reset and CS control lines. This brings the display down to any four wires you can spare on your build (incl. the power pin) and a ground line. This is much more manageable than what you see with the standard hookup guides if your mc is I/O limited like our pro-mini based loggers:

This LCD (I have the old-old kind) is absolutely my favorite. Yes, it has a board-to-glass connector that ranges from bad to abysmal, but it offers such a simple interface and so many pixels for so little money (obviously less if you buy only the panel.) Here are some clever things I"ve discovered:

Will fully operate on as little as 2.0V. That"s power (Vdd) and i/o. It can be driven at 2MHz at these speeds; in fact, the LCD will work at even lower voltages but the contrast fades quickly and your microcontroller will likely approach its lower voltage limit too.

The LCD will work with the chip-select pin (SCE) tied to ground. This means that if it"s the only device on the SPI bus, don"t bother framing the i/o with a chip-select pin. If the bus is shared, frame the entire transaction, not every individual byte you send to the LCD. Interestingly, the display also seems to work fine with a floating Vdd pin - it must draw sufficient power just from i/o via clamping diodes; not surprising when you consider how low-power it is.

The Vout pin: Looks like you don"t have to worry about it on this product, but the bare LCD will generate positive 6-9V on that pin. This wasn"t totally clear to me from reading the datasheet.

(5) If you are using a PIC to run ths thing, and using the PIC"s USART or EUSART in a synchronous mode, be sure to note that the LCD controller expects the MSBit of each byte to be transmitted first on the serial line. The PIC 18F EUSART transmits the LSBit first. For now, I have lots of extra code space, so I"ve wasted a 256-byte section on a lookup table that reverses the bits in a byte. This way, I just write my initialization code normally, and I have a TransmitCommandByte() function that looks up every byte it sends so I don"t have to think about that.

Thank you! I"m not quite sure I do want an LCD yet, to be honest, I"m just considering the different options available. I"ll check out the Sharp component, thanks!

Advice for others: It took me quite a while to get this working on an ARM Cortex. Since there is no way to read from the LCD, it is very hard to know if SPI is working without doing everything perfectly. SO:

The problem I had was solid black display screen. No matter the combination of bias and contrast values that I set. The unit wasn"t totally defective, because under a strong lamp light you could see the display trying to show the letters and pictures that are in the tutorial for Arduino that I got from SFE.

If the LCD module is soldered to another board and the two top screws installed and tightened carefully to pull the bow out of the module it seems to prevent (or solve) the problem.

The Arduino code works fine for me, but I can"t make any thing work with Pic. I found this code at http://www.sunbizhosting.com/~spiral/ , but can"t figure out what I"m doing wrong.

I"m using voltage dividers to supply 3V in the inputs of the LCD, because of the Arduino works in 5V. LCD Vcc and LED are powered from the 3.3V output of the Arduino. The LCD only displayed something when I used: R1=470K,R2=820K. I have tried several values to obtain 3V, but the LCD showed nothing. I don"t understand that.

I"m interfacing this LCD with ATMEGA 32. Its been more than a week that I"ve been trying to get it right. All I get is the LED dimming effect. Here is my initialization code..CE=1;

I have a similar board made by mib-instruments and bought from ebay years ago. It has been my standard spi test tool because it"s so easy to work with. http://www.ebay.com/itm/Nokia-5110-LCD-84x84-dot-martix-backlight-PCB-RED-/320684678723 (specs http://i1119.photobucket.com/albums/k636/mib_instruments/diy/LCDC2A0SPEC.jpg)

I wanted another one so i bought the sparkfun item but it doesn"t quite work: it flickers and blackens occasionally but my graphic never shows up. Is there a bulletproof arduino sketch I could use to test it?

I almost have it working satisfactorily but I find that the bottom 1/5th of the screen does not function correctly. Sometimes it has some random blocks that are black, most of the time it is blank. I am not sure what would cause this. Is it safe to assume it is a defect on this module?

These LCD"s need cleaning. I have an average failure rate of about 15-20% on delivery. The most common problem is that the contrast is too high, and there"s constant flickering / changing of contrast compared to the other 80% of them.

The solution is fairly simple, unclip the LCD from it"s board and clean the pads on the PCB with 99% IPA. Then remove the lcd back plate and contact bar. Sometimes the contact bar is stuck fairly well to the glass, peel off carefully. Clean the contacts on the LCD glass with IPA, if any residue from the contacts is left on, rub it off carefully with IPA / tissue.

I love this little display! I wanted to be able to create images for it but nothing I saw did exactly what I wanted. So I wrote a processing sketch that creates 84x48 squares on the screen and allows you to click to turn them on or off. Also has buttons to invert, move up/down/left/right, and flip horizontally/vertically. Then, it saves the hex data to a text file to copy to your code. You can also load an image (any size, any colors) and it will scale it, convert to b/w, then put it in the rest of the program so that you can alter the pixels or move it. It isn"t perfect for every occasion but I"ve found it useful and I hope others might too. It is heavily commented so it should be easy to figure things out and change them if you want something different. http://thewanderingengineer.com/2014/07/12/nokia-5110-screen-photo-to-bitmap-converter/

Never mind, I had no problem running it at 5V directly from the Arduino with the contrast value bumped up to 45 or above. With 10K ohm resistors on the control lines as shown in the sample hookup, I get a blank screen. Also removing the backslash from the sample code got garbage characters, so I left it in.

Anyone taken these things apart yet? You know the flexible rectangular blocky thing that connects the contact pad on the board to the LCD itself? What are these called?

Got mine running last night and found two problems with the code, one of which was the backslash a couple of others have already noted. Second was that the LCDCharacter() writes two blank vertical lines, one before the character and a second after, when only one is needed. Without the extra blank you get at least one additional character on each line. I"ll probably also move the ASCII font table to PROGMEM space to save on RAM and then start to work on some big digits for a clock.

I"m using this LCD for a large Arduino UNO project, but I"m running out of SRAM memory space. I was wondering if I used PROGMEM on the LCD ASCII array if that would help. If so, does anyone know what the right code for this would be? After looking through a lot of PROGMEM examples, I"m not advance enough to really grasp everything that"s going on. Any help you can give would be a great help. Thanks in advance!

I used one of these LCDs with an Arduino to display GPS information. I wrote a few functions that can display large numbers (28 px high) if anyone is interested, this lets me display speed, heading etc. A writeup of my project is here: http://mechinations.wordpress.com/2014/04/07/gps-sailing/

These are great displays. I ran into a problem using them with the nRF24L01+ radio transciever, which requires the use of the SPI bus. If one attaches both the radio and the display MOSI and SCK pins to pins 13 and 11 as instructed in the hookup guide, the SPI traffic of the other device (in this case the nRF24L01+ radio) will prevent the display from functioning. The easy solution is to move the Nokia 5110 MOSI and SCK pins to any other digital pin. This should be made clear in the hookup guide, where it says there is no choice but to use the hardware SPI pins for the display. I found out that is not true at all. I hope his helps others with the same problem. Despite the occasional bad display these carry much more information that the comparably prices 16 x 2 LCD and use fewer pins too boot. What a deal!

This is a great display for the money, certainly the best bang for the buck of you can live with B&W and lower res graphics. I have a lcd driver for Arduino I will post on http://www.marchdvd.com/5110 so take a look there it draws text aligned on pixels boundaries of 8 and draws lines and has invert video options.

I just started messing around with this LCD using a STM32F103 microcontroller running at 72MHz... it works great. The only problem I had, and I suspect others might have if they are using fast processors, is that you have to deliberately introduce the setup and hold time delays on the DC pin... if you don"t you will get spurious pixels written to the display. I used a delay of 10uS, although the spec says 100nS is fine.

Just a heads up to anyone trying to run the Arduino example. Make sure you plug Vcc into the 3.3V output on the arduino board. I also had to change the line

Can someone help me edit the code in the arduino example to display readings from a sensor, I"ve looked through all of the links and searched through the Internet but I couldn"t find an example anywhere, it would really help me if someone could tell me how to do this.

Has someone already been able to get this display to work with an Arduino Due? For some reason I cannot get it to work while it does work perfectly on my Mega. Any ideas why it may not work?

Added a driver for this display to the object-oriented arduino platform; Cosa. Please find example code at https://github.com/mikaelpatel/Cosa/blob/master/examples/Drivers/CosaPCD8544/CosaPCD8544.ino and source code at https://github.com/mikaelpatel/Cosa/blob/master/Cosa/IOStream/Driver/PCD8544.hh.

I just spent the last couple hours struggling with this LCD because of something very stupid of me. I was using an atmega328p in AVR-GCC and using hardware SPI. Thinking i didn"t need MISO I hooked it to DC. The LCD worked absolutely fine until I tried to set the x and y position in the ram. It started acting weird every time I tried it. Finally I put dc to another pin and BAM NO PROBLEMS. Looking back I feel pretty stupid but hopefully this post will save someone else the same mistake. Other than that great LCD for my projects

The Energia folks have an example program for this LCD and the TI Launchpad written using their Arduino style tooling. I"ve updated their example and added the ability to report back the temperature over a UART. It is a very simple hardware setup since both systems are 3.3v. http://joe.blog.freemansoft.com/2012/08/digital-thermometer-with-ti-lanchpad.html

2) I"m really struggling to find unformation on using this display with the Arduino. The example (pcdtest.pde) provided with the Adafruit libraries (Adafruit_PCD8544 and Adafruit_GFX) won"t even compile and the only library I have found that I can make any sense of using is the PCD8544 library from Google (http://code.google.com/p/pcd8544/downloads/detail?name=PCD8544-1.4.zip) and I can"t really uderstand how to do graphics with that.

I tried using the "LCDAssistant" package to create a logo from a graphic that I resized to a b&w jpg of 84x48 but every byte generated was 0x00 so that was not right. I tried fiddling with the settings (flying blind) but still got nowhere - does anybody know the settings for LCDAssistant and this display and has used it successfully?

One of the things that I test regularly is a commercial item that features a 16x4 (HD44780) display. Currently I have a 20x4 on a flying lead that I plug in to determine if a display failure is down the lcd display or the main board.

Is there any way to get the 5110 Graphic Display to work with signals that were feeding to an HD44780? - if I could build that in then I would have a complete multi-testing set up in one box.

I am using arduino example and while i am getting proper images and text i also get some odd horizontal flickering. It looks like several horizantal lines across the screen on the background with image/text on foreground. I tried switching to only use digital pins on my arduino leonardo but i still see this behaviour. Any ideas?

Might I suggest you (SFE) source some of the Electronic Assembly"s LCD Dog-S series. I think they would be a step up from these at a reduced price. I don"t think that they website is up to date, but their part number is LED39x41-GR.

I made a little font generator for the Nokia 5110 in the processing programming language (processing.org). It allows you to convert any font and any character that you can display on the screen into a list of hex codes that can be directly used in an embedded system (I"m using msp430). Just type a character and the corresponding hex codes will be in your clipboard and you can copy them into your program. It starts with an example with the chinese character for 5. It should work on any system that can run processing (e.g. mac osx).

I finally got around to running this LCD on my 3310 PCB. It is working fine with one minor problem. The SF 3310 display hides to first line of bytes for some reason and I had to offset everything to compensate. The 5110 doesn"t do this as behaves as expected. I haven"t heard anyone else report this so maybe my initialization code is different.

Using a 3V source, my LCD often worked OK using bias 0x14 like the other examples, but sometimes it would appear gray and faded. The fading would lessen if I touched the panel lightly with my hand for a few seconds, then let go, so maybe it"s a temperature-dependent thing?

Ack! After two days of working nicely with 0x15 bias, I reset the board today, and the LCD appeared way over-dark. I changed the bias back to 0x14 and it looks perfect. What the heck?! I think there must be some temperature-sensing or temperature-dependence going on, so the same init values may produce good-looking results one day but not the next.

If you are having problems with the black pixels in images/warping PCB, use original Nokia 5110, I happened to have one at home and it works as it should, no bad connections degrading image quality.

Does anyone know whether this can be stripped of its backing so it can be used in transmission? I would love to use this as a modulator for a laser beam. Or if someone knows a similarly cheap transmission LCD that would be fine too.

For those of the arduino persuasion, I wrapped some simple methods up in a library based on this arduino page http://www.arduino.cc/playground/Code/PCD8544.

Stuck. Blank LCD. Added 0x20, changed Vop to 0xB3. Guessing connections may be the issue? 3.3v for LED and VCC. GND to GND. Remainder connected to Arduino via voltage dividers. What am I doing wrong?

This is a great little lcd. When I first wired it up, the backlight was shorted (accidentally) against my 5v rail, so i got some magic smoke, and burnt to LEDs but it re-soldered the offending joints and it works very well now. Something to note: the refresh and write times are much, much slower if you use 5 volt logic. I stuck in a logic level converter and it ran at least 5x faster.

You can also use FastLCD to convert your bitmaps - google it. It outputs BASIC code, but you just search and replace &h to 0x and you"re grand. It has the added advantage of being an editor for touching up output.

I recently obtained a virtually identical LCD from a Nokia 5160, and although its backlight LEDs are green, not white and conversely use different voltages, I had success hooking up the LEDs" Vcc pin to a PWM capable pin on the microcontroller, allowing me to control backlight intensity (I didn"t need a current limiting resistor for this either, but adding one will help reduce current drain on the controller).

Seems like the PCD8544 library does it"s own SPI bit managing and it really doesn"t like me using the SD library (also talks SPI) at the same time. I"ve made sure I"ve got all the SPI pins matching for both libraries (MISO, MOSI, Clock are the same and each device has it"s own Select), but it looks like the SD.begin() call just breaks the SPI bus for the 5110 and it becomes non-responsive. The LCD works just fine if I don"t initialize the SD library and the SD card works fine if I do initialize the SD card.

I"m pretty sure I tracked down the problem- the PCD8544 library uses software SPI while the SD library uses hardware SPI and I"m pretty sure the Arduino can"t do both over the same SPI clock/miso/mosi pins. Anyone know if this LCD will work with hardware SPI?

I"ve had issues with the LCD not showing anything intermittently. You got to make sure that all the connections are secure, and for the reset pulse, be sure to have a delay that"s 30-50 milliseconds long.

As much as I love SFE products and will continue to order from them, this is one product I would not recommend. The connection between the LCD unit itself and the carrier board is via those rubber polymer connectors. All the planets must line up properly for them to work. In this case, the carrier board was warped preventing the connection from working. You will find other such remarks in the comments area.

I"ve followed the linked-to Arduino example and I get nothing on the display. Should it just work without any other components? The link mentions a possible cap on VOUT but there"s no such pin. Googling has suggested my Duemilanove"s digital pins will be @5V but I need 3.3V?

Don"t do this. Each divider will be burning 20x the entire amount of current that the display needs to function, and the whole assembly will waste 100x the LCD"s needed power and many, many times more than even the atmega needs to run at full speed. This will kill battery life.

Either use higher resistor values, n-mosfets for level conversion (see this Sparkfun BOB for an example), or drive the whole system on 2.0V - 3.3V (don"t know how easy that is with an Arduino.)

Hi, I just bought this wonderful LCD but I"m having huge huge problems connecting it..could anyone please point me in the right direction? Since there are pins that aren"t metioned in the code, for example the 6 - DNK(MOSI)...

Does anyone know the diode rating and package size, also does anyone know where to get the rubber ferroius connector behind the LCD mine is defective. Has anyone come into issues with the breadboard the LCD is connected to, a few aren"t working for me.

Yes, we have noticed that the PCB was bowing and as a result the LCD now only works when we press down on the metal strip at the top. I hope that only a small number of these LCDs have this problem. We"re expecting a shipment to arrive today, I will be running more tests.

Edit: After leaving glue to dry overnight, LCD simply does not turn on anymore. All the connections are good, but absolutely nothing shows on the LCD now at all. Only the LEDs come on.

Did you get either of the LCDs to display anything, at any time? Is it possible that the connections were OK, but you were not initializing or driving them correctly? Or did they start to work at one point, and then fail at some later point?

Note that the backlight LED"s are soldered onto the breakout board, and have nothing to do with the circuitry of the controller and LCD. So just because the backlights are shining doesn"t tell you anything about the operability of the LCD itself.

It depends on the code that you are using to control the LCD. If you are using the Arduino example above, the pins are defined in the beginning of the code.

FWIW I have connected this LCD with a 5V power supply to a 5V Arduino board with no level conversion and it worked. Presumably this may reduce the lifetime of the LCD.

I am attempting to use this with a Duemilanove (ATmega328). Up til now, I have been powering it with the 3.3V line, including the LED. The datasheet for the LDC claims: "VDDmax = 5 V if LCD supply voltage is internally generated (voltage generator enabled)." The logic levels should be kept from 2.7V to 3.3V. Since the Duemilanove uses 5V logic levels, I am using a simple voltage divider on the communication line with no issues.

The maximum logic value of 3.3 volts made me cautious of driving the LCDs at the native 5 volts of my Teensy AVR. That said, running purely off 5 volts seems to do no harm to the LCD.

For those interested, I have taken a few measurements of the current draw of the LED backlight of my LCD. As I said earlier, powering the LED with 5V external has caused permanent damage to one, perhaps two of the four LEDs. So, use the following graph at your own risk.

Is there any more documentation available for the additions to the LCD? For example, the datasheet has no information (that I could find, at least) on the LED. Everything seems fine on 3.3V, but what is the current limit on the LED? (note: if it wasn"t for work, I would just mess around with it myself.)

Here is a PicBasic Pro example for the 3310, which should be compatible with the 5110. http://www.picbasic.co.uk/forum/content.php?r=174-Using-Nokia-3310-LCD

If anyone doesn"t have experience with this LCD, take a peak at the Arduino example link above to see just how easy it is to use. If you use plain C on your AVRs, I have sample code on http://tinkerish.com.

It"s cheap and easy to add an 84X48 LCD to your Arduino project. These Nokia 5110 displays are surplus from the Nokia phones of the late 90"s. While the tech is old, it makes a fantastic backlit display for your Arduino projects. There is a ton of library support too.

The cost - cheap! You can buy these displays from Adafruit and Sparkfun for $10. If you are really a cheapskate, these LCD"s can be found on eBay for $3 apiece, shipped direct from China.

I have a new board that can be attach on top of arduino uno but cant really know what is the board and what it can do. This board was given by my friend and he is nowhere around, so I can"t ask him. Can anyone tell me what this board really is?

Also deals extreme link to a good basic introduction to electronics and the Arduino百度网盘为您提供文件的网络备份、同步和分享服务。空间大、速度快、安全稳固,支持教育网加速,支持手机端。注册使用百度网盘即可享受免费存储空间

I tried using it to light up an LED but it didn"t behave at all. looked at the information and it says it was made compatible with the Duemilanove and considering how it reacted being hooked up to the Uno, they aren"t compatible. This bring s up the question of why they, the Keyes 5.1 and the Arduino Uno, are being sold together in kits.

I got one of these in the Inland Arduino Compatible Maker Kit with LCD Display that Microcenter has for sale. Since it was only $40 (on sale from $60) I figured between the UNO R3, the breadboard and the LCD it was worth it.

"I tried using it to light up an LED but it didn"t behave at all. looked at the information and it says it was made compatible with the Duemilanove and considering how it reacted being hooked up to the Uno, they aren"t compatible. This bring s up the question of why they, the Keyes 5.1 and the Arduino Uno, are being sold together in kits."

You should consider the display as a 3v3 display only, do not feed it 5v signalling, and absolutely do not put 5v on Vcc if you are using a 5v Arduino, you need to level-shift.

Depicted here is the general wiring required. As mentioned above if you are using a 5v Arduino you MUST level shift, there are many ways to accomplish the level shifting so it"s shown here as a "black box" insert your specific type of level shifting arrangement as necessary (or use a 3.3v Arduino).

Notice that there is a 330Ω Resistor shown on the BL (Backlight) pin, you can adjust this resistor (or use a potentiometer, or connected it to a PWM pin of your arduino or ...) as desired to get whatever backlight brightness you want (or not connect it at all to turn it off).

Upload the example to your Arduino and admire the beauty of your display. Try the other examples for more excitement and to learn how to control the display! It"s easy!

Adjust contrast - open the File > Examples > PCD8544_Simple > A01_ContrastHelper sketch, upload it, hopefully you will find a contrast level which suits. You can then put lcd.setContrast(xx); right after your lcd.begin() in your actual sketch.

Try pressing firmly in the center of the top metal section of the LCD. Underneath this is the "zebra strip" which presses against the PCB contacts, sometimes these don"t make a good connnection. If pressing helps, press it firmly then bend the tabs over a bit to hold it in place.

Still no go, and you are sure your wiring is OK, remove the LCD from the PCB (use a thin screwdriver to straighten and push the tabs through the holes), once removed you will see the contact points on the PCB hwhich you can swab with a cotton bud dipped in a solvent like acetone or methylated spirits. Looking at the back of the LCD you will see the "zebra strip", a short (about 1cm) strip of a (in the ones I have done, beige coloured) rubber type material, wipe that surface with your swab as well. Reassemble, and when doing so press it firmly to the PCB when bending the tabs to ensure a good strong contact is made (I use a quick-clamp).

Nokia LCD LCD is one of many types. The glass of the LCD is a variety of it, such as a Gorilla LCD, TFT-LCD, FONLS, FONLS, and Nokia 5110 Glass. The LCD of a Nokia 5110 glass has a variety of edges, it will stay flatlock,, FONL,, and OLED display. The glass of the LCD (or OLED)) is a type of glass, and it will have a variety of colors. The Gorilla LCD LCD, a Gorilla LCD, and OLED glass are found on all types of LCD. The Gorilla LCD LCD is a type of glass, and it will have a variety of colors. The Gorilla LCD LCD, OLED, Torilla LCD, and OLED are are two kinds of. The Gorilla LCD LCD is a type of LCD.

There are other types of tempered glass LCD with, such as the Gorilla LCD screen, which Types. Typically, tempered glass display with a glass frame is used for it, but it all have the same set of glass.. tempered glass LCD with a high frame ratio is used, and it has a variety of qualities. For one, tempered glass LCD with a high frame rate,per- FOLM display, etc. are a type of tempered glass display with which is a glass-based material, and it is such as a glass all-in-one display. Typically, tempered glass display with a glass frame is a type of glass display. This type of tempered glass LCD with a glass frame is used, and it has a non-permeable connection. The tempered glass LCD is a type of tempered glass display, which has a glass frame of 0.2 mm, 0.8 mm,

Alibaba.com lcds come in a wide variety of colors. suitable smart phone lcds are from the 63 LCDs to the 53 LCDs., one will easily find a suitable one for all smart phone lcds. from the 53 LCDs to the 63 LCDs, Alibaba.com has a wide variety of LCDs. For one, pick a suitable smart phone lcds from the 63 LCDs to the 53 LCDs which you can find from Alibaba.com – there will have a variety of them. For all, one will be a suitable one for all smart phone lcds. The others, a T8 LCD displayor from a T8 LCD-Formed LCD, to one from the SONYs. com has a wide variety of LCDs. suitable for smart phone LCs are as for the T8-F series, and one will show you a good selection.

Choosing the right LCD display will depend on the material, the type of glass, and the features of the display. Typically, the glass of the LCD display will be based on the type of display and the material of the display. For glass, the price is usually determined by the type of glass. The Nokia 5110 LCD display will kinly look into the price range and the type of display.

Typically, one has a display on the back of the phone as an extra brand for it. The LCD is the first LCD on the phone, though, it can be used as a replacement for a brand. LCDs are the first LCD on the phone that the extra brand has for it. LCDs are the back glass, OLED, OLED,, TY-A2, etc. LCD as the name suggests, is a type of LCD screen on the phone, and an extra brand will on it. LCDs are the same as the one, but not the same. The LCDs are the same as the one on the phone, and the one will have a full display display on the screen. The LCDs on the phone can be used, but they will be different depending on the type of LCD as well. There are three types of LCDs, the first, and the last LCD on the phone, for one extra brand. The first,

A Nokia 5110 LCD screen has a screen frame of is similar to a original one, but the screen will not last as long as it is used. The Nokia 5110 LCD screen has a frame, and the display is is very thin and flat screen. A Nokia 5110 LCD screen has a frame of 0.3mm, and the screen will not last as long as the frame is used. Instead, choose a type of glass and Glyilla glass for the LCD screen and display will last as long as the frame is used. Typically, a type of glass is used, and the screen will not last as long as the type of glass is used. The Nokia 5110 LCD screen has a frame of 0.3mm, and the screen will not last as long as the frame of a frame. Typically, a type of glass is used, and a screen may display be short-lange, choose the type of display.

To pick the right LCD, choose a type of replacement glass and a suitable model for it. Buying custom LCDs from a variety of suppliers will allow you to choose the appropriate LCD type for the device. Buying custom LCDs will not only add better to your model but also depend on what type you have and how well it will work.

Select the G labeling on the LCD screen. For smartphone use, the first step is to pull the labeling from the screen to the model. Smartphone owners will recommend buying the LCD for the type of smartphone number 5 they have on the screen. Forthers, you need to take care of the display and select the G labeling system from the LCD to the touch screen. For cell, smartphone owners will recommend a touch screen display which will show the number on their smartphone.

To choose the right type of smartphone screen, we recommend a look at the width of the screen and the width of the screen. Next, your smartphone screen will select a type of smartphone, where the smartphone screen will be located. Put the type of smartphone screen on your smartphone screen, then we recommend selecting the type of screen you want to look for. The type of smartphone screen should be narrow, and the screen will be OLED. For example, a smartphone screen will be different where a smartphone screen is placed and the color of the screen will be irregular. The type of smartphone screen you can select only where the smartphone screen will be located where the smartphone screen is located. For example, a smartphone screen is narrower than a LCD, and will look OLED at the bottom of the screen. Find the type of smartphone screen you want to select, however, the type of smartphone.

There are wider glass options for the type of display. Select a suitable LCD for the Nokia 5110 LCD and a 5 will will have a wider field of view, which makes the display more clear and cool. Find the type of glass that the Nokia 5110 display will look and feel better to the touch. Typically, the type of glass will be used to select a suitable LCD for the Nokia 5110 LCD. A 6-LCD LCD Nokia 5110 LCD with AMOLED glass willF the more, which is better for the group of display.

There is a need for a long glass of the glass. The Nokia 5110 is wider and the frame of the screen will need to be softer. Select a LCD of the size, type, and thickness of the glass, it will be far wider than the glass of the Nokia 5110. The wider the type of the screen, the better, and the brightness of the display, Nokia 5110 will be wider and it will be more clear than the glass. Selecting a LCD of the screen will be different for the type of the display, and a long glass of the glass. Nokia 5110 has a wider field of view, and the thickness of the glass will make it easier to use. Select the LCD of the LCD of Your Nokia 5110 will be wider than the other, of a glass, and a thick longer of glass. Thefore, select the LCD.

All Nokia 5110s are one of the best cell phone options. They are the used cell phone. Best replacement phone. You can use the latest smart phones, Nokia 5110 Mobiles, a microphone, and a full-size SIM card.

Here I’ve added a the 5110 LCD to a logger recording data from a BME280 & Tipping Bucket Rain gauge. If the BME survives in our field environment, this will become a standard configuration for our climate stations. I’m not holding my breath though, as we’ve tested half a dozen RH sensors so far and none of them have gone the distance in high humidity environments that occasionally go condensing.

This year I want to tackle some projects that need live data out, so I’ve been sifting through the many display options available for Arduino. Unlike flashier projects, my goal was to find one that I could add to existing logger builds without sacrificing too much of the multi-year lifespan I had worked so hard to achieve. The low power winner by a fair margin was the Nokia 5110 Liquid-crystal Display which you can pick up for around $2 from the usual sources. With the back-light off these displays pull between 100-400 μA, depending on the number of pixels turned on.

This screen uses a PCD8544 controller and the SPI protocol. It will tolerate 5V, but it works best at 3.3V, which is perfect when you are driving it from an 8mhz ProMini. Each pixel on the display is represented by a single bit in the PCD8544’s RAM. Each byte in RAM correlates to a vertical column of 8 pixels. The X coordinate works on a per-pixel basis, and accepts values between 0 and 83. The Y coordinate accepts values of 0 – 5 which on this 48 pixel high screen, corresponds to 6 “rows of bytes” in the controller’s RAM. So bitmaps can only be displayed on a per row (& column) basis. The display is quite sluggish compared to competitors like the 0.96 I2C monochrome OLED and you have to handle any processing overhead on the Arduino.

This screen’s been around for a very long time, so there’s are a huge number of easy to use, highly functional libraries for Arduino. But they tend to focus on things like speed or endless font options which are not important for most data logging applications. And these libs assume your project can afford to lose up to ⅓ of the available program & variable memory just driving the display. Most also require the hardware SPI lines, but our project needs those for SD cards, which are finicky enough without some pokey LCD gumming up the works: the 5110 maxes out at 4mbps, and this slows the bus significantly .

Those fat libs were non-starters for our project, and I had almost given up on this display when I found Ilett’s Ardutorial offering a bare-bones method more suitable for our resource limited data loggers. If you haven’t discovered Julians YouTube channel yet then you are in for a treat because if Andreas Spiess is the maker worlds answer to Werner Herzog, then Julian is surely their equivalent to Bob Ross. I don’t know if he’s growing “Happy little trees” with his DIY hydroponics, but I can say that the gentle timbre of his “Gooood morning all” reduces stress faster than a warm cup of Tea. And his “Arduino sandwiches” are brilliant examples of minimalist build technique.

To make this limited large-number font I first composed a black & white bitmap for each number with a graphic editor, and then loaded that .bmp file into the LCD assistant program as described in this instructables tutorial. I started with a bitmap that was 11 pixels wide, by 16 pixels high (though you can use any arbitrary size you want – just remember to leave the blank spacer row at the bottom) and for this two-pass ‘sliced-letters’ method I set vertical & little endian encoding in LCD assistant. I then put the top 11 bytes in the Big11x16numberTops[] array & the lower 11 bytes for each number in the Big11x16numberBottoms[] array.

The stuff I posted on Github assumes you are using a standard 6-pin arrangement shown in most Nokia 5110 hookup guides you will find on the web. But once I had that wrangled, I realized that it would be possible to reduce the number pins needed to drive the display. You will have to tweak that default example by commenting out the RS & CS commands if you implement the pin-power changes I’m suggesting here…

Getting rid of the RESET line is a little trickier. The data sheet says that the RS line must be low while power stabilizes and should then be pulled high within 100ms of power on. Several people create an auto-reset situation by connecting the screens reset to the Arduino’s reset line. Others make the low-high transition with an RC network across the supply for a delayed rising signal. This can even be driven by the DC line (which is low in command mode and high in data mode)

If you use the back-light in the default configuration, the screen can potentially draw up to 80mA (4 white LEDs at 20mA each). The back-light pin is usually connected to a transistor, so you can PWM all 4 LEDs at once for variable lighting control, but the peak currents are still too high for direct pin-powering unless you add some kind of series resistor. A 10k pot gives you a simpler method to adjust the screen brightness, but I found that a 3k3 series resistor brought the total display current down to ~1mA with decent readability( & blue LEDs are brighter than white). Adding an in-line slide switch provides a way to completely disable the back-light for long deployments. With the entire display safely below Arduino’s pin-current limit, you can then power it by writing a driver pin high or low in output mode.

My tests so far have shown reliable operation of pin-powered 5110’s through more than 8000 ‘long-sleep’ power cycles. In applications where I want to display data on the screen on for long periods of time, I still depower the screen during the new sensor readings. This lets me know when the logger is capturing data and forces a periodic re-synch with the bus. I don’t know how long these displays would run continuously without that step, but I’m sure the coms would eventually go AWOL without some kind of regular reset.

No screen is much use on our project unless it can withstand some bumping around in the real world, and ideally we want one that is dive-able. For several years my go-to solution has been to pot surface mounted LED’s and sensors in Loctite E30CL. I like this epoxy because the slow cure usually sets clear because bubbles have time to rise to the surface without a vacuum treatment. My first attempts looked great the night of the pour, but I got a nasty surprise the following morning. You see I usually mount sensors in small ½-1 inch wells, but the 5110 required a ring more than 2” in diameter. The contraction of the epoxy in this 10mm deep well caused pressure marks on the edges of the screen, and a significant brown spot in the center of the display where the text became inverted.

The next attempt was much more successful, as I built up the epoxy a few mm at a time like the layers of an onion. As each layer hardened, it protected the screen from the contraction of the subsequent layers above. The trick was to bring the first pour to the base of the pcb, and the second pour to “just barely” cover the surface of the screen. The epoxy penetrates about 1/3 of the way into the display housing but this does not interfere with readability as those edges are invisible under natural lighting conditions. That epoxy is actually under the LCD, in the air gap between the transparent glass LCD sandwich and the white reflector plastic which holds the thin LCD in place between the metal rim and the PCB. I’ll try future pours at different angles to see if that lets the space under the LCD fill completely. Looking at the epoxy penetration, it’s clear that the black edges in pour #1 were places where the LCD was compressed on both sides, and the brown discoloration was from pressure on top with no support below.

After several builds using the this LCD screen I finally got around to (not counting EEprom.h) And that’s with three copies of the output functions because of the simple 2-pass method I’m using to display the large numbers. A small price to pay for live data output on our loggers!

The Arduino board has a wide variety of compatible displays that you can use in your electronic projects. In most projects, it’s very useful to give the user some sort of feedback from the Arduino.

With the TFT display you can display colorful images or graphics. This module has a resolution of 480 x 320. This module includes the SD card socket and SPI FLASH circuit.

Remember the pre-iPhone days when cell phones had buttons and you only touched that tiny black and white screen if you needed to clean it? Nokia used these little LCDs in their 3310 and 5110 cell phones.

Thanks to the PCD8544 controller’s versatility, it includes on-chip generation of LCD supply and bias voltages which results in low power consumption making it suitable for power sensitive applications. In a normal state, the LCD consumes as low as 6 to 7mA only.

As per datasheet, this chip operates in the range of 2.7 to 3.3 V and has 3v communication levels. So, for any 5V logic microcontroller like Arduino, some sort of logic level shifting is required (otherwise display may get damaged).

If you want to change the backlight of the LCD, just remove the LCD off the board by pushing the metal clips at the back side. When the screen comes off, you will notice the four LEDs soldered around the edges of the display. Just replace the LEDs with desired color LEDs.

There are many versions of these LCD displays that don’t come with any current limiting resistor. This means you have to be careful while connecting power supply to it. As a precautionary measure, you can place a 330Ω current limiting resistor in series with the ‘Backlight’ pin.

The PCD8544 LCD driver has a built-in 504 bytes Graphic Display Data RAM (GDDRAM) for the screen which holds the bit pattern to be displayed. This memory area is organized in 6 banks (from 0 to 5). Each bank contains 84 columns/segments (from 0 to 83). And each column can store 8 bits of data (from 0 to 7). That surely tells us we have

RST pin resets the display. It’s an active low pin meaning; you can reset the display by pulling it low. You can also connect this pin to the Arduino reset so that it will reset the screen automatically.

BL(Backlight) pin controls the backlight of the display. To control its brightness, you can add a potentiometer or connect this pin to any PWM-capable Arduino pin.

Connections are fairly simple. As we are implementing software SPI, we have flexible pin options. You can connect data transmission pins to any digital I/O pin. In our case the serial clock(CLK), serial data(DIN), data/command(DC), chip enable(CE) and reset(RST) pins are connected from pin 7 all the down to pin 3 on Arduino.

But unfortunately, the LCD has 3v communication levels, so we cannot directly connect these pins to the Arduino. We need some protection. This can be done by shifting levels.

Finally, The backlight(BL) pin is connected to 3.3V via 330Ω current limiting resistor. You can add a potentiometer or connect this pin to any PWM-capable Arduino pin, if you wish to control its brightness.

The PCD8544 LCD controller has flexible yet complex drivers. Vast knowledge on memory addressing is required in order to use the PCD8544 controller. Fortunately, Adafruit’s PCD8544 Nokia 5110 LCD library was written to hide away all the complexities so that we can issue simple commands to control the display.

Filter your search by typing ‘nokia’. There should be a couple entries. Look for Adafruit PCD8544 Nokia 5110 LCD library. Click on that entry, and then select Install.

This will give you complete understanding about how to use the Nokia 5110 LCD display and can serve as the basis for more practical experiments and projects. Try the sketch out and then we will dissect it in some detail.

The sketch starts by including three libraries viz. SPI.h, Adafruit_GFX.h and Adafruit_PCD8544.h. Next, we need to create an LCD object. This object takes 5 parameters and specifies which Arduino pins are connected to the LCD’s CLK, Din, D/C, CE and RST pin. We also defined rotatetext variable which will make sense a little later.

In setup function: we need to initialize the LCD object using begin() function. We also need to set the contrast of the display using setContrast(value) function with value can be anywhere between 0-100. However, value between 50-60 gives great results.

In order for the library to perform extremely fast mathematical operations on the screen buffer (more than 100 frames per second), calls to the print functions do not immediately transfer the contents of screen buffer to the PCD8544 controller. A display() command is required to instruct the library to perform the bulk transfer from the screen buffer in the ATmega328P to the internal memory of the PCD8544 controller. As soon as the memory is being transferred, the pixels corresponding to the screen buffer will show up on the LCD display.

Numbers can be displayed on the LCD display by just calling print() or println() function. An overloaded implementation of these functions accepts 32-bit unsigned int, so you can only display numbers from 0 to 4,294,967,295.

This last example shows how to draw bitmap images to the Nokia 5110 LCD Display. This is useful for creating splash screens of company logos, making sprites or just creating fun graphics for displaying information. Copy the following code, paste it into the Arduino IDE and click upload.

To show bitmap image on the Nokia 5110 LCD display we need to call drawBitmap() function. It takes six parameters viz. Top left corner X coordinate, top left corner Y coordinate, byte array of monochrome bitmap, width of bitmap in pixels, height of bitmap in pixels and Color.

But, before we can call the drawBitmap() function, we first need an image to draw. Remember, the screen resolution of Nokia 5110 LCD display is 84×48 pixels, so images larger than that will not display correctly. To get a correctly sized image, you can use your favorite drawing programs like Inkscape, Photoshop, Paint, etc., setting the canvas size to 84×48 pixels.

Once you have a bitmap, it’s time to convert it into an array that the PCD8544 controller can understand. This can be done using two ways: Online method using image2cpp and Offline method using LCD Assistant.

There’s an online application called image2cpp – http://javl.github.io/image2cpp/ which can convert your image into an array. Image2cpp is newer and much more powerful than LCD Assistant (later solution). It will allow you to:

Once you are satisfied with the outcome, you can proceed generating the data array. Simply select Code output format as Arduino Code and click on Generate code button.

There’s another application called LCD assistant – http://en.radzio.dxp.pl/bitmap_converter/which can convert your bitmap image into data array. It’s not as powerful as image2cpp but still popular among hobbyists.

The LCD screen is a 2 lines x 16 columns display. It got 16 pins that can be configurate in 2 modes (4 bits or 8 bits: meaning we can make it by wiring only 4 bits or 8 bits). We work with 4 bits.

Once done, go to: File --> Examples --> LiquidCrystal , and the program will open in a new window. Upload the program to the arduino. You should see ""Hello world"" showing up on the screen. you can change it for whatever you want in the program in the sentence "lcd.print("text to print")".

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey