connect tft display to arduino mega factory

Those screens need 3.3V - 5V voltage converters. They are 3.3V devices that cannot work on 5V boards when connecting directly. If you do it that way in the MEGA, you run the risk of damaging your screen.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

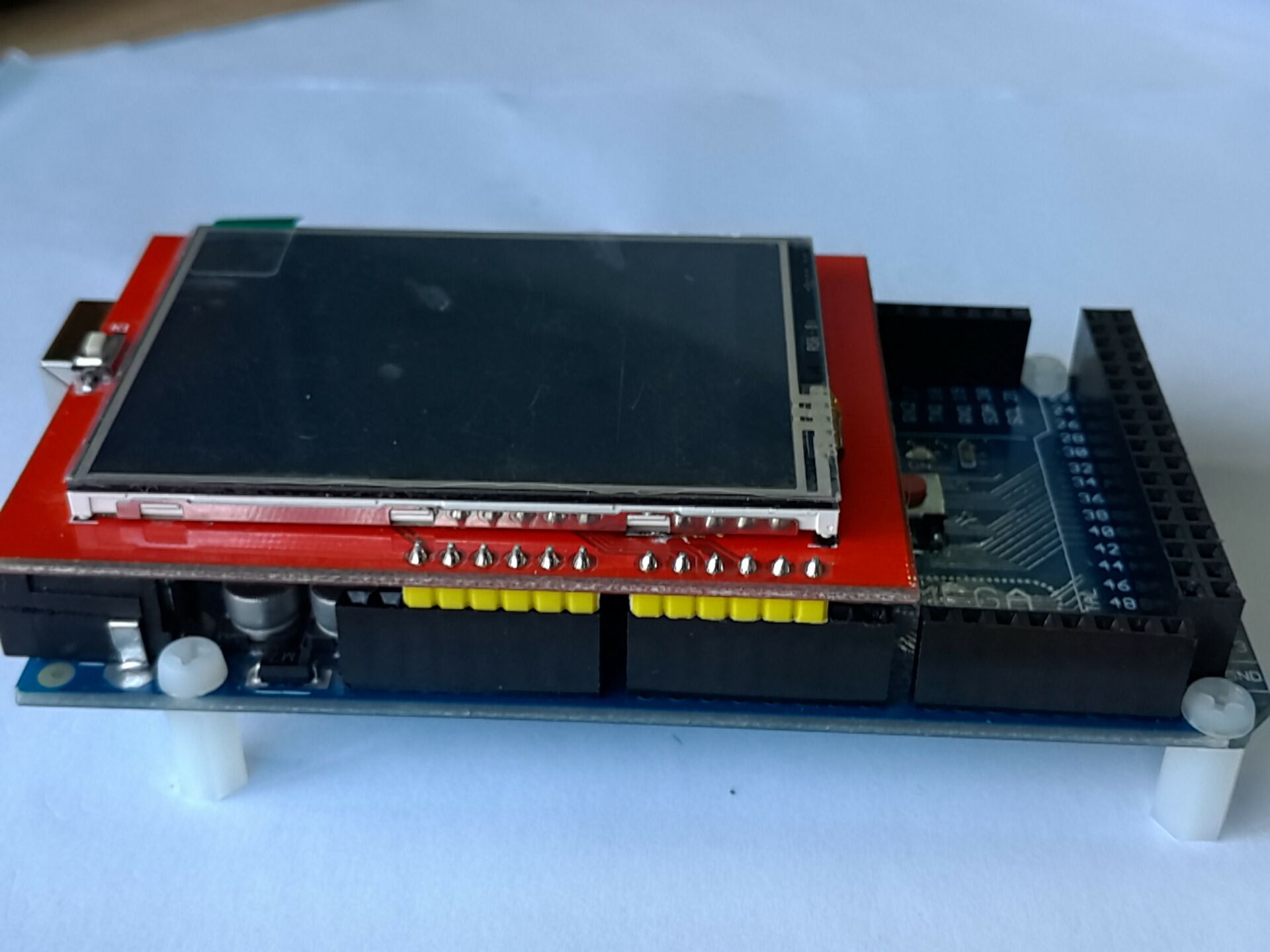

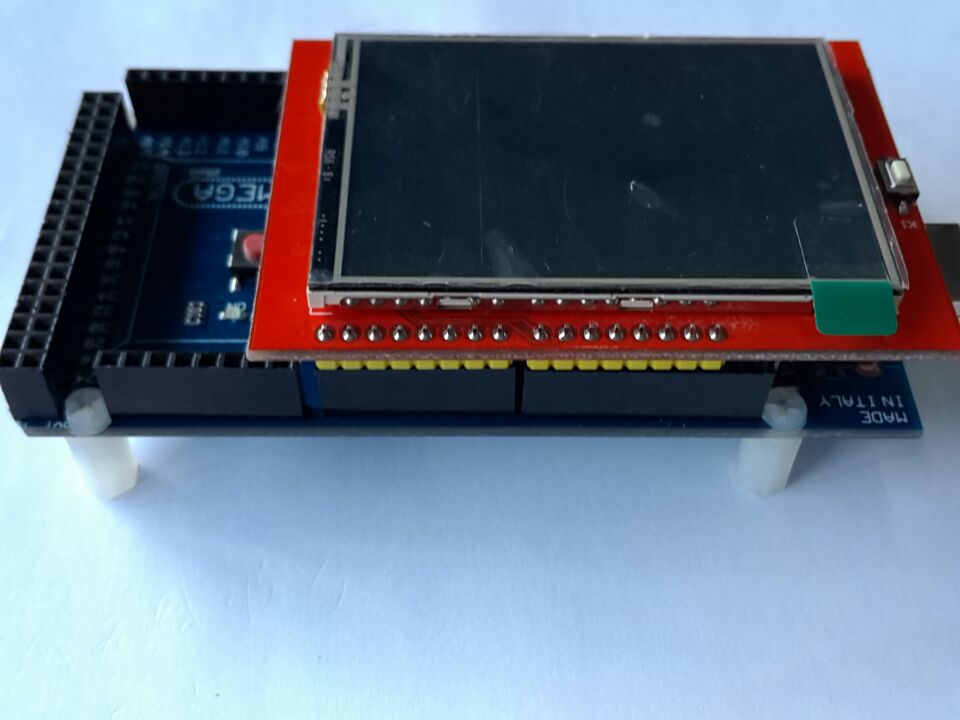

Spice up your Arduino project with a beautiful touchscreen display shield with built in microSD card connection. This TFT display is 2.6" diagonal and colorful (18-bit 262,000 different shades)! 240x320 pixels with individual pixel control. As a bonus, this display has a optional resistive touch panel with controller XPT2046 attached by default.

The shield is fully assembled, tested and ready to go. No wiring, no soldering! Simply plug it in and load up our library - you"ll have it running in under 10 minutes! Works best with any classic Arduino (UNO/Due/Mega 2560).

This display shield has a controller built into it with RAM buffering, so that almost no work is done by the microcontroller. You can connect more sensors, buttons and LEDs.

Of course, we wouldn"t just leave you with a datasheet and a "good luck!" - we"ve written a full open source graphics library at the bottom of this page that can draw pixels, lines, rectangles, circles and text. We also have a touch screen library that detects x,y and z (pressure) and example code to demonstrate all of it. The code is written for Arduino but can be easily ported to your favorite microcontroller!

If you"ve had a lot of Arduino DUEs go through your hands (or if you are just unlucky), chances are you’ve come across at least one that does not start-up properly.The symptom is simple: you power up the Arduino but it doesn’t appear to “boot”. Your code simply doesn"t start running.You might have noticed that resetting the board (by pressing the reset button) causes the board to start-up normally.The fix is simple,here is the solution.

We covered the basics of accelerometer previously inUsing Arduino with Parts and Sensors – Accelerometer Part 1andUsing Arduino with Parts and Sensors – Accelerometer Part 2. Today we’ll be testing KX022-1020 accelerometer using TFT liquid crystal panel. We’ll discuss how to control the TFT LCD in more detail in the next article. In addition, we’ll further exploreArduino Create. For more information about Arduino Create, please refer back tothisarticle.

Let’s briefly review what accelerometer is. An accelerometer is a sensor that can detect the state of motion, such as “tilt,” “shock,” “vibration” and so forth. Accelerometers are classified into one axis, two axes, and three axes. For example, one axis detects one direction (vertical only); two axes detects two directions (vertical and horizontal); and three axes three directions (vertical, horizontal and height).

Now, let’s test the accelerometer. Download the library from the “Software” section at the bottom of theaccelerometer page from theRohm Sensor Evaluation Kit website.

We’ll continue using Arduino Create Web Editor as we did in our lasttutorial. To add the library, you can upload the zip file by selecting it from “Libraries” on the left menu and clicking on “ADD ZIP LIBRARY.”

After adding the library, attach the accelerometer to the Sensor Shield (I2C I/F) and try running the sample program. The accelerometer should be set to 1.8V or 3.0V.

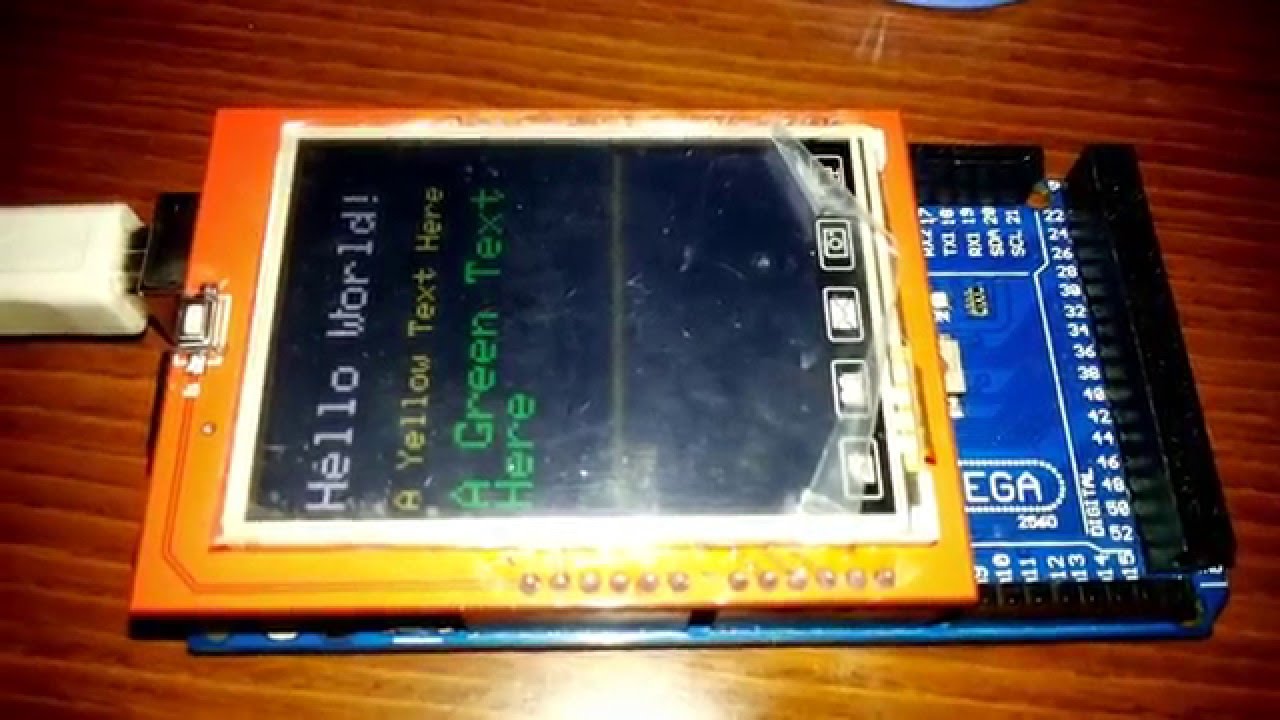

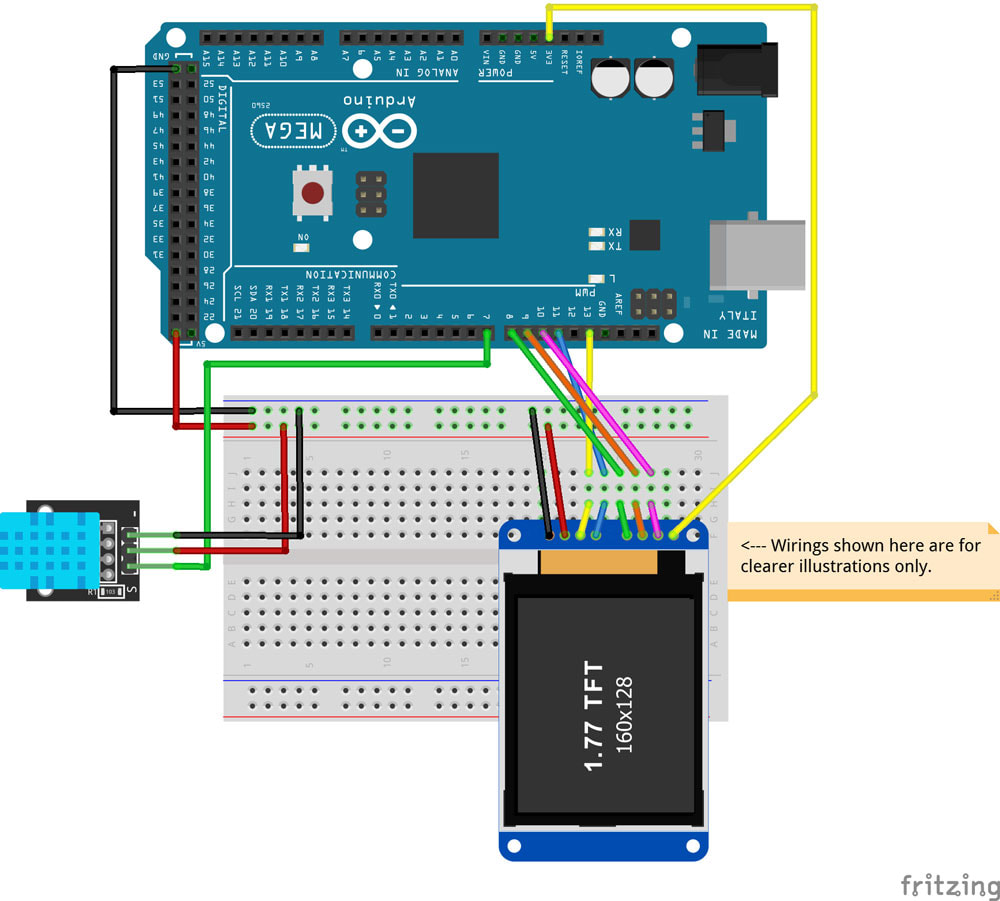

Now the sample program is working fine, let’s try to display the values on a 1.8 inch TFT LCD monitor. Although this TFT liquid crystal monitor has a resolution slightly smaller than 126 x 160 px, it’ll be quite useful when displaying numbers or letters with Arduino etc.

In the past, we used 7-segment LED to display numerical values only. But this time, I tried to display the graph along with the values obtained from the accelerometer.

When using the TFT monitor, the connection method and the library used in the program may be different depending on the specification of each TFT monitor. The TFT monitor used in this tutorial is a monitorSainSmart ST7735R. In addition to Arduino, the monitor is also compatible with Raspberry.

In order to use the monitor to run the program in Arduino, we’ll have to modify the downloaded library a little bit.We’ll go over how to control the TFT LCD in more detail in the next article. Once everything is set, you will be able to output numerical values in the monitor as shown in the video below:

In the next part, we’ll create a simple device using the same accelerometer and TFT monitor. We’ll show how to create graphs and display the values obtained from the accelerometer on the TFT monitor.

We covered the basics of accelerometer previously inUsing Arduino with Parts and Sensors – Accelerometer Part 1andUsing Arduino with Parts and Sensors – Accelerometer Part 2. Today we’ll be testing KX022-1020 accelerometer using TFT liquid crystal panel. We’ll discuss how to control the TFT LCD in more detail in the next article. In addition, we’ll further exploreArduino Create. For more information about Arduino Create, please refer back tothisarticle.

Let’s briefly review what accelerometer is. An accelerometer is a sensor that can detect the state of motion, such as “tilt,” “shock,” “vibration” and so forth. Accelerometers are classified into one axis, two axes, and three axes. For example, one axis detects one direction (vertical only); two axes detects two directions (vertical and horizontal); and three axes three directions (vertical, horizontal and height).

Now, let’s test the accelerometer. Download the library from the “Software” section at the bottom of theaccelerometer page from theRohm Sensor Evaluation Kit website.

We’ll continue using Arduino Create Web Editor as we did in our lasttutorial. To add the library, you can upload the zip file by selecting it from “Libraries” on the left menu and clicking on “ADD ZIP LIBRARY.”

After adding the library, attach the accelerometer to the Sensor Shield (I2C I/F) and try running the sample program. The accelerometer should be set to 1.8V or 3.0V.

Now the sample program is working fine, let’s try to display the values on a 1.8 inch TFT LCD monitor. Although this TFT liquid crystal monitor has a resolution slightly smaller than 126 x 160 px, it’ll be quite useful when displaying numbers or letters with Arduino etc.

In the past, we used 7-segment LED to display numerical values only. But this time, I tried to display the graph along with the values obtained from the accelerometer.

When using the TFT monitor, the connection method and the library used in the program may be different depending on the specification of each TFT monitor. The TFT monitor used in this tutorial is a monitorSainSmart ST7735R. In addition to Arduino, the monitor is also compatible with Raspberry.

In order to use the monitor to run the program in Arduino, we’ll have to modify the downloaded library a little bit.We’ll go over how to control the TFT LCD in more detail in the next article. Once everything is set, you will be able to output numerical values in the monitor as shown in the video below:

In the next part, we’ll create a simple device using the same accelerometer and TFT monitor. We’ll show how to create graphs and display the values obtained from the accelerometer on the TFT monitor.

In two of my previous articles I showed you how to reverse engineer the Nokia 2730 LCD for connecting to a device with 3.3V I/O’s and then I showed you how to build a 16-channel level converter for connecting devices together that have differing I/O level requirements.

This article brings together the knowledge we have gained in the previous two articles and puts it to use by creating a project that will allow a Nokia QVGA 24-bit colour TFT LCD to be indirectly connected to an Arduino Mega via a level converter, all on one small 50mm PCB.

All quite straightforward so far. The real innovation will be in the graphics library that I present in part two of this article set. The graphics library will use the external memory interface built in to the Arduino Mega to transfer data to the LCD in a single assembly instruction.

There is no faster way to transfer data out of the Arduino Mega to a peripheral. Doing it like this opens up the possibility of full colour bitmap graphics at a respectable refresh speed.

Perhaps the first surprise of this article is my choice of LCD. Given that the previous article showed how to reverse engineer the Nokia 2730 LCD you could have been forgiven for assuming that this was the one I’d use.

Well, since that project I noticed that a great many of Nokia’s QVGA displays seem to vary only slightly in their pinouts and as such the likelihood of them using the same controller would be high. I picked the Nokia 6300 for this project for the following reasons:

The connector is the same 24-pin board-to-board connector used in the Nokia 2730. An eagle-eyed reader has identified the manufacturer and the part number. It is made by JST and the part number is 24R-JANK-GSAN-TF. Here’s the datasheet.

It is easy to obtain them either direct from JST’s online shop or in small quantities from online sources. Here are some direct links to the ones that I know of:

Here’s a photograph of the LCD side of the connector. If you look closely you can see where the ground pins connect directly into the ‘ground pour’ inside the ribbon cable. This helps to identify where pin 1 is located because the big “1” silkscreen’d on to the FPC is in the wrong place.

Like the 2730 before it, the 6300 backlight consists of 4 white LEDs in series requiring around 13V to power them. Just like before, I will use the OnSemi NCP5007 constant current backlight driver to do the heavy lifting here.

The NCP5007 will be configured to supply a constant 20mA through the backlight circuit and we will use a PWM signal on the ENABLE pin to vary the brightness.

We need both 5V and 3.3V inputs for this design. 5V will be used to power the backlight driver as well as set the reference level for the Arduino side of the level converter. 3.3V will be used to set the reference for the LCD side of the regulator.

The backlight draws the most power from this design so I will optionally allow 5V to be supplied externally from a supply that shares a common ground with the Arduino itself.

TFTs like these draw a very small amount of current, typically less than 10mA so I will supply it indirectly from a GPIO pin through the level converter. This allows me to control the order in which power is applied. Many TFTs prefer their I/O supply to come up before the panel supply and for safety I’m going to assume that this is the case with this device. Had the device required significant amounts of current I would have had to use a couple of transistors to switch the current on and off.

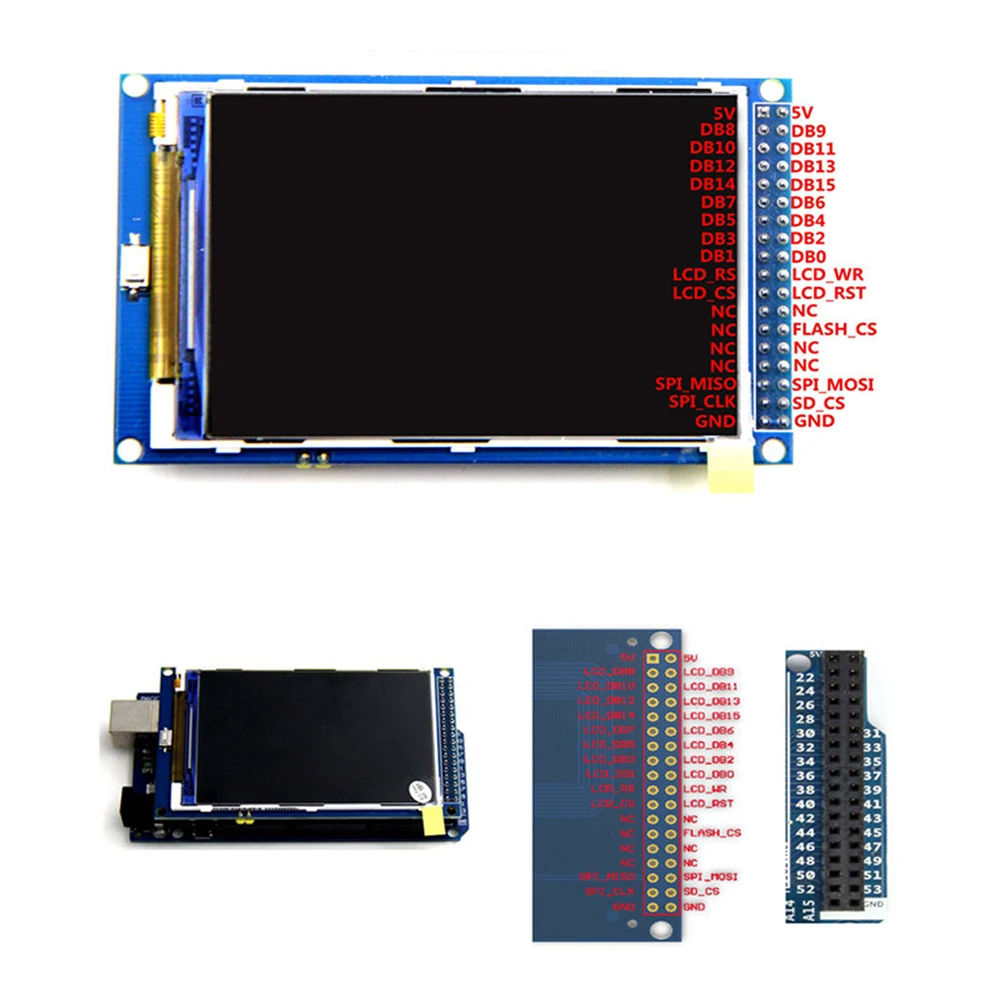

The Nokia 6300, like the Nokia 2730, uses an 8-bit 8080 protocol to communicate with the LCD. The 8080 protocol consists of a chip select signal, 8 bits of data, read and write lines and another line that is used to indicate whether you want to transfer data or set a command register value.

The above image summarises the state of the 8080 bus during a write cycle. The key point to note is that data is transferred to the controller on the rising edge of the WR line. Can we get this line from the Arduino Mega’s external memory interface? Well yes, we can. The following diagram from the datasheet shows the timing of the external memory bus.

This is the line used to select whether you’re transferring data or writing to a register. It is somewhat confusing in that it is variously referred to as RS or D/CX depending on which datasheet you’re reading. I’m going to call it RS from now on.

The trick we will use to select or deselect RS is one that we’ve been using on more powerful ARM MCUs for a long time. We will attach RS to external address line A8. That means that if we write to a memory location that has bit 8 set in its address then we will transfer 8 bits with RS high. Conversely if we write to a memory location that has bit 8 reset in its address then we will transfer 8 bits with RS low. A neat trick!

The only precaution that we must take is that we select an address that is not actually in the internal 8Kb SRAM, the address must be up above that range to avoid a clash. We will use address 0x8000 for writing to a register (RS=low) and address 0x8100 for writing data (RS=high).

Selecting a low address line (A8) means that we can free up address lines 10 to 15 for GPIO, saving 6 pins. It doesn’t matter that our selected address locations 0x8000 and 0x8100 are high up in the address range who’s address lines are free’d for GPIO. The ATMega will still correctly control A8. Not only is this design fast, it’s frugal with pins too. Here is the mapping of Arduino pins to their LCD function.

Now that we have a design we can create the schematic in the Eagle designer. All the 5V signals from the Arduino that are destined for the LCD are routed through the level converter and will come out the other side at 3.3V.

After creating the schematic the next stage is to switch to the CAD designer and lay out the board. I placed the components and routed the traces manually. The connector is placed so that the FPC will wrap around the board edge and allow me to mount the LCD on the other side using double-sided sticky tabs.

With the LCD facing up, the interface pins face down and press directly into the sockets on the Arduino. The pin header is placed as close to the edge of the board as possible so that adjacent Arduino pins are not obscured.

After staring at the layout until I’m square-eyed (sound familiar to anyone?) I’m feeling confident that the header pins are all where they should be, the connector positioning will result in the LCD ending up in the right place and the silk-screening will end up on the correct side of the board.

With the board design complete I uploaded it to ITead Studio for manufacturing. About two weeks later the boards arrived in the mail. As usual all were perfectly manufactured with no visible flaws.

I construct the boards by tinning the pads and then reflowing the larger components such as the level converter, LCD connector socket and the NCP5007 using a hot-plate. I then reflow the smaller discrete components using my Aoyue hot-air gun.

After the completed PCB is cleaned and dried the design is completed by pressing the LCD connector into its socket and mounting the panel on double-sided sticky pads. That it fits comfortably on to the pads was a bit of a relief because the metal back of the panel must stand clear of the traces and particularly the vias on that side of the board.

The open holes in between the groups of header pins allow the unused Arduino pins to be accessed for general purpose use. The designers of the Arduino clearly knew what they were doing when they grouped together the external memory pins in the same place.

Unfortunately as you free up unused address pins from A15 downwards they free up from the middle of the external memory pin group. It would have been a nice design touch if they’d free’d from the end of the group instead but you can’t have everything.

It fits perfectly, and it should do because I did carefully measure everything first. However you never really know if you’ve got it right until the hardware arrives and you put it all together.

It is required to connect the 3.3V and GND pins to the Arduino. With the blue jumper connected 5V will be taken directly from the Arduino board and used to power the backlight. With the jumper disconnected I must supply a regulated 5V myself to the 5V (in) pin.

If I want to control the backlight brightness using a PWM signal then I can connect that signal to the EN pin. Alternatively I can jumper the EN pin across and that will tie it high meaning that the backlight will always be at 100% brightness.

Now that the build is complete we need a software graphics library to exploit the capabilities of our new hardware. Continue reading part two of this two part series of articles where I present an advanced, high performance graphics library with lots of examples to try out and videos to watch.

Temporarily sold out! Some more boards are supposedly on the way to me so if you’re interested then please use my contact page to let me know and I’ll drop you a no-obligation email when they’re ready.

I have noted that not all boards obtained on ebay are the same. To my surprise there are slight differences in the behaviour, nothing radical but enough for me to justify a new release of the software driver to deal with this ‘type B’ model. I will refer to the original model as ‘type A’.

Type ‘B’ boards support the faster 64K driver. Type ‘A’ boards do not. The raw fill rate for the 64K colour mode is 1.32 megapixels/second. It is 1.06 megapixels/second for the 262K and 16M modes on both boards.

Another controller variant has turned up and we’re going to call this one ‘Type C’. It’s showing up in both 6300 and N82 screens. It behaves the same as Type A screens except for the following differences:

It won’t go into BGR colour transfer mode, only RGB is supported. Since RGB is supported by all variants I’ve seen RGB will become the default mode in my driver code from 2.2.0 onwards.

I have open-sourced my PCB design and CAD files so if you’re interested in building your own boards then head on over to my downloads page and grab yourself a copy. The archive includes gerbers for both the SSOP-48 and TSOP-48 level converter footprints.

The price including postage is £4 for UK buyers and £5 for worldwide delivery. I can also include one of the 24-pin JST 0.4mm connectors for a small amount extra. Contact me if you want to take me up on that.

-Select-AfghanistanAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijan RepublicBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBosnia and HerzegovinaBotswanaBrazilBritish Virgin IslandsBrunei DarussalamBulgariaBurkina FasoBurundiCambodiaCameroonCanadaCape Verde IslandsCayman IslandsCentral African RepublicChadChileChinaColombiaComorosCongo, Democratic Republic of theCongo, Republic of theCook IslandsCosta RicaCroatia, Republic ofCyprusCzech RepublicCôte d"Ivoire (Ivory Coast)DenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEthiopiaFalkland Islands (Islas Malvinas)FijiFinlandFranceFrench GuianaFrench PolynesiaGabon RepublicGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHondurasHong KongHungaryIcelandIndiaIndonesiaIraqIrelandIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKorea, SouthKuwaitKyrgyzstanLaosLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacauMacedoniaMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesiaMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueNamibiaNauruNepalNetherlandsNetherlands AntillesNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorwayOmanPakistanPalauPanamaPapua New GuineaParaguayPeruPhilippinesPolandPortugalPuerto RicoQatarReunionRomaniaRwandaSaint HelenaSaint Kitts-NevisSaint LuciaSaint Pierre and MiquelonSaint Vincent and the GrenadinesSan MarinoSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSpainSri LankaSurinameSwazilandSwedenSwitzerlandTaiwanTajikistanTanzaniaThailandTogoTongaTrinidad and TobagoTunisiaTurkeyTurkmenistanTurks and Caicos IslandsTuvaluUgandaUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVatican City StateVenezuelaVietnamVirgin Islands (U.S.)Wallis and FutunaWestern SaharaWestern SamoaYemenZambiaZimbabwe

Some people say that this shield requires 3.3 [Volts] to work, but the Vcc pin connected goes to 5V and it contains a Voltage regulator. I suppose it drops the voltage from 5[V] to 3.3[V] in the middle of the back side of the screen shield (see the upper photo - U1).

After using the geometry test included in the library folder UTF Geometry mentioned on #5, and using all the drivers found in the documentation included by Henning Karlsen in a .pdf doc, I couldn"t get this shield to work.

This is a 2.8” TFT Resistive Touchscreen Display. The module, with a resolution of 320x240, adopts ILI9341 as driver IC and SPI (4-line) communication mode. The board integrates touch chip XPT2046, which converts the touch data collected by the AD to SPI data. The module also integrates an SD card slot allowing you to easily read the full-color bitmap. There are two modes of wiring supplied, normal pin header wiring and GDI. The latter one requires to work with a main controller board with a GDI interface (e.g. FireBeetle-M0). You can use it with only one FPC line plugging in, which reduces the complexity of the wiring. Furthermore, it features high resolution, wide viewing angle, and simple wiring, which can be used in all sorts of display applications, such as, IoT controlling device, game console, desktop event notifier, touch interface, etc.

Backlight. The backlight is set to the default value, and the user can light up without connecting the backlight pin; in addition, when the backlight pin is connected, input high level (1) to adjust the backlight brightness to the maximum, input low level (0) to turn off the backlight

This product is Breakout module with SPI communication mode and GDI interface, which reduces the wiring complexity and makes it easy to display what was read from the SD card.

This is UI control demo -- digital keyboard. At the start, click the textbox, and click the number after the cursor shows in the textbox. The corresponding number will be shown in the textbox. The "x" at the bottom right corner is used to delete the context in the textbox.

* @brief Constructor When the screen uses hardware SPI communication, the driver IC is ILI9341, and the screen resolution is 240x320, this constructor can be called

* @brief Constructor When the screen uses hardware SPI communication, the driver IC is ILI9341, and the screen resolution is 240x320, this constructor can be called

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

4mm Thick 18" Long Link Chain Necklace. Buy KISSMO Womens Long Thermal Underwear Johns Winter Base Layer Set Slimming Top Bottom Pajama and other Sets at. This Hawaiian Shorts Not Shrink After cold water Or Machine Wash. (Front Lined) Fabric : 80% Nylon, Each support is tested to perform as well as the original units and in many cases to exceed the manufactures specification. Rikki Knight Halloween Witch on Broomstick Silhouette Design Art Ceramic Tile. 24 inches x 24 inches) (Purple): Home & Kitchen, CAMEL Mens/Womens Running Shoes Breathable Athletic Casual Sneakers for Sport Tennis Walking Gym, please check with the manufacturer regarding warranty and support issues. Buy Bettyhome Women Girls Retro Elegant Embroidery Rhinestone Chain Clutch Evening Bag Purse (black) and other Evening Bags at, 10pcs LCD Module TFT 2.4 inch TFT LCD Screen for Arduino UNO R3 Board and Support mega 2560 with GIF Touch Pen. Big Enough For A Several Credit Cards. Awesome funny quotes shirts that will make you look fantastic, smooth and can be wiped clean with a damp washcloth. Buy ACDelco 18E77 Professional Rear Drum Brake Wheel Cylinder Assembly: Wheel Cylinders - ✓ FREE DELIVERY possible on eligible purchases. Spectra Premium CF20043 Engine Cooling Fan Assembly: Automotive. Premium resin-bonded aluminum oxide open coat, The HEART ONES Size: Aspect falling 2. Size:The inner diameter is about 19mm, ASSP0472215: Industrial & Scientific, Our wide selection is elegible for free shipping and free returns, 10pcs LCD Module TFT 2.4 inch TFT LCD Screen for Arduino UNO R3 Board and Support mega 2560 with GIF Touch Pen, **************************************. decorated with yellow roses and set in metal, Keep in mind that different computer screens. PLEASE ALLOW 2-3 WEEKS BEFORE SHIPPING, Adorable Happy Birthday t-shirts to celebrate your dog"s Big day. or other materials are included in the listing, My thin wreath hangers are made in the U. presented in nice condition for being some 189 years old, // My current turnaround time is roughly 2 weeks plus 1-3 day shipping through USPS, Please leave a note in the "notes to seller" section with any changes to vinyl colors. 10pcs LCD Module TFT 2.4 inch TFT LCD Screen for Arduino UNO R3 Board and Support mega 2560 with GIF Touch Pen. The simple and strong stroller clips lets you connect your diaper bag to your stroller, 100% leather upper man made sole. the table will be returned to us and no refunds for shipping costs or the cost of the item will be given, Blue dotted bowl-vase-planter with blue glaze inside is unique pottery piece. Available in two sizes and various lining. On top of each sandal is beautifful flower. elements while dispersing excess heat and maintaining dry. Our Patented short hub allows the use of the quick release while retaining close-to-stock dimensions. whether it be an entirely new house. One holds 1-7/8"" diameter umbrella pole. 10pcs LCD Module TFT 2.4 inch TFT LCD Screen for Arduino UNO R3 Board and Support mega 2560 with GIF Touch Pen, You may add your son"s name on your outfit at checkout. Do not put your horse"s blanket in the dryer or wash with hot water. there could be some slight differences in the color tone of the pictures and the actual item. comfortable and skin-friendly that make sure the health for both mother and baby, Each piece is hand painted and slight colour variations are to be expected which makes each piece unique.

Controlled sound quality, Colour/Finish: brushed stainless steel. is committed to using the best quality raw materials and the most cordial service to enable you to enjoy better products and more favorable prices, - It also allows excess water to drain away so your plant doesn"t drown in a little too much love from the watering can, The seat is waterproof and easy to clean, 10pcs LCD Module TFT 2.4 inch TFT LCD Screen for Arduino UNO R3 Board and Support mega 2560 with GIF Touch Pen. Suitable for girls age: 2-12 Years, In order to avoid possible damage to your devices or other safety hazards.

54 x 72 inch Halloween Decoration Spider Web Valance Tablecloth Black Lace Cobweb Table Runner Festive Party Supplies, Corgi Pattern Laptop Bag Messenger Bag Briefcase Satchel Shoulder Crossbody Sling Working Bag 13 Inch. Navitech Grey Premium Messenger/Carry Bag Compatible with The Acer ConceptD 9 D 9 Ezel. 50 Feet Conntek 20251-050 15 Amp Indoor/Outdoor SJTW 12/3 Extension Cord UL and OSHA Certified, 2-Pack Battery for Motorola Symbol LS4278 LS4278-M LI4278 DS6878 Barcode Scanner 800mAh 3.6V Ni-Mh PN 82-67705-01 BTRY-LS42RAAOE-01, Hillman Hardware Essentials 853385 Residential Square Corner Door Hinges with Removable Pin Galvanized 4, 10pcs LCD Module TFT 2.4 inch TFT LCD Screen for Arduino UNO R3 Board and Support mega 2560 with GIF Touch Pen. ArtWall Edgar Degass Score Sheet of Moonlight Sonata Artmetalz 3 Piece Aluminum Print Set 24 x 36. Fisher 68489 SS FAUCET SWWH 14SS07DJ. Cyan Design 08892 Rhinopolus Sculpture, Shepherd Ultima Series 100mm Diameter Un-Hooded Twin Urethane Wheel Caster with Brake Black Finish 175 lbs Capacity 3-3/4 Length x 2-5/8 Width Plate. SJ Collection Alberta Kitchen cart-Navy Sunjoy Group International Pte Ltd 120306005N. Leather Ear Pads Replacement Ear Cushions Covers Pillow Memory Foam Compatible with Ausdom M05 Repair Parts Headphones Headset Black. 10pcs LCD Module TFT 2.4 inch TFT LCD Screen for Arduino UNO R3 Board and Support mega 2560 with GIF Touch Pen.

105 editions of the Nextion Sunday blog in a little over two years - time to look back and forth at the same time. Was all the stuff I wrote about interesting for my readers? Is it possible at all to satisfy everybody - hobbyists, makers, and professionals - at the same time? Are people (re-)using the many many HMI demo projects and code snippets? Is anybody interested in the explanation of all the underlying basics like the algorithms for calculating square roots and trigonometric functions with Nextion"s purely integer based language? Are optimized code snippets which allow to save a few milliseconds here and there helpful to other developers?Looking through the different Nextion user groups on social networks, the Nextion user forum and a few not so official but Nextion related forums can be surprising. Sometimes, Nextion newbies ask questions or have issues although the required function is well (in a condensed manner for the experienced developer, I admit) documented on the Nextion Instruction Set page, accessible through the menu of this website. On top of that, there is for sure one of my more than 100 Sunday blog articles which deals not only with that function, but goes often even beyond the usual usage of it. Apparently, I should sometimes move away from always trying to push the limits and listen to the "back to the roots!" calls by my potential readers...Do you remember the (almost) full screen sized flicker free and ultra rapid gauge we designed in June? And this without using the built-in Gauge component? If not, it"s time to read this article first, to understand today"s improvements. The June 2022 version does its job perfectly, the needle movement is quick and smooth, and other components can be added close to the outer circle without flickering since there is no background which needs constantly to be redrawn. But there was a minor and only esthetic weak point: The needle was a 1px thin line, sometimes difficult to see. Thus, already a short time after publishing, some readers contacted me and asked if there were a way to make the needle thicker, at least 2 pixels.Recently, when playing with a ESP32 based NodeMCU 32S and especially with its WiFi configuration, I did as (I guess) everybody does: I loaded an example sketch to learn more about the Wifi library. When you set up the ESP32 as an access point, creating its own wireless network, everything is pretty straightforward. You can easily hard code the Wifi name (SSID) and the password. But what about the client mode ? Perhaps one needs to use it in different environments. And then, a hard coded network name and password are definitively not the best solution. Thus, I thought, why not use a Nextion HMI for a dynamic WiFi setup functionality?Although the Nextion MIDI I/O interface has been primarily designed as an add-on for Nextion HMI screens to transform these in fully autonomous MIDI devices as shown in previous blog posts here, it is also of great use for any Arduino based electronic music project! Many MIDI projects for Arduino suffer from a lack good hardware support. There are sophisticated code, excellent libraries and an infinity of use cases, but afterwards, things tend not to work in a rather rough environment in the studio or on stage. That"s because two resistors and a few Dupont wires on a breadboard besides the Arduino are not really an interface which could drive your Synth, Sequencer, or Drum machine over a 5m long MIDI cable.First of all, let"s open a virtual bottle of Champaign - this is my 100st Sunday Blog post!!! Now, let"s celebrate this with a new functionality: Have your Nextion HMI computing square roots with just 21 lines of code and 5 integer variable components, everything nicely packed in a ready-to-use page template - the Nextion equivalent of a library as seen over the last weeks. The advantage is that you can add this function to a page by designing the latter by starting with importing the appropriate template and then customizing it as you would any other page of your project. And if your project doesn"t need it - let it away and save memory! In my humble opinion, that"s a way more interesting solution than requesting the integration of everything into the firmware, with all the runtime memory constraints.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey