lcd panel cof data manufacturer

COF IC is the only IC that connects TV PANEL with the T-CON board physically. SO today in this article I will explain full information about COF IC and also tell you how to get and download COF IC datasheet. If you want to know the process of COF IC downloading, read this article very carefully.

You can not COF IC data from the official site of any number COF IC. You already know about me and here I’ll give you Panel COF data downloading link which I get while repairing. And if you do not get your COF data which you need to comment down below. I will update you on the COFdatasheet as soon as possible.

If you are an Electronics technician especially LCD/LED, Definitely you have to know about COF IC. How to work COF IC and working principle of this IC. Also you have to know the voltage value of this IC. If you are interested to know about COF IC voltage value click here and know how many types of voltage has present in this IC.

Every single panel have their own development and manufacturing COF IC. I make a video on this topic and post an article, If you want to see click here.

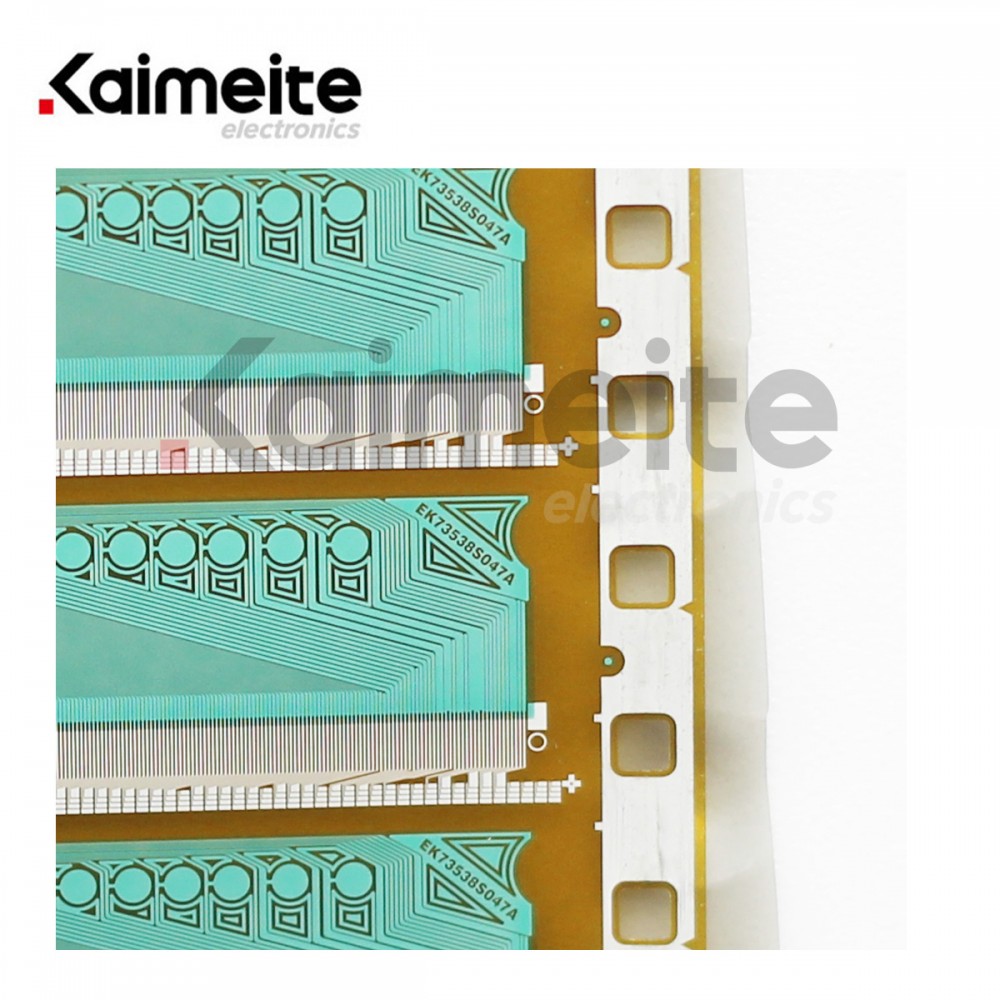

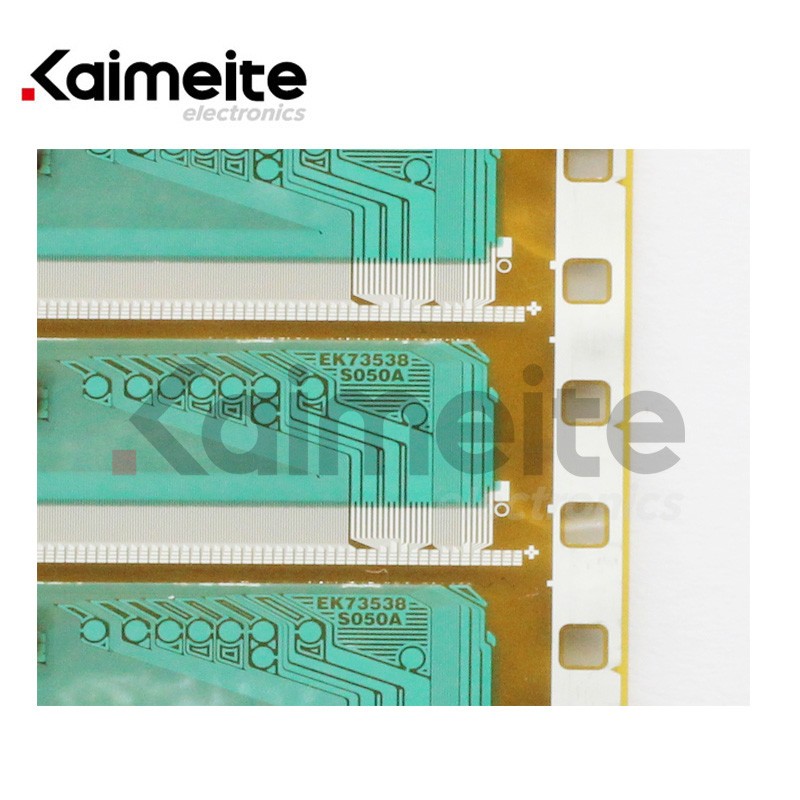

It comes with sufficient film thickness that is not only flexible but can be easily used for any purpose. In addition to this, the panel repair factory COF IC possesses pretest capability which makes it in high demand for product fabrication applications.

It comes with sufficient film thickness that is not only flexible but can be easily used for any purpose. In addition to this, the panel repair factory COF IC possesses pretest capability which makes it in high demand for product fabrication applications.

data:image/svg+xml;base64,PD94bWwgdmVyc2lvbj0nMS4wJyBlbmNvZGluZz0naXNvLTg4NTktMSc/Pgo8c3ZnIHZlcnNpb249JzEuMScgYmFzZVByb2ZpbGU9J2Z1bGwnCiAgICAgICAgICAgICAgeG1sbnM9J2h0dHA6Ly93d3cudzMub3JnLzIwMDAvc3ZnJwogICAgICAgICAgICAgICAgICAgICAgeG1sbnM6cmRraXQ9J2h0dHA6Ly93d3cucmRraXQub3JnL3htbCcKICAgICAgICAgICAgICAgICAgICAgIHhtbG5zOnhsaW5rPSdodHRwOi8vd3d3LnczLm9yZy8xOTk5L3hsaW5rJwogICAgICAgICAgICAgICAgICB4bWw6c3BhY2U9J3ByZXNlcnZlJwp3aWR0aD0nMzAwcHgnIGhlaWdodD0nMzAwcHgnIHZpZXdCb3g9JzAgMCAzMDAgMzAwJz4KPCEtLSBFTkQgT0YgSEVBREVSIC0tPgo8cmVjdCBzdHlsZT0nb3BhY2l0eToxLjA7ZmlsbDojRkZGRkZGO3N0cm9rZTpub25lJyB3aWR0aD0nMzAwLjAnIGhlaWdodD0nMzAwLjAnIHg9JzAuMCcgeT0nMC4wJz4gPC9yZWN0Pgo8dGV4dCB4PScxMzguMCcgeT0nMTcwLjAnIGNsYXNzPSdhdG9tLTAnIHN0eWxlPSdmb250LXNpemU6NDBweDtmb250LXN0eWxlOm5vcm1hbDtmb250LXdlaWdodDpub3JtYWw7ZmlsbC1vcGFjaXR5OjE7c3Ryb2tlOm5vbmU7Zm9udC1mYW1pbHk6c2Fucy1zZXJpZjt0ZXh0LWFuY2hvcjpzdGFydDtmaWxsOiMzQjQxNDMnID5DPC90ZXh0Pgo8dGV4dCB4PScxNjUuNicgeT0nMTcwLjAnIGNsYXNzPSdhdG9tLTAnIHN0eWxlPSdmb250LXNpemU6NDBweDtmb250LXN0eWxlOm5vcm1hbDtmb250LXdlaWdodDpub3JtYWw7ZmlsbC1vcGFjaXR5OjE7c3Ryb2tlOm5vbmU7Zm9udC1mYW1pbHk6c2Fucy1zZXJpZjt0ZXh0LWFuY2hvcjpzdGFydDtmaWxsOiMzQjQxNDMnID51PC90ZXh0Pgo8cGF0aCBkPSdNIDE4OC40LDE1MC4wIEwgMTg4LjQsMTQ5LjggTCAxODguNCwxNDkuNyBMIDE4OC40LDE0OS41IEwgMTg4LjMsMTQ5LjMgTCAxODguMywxNDkuMiBMIDE4OC4yLDE0OS4wIEwgMTg4LjEsMTQ4LjkgTCAxODguMCwxNDguNyBMIDE4Ny45LDE0OC42IEwgMTg3LjcsMTQ4LjUgTCAxODcuNiwxNDguNCBMIDE4Ny41LDE0OC4zIEwgMTg3LjMsMTQ4LjIgTCAxODcuMiwxNDguMSBMIDE4Ny4wLDE0OC4xIEwgMTg2LjgsMTQ4LjAgTCAxODYuNywxNDguMCBMIDE4Ni41LDE0OC4wIEwgMTg2LjMsMTQ4LjAgTCAxODYuMSwxNDguMCBMIDE4Ni4wLDE0OC4xIEwgMTg1LjgsMTQ4LjEgTCAxODUuNiwxNDguMiBMIDE4NS41LDE0OC4yIEwgMTg1LjMsMTQ4LjMgTCAxODUuMiwxNDguNCBMIDE4NS4xLDE0OC41IEwgMTg0LjksMTQ4LjcgTCAxODQuOCwxNDguOCBMIDE4NC43LDE0OC45IEwgMTg0LjcsMTQ5LjEgTCAxODQuNiwxNDkuMiBMIDE4NC41LDE0OS40IEwgMTg0LjUsMTQ5LjYgTCAxODQuNSwxNDkuNyBMIDE4NC40LDE0OS45IEwgMTg0LjQsMTUwLjEgTCAxODQuNSwxNTAuMyBMIDE4NC41LDE1MC40IEwgMTg0LjUsMTUwLjYgTCAxODQuNiwxNTAuOCBMIDE4NC43LDE1MC45IEwgMTg0LjcsMTUxLjEgTCAxODQuOCwxNTEuMiBMIDE4NC45LDE1MS4zIEwgMTg1LjEsMTUxLjUgTCAxODUuMiwxNTEuNiBMIDE4NS4zLDE1MS43IEwgMTg1LjUsMTUxLjggTCAxODUuNiwxNTEuOCBMIDE4NS44LDE1MS45IEwgMTg2LjAsMTUxLjkgTCAxODYuMSwxNTIuMCBMIDE4Ni4zLDE1Mi4wIEwgMTg2LjUsMTUyLjAgTCAxODYuNywxNTIuMCBMIDE4Ni44LDE1Mi4wIEwgMTg3LjAsMTUxLjkgTCAxODcuMiwxNTEuOSBMIDE4Ny4zLDE1MS44IEwgMTg3LjUsMTUxLjcgTCAxODcuNiwxNTEuNiBMIDE4Ny43LDE1MS41IEwgMTg3LjksMTUxLjQgTCAxODguMCwxNTEuMyBMIDE4OC4xLDE1MS4xIEwgMTg4LjIsMTUxLjAgTCAxODguMywxNTAuOCBMIDE4OC4zLDE1MC43IEwgMTg4LjQsMTUwLjUgTCAxODguNCwxNTAuMyBMIDE4OC40LDE1MC4yIEwgMTg4LjQsMTUwLjAgTCAxODYuNCwxNTAuMCBaJyBzdHlsZT0nZmlsbDojMDAwMDAwO2ZpbGwtcnVsZTpldmVub2RkO2ZpbGwtb3BhY2l0eToxO3N0cm9rZTojMDAwMDAwO3N0cm9rZS13aWR0aDowLjBweDtzdHJva2UtbGluZWNhcDpidXR0O3N0cm9rZS1saW5lam9pbjptaXRlcjtzdHJva2Utb3BhY2l0eToxOycgLz4KPC9zdmc+Cg==

data:image/svg+xml;base64,PD94bWwgdmVyc2lvbj0nMS4wJyBlbmNvZGluZz0naXNvLTg4NTktMSc/Pgo8c3ZnIHZlcnNpb249JzEuMScgYmFzZVByb2ZpbGU9J2Z1bGwnCiAgICAgICAgICAgICAgeG1sbnM9J2h0dHA6Ly93d3cudzMub3JnLzIwMDAvc3ZnJwogICAgICAgICAgICAgICAgICAgICAgeG1sbnM6cmRraXQ9J2h0dHA6Ly93d3cucmRraXQub3JnL3htbCcKICAgICAgICAgICAgICAgICAgICAgIHhtbG5zOnhsaW5rPSdodHRwOi8vd3d3LnczLm9yZy8xOTk5L3hsaW5rJwogICAgICAgICAgICAgICAgICB4bWw6c3BhY2U9J3ByZXNlcnZlJwp3aWR0aD0nODVweCcgaGVpZ2h0PSc4NXB4JyB2aWV3Qm94PScwIDAgODUgODUnPgo8IS0tIEVORCBPRiBIRUFERVIgLS0+CjxyZWN0IHN0eWxlPSdvcGFjaXR5OjEuMDtmaWxsOiNGRkZGRkY7c3Ryb2tlOm5vbmUnIHdpZHRoPSc4NS4wJyBoZWlnaHQ9Jzg1LjAnIHg9JzAuMCcgeT0nMC4wJz4gPC9yZWN0Pgo8dGV4dCB4PSczNS4wJyB5PSc1My42JyBjbGFzcz0nYXRvbS0wJyBzdHlsZT0nZm9udC1zaXplOjIzcHg7Zm9udC1zdHlsZTpub3JtYWw7Zm9udC13ZWlnaHQ6bm9ybWFsO2ZpbGwtb3BhY2l0eToxO3N0cm9rZTpub25lO2ZvbnQtZmFtaWx5OnNhbnMtc2VyaWY7dGV4dC1hbmNob3I6c3RhcnQ7ZmlsbDojM0I0MTQzJyA+QzwvdGV4dD4KPHRleHQgeD0nNTEuMCcgeT0nNTMuNicgY2xhc3M9J2F0b20tMCcgc3R5bGU9J2ZvbnQtc2l6ZToyM3B4O2ZvbnQtc3R5bGU6bm9ybWFsO2ZvbnQtd2VpZ2h0Om5vcm1hbDtmaWxsLW9wYWNpdHk6MTtzdHJva2U6bm9uZTtmb250LWZhbWlseTpzYW5zLXNlcmlmO3RleHQtYW5jaG9yOnN0YXJ0O2ZpbGw6IzNCNDE0MycgPnU8L3RleHQ+CjxwYXRoIGQ9J00gNjYuNCw0Mi4wIEwgNjYuNCw0MS45IEwgNjYuNCw0MS44IEwgNjYuNCw0MS43IEwgNjYuMyw0MS42IEwgNjYuMyw0MS41IEwgNjYuMiw0MS40IEwgNjYuMiw0MS4zIEwgNjYuMSw0MS4zIEwgNjYuMSw0MS4yIEwgNjYuMCw0MS4xIEwgNjUuOSw0MS4xIEwgNjUuOCw0MS4wIEwgNjUuNyw0MS4wIEwgNjUuNiw0MC45IEwgNjUuNSw0MC45IEwgNjUuNSw0MC45IEwgNjUuNCw0MC44IEwgNjUuMyw0MC44IEwgNjUuMiw0MC44IEwgNjUuMSw0MC45IEwgNjUuMCw0MC45IEwgNjQuOSw0MC45IEwgNjQuOCw0MC45IEwgNjQuNyw0MS4wIEwgNjQuNiw0MS4wIEwgNjQuNSw0MS4xIEwgNjQuNCw0MS4yIEwgNjQuNCw0MS4yIEwgNjQuMyw0MS4zIEwgNjQuMiw0MS40IEwgNjQuMiw0MS41IEwgNjQuMiw0MS42IEwgNjQuMSw0MS43IEwgNjQuMSw0MS44IEwgNjQuMSw0MS45IEwgNjQuMSw0Mi4wIEwgNjQuMSw0Mi4wIEwgNjQuMSw0Mi4xIEwgNjQuMSw0Mi4yIEwgNjQuMSw0Mi4zIEwgNjQuMiw0Mi40IEwgNjQuMiw0Mi41IEwgNjQuMiw0Mi42IEwgNjQuMyw0Mi43IEwgNjQuNCw0Mi44IEwgNjQuNCw0Mi44IEwgNjQuNSw0Mi45IEwgNjQuNiw0My4wIEwgNjQuNyw0My4wIEwgNjQuOCw0My4xIEwgNjQuOSw0My4xIEwgNjUuMCw0My4xIEwgNjUuMSw0My4xIEwgNjUuMiw0My4yIEwgNjUuMyw0My4yIEwgNjUuNCw0My4yIEwgNjUuNSw0My4xIEwgNjUuNSw0My4xIEwgNjUuNiw0My4xIEwgNjUuNyw0My4wIEwgNjUuOCw0My4wIEwgNjUuOSw0Mi45IEwgNjYuMCw0Mi45IEwgNjYuMSw0Mi44IEwgNjYuMSw0Mi43IEwgNjYuMiw0Mi43IEwgNjYuMiw0Mi42IEwgNjYuMyw0Mi41IEwgNjYuMyw0Mi40IEwgNjYuNCw0Mi4zIEwgNjYuNCw0Mi4yIEwgNjYuNCw0Mi4xIEwgNjYuNCw0Mi4wIEwgNjUuMiw0Mi4wIFonIHN0eWxlPSdmaWxsOiMwMDAwMDA7ZmlsbC1ydWxlOmV2ZW5vZGQ7ZmlsbC1vcGFjaXR5OjE7c3Ryb2tlOiMwMDAwMDA7c3Ryb2tlLXdpZHRoOjAuMHB4O3N0cm9rZS1saW5lY2FwOmJ1dHQ7c3Ryb2tlLWxpbmVqb2luOm1pdGVyO3N0cm9rZS1vcGFjaXR5OjE7JyAvPgo8L3N2Zz4K

The present invention relates to a chip-on-film (COF) tape, and more particularly to a composite packaged COF tape and a corresponding COF bonding method. BACKGROUND OF THE INVENTION

A liquid crystal display (LCD) is a type of flat panel display (FPD) which displays images by the properties of the liquid crystal material. In comparison with other display devices, the LCD has the advantages of being lightweight, compact, having a low driving voltage, and having low power consumption and thus has already become the mainstream product in the consumer market. In the traditional manufacturing process of an LCD panel, it comprises a front-end array process, a mid-end cell process, and a back-end modulation process. The front-end array process is used to produce thin-film transistor (TFT) substrates (also called array substrates) and color filter (CF) substrates; the mid-end cell process is used to combine the TFT substrate with the CF substrate, then fill liquid crystal into a space therebetween, and then they are cut to form panels compatible with a suitable product size; and the back-end modulation process is used to execute an installation process on the combined panel, a backlight module, a panel driver circuit, an outer frame, etc.

As mentioned above, LCD driver chips are important components of the LCD, and the main function thereof is to output the needed voltage to pixels, so as to control the twist degree of the liquid crystal molecules. There are two types of LCD driver chips: one is the source driver chip arranged on the X-axis, the other is the gate driver chip arranged on the Y-axis. In other words, the source driver chips control image signals, and the gate driver chips control gate switch signals, so they have different functions for the LCD panel. Simply speaking, images of an LCD are formed by scanning lines one by one. The gate driver chip controls the vertical signals. If the scanning is started from the topmost line, the first pin of the gate driver chip is set to be switched on, and the others are set to be switched off. The signals in the source driver chip are the real signal (horizontal), and the sent signal is only accepted by the horizontal pixels of the first line. After the signal of the first line is transmitted, the second line will be the next one, while the content of the source driver chip is changed to the second line, and the second pin of the gate driver chip is switched on, and the others are switched off, so that the data is transmitted to the second line.

Furthermore, the assembly of the driver chips of the back-end modulation process is an assembling technology which combines the packaged source driver chips and the packaged gate driver chip with the LCD panel. There are various packaging types of the driver chip for an LCD, such as quad fiat package (QFP), chip on glass (COG), tape automated bonding (TAB), chip on film (COF), etc. The COF structure has flexibility and smaller circuit pitches, so has become the mainstream technology of the package of driver chips.

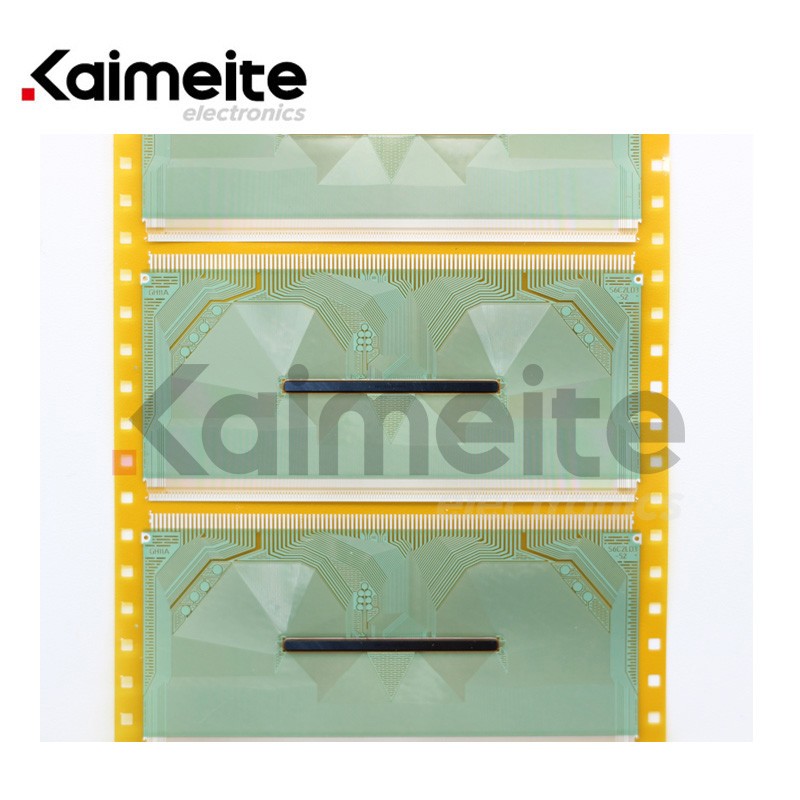

Usually, a tape-packaged COF is processed by rolling and delivering in whole the tape, and in the traditional manufacture of an LCD panel, it is necessary to provide the above-mentioned COFs bonded to two edges thereof. Referring now to FIGS. 1A, 1B and 2, a top view of a traditional source COF tape is illustrated in FIG. 1A; a top view of a traditional gate COF tape is illustrated in FIG. 1B; and FIG. 2 is a schematic top view showing that the traditional source and gate COFs are bonded on a liquid crystal panel. Specially explaining, for conveniently describing, the above-mentioned figures are shown in simplification, wherein the number of traces is simplified, and some details which are unrelated to the explanation are also omitted.

As shown in FIG. 1A, a source COF tape 80 mainly comprises a base tape 80 aand a plurality of source COFs 81, wherein the source COFs 81 are arranged on the base tape 80 a,and by a plurality of punching processes the needed source COFs 81 can be cut from the base tape 80 aof the source COF tape 80.

As shown in FIG. 1B, a gate COF tape 90 mainly comprises a base tape 90 aand a plurality of gate COFs 91, wherein the gate COFs 91 are arranged on the base tape 90 a,and by a plurality of punching processes the needed gate COFs 91 can be cut from the base tape 90 aof the gate COF tape 90.

Moreover, as shown in FIG. 2, a liquid crystal panel 100 has a first side edge 110 and a second side edge 120 which are perpendicular to each other. By a plurality of processes of thermo-compression bonding the source COFs 81 can be bonded to the first side edge 110 of the liquid crystal panel 100, and the gate COFs 91 can be bonded to the second side edge 120 of the liquid crystal panel 100, so as to accomplish the assembly operation of the driver chips of the liquid crystal panel 100.

As described above, because the trend in developing LCD panels tends towards increasing the size of the panels, and the request for productivity is higher and higher, bonding two edges of an LCD at the same time has become a newly developing trend. However, it is necessary to provide both the above-mentioned source COFs 81 and the gate COFs 91. If the two different types of COF need to be provided simultaneously, it is necessary to prepare two sets of independent operating equipment, thus increasing the cost of the equipment.

As a result, it is necessary to provide a COF tape and a corresponding COF bonding method to solve the problems existing in the conventional technology. SUMMARY OF THE INVENTION

The present invention provides a composite packaged chip-on-film (COF) tape and a corresponding COF bonding method, which can solve the problems existing in the conventional technology: that the bonding operation of two types of COF can not be processed with a single tape and equipment at the same time.

To achieve the above object, the present invention provides a COF tape, which comprises: a base tape; a plurality of first COFs; and a plurality of second COFs; wherein the first COFs and the second COFs are arranged on the base tape.

In one embodiment of the present invention, in a cycle section of the COF tape, the number of the first COFs and the second COFs is corresponding to the number of the first COFs and the second COFs needed on a liquid crystal panel.

In one embodiment of the present invention, in the cycle section, n of the first COFs and n of the second COFs are arranged in alternation firstly, and then m of the first COFs are arranged thereafter.

providing a COF tape comprising a base tape, a plurality of first COFs and a plurality of second COFs, wherein the first COFs and the second COFs are arranged on the base tape, and then a part of the COF tape is pulled out;

providing a punching mechanism and a moving platform, wherein the punching mechanism comprises a first punching head and a second punching head which are disposed above the COF tape, and the moving platform is disposed under the corresponding COF tape, and the first punching head punches the corresponding first COFs onto the moving platform and/or the second punching head punches the corresponding second COFs onto the moving platform;

providing a liquid crystal panel having a first side edge and a second side edge perpendicular to each other; and providing a first bonding head and a second bonding head, wherein the first bonding head picks up the corresponding first COFs on the moving platform to bond onto the corresponding first side edge of the liquid crystal panel, and/or the second bonding head picks up the corresponding second COFs on the moving platform to bond onto the corresponding second side edge of the liquid crystal panel.

In one embodiment of the present invention, the steps of punching and bonding are repeated, so as to accomplish bonding operations of all of the first COFs and the second COFs of the liquid crystal panel.

In one embodiment of the present invention, in a cycle section of the COF tape, the number of the first COFs and the second COFs is correspond to the number of the first COFs and the second COFs needed on a liquid crystal panel.

In one embodiment of the present invention, in the cycle section, the number of the first COFs is n+m, and the number of the second COFs is n; and wherein n of the first COFs and n of the second COFs are arranged in alternation firstly, and then m of the first COFs are arranged thereafter.

In one embodiment of the present invention, according to an arranged situation of the first COFs and the second COFs on the COF tape, the first punching head and the second punching head can actuate alone or together, so as to punch the first COFs and/or the second COFs onto the moving platform.

In one embodiment of the present invention, according to a placed situation in which the first COFs and the second COFs are placed on the moving platform, the first bonding head and the second bonding head can actuate alone or together, so as to bond the first COFs and/or the second COFs onto the liquid crystal panel.

providing a COF tape comprising a base tape, a plurality of first COFs and a plurality of second COFs, wherein the first COFs and the second COFs are arranged on the base tape, and in a cycle section of the COF tape, the number of the first COFs is n+m, and the number of the second COFs is n; and wherein n of the first COFs and n of the second COFs are arranged in alternation firstly, and then m of the first COFs are arranged thereafter; and then the part of that n of the first COFs and n of the second COFs which are arranged on the COF tape is pulled out;

providing a punching mechanism and a moving platform, wherein the punching mechanism comprises a first punching head and a second punching head which are disposed above the COF tape, and the moving platform is disposed under the corresponding COF tape, and the first punching head punches the corresponding first COFs onto the moving platform and the second punching head punches the corresponding second COFs onto the moving platform;

providing a first bonding head and a second bonding head, wherein the first bonding head picks up the corresponding first COFs on the moving platform to bond onto the corresponding first side edge of the liquid crystal panel, and the second bonding head picks up the corresponding second COFs on the moving platform to bond onto the corresponding second side edge of the liquid crystal panel.

In one embodiment of the present invention, the foregoing steps are repeated, so as to accomplish bonding operations of the part of that n of the first COFs and n of the second COFs which are arranged on the COF tape.

picking up the corresponding first COFs on the moving platform by the first bonding head to bond onto the corresponding first side edge of the liquid crystal panel.

In one embodiment of the present invention, the foregoing steps are repeated, so as to accomplish bonding operations of the part of that m of the first COFs which are arranged on the COF tape.

Hence, the present invention provides a COF tape and a corresponding COF bonding method, wherein it can simultaneously process the bonding operations of the two types of COF by using only one COF tape and one set of equipment, so as to lower the cost and increase the productivity. DESCRIPTION OF THE DRAWINGS

FIGS. 4A-4H are schematic views showing steps of that the COF tape is bonded on a liquid crystal panel according to the first preferred embodiment of the present invention;

FIGS. 6A-6C are schematic views showing the steps in which the COF tape is bonded on a liquid crystal panel according to the second preferred embodiment of the present invention.

Referring now to FIG. 3, which is a top view of a composite packaged chip-on-film (COF) tape according to a first preferred embodiment of the present invention. Specially explaining, for conveniently describing, the figures of the present invention are shown in simplification, wherein the number of traces is simplified, and some details which are unrelated to the explanation are also omitted.

As shown in FIG. 3, a composite packaged COF tape 10 mainly comprises a base tape 10 a,a plurality of first COFs 11, and a plurality of second COFs 12, wherein the first COFs 11 and the second COFs 12 are arranged on the base tape 10 ain a certain rule. In the preferred embodiment, the first COFs 11 and the second COFs 12 are alternately arranged on the base tape 10 a. Additionally, the pulled directions of the base tape 10 aof the COF tape 10 are shown by arrows in the figures of the present invention.

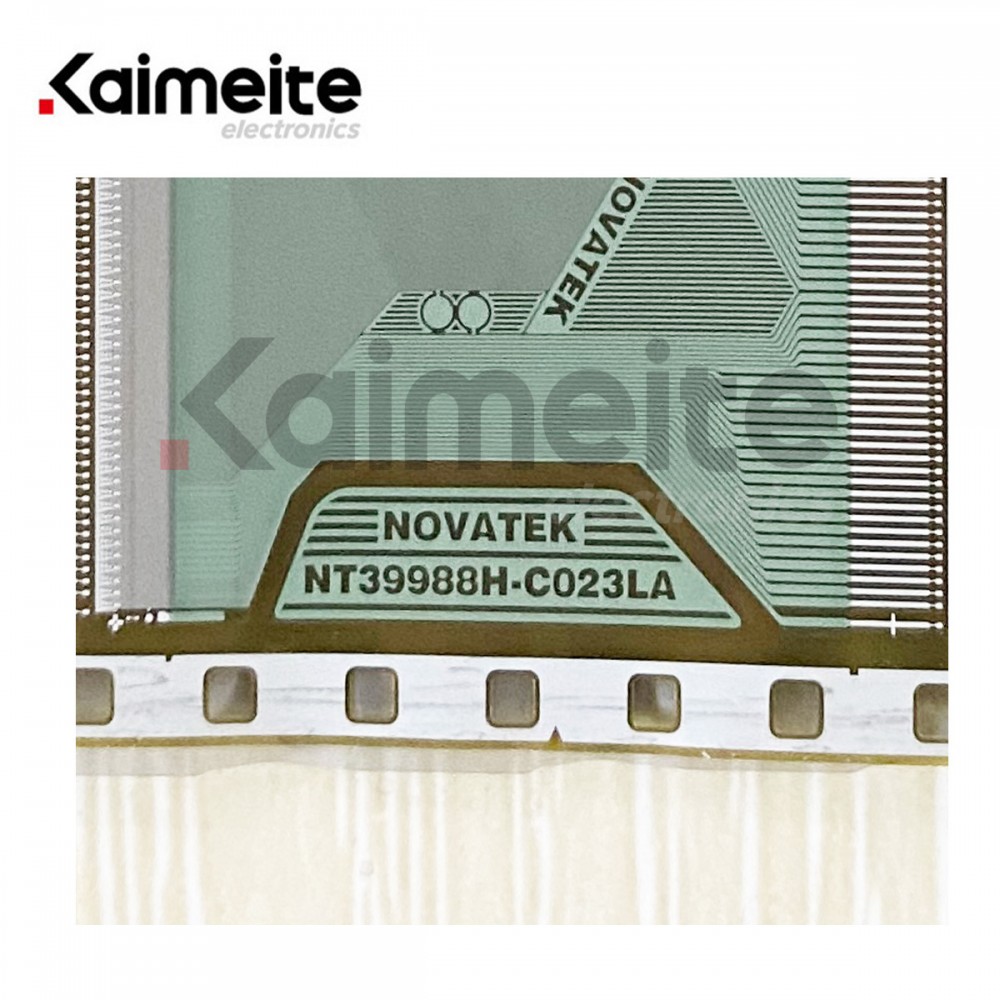

In FIG. 3, the first COF 11 can be a COF of a source driver IC, and the interior structures thereof are shown in simplification, and are not labeled. The first COF 11 comprises a flexible substrate, a driver chip, a plurality of output-side traces, and a plurality of input-side traces. The flexible substrate of the first COF 11 is provided with an output edge and an input edge. The output edge is connected with a liquid crystal panel (not shown), and the input edge is the side edge opposite to the output edge, which is connected with a circuit board (not shown).

In addition, the second COF 12 can be a COF of a gate driver IC, and the interior structures thereof are shown in simplification, and are not labeled. The second COF 12 comprises a flexible substrate, a driver chip, and a plurality of output-side traces. The flexible substrate of the second COF 12 is provided with an output edge. The output edge is connected with the liquid crystal panel (not shown).

Referring now to FIGS. 4A-4H, which are schematic views showing the steps in which the COF tape 10 is bonded on a liquid crystal panel according to the first preferred embodiment of the present invention. A COF bonding operation of the present invention, for example, is provided with an anisotropic conductive film (ACF) between the output edge of the COFs 11, 12 and contacts of the edge of the liquid crystal panel, and then the contacts of the output edge are electronically connected to the contacts of the liquid crystal panel by heating and pressing on the output edge, so as to accomplish a bonding action with the liquid crystal panel. The above-mentioned bonding method is also called thermo-compression bonding. However, the method for assembling COF onto the liquid crystal panel is not limited in the present invention. Other methods for assembling COF onto the liquid crystal panel can be adopted in the present invention.

The steps in which the COF tape 10 bonded onto a liquid crystal panel according to the first preferred embodiment of the present invention are described as follows:

Firstly, as shown in FIG. 4A, a COF tape 10 is provided, which comprises a base tape 10 a,a plurality of first COFs 11, and a plurality of second COFs 12, wherein the first COFs 11 and the second COFs 12 are alternately arranged on the base tape 10 a,and then part of the COF tape 10 is pulled out.

Then, as shown in FIGS. 4A and 4B, a punching mechanism 20 and a moving platform 30 are provided. The punching mechanism 20 comprises a first punching head 21 and a second punching head 22 which are disposed above the COF tape 10; and the moving platform 30 is correspondingly disposed under the COF tape 10. Then, as shown in FIG. 4B, the first punching head 21 punches the corresponding first COF 11 thereunder onto the moving platform 30, and the second punching head 22 punches the corresponding second COF 12 thereunder onto the moving platform 30 at the same time.

Then, as shown in FIG. 4C, the moving platform 30 is moved out to a certain position, which is preferably close to the next operating area. Then, as shown in FIGS. 4D and 4E, a liquid crystal panel 100 is provided. The liquid crystal panel 100 has a first side edge 110 and a second side edge 120 which are perpendicular to each other. Furthermore, a first bonding head 41 is provided. The first bonding head 41 picks up the corresponding first COF 11 on the moving platform 30 (as shown in FIG. 4D), and the first bonding head 41 bonds the corresponding first COF 11 onto the first side edge 110 of the liquid crystal panel 100 (as shown in FIG. 4E). Then, as shown in FIGS. 4F and 4G, a second bonding head 42 is provided. The second bonding head 42 picks up the corresponding second COF 12 on the moving platform 30 (as shown in FIG. 4F), and the second bonding head 42 bonds the corresponding second COF 12 onto the second side edge 120 of the liquid crystal panel 100 (as shown in FIG. 4G).

Lastly, as shown in FIG. 4H, the above-mentioned punching, moving and bonding steps can be repeated. In the preferred embodiment, because the numbers of the first COFs 11 and the second COFs 12 are the same, by repeating the above-mentioned punching, moving and bonding steps, the bonding operation of the other first COFs 11 and second COFs 12 onto the liquid crystal panel 100 is accomplished.

As described above, the COF tape 10 according to the first preferred embodiment of the present invention is a composite packaged COF tape 10, wherein the first COFs 11 and the second COFs 12 therein are arranged alternately on the base tape 10 a;the first COFs 11 and the second COFs 12 are punched onto the moving platform 30 by the punching mechanism 20; and the first COFs 11 and the second COFs 12 are bonded onto the two side edges of the liquid crystal panel 100 by the first bonding head 41 and the second bonding head 42 respectively. Therefore, the present invention can save the purchase cost of the COF tapes and the cost of related equipment. That is to say, it can simultaneously process the bonding operations of the two types of COF by using only one COF tape and one set of equipment, thus lowering the cost and increasing the productivity.

However, in a cycle section of the COF tape 10, the numbers of the first COFs 11 and the second COFs 12 thereof correspond to the numbers of the first COFs 11 and the second COFs 12 needed on the liquid crystal panel 100. Therefore, when the numbers of the first COFs 11 and the second COFs 12 needed on the liquid crystal panel 100 are different, it is necessary to adjust the numbers of the first COFs 11 and the second COFs 12 on a cycle section of the COF tape 10, their arranging order and following punching-bonding processes.

Referring now to FIG. 5, which is a top view of a composite packaged COF tape according to a second preferred embodiment of the present invention. The COF tape 10′ of the second embodiment is similar to the COF tape 10 of the first embodiment, thus using similar terms and numerals to the foregoing embodiment, the difference of this embodiment being that: in the COF tape 10′ of the second embodiment, the number of the first COFs 11 is greater than the number of the second COFs 12. For example, the number of the first COFs 11 is n+m; the number of the second COFs 12 is n. Therefore, there are two sections in a cycle section of the embodiment: in a first section, the numbers of the first COFs 11 and the second COFs 12 are the same, so that the first COFs 11 and the second COFs 12 are arranged alternately on the base tape 10 a(such as in the first preferred embodiment of the present invention); but in a second section, there are only m of the first COFs 11 on the COF tape 10′, that is, there are m of the first COFs 11 continually arranged on the COF tape 10′ after last second COFs 12. Hence, the COF tape 10′ of the second embodiment can insure that: in a cycle section thereof, the numbers of the first COFs 11 and the second COFs 12 exactly the same as the number of the first COFs 11 and the second COFs 12 needed on the liquid crystal panel 100′.

Referring now to FIGS. 6A-6C, which are schematic views showing the steps in which the COF tape 10′ is bonded on a liquid crystal panel according to the second preferred embodiment of the present invention. The steps in which the COF tape 10 is bonded onto a liquid crystal panel according to the second preferred embodiment of the present invention can be divided in two stages: in the first stage, because the numbers of the first COFs 11 and the second COFs 12 are the same, the same steps as that of FIGS. 4A-4F are adopted; but when the first stage is finished, it is necessary to process a bonding for the rest the first COFs 11 alone.

As shown in FIG. 6A, the first punching head 21 punches the first COF 11 thereunder onto the moving platform 30. At this moment, it is unnecessary to consider the second punching head 22 as corresponding to any of the second COF 12, and it does not process a punching action. Then, the moving platform 30 is moved out to a certain position.

As shown in FIG. 6B, the first bonding head 41 picks up the first COF 11 on the moving platform 30, and bonds the first COF 11 onto the first side edge 110′ of the liquid crystal panel 100′.

The above-mentioned punch-bonding steps can be repeated, until such time as the bonding operation of the first COFs 11 onto the first side edge 110′ of the liquid crystal panel 100′ is completed (as shown in FIG. 6).

The rule of how the first COFs 11 and the second COFs 12 are arranged on the COF tape 10 is not limited in the present invention. However, no matter what the arranging rule is, the corresponding punch-bonding steps are necessary. Moreover, if the interference between the first bonding head 41 and the second bonding head 42 on the moving platform 30 can be avoided, the first bonding head 41 and the second bonding head 42 can further take and bond the first COFs 11 and the second COFs 12 simultaneously.

That is to say, in the present invention, according to the situation in which the first COFs 11 and the second COFs 12 are arranged on the COF tape 10, 10′, the first punching head 21 and the second punching head 22 of the punching mechanism 20 can actuate alone or together, and punch the first COFs 11 and/or the second COFs 12 onto the moving platform 30. According to the situation in which the first COFs 11 and the second COFs 12 are placed on the moving platform 30, the first bonding head 41 and the second bonding head 42 can actuate alone or together.

In another words, in the present invention, the first punching head 21 punches the corresponding first COFs 11 onto the moving platform 30 and/or the second punching head 22 punches the corresponding second COFs 12 onto the moving platform 30; and the first bonding head 41 picks up the corresponding first COFs 11 on the moving platform 30 to bond onto the corresponding first side edge 110 of the liquid crystal panel 100, and/or the second bonding head 42 picks up the corresponding second COFs 12 on the moving platform 30 to bond onto the corresponding second side edge 120 of the liquid crystal panel 100.

As described above, a single traditional COF tape only provides one type of COF. If two different types of COF need to be provided simultaneously, it is necessary to prepare two sets of independent operating equipment, thus increasing the cost of the equipment. In the present invention, by providing of a composite packaged COF tape 10 which comprises a plurality of first COFs 11 and a plurality of second COFs 12 arranged alternately on the base tape 10 a, and by providing of a punching mechanism 20, a moving platform 30, and bonding heads 41 and 42, the first COFs 11 and the second COFs 12 are respectively bonded onto two side edges of a liquid crystal panel 100, and the action is repeated until the bonding operation of all of the first COFs 11 and the second COFs 12 of the liquid crystal panel 100 is completed. Therefore, the present invention can save the purchase cost of the COF tapes and the cost of related equipment, and it can simultaneously process the bonding operations of the two types of COF by using only one COF tape and one set of equipment, thus lowering the cost and increasing the productivity.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

TAB COF IC supplier in India. Panel Repair Factory is the biggest COF IC Dealer worldwide. We have the largest COF IC stock in the world with around 1500 different COF IC, COF IC supplier in Delhi, COF IC Dealer in India

Panel repair factory is one of the top COF IC suppliers. COF stands for Chip on film. Each of them comes with a wide range of features and specifications. The COF IC supplied by panel repair factory is capable of receiving Signals and digital data and in turn, reversing it into analogue signals which are then sent to the receiver device. The COF IC is commonly used in LCD TVs and O LED devices. It is capable of high accuracy and ensures panel pixel uniformity. It is highly useful in the interconnection of the LCD driver ICs. It comes with sufficient film thickness that is not only flexible but can be easily used for any purpose. In addition to this, the panel repair factory COF IC possesses pretest capability which makes it in high demand for product fabrication applications. It combines the power of interconnection Technology that covers all the needs of LCD panel applications that feature high resolution. It is suitable for use with all electronic products whether they are lightweight or heavyweight.With it, you can easily package IC chips of any dimension. It is also capable of packing multiple chips and passive components within its circuit films.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Established in 1998, Winstar Display Co., Ltd. is a reliable LCD Display Module Manufacturer and LCD Panel Supplier. Winstar has development of high-quality display module products. We operate worldwide, configure, service products, and also provide logistics support to deliver products and services competitively. We provide LCM Modules including monochrome TN/STN/FSTN LCM, COG LCD, TFT LCM / TFT panels, FSC-LCD, graphic LCM, character LCD displays, OLED display modules (PMOLED), custom LCD displays, OLED and LCD panel.

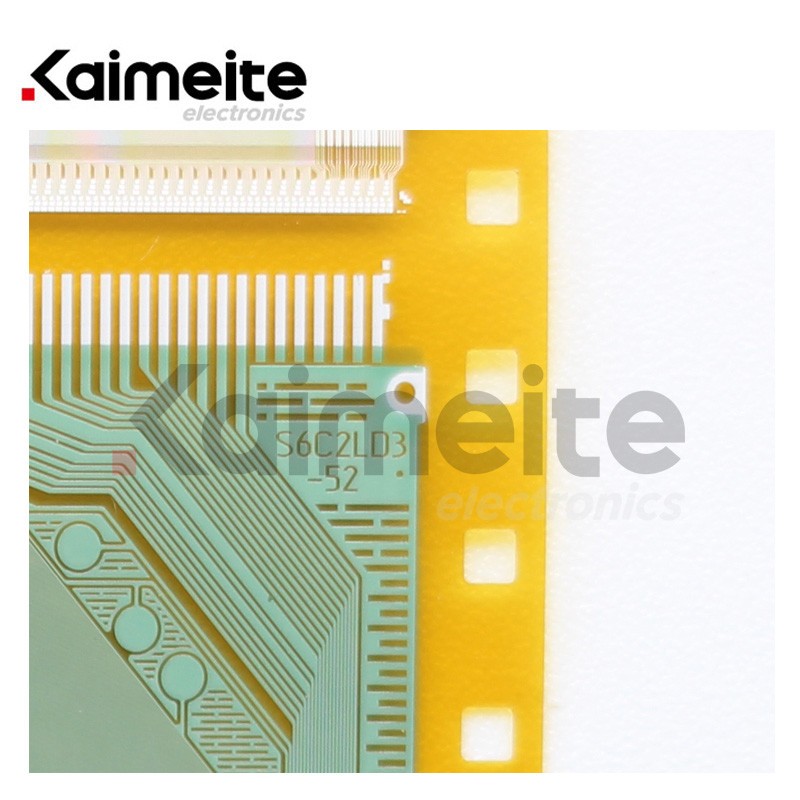

The S6C2LD3-52,from CHIMEI,is LCD driver IC-COF IC TAB.what we offer have competitive price in the global market,which are in original and new parts.If you would like to know more about the products or apply a lower price, please contact us through the “online chat” or send a quote to us!

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey