tft lcd layers pricelist

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

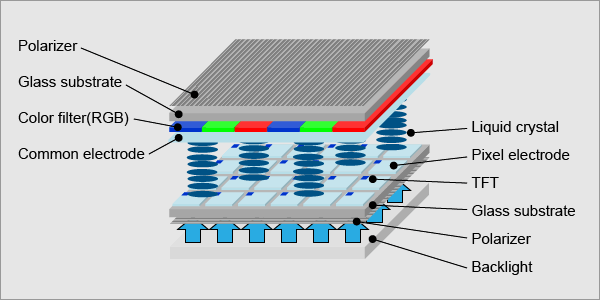

The liquid crystal displays used in calculators and other devices with similarly simple displays have direct-driven image elements, and therefore a voltage can be easily applied across just one segment of these types of displays without interfering with the other segments. This would be impractical for a large display, because it would have a large number of (color) picture elements (pixels), and thus it would require millions of connections, both top and bottom for each one of the three colors (red, green and blue) of every pixel. To avoid this issue, the pixels are addressed in rows and columns, reducing the connection count from millions down to thousands. The column and row wires attach to transistor switches, one for each pixel. The one-way current passing characteristic of the transistor prevents the charge that is being applied to each pixel from being drained between refreshes to a display"s image. Each pixel is a small capacitor with a layer of insulating liquid crystal sandwiched between transparent conductive ITO layers.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

TFT stands for Thin-Film Transistor. TFT technology is a new standard these days for manufacturing displays, monitors, laptop screens, and other devices. TFT LCD displays can show crisp text, vivid colors, fast animations, and complex graphics.

TFT LCD monitors, also called flat panel displays, are replacing the old style cathode ray tubes (CRTs) as the displays of choice. Almost all LCD monitors today take advantage of the TFT technology.

Each pixel on a TFT display is backed by a tiny transistor. Transistors are so small these days, they need only a very minimal charge to control what they do. TFT displays are much more energy efficient than regular CRT screens that need a powerful light source.

TFT displays also allow for very fast re-drawing of the display, so the image has very little chance to flicker. This was not always the case with flat-panel monitors. Original passive matrix LCD displays were not able to refresh at very high rates and therefore could not keep up with fast moving images. A TFT monitor refresh rate is very high resulting in a display that can be used for video, gaming, and all forms of multimedia.

A TFT monitor delivers crisp text, vibrant colors, and an improved response time for multimedia applications. Today"s standard for response rate in TFT monitors is 16 ms or less.

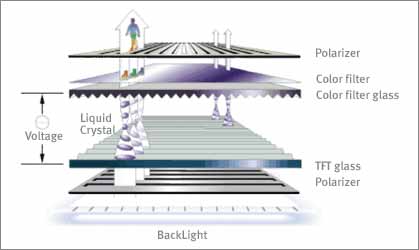

In general, a LCD display comprises of a layer of LCD material and one or more polarizing layers made of plastic, glass, or some other material. A LCD display has a sandwich-like structure with liquid crystals filled between two glass (or plastic or polycarbonate) plates.

Liquid crystals in LCD monitor act as a dynamic polarizing agent. They change their orientation when you place a voltage across an LCD cell. The orientation of the polarizing agent under the LCD layer either blocks or passes light.

A TFT display is an advanced LCD display. A TFT monitor uses so-called thin-film transistor technology to project a picture on the screen. Transistors in a TFT display are used to change the orientation of the polarizing agent.A typical 17-inch TFT monitor has about 1.3 million pixels and 1.3 million transistors. The following text explains TFT in a greater detail...

When you look at a passive-LCD technology, the cells act as capacitors. When you charge a cell, the liquid crystal flips to one position. When you stop supplying charge to the cell, it voluntarily bleeds off its voltage and the liquid crystal slowly twists back to its original position.

Passive LCD panels cannot quickly change the orientation of the crystal. Well, it is quick, but not quick enough to display fast-moving graphics. To overcome this slowness, engineers came up with active-LCD technology. Active-LCD displays use transistors to actively change the orientation of crystals. That is where TFT comes from. T in TFT for transistor. This method allows for faster control of the LCD cell but is also more complex.

While passive-LCD displays start to blur with images moving faster than 8 to 15 frames/sec, TFT displays can display full-motion video and graphics because they use fast switching transistors.

Now that we know how a LCD works and what it behind TFT, we can start talking about color. Each pixel in a color TFT LCD is subdivided into three subpixels. One of the subpixels is capable of producing red, the other one green, and the last one blue color. Red, green, and blue are the basic colors. Any other color can be produced by mixing up these three. One set of RGB subpixels is equal to one pixel.

Old TFT displays and the small ones in simple applications such as calculators are reflective TFT. A reflective TFT display has no backlight. The polarizing agent at the rear of the TFT display is simply a mirror layer behind the TFT panel. The agent merely reflects incoming light from the front of the display. You need to be in a well-lit room to be able to read this type of display.

The next step in a TFT LCD design was to add a light source to it. More advanced TFT displays have added sidelights or front lights to these displays. Sidelights and front lights are virtually the same as backlights. The difference is just the position of the light. Front lights sit on the side or slightly in front of the TFT layers. They are designed so that the light they produce shines through the TFT panel and bounces off the reflective polarizing agent back through the display.

A transmissive TFT uses a backlight. Most TFT LCD panels today are designed with a backlight. The source of the light is mounted at the rear side of the LCD panel and shines light towards your eyes through the TFT panel"s polarizing medium (liquid crystal). Small displays, such as cell phones or calculators, use light source that is placed along the sides of the display.

The common TFT-display backlight is the CCFL (cold-cathode fluorescent lamp). CCFLs are similar to fluorescent light tubes that you commonly find in offices and homes. Their advantage is that they are small, inexpensive, replaceable, and cheap.

The polarizing medium in a TFT that transmits or blocks the backlight is clear, so any light shining on the display from the front competes with the backlight. If the light source shining on the front of the TFT display is strong enough, such as sun on a sunny day, it simply overpowers your laptop TFT display"s backlight and the display image is washed out. A reflective TFT display is usually a better choice for applications with high ambient light.

LED technology has only recently achieved the white light necessary to illuminate these panels. LEDs are the choice these days because they are stable over temperature ranges, durable, and very energy efficient. That is why if you buy a laptop with a TFT LED back-lighted display, it is possible that it will go for as much as 8 hours with your battery.

Our company specializes in developing solutions that arerenowned across the globe and meet expectations of the most demanding customers. Orient Display can boast incredibly fast order processing - usually it takes us only 4-5 weeks to produce LCD panels and we do our best to deliver your custom display modules, touch screens or TFT and IPS LCD displays within 5-8 weeks. Thanks to being in the business for such a noteworthy period of time, experts working at our display store have gained valuable experience in the automotive, appliances, industrial, marine, medical and consumer electronics industries. We’ve been able to create top-notch, specialized factories that allow us to manufacture quality custom display solutions at attractive prices. Our products comply with standards such as ISO 9001, ISO 14001, QC 080000, ISO/TS 16949 and PPM Process Control. All of this makes us the finest display manufacturer in the market.

Take your design to the next level with our range of TFT Displays including latest IPS TFT, circular and bar shape as well as large size TFT. With or without touch, these are fully customisable to your system requirements.

TFT-LCD technology is now fairly mature. As a result, manufacturing processes are efficient and production yields are high, leading to very competitive unit prices. Upgrading from a monochrome display to a TFT is now an affordable way to give your product an uplift.

Users of industrial display devices are wanting the same experience they have come to expect from a consumer device with all-round viewing angles. Switching to a superior IPS TFT display has become very cost effective as production increases and unit prices decrease.

Choosing a circular display for your next product design could really set you apart from your competition. Models are available from 1" to 4.2"in TFT, PMOLED and AMOLED, we have something to suit every application.

Large TFT display systems are increasingly being used for transportation information, retail signage and vending machines and kiosks. We can supply a large range of TFT solutions up to 65" diameter and in bar-style, square or rectangular configurations.

We are now offering increasing cover lens customisation options and processes to make your TFT LCD user interface truly stand out! Anders’ experienced marketers and engineers work with our manufacturing partners around the world to keep informed of the latest innovations, including mirrored glass,tinted glass, spot-facing, three dimension glass, and many more!

See below our range of TFT Displayswith sizes ranging from0.96" to 64.5" and including circular and bar type shape. All our displays can be tailored to suit your application antimicrobial coating technology,

A TFT display is a form of Liquid Crystal Display with thin film transistors for controlling the image formation. The TFT technology works by controlling brightness in red, green and blue sub-pixels through transistors for each pixel on the screen.

Compare IPS vs TFT displays - the TFT display is the display of choice for industrial designs, but it can have its limitations. A newer technology called IPS (in plane switching) offers better viewing angles and colours, but is it really the best choice - we discuss benefits and negatives of both types of TFT display.

Reports suggest that Apple is getting closer to implementing MicroLED in its future product releases, including the Apple Watch, with the display technology potentially offering a number of benefits compared to other methods. AppleInsider explains how the current TFT and OLED display technologies work, and how MicroLED differs.

The most common display technology used by consumer products today, and the oldest of the technologies examined in this article, TFT"s full name of TFT LCD stands for Thin-film-transistor liquid-crystal display. This technology is extensively used by Apple in its products, found in iPads, iPhones, MacBooks, and iMac lines.

The LCD part relates to the concept of defining small translucent or transparent areas in a thin and flexible liquid crystal-filled panel, like the displays used in calculators. Passing current through the segment changes the molecular properties of the defined segment area, allowing it to switch between being see-through or opaque.

TFT takes this a stage further, by effectively covering an entire panel with a grid of isolated liquid crystal segments, which again can vary between opaque and transparent based on the level of electrical current. In this case, there are far more segments needed to make up the display than with a normal calculator.

Polarizing filters on either side of the TFT display sandwich are used to prevent light from passing through directly, with the liquid crystal reaction of each segment affecting polarized light passing through the first filter to go through the second.

Sometimes these types of display are known as "LED," but this somewhat of a misnomer, as this actually refers to the use of Light Emitting Diodes as a light source. The LED backlight shines light through the various layers making up the TFT LCD.

TFT LCD screens continue to be widely used in production for a number of reasons. Manufacturers have spent a long time perfecting the production of the display panels to make it as cheap as possible, while its high usage allows it to benefit from economies of scale.

Used in consumer devices in a similar way to TFT LCD, OLED (Organic Light-Emitting Diode) is a display technology that is similar in the basic concept, but differs considerably in its execution. Again, the idea is for a thin panel to be divided up into segments, with charge applied to each section to alter its molecular properties, but that"s where the techniques diverge.

These self-emitting pixels gives OLED a considerable advantage over LCD-based systems in a number of areas. Most obviously, by not needing a backlight, OLED panels can be made far thinner than an equivalent LCD-based display, allowing for the production of thinner devices or more internal area for other components, like a larger battery.

The power efficiency of OLED panels can be far greater, as while a TFT screen requires an always-on backlight, the brightness of OLED pixels themselves determine power usage, with a black pixel consuming no power at all. OLED screens are also faster to respond than LCD displays, making them more useful for VR displays, where response time needs to be as rapid as possible.

This also allows OLED to provide superior contrast ratios compared to TFT, as the lack of backlight bleed-through that occurs in TFT simply doesn"t happen in OLED.

Despite the advantages, OLED is still lagging behind TFT in terms of adoption. The cost of production is far higher, in part due to the need for extremely clean environments, as a single speck of dust can potentially ruining a display during fabrication.

Using extremely small LEDs, three MicroLEDs are put together to create each pixel, with each subpixel emitting a different color from the usual red, blue, and green selection. As each LED emits light, there is no need for a backlight as used in TFT screens.

MicroLED offers the same lower power consumption and high contrast ratio benefits as OLED when compared to TFT. However, MicroLED is also capable of producing a far brighter image than OLED, up to 30 times brighter, and is in theory more efficient in converting electricity into light.

As a relatively new and in-development technology, the cost of MicroLED production is extremely high in comparison to the more established OLED and TFT mass production lines, in part due to lower than required yields. Manufacturing equipment vendors have produced hardware for MicroLED production that cuts defects in half and reduces deposition deviance from 3 nanometers down to 1 nanometer, but it is unclear if this is enough to help mass production move forward.

Quantum Dots are photoluminescent particles included in an LED-backed TFT display that can produce brighter and more vibrant colors, with the colors produced depending on their size. While available in current QLED televisions, the technology is only really being used to enhance the backlight, rather than being used to illuminate individual pixels.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

To create an LCD, you take two pieces ofpolarized glass. A special polymer that creates microscopic grooves in the surface is rubbed on the side of the glass that does not have the polarizing film on it. The grooves must be in the same direction as the polarizing film. You then add a coating of nematic liquid crystals to one of the filters. The grooves will cause the first layer of molecules to align with the filter"s orientation. Then add the second piece of glass with the polarizing film at a right angle to the first piece. Each successive layer of TN molecules will gradually twist until the uppermost layer is at a 90-degree angle to the bottom, matching the polarized glass filters.

As light strikes the first filter, it is polarized. The molecules in each layer then guide the light they receive to the next layer. As the light passes through the liquid crystal layers, the molecules also change the light"s plane of vibration to match their own angle. When the light reaches the far side of the liquid crystal substance, it vibrates at the same angle as the final layer of molecules. If the final layer is matched up with the second polarized glass filter, then the light will pass through.

If we apply an electric charge to liquid crystal molecules, they untwist. When they straighten out, they change the angle of the light passing through them so that it no longer matches the angle of the top polarizing filter. Consequently, no light can pass through that area of the LCD, which makes that area darker than the surrounding areas.

Building a simple LCD is easier than you think. Your start with the sandwich of glass and liquid crystals described above and add two transparent electrodes to it. For example, imagine that you want to create the simplest possible LCD with just a single rectangular electrode on it. The layers would look like this:

The LCD needed to do this job is very basic. It has a mirror (A) in back, which makes it reflective. Then, we add a piece of glass (B) with a polarizing film on the bottom side, and a common electrode plane (C) made of indium-tin oxide on top. A common electrode plane covers the entire area of the LCD. Above that is the layer of liquid crystal substance (D). Next comes another piece of glass (E) with an electrode in the shape of the rectangle on the bottom and, on top, another polarizing film (F), at a right angle to the first one.

The electrode is hooked up to a power source like a battery. When there is no current, light entering through the front of the LCD will simply hit the mirror and bounce right back out. But when the battery supplies current to the electrodes, the liquid crystals between the common-plane electrode and the electrode shaped like a rectangle untwist and block the light in that region from passing through. That makes the LCD show the rectangle as a black area.

With the continuous innovation of display technology, the types of lcd monitor module screens have become more and more, and different types of display products have also been applied to different industry terminals. What are the most fundamental differences between TFT color screen and monochrome screen?

The working reasons of the TFT color display screen and the monochrome screen are completely different. The monochrome screen is composed of 7 pen segments, and there are many points in a range, called pixels. The monochrome screens are all made of fixed size. These points are arranged in an array; for example, 12864 is composed of 64 points in the horizontal direction 128X and the vertical direction. There are many names for monochrome screens, such as pen-segment LCD screens, pattern LCD screens, dot matrix screens, digital screens, and so on.

The TFT color screen is filled with liquid crystal material between two parallel plates, and the arrangement of molecules inside the liquid crystal material is changed by voltage so as to achieve the purpose of shading and transmitting light to display images with different shades and staggered patterns. Adding a filter layer of three primary colors between the plates can realize the display of color images. Therefore, the working principle of TFT color screen and monochrome screen is completely different.

Monochrome TFT display screens are generally used in calculators, watches, remote controls, telephones and so on. But, TFT color screens are widely used, such as handheld terminals, high-end mobile phones, smart homes, Internet of Things equipment, health care, artificial intelligence, video phones, walkie-talkies. More and more terminal products will be more inclined to choose TFT color screen as the display device of the terminal products.

TFT color screens are more expensive than monochrome TFT display screens, because the raw materials and production processes are different, and TFT color screens require higher raw materials, and the processing technology is also very complicated, the cost is higher, and the product performance And it is more popular among people. Monochrome TFT display screens generally have the problem of high MOQ. Because of their low price, monochrome TFT display screen manufacturers generally increase the quantity of order.

TFT color screen and monochrome screen are currently the two most common types of display screens on the market. There is no certainty who is better, only what kind of display screen is more suitable. Both TFT color screens and monochrome screens have their own advantages and disadvantages. It is better for everyone to be rational in the selection.

TFT (Thin-Film Transistor) Displays are active-matrix LCDs with full RGB color screens. These screens feature bright, vivid colors and have the ability to show fast animations, complex graphics and crisp custom fonts. TFTs are perfect displays for providing a rich user interface for all types of products. While typically used in consumer devices like personal DVD players and handheld devices, TFTs are also well suited for industrial application.

TFTs are Active-Matrix LCDs that have tiny switching transistors and capacitors. These tiny transistors control each pixel on the display and require very little energy to actively change the orientation of the liquid crystal in the display. This allows for faster control of each Red, Green and Blue sub-pixel cell thus producing clear fast-moving color graphics.

The transistors in the TFT are arranged in a matrix on the glass substrate. Each pixel on the display remains off until addressed by applying a charge to the transistor. Unlike conventional Passive-Matrix displays, in order to activate a specific pixel, the corresponding row is turned on and a charge is sent down the proper column. This is where only the capacitor at the designated pixel receives a charge and is held until the next refresh cycle. Essentially, each transistor acts as an active switch. By incorporating an active switch, this limits the number of scan lines and eliminates cross-talk issues.

MVA (Multi-domain Vertical Alignment) displays can offer wide viewing angles, good black depth, fast response times, and good color reproduction and depth. Each pixel within a MVA type TFT consists of three sub-pixels (Red, Green and Blue). Each of these sub-pixels is divided further into two or more sub-pixels, where the liquid crystals are randomly lined up due to the ridged polarized glass. When a charge is applied to the transistor, the crystals twist. With these crystals being randomly placed, it allows the backlight to shine through in all different directions keeping the intended color saturation retained while giving the display a 150deg. viewing angle.

In-Plane Switching (IPS) TFTs were developed to improve on the poor viewing angle and the poor color reproduction of TN TFT panels at that time. The crystal molecules move parallel to the panel plane instead of perpendicular to it. This change reduces the amount of light scattering in the matrix, which gives IPS its characteristic wide viewing angles and good color reproduction. Because of its wide viewing angle and accurate color reproduction (with almost no off-angle color shift), IPS is widely employed in high-end monitors aimed at professional graphic artists.

IPS (In-Plane Switching) displays provide consistent, accurate color from all viewing angles without blur or grayscale inversion. IPS displays show clear images with fast response time, and no halo effect is produced when touched. Each pixel within an IPS type TFT consists of three sub-pixels (Red, Green and Blue). Each sub-pixel has a pair of electrodes to control the twisting of the Liquid Crystals. Unlike TN type TFTs where the electrodes are on opposing plates, the electrodes in an IPS TFT are on only one of the glass plates (i.e. in the same plane). When voltage is applied to the electrodes, all the Liquid Crystal molecules align in parallel with that plane and allow light to pass through to the polarizers and RGB color filters. In effect, TN displays force the Liquid Crystal molecules perpendicular to the glass which blocks some light from coming out at wide angles, while IPS displays keep the Liquid Crystal molecules in line to allow light through at all angles.

Low-temperature polycrystalline silicon (LTPS) is polycrystalline silicon that has been synthesized at relatively low temperatures (~650 °C and lower) compared to in traditional methods (above 900 °C). LTPS is important for display industries, since the use of large glass panels prohibits exposure to deformative high temperatures. More specifically, the use of polycrystalline silicon in thin-film transistors (LTPS-TFT) has high potential for large-scale production of electronic devices like flat panel LCD displays or image sensors.

Transflective LCDs combine elements of both transmissive and reflective characteristics. Ambient light passes through the LCD and hits the semi-reflective layer. Most of the light is then reflected back through the LCD. However some of the light will not be reflected and will be lost. Alternately a backlight can be used to provide the light needed to illuminate the LCD if ambient light is low. Light from the backlight passes through a semi-reflective layer and illuminates the LCD. However as with ambient lighting some of the light does not penetrate the semi-reflective layer and is lost.

Transflective LCDs are used in devices that will operate in a wide variety of lighting conditions (from complete darkness to full sunlight). Under dim lighting conditions transflective LCDs offer visual performance similar to transmissive LCDs, whilst under bright lighting conditions they offer visual performance similar to reflective LCDs. However this performance is a tradeoff because the transflective mode is less efficient due to some light loss.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey