lcd module vex quotation

The VEX IQ Robot Brain has 12 identical Smart Ports. Plug any VEX IQ device into any port and the device is automatically detected - there are no dedicated input or output banks. Smart Port devices include: Smart Motor, Distance Sensor, Color Sensor, Gyro Sensor, Touch LED, and Bumper Switch.

The VEX IQ Brain comes loaded with default programs that get you up and running quickly. No computer or programming required. The Driver Control program gives you instant control of up to four drive motors and four additional mechanism motors, plus features for limit switches. Multiple pre-loaded autonomous programs will allow robots to move by themselves using sensors.

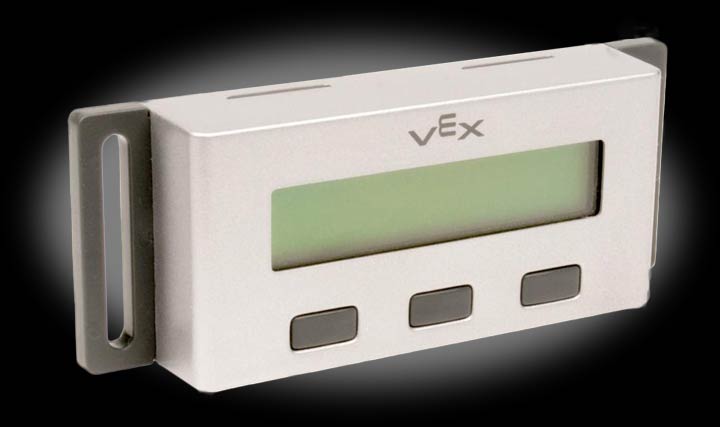

The backlit LCD makes VEX IQ simple to use. Using the 4-button interface, you can start your favorite program or configure the Driver Control program. Your VEXcode programs can write messages on-screen to customize your robot and simplify program debugging. Smartphone-like icons keep you in touch with your battery level and wireless connection.

All devices connected to the Brain support Event Programming. This simplifies the software by allowing events to trigger software. Traditional programming methods involve continuous running loops that check values over and over again, looking for a change. This method creates code that is difficult to visualize and learn. Event programming looks like: "when the button is pressed do ...", "when the angle is 90 degrees do ...", "when the motor stops do ...". Instead of constantly polling each device to see if the event has occurred, the VEX IQ system allows each smart module to report back if the event occurs. When the event occurs, the smart module tells the brain what occurred. Not only is software simplified, but the Brain does not have to constantly poll each sensor about what is happening, which increases overall system performance.

The VEX ARM® Cortex®-based Microcontroller coordinates the flow of all information and power on the robot. It has built in bi-directional communication for wireless driving, debugging and downloading using the VEXnet wireless link. The Microcontroller is the brain of every VEX robot.

VEXnet devices contain internal processors and run on special software called Firmware (or Master Code). Firmware is updated periodically to provide additional functionality or fix bugs. To fully unlock the potential of VEX Robotics VEXnet devices, it"s important to ensure that all applicable drivers are installed and firmware is updated.

Extension cables are used to extend the length of a 3-wire cable such that a motor or motor controller can be farther from a VEX ARM® Cortex®-based Microcontroller 3-wire application.

. It appears this defect is still present in current EasyC V4. If I can’t devise an acceptable solution within the library itself, I suppose I could require the author of the importing project to declare a global “char LCD_Content[32]”. [/EDIT]

The number printing function “LCD_PrintNum(num,len,base)” is pretty cool. You can specify any base from 2 to 36 for unsigned numbers (e.g., base=2 for binary; base=16 for hexadecimal). Signed values are printed by specifying negative base numbers (e.g., base=-10 for a signed decimal format). If you specify base=0, you get special signed decimal format where positive numbers get a ‘+’ sign out front; handy for displaying deltas and offsets. You can specify a minimum length and it will pad out to that length (decimal formats pad with spaces, and non-decimal formats pad with leading zeros).

Trivia / Joke Challenge: type in the code that you see in the article that makes the LCD read "Bumper: pressed" or "Bumper: released." Modify this so that your screen initially asks a question, and then when the bumper is pressed, it asnwers the question. Or gives the punch line. It should be appropriate.

Take the skeleton code that you were emailed before entitled, "virtual counter with while loops skeleton code."Make a new version in which you embed the LCD display code so that the LCD display counts "one," "two," "three," etc as you push the bumper switch.

Visit our new website www.idesignsol.ca. Free Shipping on orders over $250. Authorized VEX Robotics dealer in Canada only. Please note: some products may no longer be available in your region. Please email us for questions or concerns. If you"re waiting on a VEX order you placed with us, and you reside in the US, your order will be fulfilled. Additional Note: For any items that you are ordered on PRE-ORDER or out of stock, you are agreeing to our Pre-Order Policy as detailed on our Terms & Conditions page.

Anyway, by adding a Wait(1000) statement at the beginning of the code, we were able to get printf to the terminal and serial output to the SparkFun SerLCD display consistently. After we discovered this little trick, we then stumbled across a chiefdelphi thread that came to the same conclusion:

Interestingly, the thread also said that they couldn’t get printf to work with WPILib when they had a function other than main(). We may experiment with that a bit more another day. However, I’m hoping that this info is helpful to anyone else having problems using printf or serial out with WPILib. Because if you can get it to work, than you can have a nice inexpensive serial LCD display for your vex (http://www.sparkfun.com/commerce/product_info.php?products_id=9393).

Products»All Products»Power & UPS»Batteries & Ultracapacitors»Standard DC-DC Power»Smart DC-DC Power»Smart Battery Chargers»Galvanically Isolated Power Supplies»24V Output Supplies»Ultracapacitor Chargers»Adjustable Output Power Supplies»Universal Chargers»Uninterruptible Power Supplies»Embedded Boards»I/O & Communication»Embedded CAN bus Modules»Embedded Ethernet Switches»Embedded Digital IO Modules»Embedded Analog IO Modules»Embedded Serial IO Modules»PCIe Mini Cards»Embedded Power Supplies»Standard Embedded Power»Smart Embedded Power»PC/104 Power Supplies»Embedded UPS Modules»Embedded Motherboards»PC/104 Motherboards»ETX Motherboards»COM Express Motherboards»EPIC Motherboards»EBX Motherboards»Mini-ITX Motherboards»Micro-ATX Motherboards»Industrial ATX Motherboards»Embedded GPS Modules»GPS Receiver Modules»Embedded GPS Antennas»CPU Boards & SBC»PC/104 SBC»EPIC SBC»ETX SBC»EBX SBC»Mini-ITX SBC»ARM CPU Modules»Micro-ATX SBC»Embedded ATX SBC»Com Express SBC»Embedded Ultracapacitor Modules»Embedded Battery Modules»Embedded Video Cards»Systems»Fanless Box PC»Wide Temperature»Industrial Automation Computers»Rugged Vehicle Computers»Railway Computers»Vehicle Tracking Systems»Industrial Rackmount Computers»Wide Temperature Systems»Digital Displays»Marine Monitors»Rugged LCD Displays»Wide Temperature LCD Displays»Waterproof LCD Panels»Advertising LCD Displays»Stretched Bar LCD»Sunlight Readable LCD Displays»Public Transportation LCD Displays»Railway LCD Displays»Outdoor LCD Displays»High Brightness LCD Displays»Extended Temperature LCD Displays»Industrial Monitors»Panel Computing»Marine Panel PC»Infotainment Panel PC»Wide Temperature Panel PC»HMI Panel PC»Modular Panel PC»Mobile Computing»Rugged Tablets»Rugged Windows Tablets»Rugged Android Tablets»Rugged PDA»Antennas»GPS Antennas»External GPS Antennas»Passive GPS Antennas»Active GPS Antennas»Marine GPS Antennas»Internal GPS Antennas»GNSS Antennas»GLONASS Antennas»Multi-Band Antennas»GPS-GLONASS Antennas»Iridium Antennas»GPS & RF Signal Distribution»GPS Amplifiers»Low Noise Amplifiers»GPS Receivers»Marine GPS Receivers»GPS Attenuators»GPS Combiners»GPS Splitters»Active GPS Splitters»Military GPS Splitters»Rackmount GPS Splitters»Passive GPS Splitters»Repeaters»GPS Repeaters»GLONASS Repeaters»GPS Filters»Enclosures & Chassis»PC/104 Chassis»Rugged Mini-ITX Cases»EPIC Enclosures»EBX Enclosures»Memory & Storage»Memory»Flash Storage»Industrial SSD»SATA Disk On Modules»Industrial Micro SD Cards»Industrial SD Cards»Industrial CompactFlash Cards»Sensors»Industrial Networking»Manufactured by Tri-M»Power & UPS»Standard Power Supplies»HE104: 60 Watt»HE104-DX: 60 Watt»HE104-75W: 75 Watt»HE104+DX: 108 Watt»HE-HP: 100 Watt»Smart Power Supplies (PowerOS)»HESC-SERD: 60 Watt»HESC104+: 108 Watt»HPS3512: 203 Watt»HPSP-XYZ: 240W Programmable»V12SC-SER[-UPS]»TPS1000: 35 Watt, 42 Watt»TPSi1075: 75 Watt, Isolated»TPSi1085: 85 Watt, Isolated»HPSC104-SER: 160 Watt»HESC104: 60 Watt»TPS1035»TPC1000»HPS3524»Smart UPS (PowerOS)»TUP1000: Ultracapacitor UPS»V5SC-SER-UPS: NiMh Battery UPS»UltraUPS»V12SC-SER[-UPS]»Ultra Capacitor Packs»TBP4xxx»Battery Backup Packs»BAT-NiMh45»BAT104-NiMh»BAT104-NiCd»BAT-SLA(25/45)»UltraUPS»Heavy Duty Transient Stopper»CPU Modules»I/O & Communication»Input / Output»IO104-60IN: PC104 I/O Board»IR104 PC/104 Relay Module»Communication»TCB1000 PC/104 Com Board»FlexCom104-GPS»Enclosures»VersaTainer: PC104 & EBX»CanTainer: PC104»FlexTainer: EPIC, MITX, EBX»GPS & Networking»GPS & Networking Boards»FlexCom104-GPS»Antennas»Mighty Mouse: Small GPS Antenna»Micro Mouse: Micro GPS Antenna»Big Brother»Re-Radiators»Super-Radiator»Xtreme-Radiator»Vehicle GPS Repeater»Complete System Solutions»HECS1000 System»UltraUPS Complete Backup Solution»Support Products & Accessories»PC104-T AC Termination Modules»Extract104»TS-I2C Temperature Sensor»DA104»VSX-2812 Video Modules»ISA104X1»Postcode104»Legacy Products»Distributed by Tri-M»Diamond Systems»Single Board Computers»Aurora PC/104 SBC»Helios PC/104 SBC»Neptune EPIC SBC»Pluto ETX SBC»Hercules III EBX SBC»IEI»IEI Mobile»MicroMax Computer Intelligence»San Jose Technology (SANAV)»GNSS Repeaters»RK-306»RK-106»Innodisk»GPS Networking»Litemax»Spanpixel»Durapixel»Navpixel»Aaeon Electronics»Systems»Fanless Embedded Computers»Entry-Level Box PC»ICOP Technology»ICOP-2811»VDX2-6554»VEX-6254»VSX-2812S»86Duino Enjoy Desktop 3D Printer»MPLSelector Guides»Power Selector Guide»Backup Power SelectorServices»Conformal Coating»HumiSeal 1B31»Laser Engraving & EtchingTri-M Rugged»PowerOS»Mining Applications»Mining Application Story»Rail & ITS Applications»Automation & Manufacturing»Mil-Aero Defence & Aerospace»Aerospace Application StorySupportAbout Us»About Us»Privacy PolicywebstoreTriple Programmable PSUQuote Request

Robot programming is unique, in that your code has to interact with either physical devices (a "real" robot) or a virtual robot (a mimic). Part of what you will do is configure the devices that are included in your robot, and then use Blockly to add them to your programming. For VEX IQ, you can use the "Detect Sensors" button to poll a physical robot and fill most of this out automatically.

The Blockly toolbox contains the code blocks you will be using, divided into functional subsets. The first six are for use in programming VEX robots and mimics, and the others are standard Blockly blocks. We will go over these in more detail below.

Temperature Sensor is an advanced feature. If you have integrated a non-VEX temperature sensor into your VEX IQ Brain, you can read its value here in degrees F.

Check <> button returns the value of the VEX IQ Brain check, up and down buttons. Returns True if the specified button is pressed, and False otherwise.

Here is an example of a Blockly VEX IQ program that uses a function call to roll dice, and then makes the robot turn right or left depending on the dice results. The dice-rolling function is called "Roll Dice" and is defined below under the main program.

The VEX-6254 is a low cost PC/104 module with a fanless and low power design ideal for the new generation of IoT demands. It"s purpose is to provide a competitive, reliable and stable embedded computing platform for extreme and varied environments.

The VEX-6254 utilises the latest Vortex86EX 400MHz processor from DM&P which guarantees long-term lifetime and strict revision control. The module supports multiple I/O and bus interfaces on-board making it ideal for a wide range of embedded applications. It comes with plenty of features including 8 channels of 11-bit analog input, a 10/100 Ethernet port, three RS-232 serial ports, two USB 2.0 ports, a CAN bus interface, an I2C bus and a 16-bit GPIO port.

Impulse can support you throughout the development and deployment cycle of using the VEX-6254 PC/104 module in your new embedded OEM design. For more information about the VEX-6254 and our value added engineering services please contact our technical sales team on +44 (0)1728 337 800 or alternatively submit an enquiry.Enquire about the VEX-6254

My previous post described how VEX Integrated Motor Encoders (IMEs) work in general, and how they physically get connected together on your robot, aimed at someone who has never used them before. I intended this post to be more a in-depth discussion about the different uses of IMEs and things to look out for. However, the research I did on the VEX Forum for this post, combined with our team’s experiences this year (written in blue), have brought me to the firm conclusion that our team will never use them again. (Perhaps someday I will eat these words, but I doubt it unless the technology is upgraded.)

In lieu of my original intention, this post is now intended to be a resource for other VEX users that pulls together information from many disparate VEX Forum posts, all in one place, so you don’t have to go searching for the information in 20 different threads, a little bit here, a little bit there. If you’re having problems with your robot, and think it might be because of your integrated motor encoders (or cannot figure out what could possibly be the cause), please read on and see what you think based on the information that knowledgeable people such as the awesome jpearman have provided. This post is long, so here’s a table of contents:

That port that the daisy chain gets plugged into is labeled “I2C”, which stands for Inter Integrated Circuit; it’s a communication protocol that was intended to be used for processors to talk to each other inside the same device (on the same printed circuit board, even). It was never intended to be used over many feet of wire, the way VEX uses them.

The communication protocol between the cortex and IMEs is incredibly complex, and off-this-planet different from the way standard VEX sensors work. Here’s the description from the VEX Forum(from rockstar jpearman) of a typical sequence to send one byte of data from the master to a slave (edited slightly from his original, since I have not included all of his technical background; see original post for full details).

Attachment to the motor. This is the easiest one to test and fix; for some users, a change here could make all the difference. VEX Forum commenters widely report that screwing the black IME cap onto the motor too tightly prevents the black-and-white gear from spinning freely (and hence, counting properly). Other users reported poor results when the gear was dirty or greasy. (And, like any gear, if it has any damaged teeth, it’s obviously not going to function.)

Electromagnetic interference/noise. The complex signal running through the 4-wire cables can apparently be affected (badly) by external forces that are commonly present on VEX robots, like current running through neighboring wires that the 4-wire is bundled with, or if the 4-wire is running past a motor that is turned on (less certain about this last claim). From this VEX Forum thread, technik3k says [with my emphasis added in bold]:

jpearman sums things up rather nicely in this comment on a post from pretty early on in the IME’s existence, and I’m not sure why I only learned about it today, 5 years later. (If you don’t know what pulse width modulation is, please see my earlier post on VEX motors, or my post on motor controllers.)

Skipping gears (or wheel slippage). No one on the VEX Forum mentioned skipping gears, but this happened to us this year. Because the IME is on the drive shaft (as opposed to optical encoders, which are placed on the movement shaft, at the end of the gearbox), if the gearbox experiences slippage, the motor will be turning (and the IME counting), but the movement arm will not, resulting in a disconnect between where the IME (and your program) thinks the arm is, and where it actually is. For us, we had a systematic problem where the drive shaft motor with the IME (one of many moving the forklift) was coming away from its idler gear when our forklift was at the bottom of its motion, so every time the arm took a lap going up and then down, the IME would get off from its correct count by X clicks; after the forklift went up & down 10 times, our count would be off by 10X.

Static discharge (ESD – electrostatic discharge). There are many people talking about this on the VEX Forum. People in dry climates do say that they have clearly had their IMEs go offline due to static (mecanum wheels appear to be a big culprit). Robot drives around on rubber wheels and foam mats for a while, then robot touches field perimeter and the static that has built up finds a way to ground, and then the cortex/IMEs just can’t handle it (that’s my technical description). It’s real enough that at Worlds they treat the mats with anti-static spray. Here’s jpearman’s full-length discussion on ESD. The highlights:

Condition #2 above is described in the easyC/RobotC table above. jpearman says in his post that “Condition 1 is very rare, I have never experienced it.” However, we have, and so have a lot of other teams, and The Vex Raptors have given it the name “ghosting.” Read on.

[Note: many of the VEX Forum quotes included below are from RobotC users in the early days of the IME; RobotC did release an upgrade that cleared up these problems for many RobotC users (though the fact that very few top teams use IMEs should still say something). I have included their quotes here because they are exactly the types of behaviour that our robot experienced with easyC this season (2016-17). I can tell you with 100% certainty that we experienced ghosting as recently as January 2017 with easyC, and I have seen some RobotC Forum posts during the Starstruck season report behavior that still sounds a lot like ghoting to me.]

This is the real reason I’m never using IMEs again. Only after doing research for this post did I come to finally understand the (probable) cause of the bizarre problems that our robot has been having this season. The Vex Raptors on the VEX Forum are referring to this problem as “ghosting,” or the CPU getting, essentially, stuck running the last command that it received. In our lab, disabling field control or removing the VEXnet key did not even make the robot stop; the only remedy was turning the robot off. This is actually kind of difficult/dangerous if it’s stuck in a mode where the chassis is on—usually an adult has to jump onto the field and lift it off the ground while someone else reaches in and turns it off.

On one occasion, it actually got stuck on the LCD screen in the pre-autonomous section. We were on the practice field at States, and nothing would get it to reset, including turning the robot on and off, or changing the batteries. However, since we were at a competition, we had the 9-volt battery plugged into the cortex, which was keeping it “alive” through the battery change, and keeping it from resetting. For the rest of the day, we unplugged the 9-volt in between matches when we changed batteries, just to make sure that the cortex was really power-cycling.

So while jpearman in his ESD post (which was from a while back, albeit) said that the cortex crashing from ESD was extremely rare, here are some threads from the VEX Forum, that might make you feel better if this has been happening to you. It made me feel a lot better to know that all of these random, un-reproducible, unpredictable problems we have had since the beginning of our season were not because of something the girls were doing to the robot, or not doing to the robot, or something related to their programming (all of which seemed fine; also, we’re a big checklist-to-reduce-human-error kind of team).

We have had issues with static electricity and the IMEs. With the IMEs in, after about 30 seconds or more into driving the robot, the robot would just start being out of control. Disconnecting from Vexnet would not stop the robot. Disconnecting the IMEs did resolve the problem so the team is now using shaft encoders. –blatwell

Last year, several teams I know, including mine, encountered a similar issue (robot “ghosting” the last commands it received from the controller forever until it is turned off, but only while IMEs are plugged in). Most of us theorized that the problem is static electricity being collected by the IMEs sent to the cortex. We refer to this as ESD (Electro-Static Discharge). –The VEX Raptors

Team 24C and our team have both had problems with IMEs collecting static electricity and sending it to the brain. This can cause several different problems, most notably the robot doing whatever it was doing when it bugged out, infinitely until you turn it off. –The VEX Raptors

My experience with IMEs this year was that they failed on 50% of the runs after [our] lift moved up and down several times. After reading up on vexforum the only thing that became clear was that nobody really knows for sure what is going on. So, since we had plenty of other issues to deal with – we just moved to quad encoders and it worked flawlessly.…

Read through the various VEX Forum posts linked here, and you will see a lot of people report things like: their 5 IMEs were working fine for several months, and now nothing they can do will get the last 2 in the chain working and they’ve tried everything, and please help! … and here’s another update from the next day … now they turned the robot on, and all the IMEs are working fine. Over the course of the season for our robot:

Unplug the daisy-chain from the cortex every time you turn off/on the robot to make sure they are really really reset. I so wish I had known this when my team was using them. VEX Forum user Gold Rush says in this post:

Re-download your firmware onto the cortex. Per edjubuh on the VEX Forum (as mentioned above under Ghosting), try force-re-downloading the RobotC or easyC firmware onto the cortex (possibly on a regular basis, if it appears to have any temporary positive effects).

Troubleshooting process. The awesome jpearman on the VEX Forum offers a useful, systematic process of troubleshooting your IME system when you have (a) a system that used to work that now doesn’t, or (b) an IME daisy chain that stops working half-way through. In the second comment/response in this thread, he walks through the process of, essentially, rebuilding your chain from one motor on up, in a way that ensures that each IME and connecting cable is functional.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey