hd tft display vs amoled quotation

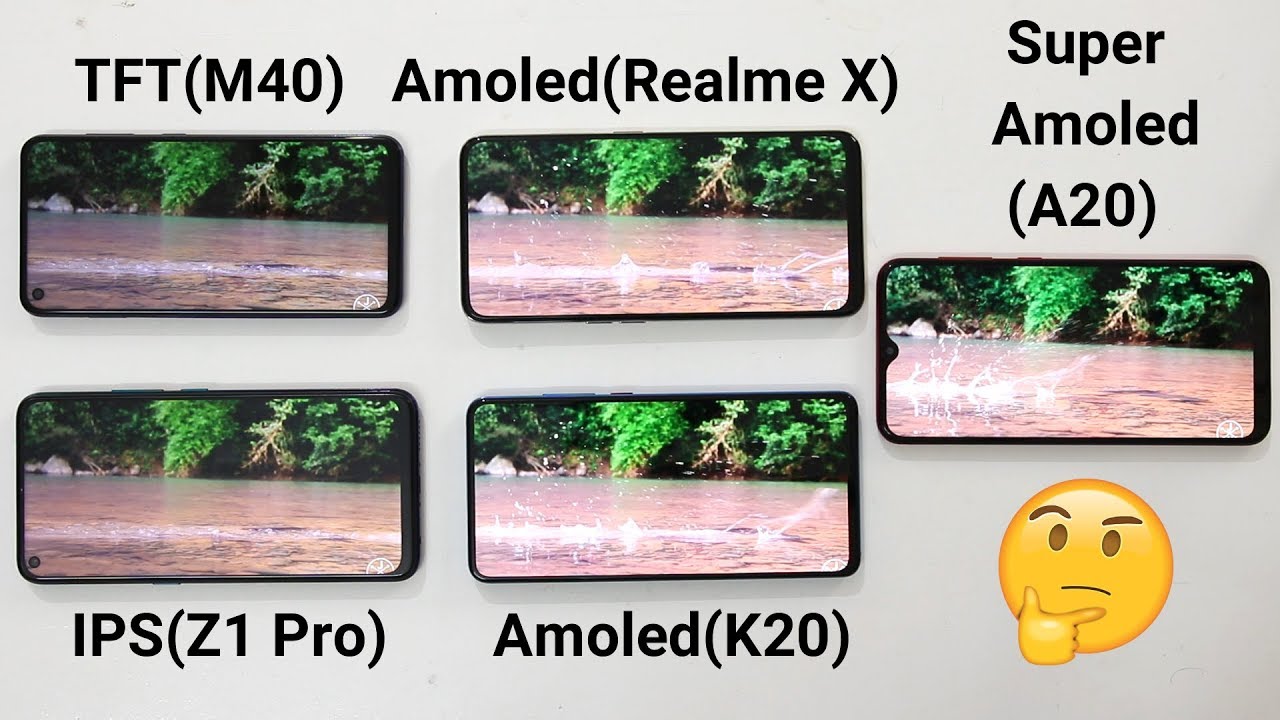

AMOLED and TFT are two types of display technology used in smartphones. AMOLED (active-matrix organic light-emitting diode) displays are made up of tiny organic light-emitting diodes, while TFT (Thin-Film Transistor) displays use inorganic thin-film transistors.

AMOLEDs are made from organic materials that emit light when an electric current is passed through them, while TFTs use a matrix of tiny transistors to control the flow of electricity to the display.

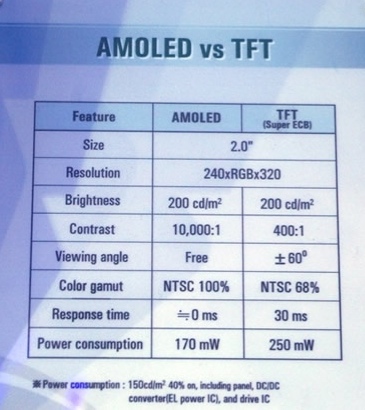

Refresh Rate: Another key difference between AMOLED and TFT displays is the refresh rate. The refresh rate is how often the image on the screen is updated. AMOLED screens have a higher refresh rate than TFT screens, which means that they can display images more quickly and smoothly.

Response Time: The response time is how long it takes for the pixels to change from one colour to another. AMOLED screens have a shorter response time than TFT screens..

Colour Accuracy/Display Quality: AMOLED screens are more accurate when it comes to displaying colours. This is because each pixel on an AMOLED screen emits its own light, which means that the colours are more pure and true to life. TFT screens, on the other hand, use a backlight to illuminate the pixels, which can cause the colours to appear washed out or less vibrant.

Viewing Angle: The viewing angle is the angle at which you can see the screen. AMOLED screens have a wider viewing angle than TFT screens, which means that you can see the screen from more angles without the colours looking distorted.

Power Consumption: One of the main advantages of AMOLED displays is that they consume less power than TFT displays. This is because the pixels on an AMOLED screen only light up when they need to, while the pixels on a TFT screen are always illuminated by the backlight.

Production Cost: AMOLED screens are more expensive to produce than TFT screens. This is because the manufacturing process for AMOLED screens is more complex, and the materials used are more expensive.

Availability: TFT screens are more widely available than AMOLED screens and have been around for longer. They are typically used in a variety of devices, ranging from phones to TVs.

Usage: AMOLED screens are typically used in devices where power consumption is a concern, such as phones and wearable devices. TFT screens are more commonly used in devices where image quality is a higher priority, such as TVs and monitors.

AMOLED and TFT are two different types of display technology. AMOLED displays are typically brighter and more vibrant, but they are more expensive to produce. TFT displays are cheaper to produce, but they are not as bright or power efficient as AMOLED displays.

The display technology that is best for you will depend on your needs and preferences. If you need a screen that is bright and vibrant, then an AMOLED display is a good choice. If you need a screen that is cheaper to produce, then a TFT display is a good choice. However, if you’re worried about image retention, then TFT may be a better option.

Nauticomp Inc.provides world-class fully customizable touchscreen displays for commercial and industrial settings. With features like sunlight readability, brightness adjustability, infrared lighting, full backlighting, all-weather capabilities, etc., our displays are second to none. Contact us today to learn more.

TFT is an abbreviation for Thin Film Transistor, a flat panel display used to improve the operation and utility of LCD screens. In order to portray an appearance to the audience, a liquid crystal display (LCD) utilizes a crystalline-filled fluid to modify rear lighting polarized origin through the use of an electromagnetic force among two relatively thin metal wires such as indium oxide (ITO). However, color TFT displays are associated with this method, which can be employed in both divided and pixelated display systems.

With motion pictures displayed on an LCD, the intrinsic sluggish rate of increase between liquid phases over a significant number of pixel components can be an issue due to capacitance impacts, which can create a blurring of the visuals. Placing a high-velocity LCD control device inside the formation of a thin-film transistor immediately next to the cell component just on a glass screen, the issue of LCD picture speed may be substantially improved, and image blur can be eliminated for all useful purposes entirely.

Organic light-emitting diodes (AMOLEDs) are a type of flat light-emitting advanced technologies that are created by interspersing a succession of organic thin sheets over two conducting conductors. An electrical charge causes a brilliant light to be produced when the current flows. AMOLED displays are light-emitting screens that do not require a backlight, making them thinner and more energy-efficient than liquid crystal displays (LCDs) (which will need a white backlight).

AMOLED displays are not only thin and fuel-intensive, but they also deliver the highest image quality available, so they can be made translucent, elastic, bendable, or even rollable and stretchy in the future, allowing for a variety of applications. AMOLEDs are a revolutionary technology in terms of display devices! It is possible to create an AMOLED by sandwiching a sequence of thin films across phase conductors. Electric charge causes a brilliant light to be emitted when the current flows through the coil.

The color display is fantastic. Color intensity, sharpness, and luminance settings that are second to none and can be customized to meet the needs of any application.

Half-Life has been expanded. TFT displays have a far longer half-life than its LED equivalents, and they are available in a number of sizes, which might have an effect on the device"s half-life based on the phone"s usage as well as other variables. Touch panels for TFT screens can be either resistant or capacitance in nature.

Due to the apparent glass panels, there is limited functionality. For instance, there are ineffective for outdoor use because the glass can display glares from its natural lighting)

They rely on backlight to give illumination rather than generating their own light. Hence they require constructed light-creating diodes (LEDs) in their backlit display framework to ensure enough brightness.

Backlighting is unnecessary for AMOLEDs. LCDs produce images by selectively blocking parts of the illumination, whereas AMOLEDs produce light. AMOLEDs utilize less energy than LCDs since they don"t need backlighting. This is critical for battery-powered devices such as phones.

While AMOLED light-emitting sheets are lightweight, the substrate can also be elastic rather than stiff. AMOLED films are not limited to glass-like LEDs and LCDs.

AMOLEDs offer 170-degree ranges of vision. LCDs operate by obscuring the light. Hence they have intrinsic viewing obstacles. In addition, AMOLEDs have a substantially wider viewing spectrum.

AMOLEDs outperform LEDs. Since AMOLED organic coatings are less than LED inorganic crystal levels, AMOLED conducting and particle emitters layers can just be multi-layered. Also, LEDs and LCDs need glass backing, which absorbs light. AMOLEDs don"t need it.

AMOLEDs seem to be simpler to implement and larger. AMOLEDs are constructed of polymers and may be produced into big sheets. It takes a lot of extra liquid crystals to build and set down.

While red and green AMOLED sheets have a greater lifespan (46,000 to 230,000 hours), azure compounds have significantly shorter longevity (up to roughly 14,000 hours).

Due to the fact that AMOLED displays inherently emit illumination, they do not need a backlight when used on a monitor screen. Conversely, LCDs require backlights since the liquid crystals themselves are incapable of producing light under their own. Direct light emission from AMOLED displays also allows for the developing of lightweight display devices than others using TFT LCDs.

LCD displays have a higher brightness than AMOLED panels. This is owing to the LCD"s usage of led backlight, which may provide a brilliant illumination of the entire display. Despite the fact that AMOLEDs produce high levels of brilliance from their illumination, they will never be able to match the intensity of LCD lighting.

LCD screens use less power than AMOLED displays, which provides a slight advantage. The amount of energy consumed by AMOLED displays is dependent on the intensity of the screen. Lowered luminance results in lower energy usage, however, it might not be the best solution because the contrast would suffer as a result of the decreased brightness. In some situations, such as when to use an AMOLED device in direct sunlight, it is not an optimal situation.

However, the backlit keys of TFT displays account for the majority of their power usage. TFT screens" efficiency is considerably improved when the backlight is set to a lesser brightness level than the default setting. For example, replacing the light of an LCD TV with just an Led flash will have no effect on the image quality, but will result in lower power usage than replacing the light of an AMOLED TV.

With the exception of phones, numerous other technologies make use of displays to allow customers to engage in direct communication with them. To determine whether or not TFT LCD will be able to withstand the development of AMOLED innovation, we should first review the benefits of LCD technology. The backlighting quality ensures that whites are strong and brightness is superb but will deplete a battery much more quickly than just an AMOLED display. Furthermore, the cost of LCD screens is a considerable consideration. In addition to being less expensive and more easily accessible, they are produced in standard industry sizes, allowing them to be purchased for innovative products with relative ease.

Tried and trusted TFT technology works by controlling brightness in red, green and blue sub-pixels through transistors for each pixel on the screen. The pixels themselves do not produce light; instead, the screen uses a backlight for illumination.

By contrast the Active Matrix OLED (AMOLED) display requires no backlight and can light up or turn off each of their pixels independently. As the name suggests, they are made of organic material.

An AMOLED display has many other benefits which make it a superior looking display including exceptional vieiwng angles and a display that looks practically black when it is switched off.

So, why use a TFT display? Well, it is a mature technology meaning the manufacturing processes are efficient, yields high and cost much lower than AMOLED.

TFT displays also have a much longer lifespan than AMOLED displays and are available in a far greater range of standard sizes, which can be cut down to fit a space restricted enclosure for a relatively low cost adder.

Which type of display you choose really depends on your application, environment and users, so why not get in touch with us today to discuss your requirements.

When we purchase a new smartphone we go through a list of specifications that includes the processor, software, cameras, display type, battery, etc. The display of the smartphone is something which has always been a concern for people. And smartphone technology has advanced so much in the past decade that you get several display technology options to choose from.

Today, a smartphone is not just a means to send and receive calls and texts. It has become a general necessity, so choosing the right technology should be your main priority. Coming back to displays, as we said there are plenty of display types available right now.

Two of the main contenders for display technologies that are widely available are AMOLED and LCD. Here in this article, we will be comprising AMOLED vs LCD and find out which one is better for you.

Starting with the AMOLED first, it is a part of the OLED display technology but with some more advanced features. To completely know about it must understand its all three components. The first one is LED, “Light Emitting Diode”. Then we have “O” which stands for organic and makes the OLED.

It actually means that organic material is placed with two conductors in each LED, which helps to produce the light. And the “AM” in AMOLED means Active Matrix, it has the capability to increase the quality of a pixel.

The AMOLED display is similar to the OLED in various factors like high brightness and sharpness, better battery life, colour reproduction, etc. AMOLED display also has a thin film transistor, “TFT” that is attached to each LED with a capacitor.

TFT helps to operate all the pixels in an AMOLED display. This display might have a lot of positives but there are a few negatives too let’s point both of them out.

A major issue with these displays is of burning of pixels. After showing a specific image or colour for a longer period of time, the pixel can get burned. And if there is a problem with a single pixel it will affect the entire display.

Low outdoor visibility, usually the AMOLED Displays are quote not bright in direct sunlight and outdoor readability could be a problem for some devices but average screen brightness.

The LCD stands for “Liquid Crystal Display”, and this display produces colours a lot differently than AMOLED. LCD display uses a dedicated backlight for the light source rather than using individual LED components.

The LCD displays function pretty simply, a series of thin films, transparent mirrors, and some white LED lights that distributes lights across the back of the display.

As we have mentioned, an LCD display always requires a backlight and also a colour filter. The backlight must have to pass through a thin film transistor matrix and a polarizer. So, when you see it, the whole screen will be lit and only a fraction of light gets through. This is the key difference comparing AMOLED vs LCD and this is what differentiates these two display technologies.

The LCD displays are cheaper compared to the AMOLED as there is only one source of light which makes it easier to produce. Most budget smartphones also use LCD displays.

LCD displays have bright whites, the backlight emits lots of light through pixels which makes it easy to read in outdoors. It also shows the “Accurate True to Life” colours, which means it has the colours that reflect the objects of the real world more accurately than others.

LCDs also offer the best viewing angle. Although it may depend on the smartphone you have. But most high-quality LCD displays support great viewing angles without any colour distortion or colour shifting.

The LCD displays can never show the deep blacks like AMOLED. Due to the single backlight, it always has to illuminate the screen making it impossible to show the deep blacks.

The LCDs are also thicker than other displays because of the backlight as it needs more volume. So, LCD smartphones are mostly thicker than AMOLED ones.

Both of these display technologies have their own Pros and Cons. Taking them aside everything ends up with the user preferences as people might have different preferences among different colours and contrast profiles. However, a few factors might help you to decide which one fits perfectly for you.

Let’s start with the pricing. Most AMOLED display smartphones always cost more than an LCD smartphone. Although the trend is changing a bit. But still, if you want to get a good quality AMOLED display you have to go for the flagship devices.

The colors are also very sharp and vibrant with the AMOLED displays. And they look much better than any LCD display. The brightness is something where LCDs stood ahead of the AMOLED display. So using an LCD display outdoors gives much better results.

The last thing is battery consumption, and there is no one near the AMOLED displays in terms of battery. As of now, all smartphones feature a Dark Mode and most of the apps and UI are dark black with a black background. This dark UI on smartphones doesn’t require any other light, it gives the AMOLED displays a boost in battery performance.

Looking at all these factors and comparing AMOLED vs LCD displays, the AMOLED displays are certainly better than the LCDs. Also, the big display OEMs, like Samsung and LG are focusing more the OLED technologies for their future projects. So, it makes sense to look out for AMOLED displays. That being said, if we see further enhancements in the LCD technology in terms of battery efficiency and more, there is no point to cancel them at this moment.

New Delhi: The technology used in mobile displays in the modern day smartphones has progressed significantly. In the era of touchscreen smartphones, the display technology has become one of its primary selling points, and certainly its most unique feature. Not only we want the touch screens to offer crisp text, vibrant images, blur-free video and enough brightness, we want them at low cost too.

For instance, HTC One uses Super LCD3 tech, in its 4.7in screen which gives a resolution of 1920 x 1080 pixels, with pixel density of 469 pixels per inch (ppi). This results in super display in terms of crispness and colour reproduction. HTC says the SLCD technology gives the phone better power management, improved viewing angles and is easier to produce.

The Thin film transistor liquid crystal display (TFT LCD) technology is the most common display technology used in mobile phones. A variant of liquid crystal display (LCD), the technology uses TFT technology to enhance image quality. It offers better image quality and higher resolutions as compared to earlier generation LCD displays.

IPS LCD Stands for In Plane Switching liquid Crystal Display. This technology offers better display quality as compared to the TFT-LCD display. The good part about IPS LCD is that it offers better viewing angles and consumes less power. Due to higher costs, it is found only on high-end smartphones. Apple uses a high resolution (640x960 pixels) version of IPS LCD in its iPhone 4, which is also called Retina Display.

Organic Light Emitting Diode (OLED) display technology is much better as compared to the LCD display technology because of its excellent colour reproduction, faster response times, wider viewing angles, higher brightness and extremely light weight designs.

Since these display forms are easier to produce, they can be made to larger sizes. Because OLEDs are essentially plastics, they can be made into large, thin sheets.

AMOLED stands for Active Matrix Organic Light Emitting Diode. A step ahead of OLED screens, the AMOLED screens can control each pixel individuality while maintaining the properties of an OLED panel. AMOLED screens use a different subpixel arrangement which can reduce the image quality a bit.

AMOLED screens have all the attributes of an OLED display like excellent colour reproduction, faster response times, wider viewing angles, higher brightness and extremely light weight designs.

Super AMOLED display technology is an advanced version of AMOLED display. Samsung uses this term for the AMOLED panels that they develop. Super AMOLED screens are built with capacitive touch sensors on the display itself. Super AMOLED display is much more responsive than an AMOLED display. Samsung top-of-the-line Galaxy SII comes engineered with Super AMOLED display technology. Samsung has already took it"s SMOLED screen to next levels by developing Super AMOLED+, HD Super AMOLED+ and FHD Super AMOLED+ screens.

It is a name given by Apple to the high-resolution screen technology introduced on the iPhone 4 in June 2010. Something is a Retina Display when it offers a density of pixels above 163 pixels per inch. The company calls it the Retina display because its pixels cannot be individually identified by a human eye, thus rendering a super sharp display, more crisp text and more clear pictures.

Retina Display is designed to smooth the jagged edges of pixels are provide a higher-quality image than previously available on mobile devices. Apple claims that its resolution is so good that it makes it impossible for the human eye to distinguish individual pixels. Its effects shows up in text, images and videos.

Color boost is simply Moto"s marketing term for their new display. Although it now uses LCD displays, the company fine-tuned its panels to match the saturation of OLED displays while maintaining the higher performance of LCD. It"s somewhere in the middle ground.

Thanks for the display technology development, we have a lot of display choices for our smartphones, media players, TVs, laptops, tablets, digital cameras, and other such gadgets. The most display technologies we hear are LCD, TFT, OLED, LED, QLED, QNED, MicroLED, Mini LED etc. The following, we will focus on two of the most popular display technologies in the market: TFT Displays and Super AMOLED Displays.

TFT means Thin-Film Transistor. TFT is the variant of Liquid Crystal Displays (LCDs). There are several types of TFT displays: TN (Twisted Nematic) based TFT display, IPS (In-Plane Switching) displays. As the former can’t compete with Super AMOLED in display quality, we will mainly focus on using IPS TFT displays.

OLED means Organic Light-Emitting Diode. There are also several types of OLED, PMOLED (Passive Matrix Organic Light-Emitting Diode) and AMOLED (Active Matrix Organic Light-Emitting Diode). It is the same reason that PMOLED can’t compete with IPS TFT displays. We pick the best in OLED displays: Super AMOLED to compete with the LCD best: IPS TFT Display.

If you have any questions about Orient Display displays and touch panels. Please feel free to contact: Sales Inquiries, Customer Service or Technical Support.

Steven Van Slyke and Ching Wan Tang pioneered the organic OLED at Eastman Kodak in 1979. The first OLED product was a display for a car stereo, commercialized by Pioneer in 1997. Kodak’s EasyShare LS633 digital camera, introduced in 2003, was the first consumer electronic product incorporating a full-color OLED display. The first television featuring an OLED display, produced by Sony, entered the market in 2008. Today, Samsung uses OLEDs in all of its smartphones, and LG manufactures large OLED screens for premium TVs. Other companies currently incorporating OLED technology include Apple, Google, Facebook, Motorola, Sony, HP, Panasonic, Konica, Lenovo, Huawei, BOE, Philips and Osram. The OLED display market is expected to grow to $57 billion in 2026.

AMOLED (Active Matrix Organic Light Emitting Diode) is a type of OLED display device technology. OLED is a type of display technology in which organic material compounds form the electroluminescent material, and active matrix is the technology behind the addressing of individual pixels.

An AMOLED display consists of an active matrix of OLED pixels generating light (luminescence) upon electrical activation that have been deposited or integrated onto a thin-film transistor (TFT) array, which functions as a series of switches to control the current flowing to each individual pixel.

Typically, this continuous current flow is controlled by at least two TFTs at each pixel (to trigger the luminescence), with one TFT to start and stop the charging of a storage capacitor and the second to provide a voltage source at the level needed to create a constant current to the pixel, thereby eliminating the need for the very high currents required for PMOLED.

TFT backplane technology is crucial in the fabrication of AMOLED displays. In AMOLEDs, the two primary TFT backplane technologies, polycrystalline silicon (poly-Si) and amorphous silicon (a-Si), are currently used offering the potential for directly fabricating the active-matrix backplanes at low temperatures (below 150 °C) onto flexible plastic substrates for producing flexible AMOLED displays. Brightness of AMOLED is determined by the strength of the electron current. The colors are controlled by the red, green and blue light emitting diodes. It is easier to understand by thinking of each pixel is independently colored, mini-LED.

IPS technology is like an improvement on the traditional TFT LCD display module in the sense that it has the same basic structure, but with more enhanced features and more widespread usability compared with the older generation of TN type TFT screen (normally used for low-cost computer monitors). Actually, it is called super TFT. IPS LCD display consists of the following high-end features. It has much wider viewing angles, more consistent, better color in all viewing directions, it has higher contrast, faster response time. But IPS screens are not perfect as their higher manufacturing cost compared with TN TFT LCD.

Utilizing an electrical charge that causes the liquid crystal material to change their molecular structure allowing various wavelengths of backlight to “pass-through”. The active matrix of the TFT display is in constant flux and changes or refreshes rapidly depending upon the incoming signal from the control device.

IPS (In-Plane Switching) lcd is still a type of TFT LCD, IPS TFT is also called SFT LCD (supper fine tft ),different to regular tft in TN (Twisted Nematic) mode, theIPS LCD liquid crystal elements inside the tft lcd cell, they are arrayed in plane inside the lcd cell when power off, so the light can not transmit it via theIPS lcdwhen power off, When power on, the liquid crystal elements inside the IPS tft would switch in a small angle, then the light would go through the IPS lcd display, then the display on since light go through the IPS display, the switching angle is related to the input power, the switch angle is related to the input power value of IPS LCD, the more switch angle, the more light would transmit the IPS LCD, we call it negative display mode.

The regular tft lcd, it is a-si TN (Twisted Nematic) tft lcd, its liquid crystal elements are arrayed in vertical type, the light could transmit the regularTFT LCDwhen power off. When power on, the liquid crystal twist in some angle, then it block the light transmit the tft lcd, then make the display elements display on by this way, the liquid crystal twist angle is also related to the input power, the more twist angle, the more light would be blocked by the tft lcd, it is tft lcd working mode.

A TFT lcd display is vivid and colorful than a common monochrome lcd display. TFT refreshes more quickly response than a monochrome LCD display and shows motion more smoothly. TFT displays use more electricity in driving than monochrome LCD screens, so they not only cost more in the first place, but they are also more expensive to drive tft lcd screen.The two most common types of TFT LCDs are IPS and TN displays.

The Xiaomi Mi 10T and the Mi 10T Pro are Xiaomi"s latest flagship-killer grade smartphones. By nomenclature, they succeed in the Mi 9T and the Mi 9T Pro, respectively. The Mi 10T duo gets a range of updates over the Mi 9T — rebranded Redmi K20 series — including the newer, more advanced, and 5G-enabled Qualcomm Snapdragon 865 mobile platform, a 20% larger battery, improved haptics, cameras with up to 108MP resolution, etc. But before you notice any of that adding vigor to the action, the first and the most glaring feature you"re bound to notice on the Mi 10T or the Mi 10T Pro is the new, larger, and smoother hole-punch display used on these devices.

For Mi 10T and the Mi 10T, Xiaomi has chosen a 144Hz LCD that supports dynamic refresh rate switching. Their choice seemingly defies the common belief that AMOLED displays are better than LCDs, especially when we speak of flagships and flagship killers. Xiaomi challenges the notions about AMOLEDs" qualitative superiority with claims about having tuned the color profiles of the display incisively. To justify these claims, they sling catchphrases such as DCI-P3, AdaptiveSync, and more, and we"ll be addressing the relevance of each of those in the sections below.

I must remark that the vision and the perception of quality, as well as the color of a display are subjective. Therefore, instead of critically assessing the Mi 10T Pro"s display in isolation, I will also be relying majorly on comparing with the Redmi K20 Pro (which is rebranded as the Mi 9T Pro for the European market). For tangible comparison and conclusions, I"m using the free version of the Display Tester app that features a horde of qualitative tests to analyze the display on any Android device.

Meanwhile, I must also point out while setting up the Mi 10T Pro initially, the display felt as good to me as an AMOLED display in terms of color accuracy and saturation despite being aware that it is an LCD. Irrespective of that, I have taken ample precautions to prevent my first impressions from influencing my analysis of the display.

LCD and AMOLED displays operate quite differently. An LCD uses a backlight as its only source of light compared to an AMOLED display on which individual pixel lights up to show different colors. An LCD comprises many more layers than an AMOLED, and that typically leads to LCDs having lower brightness than OLED or AMOLED displays.

As per Xiaomi"s official listing, the Mi 10T series devices have a typical brightness of 450nits, which can peak to up to 600 nits with the sunlight mode. On the other hand, the Mi 9T"s AMOLED display is officially claimed to have a typical brightness of 430nits, peaking to 650nits under strong sunlight.

Although both displays are fairly bright and legible — even under a strong light source, the Mi 9T Pro"s AMOLED display feels much brighter than the Mi 10T Pro"s LCD. To quantify this, I used the Lux Light Meter Free app on the Samsung Galaxy Note 20 Ultra (which is one of the finest smartphones I"ve used lately, as mentioned in my review) and noted the brightness values (in lux) by holding the Note 20 Ultra"s ambient sensor against the display of both the smartphones. For more accuracy, I took three readings per device and then estimated the mean value. Besides, I also took the readings from a distance of ~5cm from the smartphones in a pitch dark room for an affirmative conclusion.

In the first test, the app measures the brightness of the Mi 10T Pro"s display to be 561lux (179nits). The Mi 9T Pro, on the other hand, yields a much higher brightness of 1142lux (364nits). Of course, since the values are measured using a smartphone"s ambient light sensor, they cannot be treated as absolute values. However, we can — very conveniently — use them for comparison. Based on these values, the Mi 10T Pro"s LCD comes out to be only half as bright as the Mi 9T Pro"s AMOLED.

For the second test, the ambient brightness value of the Mi 10T Pro"s display is 411lux (130nits), whereas the brightness of Mi 9T Pro"s display is measured to be 830lux (264nits). The Mi 10T Pro, once again, is left behind by a margin of over 100%. As we go farther away from the phones, a similar factor of approximated two times more brightness with the Mi 9T Pro is observed compared to the Mi 10T Pro while measuring their brightness values from distances of 1ft and 2ft. The methodology isn"t fool-proof, but it satisfies our requirement of quantifying the displays" brightness — although with a reasonable margin of error.

Quite evidently, the Mi 9T Pro"s AMOLED display appears brighter than the LCD on the Mi 10T Pro. But at the same time, we see that the LCD has a more uniform color throughout the display. The LCD"s white color also has a closer-to-neutral color temperature than the AMOLED display.

To examine further, we will be taking a few more tests from the Display Tester app into consideration — starting with the Contrast tests. For all of the following tests, the "Auto" Color Scheme has been selected on the smartphones" Display Settings. This is the default option that both of these devices ship with. While you get the option to change the white balance on both devices and even tweak values of RGB, Hue, Saturation, Contrast, and Gamma on the Mi 10T, most of the users are unlikely to fiddle with those settings.

AMOLEDs typically offer more contrast as compared to LCDs. Contrast ratio, which is expressed as the ratio of the luminescence (or the brightness) of the brightest pixels of the display to those of the darkest, is often used for advertising the accuracy of details produced by TVs and displays. On AMOLED displays, the color black is presented by turning off pixels, and this is why we often hear about AMOLEDs presenting the "true black" color. This allows the contrast ratio of AMOLED displays to tend to a significantly high value as compared to LCDs.

In practical usage, high contrast or a contrast ratio means a clearer distinction between parts of the screen. Besides the fact that AMOLED displays are usually brighter than LCDs, as we saw in the section above, the former can also get much dimmer, and therefore, allow better readability in low lighting.

Despite this variance in the quantitative values, both smartphones do not show any significant difference in terms of the quality of any content. In fact, the Contrast test from the Display Tester app reveals that the Mi 10T offers a much better distinction between different colors at low brightness.

Overall, the higher contrast allows bright shades of colors to pop out, especially dark colors dominate the frame. For instance, the visuals of a well-illuminated city or fireworks at night will appear better on the Mi 9T Pro than on the Mi 10T Pro"s display.

AMOLED displays are typically known to offer deeper and more saturated colors. However, saturation does not translate to accuracy, and Xiaomi has big claims regarding the latter. They claim that the Mi 10T Pro covers 98% colors of the DCI-P3 and 96% of the NTSC color gamuts. Besides, The Mi 10T Pro is claimed to have a Delta E value (∆E is the difference between real-life colors and the ones produced by the display; lower is better and 0 is the best) of 0.63.

In a real-life comparison with the Mi 9T Pro"s AMOLED display, the LCD on Mi 10T Pro offers more distinction between adjoining colors. The different boxes for each of the colors in the Display Tester app"s Saturation test are slightly more distinguishable on the Mi 10T Pro than the 9T Pro.

The Mi 10T series takes a significant lead against the Mi 9T in terms of refresh rate — or the frequency at which each pixel of a display is updated or refreshed. The Mi 10T/10T Pro gets a 144Hz display, which means it refreshes every ~7ms, which is more than twice as fast as the ~16.7ms taken by the standard 60Hz display on the Mi 9T duo. As a result of more frequent refreshing, animations and transitions on the Mi 10T Pro"s display appear much smoother and fluid than the Mi 9T, which leads to a more enjoyable experience while gaming on the smartphones. A 144Hz refresh rate implies that the display can process and present videos or game-related content at 144 frames per second (fps) without lagging. And before you ask, here are all the Android games that support gameplay at 120fps or higher.

While the 144Hz refresh rate is in itself a major advantage, especially for gaming enthusiasts, the Mi 10T devices also support AdaptiveSync. The Mi 10T"s screen supports variable refresh rates and can adjust it based on the content that is being displayed. The refresh rate values supported by the display include 30Hz, 48Hz, 50Hz, 60Hz, 90Hz, 120Hz, and 144Hz. By synchronizing refresh rate with the frame rate of the content (or in multiples), the Mi 10T Pro eliminates any instances of screen tearing or visual artifacts. To learn more, read our explainer on the relevance of refresh rate on smartphone displays.

The "Adaptive" bit comes in play when the display smartly adjusts to the frame rate based on the content instead of applying a blanket rule per-app as the Galaxy Note 20 Ultra does. For instance, a movie shot at 24fps will invoke a frame rate of 48Hz, whereas a TV show shot at 25fps will cause the display to refresh at 50Hz, and the Mi 10T can work at different refresh rates within the same video content app — say Netflix.

Besides cost, AdaptiveSync is one of the primary reasons that Xiaomi has opted for an LCD instead of an AMOLED. A manufacturer must tune the display color profiles and gamma values for different refresh rates, and achieving this with an LCD is much easier than an AMOLED. This becomes more imperative to ensure the Mi 10T Pro"s display switches refresh rate seamlessly between different apps or forms of content without any visible alteration in the color output. This also gives it an advantage over devices like the OnePlus 8T which, despite their 120Hz refresh rates, can only operate at fixed refresh rate values such as 60Hz, 90Hz, and 120Hz.

It is worth noting that Xiaomi"s AdaptiveSync differs from active sync features used by GPU manufacturers like NVIDIA. The latter allows supported displays to adjust the display"s refresh rate precisely to match the content"s frame rate in real-time. For example, if the game switches from 80fps to 65fps (due to a change of scene or processing incapabilities), the refresh rate of a display with NVIDIA"s VSync support will automatically lower from 80Hz to 65Hz in real-time. However, this is not supported on any smartphone other than the flouted first-gen Razer Phone from a couple of years ago.

Looking at the display, the Mi 10T Pro definitely feels like a legible upgrade over the Mi 9T Pro but with minor compromises in terms of screen brightness and contrast. To redress those shortcomings, Xiaomi relies on a color-accurate, fluid, and much smoother user experience.

AMOLED (active-matrix organic light-emitting diode, OLED display device technology. OLED describes a specific type of thin-film-display technology in which organic compounds form the electroluminescent material, and active matrix refers to the technology behind the addressing of pixels.

An AMOLED display consists of an active matrix of OLED pixels generating light (luminescence) upon electrical activation that have been deposited or integrated onto a thin-film transistor (TFT) array, which functions as a series of switches to control the current flowing to each individual pixel.

Typically, this continuous current flow is controlled by at least two TFTs at each pixel (to trigger the luminescence), with one TFT to start and stop the charging of a storage capacitor and the second to provide a voltage source at the level needed to create a constant current to the pixel, thereby eliminating the need for the very high currents required for passive-matrix OLED operation.

TFT backplane technology is crucial in the fabrication of AMOLED displays. In AMOLEDs, the two primary TFT backplane technologies, polycrystalline silicon (poly-Si) and amorphous silicon (a-Si), are currently used offering the potential for directly fabricating the active-matrix backplanes at low temperatures (below 150 °C) onto flexible plastic substrates for producing flexible AMOLED displays.

AMOLED was developed in 2006. Samsung SDI was one of the main investors in the technology, and many other display companies were also developing it. One of the earliest consumer electronics products with an AMOLED display was the BenQ-Siemens S88 mobile handsetiriver Clix 2 portable media player.Nokia N85 followed by the Samsung i7110 - both Nokia and Samsung Electronics were early adopters of this technology on their smartphones.

Manufacturers have developed in-cell touch panels, integrating the production of capacitive sensor arrays in the AMOLED module fabrication process. In-cell sensor AMOLED fabricators include AU Optronics and Samsung. Samsung has marketed its version of this technology as "Super AMOLED". Researchers at DuPont used computational fluid dynamics (CFD) software to optimize coating processes for a new solution-coated AMOLED display technology that is competitive in cost and performance with existing chemical vapor deposition (CVD) technology. Using custom modeling and analytic approaches, Samsung has developed short and long-range film-thickness control and uniformity that is commercially viable at large glass sizes.

The amount of power the display consumes varies significantly depending on the color and brightness shown. As an example, one old QVGA OLED display consumes 0.3 watts while showing white text on a black background, but more than 0.7 watts showing black text on a white background, while an LCD may consume only a constant 0.35 watts regardless of what is being shown on screen.

AMOLED displays may be difficult to view in direct sunlight compared with LCDs because of their reduced maximum brightness.Super AMOLED technology addresses this issue by reducing the size of gaps between layers of the screen.PenTile technology is often used for a higher resolution display while requiring fewer subpixels than needed otherwise, sometimes resulting in a display less sharp and more grainy than a non-PenTile display with the same resolution.

The organic materials used in AMOLED displays are very prone to degradation over a relatively short period of time, resulting in color shifts as one color fades faster than another, image persistence, or burn-in.

As of 2010, demand for AMOLED screens was high and, due to supply shortages of the Samsung-produced displays, certain models of HTC smartphones were changed to use next-generation LCD displays from the Samsung-Sony joint-venture SLCD in the future.

Flagship smartphones sold in 2020 and 2021 used either a Super AMOLED. Super AMOLED displays, such as the one on the Samsung Galaxy S21+ / S21 Ultra and Samsung Galaxy Note 20 Ultra have often been compared to IPS LCDs, found in phones such as the Xiaomi Mi 10T, Huawei Nova 5T, and Samsung Galaxy A20e.ABI Research, the AMOLED display found in the Motorola Moto X draws just 92 mA during bright conditions and 68 mA while dim.

"Super AMOLED" is a marketing term created by Samsung for an AMOLED display with an integrated touch screen digitizer: the layer that detects touch is integrated into the display, rather than overlaid on top of it and cannot be separated from the display itself. The display technology itself is not improved. According to Samsung, Super AMOLED reflects one-fifth as much sunlight as the first generation AMOLED.One Glass Solution (OGS).

Future displays exhibited from 2011 to 2013 by Samsung have shown flexible, 3D, transparent Super AMOLED Plus displays using very high resolutions and in varying sizes for phones. These unreleased prototypes use a polymer as a substrate removing the need for glass cover, a metal backing, and touch matrix, combining them into one integrated layer.

Also planned for the future are 3D stereoscopic displays that use eye-tracking (via stereoscopic front-facing cameras) to provide full resolution 3D visuals.

Kim, Yang Wan; Kwak, Won Kyu; Lee, Jae Yong; Choi, Wong Sik; Lee, Ki Yong; Kim, Sung Chul; Yoo, Eui Jin (2009). "40 Inch FHD AM-OLED Display with IR Drop Compensation Pixel Circuit". SID Symposium Digest of Technical Papers. 40: 85. doi:10.1889/1.3256930. S2CID 110871831.

Lee, Myung Ho; Seop, Song Myoung; Kim, Jong Soo; Hwang, Jung Ho; Shin, Hye Jin; Cho, Sang Kyun; Min, Kyoung Wook; Kwak, Won Kyu; Jung, Sun I; Kim, Chang Soo; Choi, Woong Sik; Kim, Sung Cheol; Yoo, Eu Jin (2009). "Development of 31-Inch Full-HD AMOLED TV Using LTPS-TFT and RGB FMM". SID Symposium Digest of Technical Papers. 40: 802. doi:10.1889/1.3256911. S2CID 110948118.

Hamer, John W.; Arnold, Andrew D.; Boroson, Michael L.; Itoh, Masahiro; Hatwar, Tukaram K.; Helber, Margaret J.; Miwa, Koichi; Levey, Charles I.; Long, Michael; Ludwicki, John E.; Scheirer, David C.; Spindler, Jeffrey P.; Van Slyke, Steven A. (2008). "System design for a wide-color-gamut TV-sized AMOLED display". Journal of the Society for Information Display. 16: 3. doi:10.1889/1.2835033. S2CID 62669850.

Lin, Chih-Lung; Chen, Yung-Chih (2007). "A Novel LTPS-TFT Pixel Circuit Compensating for TFT Threshold-Voltage Shift and OLED Degradation for AMOLED". IEEE Electron Device Letters. 28 (2): 129. Bibcode:2007IEDL...28..129L. doi:10.1109/LED.2006.889523. S2CID 11194344.

Sarma, Kalluri R.; Chanley, Charles; Dodd, Sonia R.; Roush, Jared; Schmidt, John; Srdanov, Gordana; Stevenson, Matthew; Wessel, Ralf; Innocenzo, Jeffrey; Yu, Gang; O"Regan, Marie B.; MacDonald, W. A.; Eveson, R.; Long, Ke; Gleskova, Helena; Wagner, Sigurd; Sturm, James C. (2003). "Active-matrix OLED using 150°C a-Si TFT backplane built on flexible plastic substrate (Proceedings Paper)". SPIE Proceedings. 5080: 180. doi:10.1117/12.497638. S2CID 12958469. "Archived copy" (PDF). Archived from the original (PDF) on 28 June 2011. Retrieved 2010-09-06.link)

Reid Chesterfield, Andrew Johnson, Charlie Lang, Matthew Stainer, and Jonathan Ziebarth, "Solution-Coating Technology for AMOLED Displays Archived 16 May 2011 at the Wayback Machine", Information Display Magazine, January 2011.

Dong, Mian; Choi, Yung-Seok Kevin; Zhong, Lin (2009). "Power modeling of graphical user interfaces on OLED displays". Proceedings of the 46th Annual Design Automation Conference on ZZZ - DAC "09. p. 652. doi:10.1145/1629911.1630084. ISBN 9781605584973. S2CID 442526.

"AMOLED vs LCD: differences explained". Android Authority. 8 February 2016. Archived from the original on 27 December 2016. Retrieved 6 February 2017.

Tim Carmody (10 November 2010). "How Super AMOLED displays work". Wired. Wired.com. Archived from the original on 28 September 2012. Retrieved 10 October 2012.

Ashtiani, Shahin J.; Reza Chaji, G.; Nathan, Arokia (2007). "AMOLED Pixel Circuit With Electronic Compensation of Luminance Degradation". Journal of Display Technology. 38 (1): 36. Bibcode:2007JDisT...3...36A. doi:10.1109/JDT.2006.890711. S2CID 44204246.

"AMOLED vs LCD: Which screen is best for your phone?". digitaltrends.com. 29 August 2014. Archived from the original on 29 March 2018. Retrieved 6 May 2018.

An organic light-emitting diode (OLED or organic LED), also known as organic electroluminescent (organic EL) diode,light-emitting diode (LED) in which the emissive electroluminescent layer is a film of organic compound that emits light in response to an electric current. This organic layer is situated between two electrodes; typically, at least one of these electrodes is transparent. OLEDs are used to create digital displays in devices such as television screens, computer monitors, and portable systems such as smartphones and handheld game consoles. A major area of research is the development of white OLED devices for use in solid-state lighting applications.

There are two main families of OLED: those based on small molecules and those employing polymers. Adding mobile ions to an OLED creates a light-emitting electrochemical cell (LEC) which has a slightly different mode of operation. An OLED display can be driven with a passive-matrix (PMOLED) or active-matrix (AMOLED) control scheme. In the PMOLED scheme, each row and line in the display is controlled sequentially, one by one,thin-film transistor (TFT) backplane to directly access and switch each individual pixel on or off, allowing for higher resolution and larger display sizes.

An OLED display works without a backlight because it emits its own visible light. Thus, it can display deep black levels and can be thinner and lighter than a liquid crystal display (LCD). In low ambient light conditions (such as a dark room), an OLED screen can achieve a higher contrast ratio than an LCD, regardless of whether the LCD uses cold cathode fluorescent lamps or an LED backlight. OLED displays are made in the same way as LCDs, but after TFT (for active matrix displays), addressable grid (for passive matrix displays) or indium-tin oxide (ITO) segment (for segment displays) formation, the display is coated with hole injection, transport and blocking layers, as well with electroluminescent material after the first 2 layers, after which ITO or metal may be applied again as a cathode and later the entire stack of materials is encapsulated. The TFT layer, addressable grid or ITO segments serve as or are connected to the anode, which may be made of ITO or metal.transparent displays being used in smartphones with optical fingerprint scanners and flexible displays being used in foldable smartphones.

Research into polymer electroluminescence culminated in 1990, with J. H. Burroughes et al. at the Cavendish Laboratory at Cambridge University, UK, reporting a high-efficiency green light-emitting polymer-based device using 100nm thick films of poly(p-phenylene vinylene).plastic electronics and OLED research and device production grew rapidly.et al. at Yamagata University, Japan in 1995, achieved the commercialization of OLED-backlit displays and lighting.

In 1999, Kodak and Sanyo had entered into a partnership to jointly research, develop, and produce OLED displays. They announced the world"s first 2.4-inch active-matrix, full-color OLED display in September the same year.

Manufacturing of small molecule OLEDs was started in 1997 by Pioneer Corporation, followed by TDK in 2001 and Samsung-NEC Mobile Display (SNMD), which later became one of the world"s largest OLED display manufacturers - Samsung Display, in 2002.

The Sony XEL-1, released in 2007, was the first OLED television.Universal Display Corporation, one of the OLED materials companies, holds a number of patents concerning the commercialization of OLEDs that are used by major OLED manufacturers around the world.

During operation, a voltage is applied across the OLED such that the anode is positive with respect to the cathode. Anodes are picked based upon the quality of their optical transparency, electrical conductivity, and chemical stability.electrons flows through the device from cathode to anode, as electrons are injected into the LUMO of the organic layer at the cathode and withdrawn from the HOMO at the anode. This latter process may also be described as the injection of electron holes into the HOMO. Electrostatic forces bring the electrons and the holes towards each other and they recombine forming an exciton, a bound state of the electron and hole. This happens closer to the electron-transport layer part of the emissive layer, because in organic semiconductors holes are generally more mobile than electrons. The decay of this excited state results in a relaxation of the energy levels of the electron, accompanied by emission of radiation whose frequency is in the visible region. The frequency of this radiation depends on the band gap of the material, in this case the difference in energy between the HOMO and LUMO.

Polymer light-emitting diodes (PLED, P-OLED), also light-emitting polymers (LEP), involve an electroluminescent conductive polymer that emits light when connected to an external voltage. They are used as a thin film for full-spectrum colour displays. Polymer OLEDs are quite efficient and require a relatively small amount of power for the amount of light produced.

Typical polymers used in PLED displays include derivatives of poly(p-phenylene vinylene) and polyfluorene. Substitution of side chains onto the polymer backbone may determine the colour of emitted lightring opening metathesis polymerization.

The bottom-emission organic light-emitting diode (BE-OLED) is the architecture that was used in the early-stage AMOLED displays. It had a transparent anode fabricated on a glass substrate, and a shiny reflective cathode. Light is emitted from the transparent anode direction. To reflect all the light towards the anode direction, a relatively thick metal cathode such as aluminum is used. For the anode, high-transparency indium tin oxide (ITO) was a typical choice to emit as much light as possible.thin film transistor (TFT) substrate, and the area from which light can be extracted is limited and the light emission efficiency is reduced.

In "white + color filter method," red, green, and blue emissions are obtained from the same white-light LEDs using different color filters.uneven degradation rate of blue pixels vs. red and green pixels. Disadvantages of this method are low color purity and contrast. Also, the filters absorb most of the light waves emitted, requiring the background white light to be relatively strong to compensate for the drop in brightness, and thus the power consumption for such displays can be higher.

Transparent OLEDs use transparent or semi-transparent contacts on both sides of the device to create displays that can be made to be both top and bottom emitting (transparent). TOLEDs can greatly improve contrast, making it much easier to view displays in bright sunlight.Head-up displays, smart windows or augmented reality applications.

In contrast to a conventional OLED, in which the anode is placed on the substrate, an Inverted OLED uses a bottom cathode that can be connected to the drain end of an n-channel TFT especially for the low cost amorphous silicon TFT backplane useful in the manufacturing of AMOLED displays.

The most commonly used patterning method for organic light-emitting displays is shadow masking during film deposition,photochemical machining, reminiscent of old CRT shadow masks, are used in this process. The dot density of the mask will determine the pixel density of the finished display.−5Pa. An oxygen meter ensures that no oxygen enters the chamber as it could damage (through oxidation) the electroluminescent material, which is in powder form. The mask is aligned with the mother substrate before every use, and it is placed just below the substrate. The substrate and mask assembly are placed at the top of the deposition chamber.virtual reality headsets.

Although the shadow-mask patterning method is a mature technology used from the first OLED manufacturing, it causes many issues like dark spot formation due to mask-substrate contact or misalignment of the pattern due to the deformation of shadow mask. Such defect formation can be regarded as trivial when the display size is small, however it causes serious issues when a large display is manufactured, which brings significant production yield loss. To circumvent such issues, white emission devices with 4-sub-pixel color filters (white, red, green and blue) have been used for large televisions. In spite of the light absorption by the color filter, state-of-the-art OLED televisions can reproduce color very well, such as 100% NTSC, and consume little power at the same time. This is done by using an emission spectrum with high human-eye sensitivity, special color filters with a low spectrum overlap, and performance tuning with color statistics into consideration.

Transfer-printing is an emerging technology to assemble large numbers of parallel OLED and AMOLED devices efficiently. It takes advantage of standard metal deposition, photolithography, and etching to create alignment marks commonly on glass or other device substrates. Thin polymer adhesive layers are applied to enhance resistance to particles and surface defects. Microscale ICs are transfer-printed onto the adhesive surface and then baked to fully cure adhesive layers. An additional photosensitive polymer layer is applied to the substrate to account for the topography caused by the printed ICs, reintroducing a flat surface. Photolithography and etching removes some polymer layers to uncover conductive pads on the ICs. Afterwards, the anode layer is applied to the device backplane to form the bottom electrode. OLED layers are applied to the anode layer with conventional vapor deposition, and covered with a conductive metal electrode layer. As of 2011mm × 400mm. This size limit needs to expand for transfer-printing to become a common process for the fabrication of large OLED/AMOLED displays.

Experimental OLED displays using conventional photolithography techniques instead of FMMs have been demonstrated, allowing for large substrate sizes (as it eliminates the need for a mask that needs to be as large as the substrate) and good yield control.

For a high resolution display like a TV, a thin-film transistor (TFT) backplane is necessary to drive the pixels correctly. As of 2019, low-temperature polycrystalline silicon (LTPS)– TFT is widely used for commercial AMOLED displays. LTPS-TFT has variation of the performance in a display, so various compensation circuits have been reported.excimer laser used for LTPS, the AMOLED size was limited. To cope with the hurdle related to the panel size, amorphous-silicon/microcrystalline-silicon backplanes have been reported with large display prototype demonstrations.indium gallium zinc oxide (IGZO) backplane can also be used.

OLEDs can be printed onto any suitable substrate by an inkjet printer or even by screen printing,plasma displays. However, fabrication of the OLED substrate as of 2018 is costlier than that for TFT LCDs.registration — lining up the different printed layers to the required degree of accuracy.

OLED displays can be fabricated on flexible plastic substrates, leading to the possible fabrication of flexible organic light-emitting diodes for other new applications, such as roll-up displays embedded in fabrics or clothing. If a substrate like polyethylene terephthalate (PET)

OLEDs enable a greater contrast ratio and wider viewing angle compared to LCDs, because OLED pixels emit light directly. This also provides a deeper black level, since a black OLED display emits no light. Furthermore, OLED pixel colors appear correct and unshifted, even as the viewing angle approaches 90° from the normal.

OLEDs also have a much faster response time than an LCD. Using response time compensation technologies, the fastest modern LCDs can reach response times as low as 1ms for their fastest color transition, and are capable of refresh frequencies as high as 240Hz. According to LG, OLED response times are up to 1,000 times faster than LCD,μs (0.01ms), which could theoretically accommodate refresh frequencies approaching 100kHz (100,000Hz). Due to their extremely fast response time, OLED displays can also be easily designed to be strobed, creating an effect similar to CRT flicker in order to avoid the sample-and-hold behavior seen on both LCDs and some OLED displays, which creates the perception of motion blur.

The biggest technical problem for OLEDs is the limited lifetime of the organic materials. One 2008 technical report on an OLED TV panel found that after 1,000hours, the blue luminance degraded by 12%, the red by 7% and the green by 8%.hours to half original brightness (five years at eight hours per day) when used for flat-panel displays. This is lower than the typical lifetime of LCD, LED or PDP technology; each rated for about 25,000–40,000hours to half brightness, depending on manufacturer and model. One major challenge for OLED displays is the formation of dark spots due to the ingress of oxygen and moisture, which degrades the organic material over time whether or not the display is powered.

However, some manufacturers" displays aim to increase the lifespan of OLED displays, pushing their expected life past that of LCD displays by improving light outcoupling, thus achieving the same brightness at a lower drive current.cd/m2 of luminance for over 198,000hours for green OLEDs and 62,000hours for blue OLEDs.hours for red, 1,450,000hours for yellow and 400,000hours for green at an initial luminance of 1,000cd/m2.

The OLED material used to produce blue light degrades much more rapidly than the materials used to produce other colors; in other words, blue light output will decrease relative to the other colors of light. This variation in the differential color output will change the color balance of the display, and is much more noticeable than a uniform decrease in overall luminance.

Blue TADF emitters are expected to market by 2020WOLED displays with phosphorescent color filters, as well as blue OLED displays with ink-printed QD color filters.

Water can instantly damage the organic materials of the displays. Therefore, improved sealing processes are important for practical manufacturing. Water damage especially may limit the longevity of more flexible displays.

As an emissive display technology, OLEDs rely completely upon converting electricity to light, unlike most LCDs which are to some extent reflective. E-paper leads the way in efficiency with ~ 33% ambient light reflectivity, enabling the display to be used without any internal light source. The metallic cathode in an OLED acts as a mirror, with reflectance approaching 80%, leading to poor readability in bright ambient light such as outdoors. However, with the proper application of a circular polarizer and antireflective coatings, the diffuse reflectance can be reduced to less than 0.1%. With 10,000 fc incident illumination (typical test condition for simulating outdoor illumination), that yields an approximate photopic contrast of 5:1. Advances in OLED technologies, however, enable OLEDs to become actually better than LCDs in bright sunlight. The AMOLED display in the Galaxy S5, for example, was found to outperform all LCD displays on the market in terms of power usage, brightness and reflectance.

While an OLED will consume around 40% of the power of an LCD displaying an image that is primarily black, for the majority of images it will consume 60–80% of the power of an LCD. However, an OLED can use more than 300% power to display an image with a white background, such as a document or web site.

OLEDs use pulse width modulation to show colour/brightness gradations, so even if the display is at 100% brightness, any pixel that"s, for example, 50% grey will be off for 50% of the time, making for a subtle strobe effect. The alternative way to decrease brightness would be to decrease the constant power to the OLEDs, which would result in no screen flicker, but a noticeable change in colour balance, getting worse as brightness decreases.

Almost all OLED manufacturers rely on material deposition equipment that is only made by a handful of companies,Canon Tokki, a unit of Canon Inc. Canon Tokki is reported to have a near-monopoly of the giant OLED-manufacturing vacuum machines, notable for their 100-metre (330 ft) size.Apple has relied solely on Canon Tokki in its bid to introduce its own OLED displays for the iPhones released in 2017.

OLED technology is used in commercial applications such as displays for mobile phones and portable digital media players, car radios and digital cameras among others, as well as lighting.Philips Lighting has made OLED lighting samples under the brand name "Lumiblade" available onlineNovaled AG based in Dresden, Germany, introduced a line of OLED desk lamps called "Victory" in September, 2011.

Nokia introduced OLED mobile phones including the

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey