creating a pcb for lcd touch screen factory

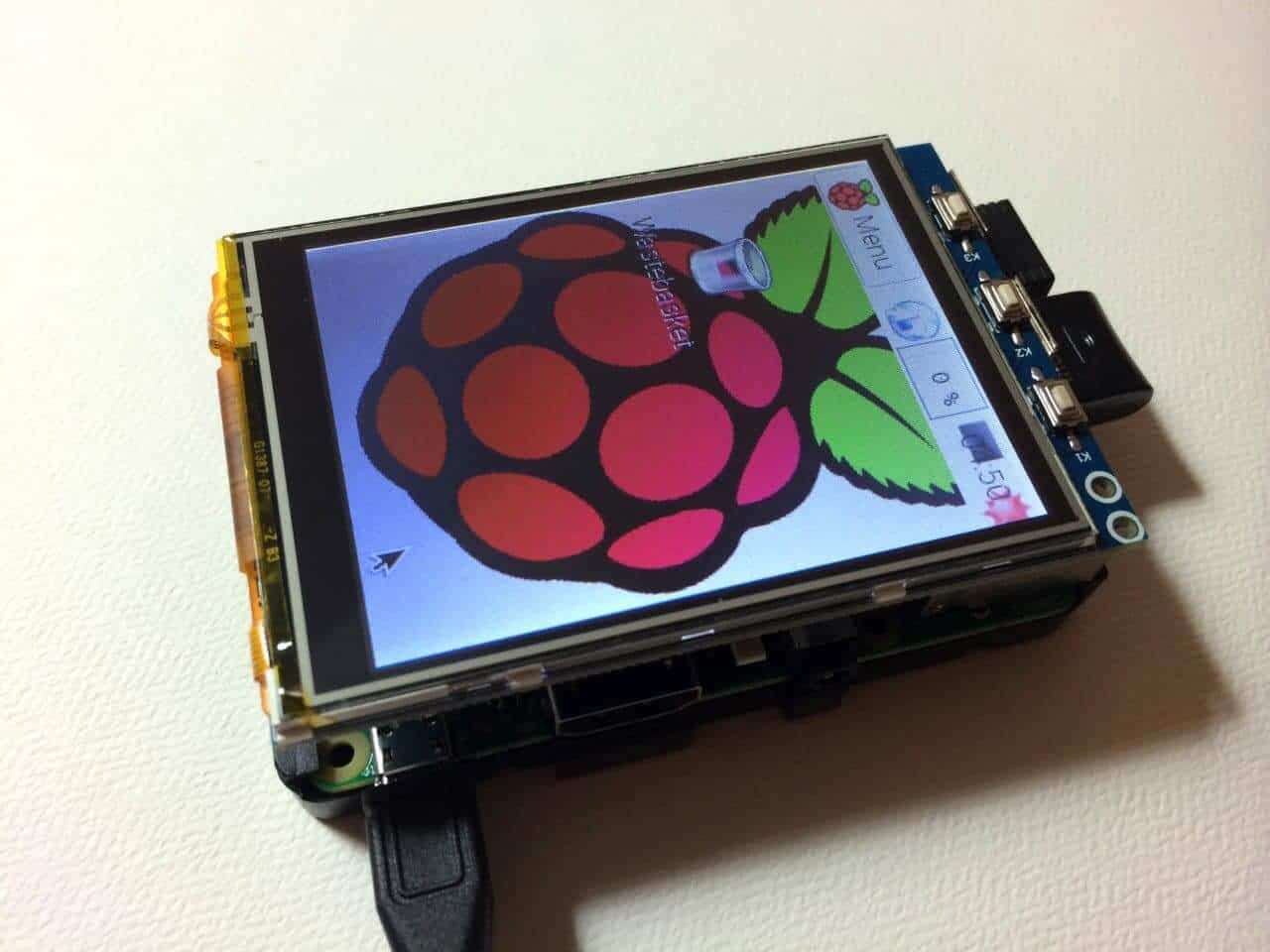

We worked with the client to determine what they wanted to have the touch-screen display do and what it should look like. We then picked an appropriate touch-screen based on the size, resolution, and availability.

As the electronics were being designed, we also started work on the software. This is where the software commands to control the display as well as the client"s graphical interface were created.

In addition to the previous steps, we also needed to create a mounting system for the display. Since the display we chose had no mounting holes of its own, we had to design in Solidworks a cradle that both held the display and the driver board to come. This cradle would then attach to the project case. Because we have two 3D printers in-house, we were able to quickly iterate plastic prototypes until we had the ideal cradle.

Once the cradle was designed, we then worked out what hardware was needed to mount everything together. Also, we needed to create a rubber gasket based on the design parameters of the cradle and the display. This was all done in Solidworks by creating a virtual assembly of the entire project.

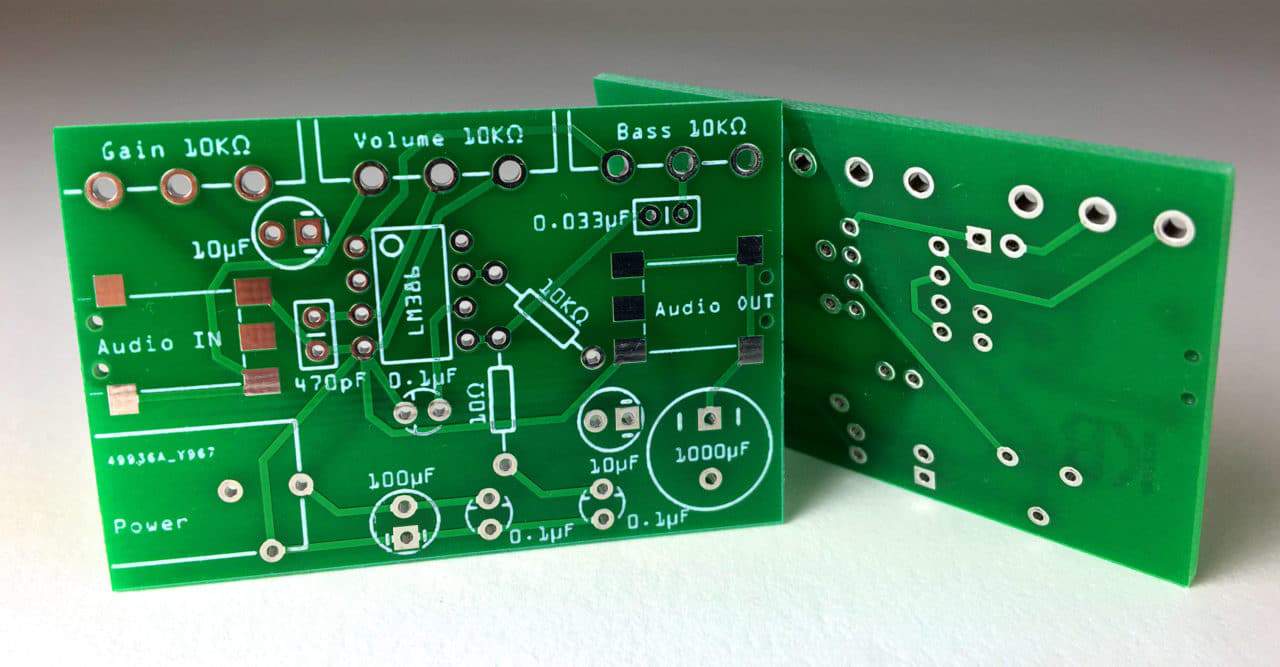

The cradle design dictated the size of the circuit board driver for the display. With that information now determined, the circuit board was designed.

And lastly, the display was built in-house using our surface-mount machinery and skilled technicians. Once assembled, the driver board was programmed with the custom software and tested.

A PCB is sort of like a layer cake or lasagna- there are alternating layers of different materials which are laminated together with heat and adhesive such that the result is a single object.

The base material, or substrate, is usually fiberglass. Historically, the most common designator for this fiberglass is "FR4". This solid core gives the PCB its rigidity and thickness. There are also flexible PCBs built on flexible high-temperature plastic (Kapton or the equivalent).

You will find many different thickness PCBs; the most common thickness for SparkFun products is 1.6mm (0.063"). Some of our products- LilyPad boards and Arudino Pro Micro boards- use a 0.8mm thick board.

Cheaper PCBs and perf boards (shown above) will be made with other materials such as epoxies or phenolics which lack the durability of FR4 but are much less expensive. You will know you are working with this type of PCB when you solder to it - they have a very distictive bad smell. These types of substrates are also typically found in low-end consumer electronics. Phenolics have a low thermal decomposition temperature which causes them to delaminate, smoke and char when the soldering iron is held too long on the board.

The next layer is a thin copper foil, which is laminated to the board with heat and adhesive. On common, double sided PCBs, copper is applied to both sides of the substrate. In lower cost electronic gadgets the PCB may have copper on only one side. When we refer to a double sided or 2-layer board we are referring to the number of copper layers (2) in our lasagna. This can be as few as 1 layer or as many as 16 layers or more.

The copper thickness can vary and is specified by weight, in ounces per square foot. The vast majority of PCBs have 1 ounce of copper per square foot but some PCBs that handle very high power may use 2 or 3 ounce copper. Each ounce per square translates to about 35 micrometers or 1.4 thousandths of an inch of thickness of copper.

The layer on top of the copper foil is called the soldermask layer. This layer gives the PCB its green (or, at SparkFun, red) color. It is overlaid onto the copper layer to insulate the copper traces from accidental contact with other metal, solder, or conductive bits. This layer helps the user to solder to the correct places and prevent solder jumpers.

In the example below, the green solder mask is applied to the majority of the PCB, covering up the small traces but leaving the silver rings and SMD pads exposed so they can be soldered to.

Soldermask is most commonly green in color but nearly any color is possible. We use red for almost all the SparkFun boards, white for the IOIO board, and purple for the LilyPad boards.

The white silkscreen layer is applied on top of the soldermask layer. The silkscreen adds letters, numbers, and symbols to the PCB that allow for easier assembly and indicators for humans to better understand the board. We often use silkscreen labels to indicate what the function of each pin or LED.

Silkscreen is most commonly white but any ink color can be used. Black, gray, red, and even yellow silkscreen colors are widely available; it is, however, uncommon to see more than one color on a single board.

Breadboards are great for prototyping circuits, but they aren’t so good for actually using the thing you’re building. At some point, you’ll probably want to make a project more permanent. The best way to do that is to put it on a PCB.

In this tutorial, I’ll walk you through the process of designing a PCB layout and getting it printed by a custom PCB manufacturer. The performance of your circuit will depend greatly on how it’s laid out on the PCB, so I’ll give you lots of tips on how to optimize your design.

You can always etch PCBs at home with a process that’s similar to developing prints from photographic film. But that method is messy and it uses a lot of chemicals. It’s much easier (and cheaper) to get your PCB made by a professional manufacturer. To demonstrate the process, I’ll use an online service called EasyEDA to design a PCB layout for an LM386 audio amplifier, then I’ll have it manufactured and show you the results. Their free online design software is easy to use and the rates are very affordable.

Before you start designing your PCB, it’s a good idea to make a schematic of your circuit. The schematic will serve as a blueprint for laying out the traces and placing the components on the PCB. Plus, the PCB editing software can import all of the components, footprints, and wires into the PCB file, which will make the design process easier (more on this later).

It’s best to place all of your schematic symbols on the canvas before drawing any wires. In EasyEDA, schematic symbols are located in “Libraries”. The default EasyEDA library has most of the common symbols, but there are also “User Generated Libraries” with lots of other symbols:

Each schematic symbol you use needs to have a PCB footprint associated with it. The PCB footprint will define the component’s physical dimensions and placement of the copper pads or through holes. Now is a good time to decide which components you’ll be using.

The schematic symbols in the EasyEDA library already have footprints associated with them, but they can be changed if your’re using a different size or style:

To change the footprint associated with a schematic symbol, search in the “User Generated” libraries for a footprint that matches the component you’re using. Once you find it, click on the heart icon to “Favorite” it:

Now click on the symbol in the schematic editor, and paste the name of the new footprint into the “package” field in the right sidebar menu (watch the video below for a demonstration):

Once all of your symbols are placed on the schematic and you’ve assigned footprints to each symbol, it’s time to start drawing the wires. Rather than explain the details of all that in this article, I’ve made a video so you can watch me draw the schematic for my LM386 audio amplifier:

After all the wiring is done, it’s a good idea to label the symbols. The labels will be transferred over to the PCB layout and eventually be printed on the finished PCB. Each symbol has a name (R1, R2, C1, C2 etc.) and value (10 μF, 100 Ω, etc.) that can be edited by clicking on the label.

The next step is to import the schematic into the PCB editor, but before we do that, let’s talk about some things to keep in mind when designing your PCB.

Identify what each part of your circuit does, and divide the circuit into sections according to function. For example, my LM386 audio amplifier circuit has four main sections: a power supply, an audio input, the LM386, and an audio output. It might help to draw some diagrams at this point to help you visualize the design before you start laying it out.

Keep the components in each section grouped together in the same area of the PCB to keep the conductive traces short. Long traces can pick up electromagnetic radiation from other sources, which can cause interference and noise.

The different sections of your circuit should be arranged so the path of electrical current is as linear as possible. The signals in your circuit should flow in a direct path from one section to another, which will keep the traces shorter.

Each section of the circuit should be supplied power with separate traces of equal length. This is called a star configuration, and it ensures that each section gets an equal supply voltage. If sections are connected in a daisy-chain configuration, the current drawn from sections closer to the supply will create a voltage drop and result in lower voltages at sections further from the supply:

It’s not uncommon to see round, triangular, or other interesting PCB shapes. Most PCBs are designed to be as small as possible, but that’s not necessary if your application doesn’t require it.

If you plan on putting the PCB into an enclosure, the dimensions may be limited by the size of the housing. In that case, you’ll need to know the enclosure’s dimensions before laying out the PCB so that everything fits inside.

The components you use will also have an effect on the size of the finished PCB. For instance, surface mounted components are small and have a low profile, so you’ll be able to make the PCB smaller. Through hole components are larger, but they’re often easier to find and easier to solder.

The location of components like power connections, potentiometers, LEDs, and audio jacks in your finished project will affect how your PCB is laid out. Do you need an LED near a power switch to indicate that it’s on? Or do you need to put a volume potentiometer next to a gain potentiometer? For the best user experience you might have to make some compromises and design the rest of your PCB around the locations of these components.

Larger circuits can be difficult to design on a single layer PCB because it’s hard to route the traces without intersecting one another. You might need to use two copper layers, with traces routed on both sides of the PCB.

The traces on one layer can be connected to the other layer with a via. A via is a copper plated hole in the PCB that electrically connects the top layer to the bottom layer. You can also connect top and bottom traces at a component’s through hole:

Some double layer PCBs have a ground layer, where the entire bottom layer is covered with a copper plane connected to ground. The positive traces are routed on top and connections to ground are made with through holes or vias. Ground layers are good for circuits that are prone to interference, because the large area of copper acts as a shield against electromagnetic fields. They also help dissipate the heat generated by the components.

Most PCB manufacturers will let you order different layer thicknesses. Copper weight is the term manufacturers use to describe the layer thickness, and it’s measured in ounces. The thickness of a layer will affect how much current can flow through the circuit without damaging the traces. Trace width is another factor that affects how much current can safely flow through the circuit (discussed below). To determine safe values for width and thickness, you need to know the amperage that will flow through the trace in question. Use an online trace width calculator to determine the ideal trace thickness and width for a given amperage.

If you look at a professionally designed PCB, you’ll probably notice that most of the copper traces bend at 45° angles. One reason for this is that 45° angles shorten the electrical path between components compared to 90° angles. Another reason is that high speed logic signals can get reflected off the back of the angle, causing interference:

If your project uses digital logic or high speed communication protocols above 200 MHz, you should probably avoid 90° angles and vias in your traces. For slower speed circuits, 90° traces won’t have much of an effect on the performance of your circuit.

The proximity of traces to components and adjacent traces will also determine how wide your traces can be. If you’re designing a small PCB with lots of traces and components, you might need to make the traces narrow for everything to fit.

Notice the thin blue lines connecting the components. These are called ratsnest lines. Ratsnest lines are virtual wires that represent the connections between components. They show you where you need to route the traces according to the wiring connections you created in your schematic:

Now you can start arranging the components, keeping in mind the design tips mentioned above. You might want to do some research to find out if there are any special design requirements for your circuit. Some circuits perform better with certain components in specific locations. For example, in an LM386 amplifier circuit the power supply decoupling capacitors need to be placed close to the chip to reduce noise.

After you’ve arranged all of the components, it’s time to start drawing the traces. Use the ratsnest wires as a rough guide for routing each trace. However, they won’t always show you the best way to route the traces, so it’s a good idea to refer back to your schematic to verify the correct connections.

Traces can also be routed automatically using the software’s auto-router. For complicated circuits, it’s generally better to route traces manually, but try the auto-router on simpler designs and see what it comes up with. You can always adjust individual traces later.

The last thing to do before placing the order is to run a design rule check. A design rule check will tell you if any components overlap or if traces are routed too close together. The design rule check can be found by clicking the “Design Manager” button in the right side window:

Items that fail the design rule check will be listed below the “DRC Errors” folder. If you click on one of the errors, the problem trace or component will be highlighted in the PCB view:

You can specify your own settings for the design rule check by clicking the drop down menu in the upper right hand corner and going to Miscellaneous > Design Rule Settings:

At this point it’s a good idea to double check your PCB layout against your schematic to make sure that everything is connected properly. If you’re satisfied with the result, the next step is to order the PCB. EasyEDA makes this part really easy…

You can select the number of PCBs you want to order, the number of copper layers, the PCB thickness, copper weight, and even the PCB color. After you’ve made your selections, click “Save to Cart” and you’ll be taken to a page where you can enter your shipping address and billing information.

Gerber files are a set of image files that contain the patterns used to manufacture your PCB. All of the files are compressed into a single .zip file. There is a separate file for the copper traces, silk screen, and locations of drill holes and vias:

I ordered 15 PCBs for my LM386 audio amplifier circuit and the cost came out to about $15 USD. Manufacturing and shipping took about two weeks. The PCBs were well made, and I couldn’t find any defects. After I soldered on the components and tested the amplifier, it worked great. You can clone my LM386 amplifier schematic and PCB here if you want.

Making your own custom PCB is a lot of fun, and the results can be very rewarding. Hopefully this article will help you get your prototype circuit onto a PCB. Let us know in the comments if you have any questions, and let us know what PCB design projects you have planned. If you liked this tutorial and want to get more like it, be sure to subscribe!

The world is growing at a very fast pace in terms of modern technology and the effects are easily on our daily lives. Our life style has changed greatly. This technological advancement has brought many advance equipment in the world that we did not imagine about 10 years ago. The core of these equipment is electronics engineering and the nucleus is the Printed Circuit Boards (PCBs).

The PCB is something that is usually green in color and is a rigid body that holds various electronic components on it. These components are soldered upon the PCBs in the process called “PCB Assembly” or PCBA. The PCB is composed of a substrate that is made of fiber glass, the components, the copper layer that makes the traces, holes in which components are fitted and layers that can be inner layer and outer layers. At RayPCB we can deliver up to 1-36 layers for multilayer PCB prototypes and 1-10 layers for multilayer PCBs for mass production. For single sided PCB and double sided PCBs, the outer layers present but no inner layer.

The pcb substrate and components are insulated with solder mask and held together with epoxy resin. This solder mask can be green, blue or red in color as commonly found in PCB colors. Thesolder mask will allow the components to avoid short circuit with tracks or other components.

The copper traces are used to carry electronic signals from one point to the other on the PCB. These signals can be high speed digital signals or discrete analog signals. These traces can be made thick to carry power / electricity to power up components.

In most of the PCBs which are made to supply high voltage or current, there is a separate plane of ground connection. The electronic components on top layer are connected to inner GND plane or inner signals layer by means of “Vias”.

The components are assembled on the PCB to allow the PCBto function as it is designed. The most important thing is the PCB functionality. The PCB may not work even if a tiny SMT resistor is not properly placed or even if a small track is cut from the PCB manufacturer. So it is very important the components are assembledin proper way. The PCB when components are assembled is called PCBA or Assembled PCB.

The functionality of PCBs can be complex or simple depending on the specifications described by the client or user. The PCB sizes are also different depends upon requirements.

3- Solder Mask: It is the layer that is applied on top and bottom of PCB. This is used to create non-conductive region of PCB and it isolates the copper traces from each other to protect short circuit. Thesolder mask also avoids soldering on unwanted parts and assures that soldergoes on that area that is meant for soldering like holes and pads. The holes will attach the THT components on PCB while the PADs are used to hold SMT components.

PCB fabrication for components designator, like R1, C1 or some sort of description on PCB or company logo it is all made of silk screen layer. This silk screen layer provides the vital information about that PCB.

The PCBs are the majority of PCBs we see all around us in various types of devices. These are hard, rigid and solid PCBs with various thickness. The main material is the fiber glass or simple “FR4”. FR4 means “Fire Retardant – 4”. The self extinguishing property of FR-4 makes it favorable for use in many hard core industrial electronic devices. The two sides of FR-4 is laminated with thin layer of copper foil also known as copper clad laminates. Main applications where FR-4 copper clad laminates are sued in are power amplifier, switch mode power supplies, servo motor drives etc. On the other hand another type of rigid PCB circuit prototype substrate commonly used in home appliances and IT products is known as Paper Phenolic PCB. They are light weight, low density, cheap and easy to punch process. Calculators, keyboards, and mouse are some of its applications.

Theflexible PCBs are made of the substrate material like Kapton that can withstand very high temperatures while the thickness is as low as 0.005 inch. The can bend easily and are used in wearable electronics, connectors of LCD displays or laptops, connectors of keyboard and camera etc.

Alternatively another PCB base material can be used like Aluminumthat is very good at dispersing heat effectively. These types of PCBs can be used in applications requiring heat sensitive components like high power LEDs, laser diodes,ultra-thin lcd pcb etc.

THT:THT stands for“Through hole Technology”.The components with leads and wires, like resistors, capacitors, inductors, PDIP ICs, transformers, transistors, IGBTs, MOSFETS are example.

The component has to be inserted on one side of PCB and pulled by leg on other side and cut the leg and solder it. The THT components assembly is usually done by hand soldering and is relatively easy.

Before going to the actualPCB fabrication and PCB Assembly process, the manufacturer checks the PCB for any flaws or errors in the PCB that can result in malfunction. This process is called Design for Manufacturing (DFM) process. The Manufacturer must carry out these basic DFM steps to ensure flawless PCB.

1- Component LayoutConsideration: Through hole components with polarity must be checked. Like Electrolytic capacitor polarity must be checked, diode anode and cathode polarity check, SMT tantalum capacitors polarity check. ICs notch/head direction must be checked.

After performing the DFM check, the manufacturer can easily reduce the cost of manufacturing by cutting down the number of scrapped boards. This will help in quick turn around by avoiding faults at DFM level. At RayPCB we provide DFM and DFT check at circuit assembly and prototyping. At RayPCB we offer PCB OEM services,wave soldering, PCB Card testing and SMT assembly using state of the art OEM equipment.

First of all we apply thesolder paste on the areas of the printed circuit board assemblies where the components will fit. This is done by applying solder paste on the stainless steel stencil. The stencil and the PCB are hold together by a mechanical fixture and then the solder paste is applied by the applicator evenly to all opening in the board. The applicator spreads the solder paste equally. So a right amount of solder paste must be used in applicator. When the applicator is removed the paste will remain in the desired areas of PCB. The grey color solder paste is 96.5% made of tin and contains 3% of silver and 0.5% of copper and it is lead free. This solder paste will melt and creates a strong joint upon application of heat in step 3.

The second step in pcba is the automated placement of SMT components on PCB board. This is done by using pick and place robot. At the design level the designer creates a file that will be fed to the automated robot. This file has the preprogrammed X,Y coordinates of each and every components used in PCB and it identifies the location of all components. Using this information the robot will simply place the SMD devices on board accurately. The pick and place robots will pick the components from its vacuum grip and place exactly on top of solder paste.

Before the advent of robotic pick and place machines, the technician will pick the components using tweezers and place it on PCB by carefully looking at the location and avoiding any jittering hands. This resulted in high level of fatigue and eyesight weakness in technicians and resulted in slowed process of PCB assembly of SMT components. Hence the chances of mistake were high.

As the technology matured, automated robots for pick and place components eased the technicians work and resulted in fast and accurate components placement. These robots can work 24/7 without fatigue.

The third step after the components are set and solder paste applied is reflow soldering. The reflow soldering is the process where the PCBs along with the components are put on the conveyer belt. This conveyer belt then moves the PCBs and components in a big oven, which creates a temperature of 250o C. This temperature is enough for the solder to melt. The melted solder will then fix the components upon the PCB and create joints. After the PCB is treated with high temperature, it then goes in to coolers. These coolers then solidifies the solder joints in controlled fashion. This will create a permanent joint between SMT component and PCB. In the case of two sided PCBs, the PCB side which has fewer or smaller components will be treated first from step 1 to 3 as mentioned above and then comes the other side.

After the reflow soldering, there is a chance that due to some erroneous movement in PCB holding tray, the components got misaligned and may result in short circuit or open connection. These flaws are need to be identified and this identification process is called inspection. Inspection can be manual and automated.

As the PCB has the small SMT components, so visually checking the board for any misalignment or faults can result in fatigue and eye strains for technicians. So this method is not feasible for advance SMT boards due to inaccurate results. However this method is feasible for boards having THT components and lesser components density.

For the large batches of PCB, this method is feasible. This method uses the automated machine that has the high powered and high resolution cameras installed at various angles to view the solder joints from various directions. The light will reflect the solder joints in different angles according to the quality of solder joints. This automated Optical Inspection (AOI)machine is very high speed and take very short time to process large batches of PCBs.

TheX-Ray machine allows the technician to look through the PCB to see the inner layer defects. This is not a common inspection method and is only used in complex and advance PCBs. These inspection methods if not properly applied may cause rework or scrap PCB. The inspection need be done regular basis to avoid delays, labor and material cost.

The through-hole components are commonly found on many PCB boards. These components are also known as Plated through Hole (PTH). These components have leads that will pass through the hole in the PCB. These holes connect to other holes and vias by means of copper traces. When these THT components are inserted and soldered in these holes, then they are electrically connected to other hole in the same PCB as the circuit designed. These PCBs may contain some THT components and many SMD components so the soldering method as discussed above in case of SMT components like reflow soldering will not work on THT components. So the two main types of THT components soldering or prototype pcb assembly are

The manual soldering method is the common and typically takes more time than compared to automated setup for SMT. Usually one technician is designated to insert one component at a time and the board is passed on to other technician who inserts another component on the same board. So the board will move all around the assembly line to get the PTH components stuffed upon it. This makes the process lengthy and so many PCB design and manufacturing companies avoid using PTH components in their circuit design. But still the PTH components are the most favorite and common components for most of the circuit designers.

The automated version of manual soldering is wave soldering. In this method, once the PTH components are placed on the PCB, the PCB is put on the conveyer belt and is moved to specialized oven. Here a wave of molten solder is splashed on the PCB bottom layer where the components leads are present. This will solder all the pins at once. However this method is only for single sided PCBs and not for double sided because this molten solder while soldering one side of PCB can damage components on other side. After this, the pcb fabrication and assembly is moved for final inspection.

Now the PCB is ready for testing and inspection. This is the functionality test, where electrical signals and power supply is given to the PCB at the specified pins and output is checked at the specified test points or output connectors. This test requires common lab instruments like oscilloscope, DMM, function generator

This test is to check the functionality and electrical characteristics of PCB and to verify current, voltage, analog and digital signals as described in the requirements of PCB and circuit design

If any of the parameters of the PCB shows unacceptable results, then the PCB is discarded or scrapped as per the company standard procedures. Testing phase is very important because it determines the success or failure of the entire process of PCBA.

Now that the PCB is tested and declared OK from all aspects, it is time now to clean the unwanted residual flux, finger dirt and oils stains. A stainless steel based high pressure washing tool using deionized water is sufficient to clean all types of dirt. The deionized water will not damage the PCB circuit. After washing the PCB is dried by compressed air. Now the final PCB is ready for pack up and shipment.

PCB electronic products refer to the selection of competent electronicprocessing companies to help produce products in order to focus on the research and development and market development of new products. PCBA electronic product manufacturing process mainly includes material procurement, SMT chip processing, DIP plug-in processing, PCBA testing, finished product assembly and logistics distribution. Prototype pcb assembly manufacturing process is as follows:

The electronic processing factory purchaseselectronic component materials, PCB boards, and steel mesh and fixtures according to the orders placed by customers.

Material on-line production, through solder paste printing, patch, reflow soldering, AOI inspection, DIP plug-in and wave soldering and other processing links, complete the processing and soldering of PCB, there will be quality inspection in every step of processing.

The electronic processing factory carries out testing according to its own testing process, combined with the test plan provided by the customer, and repairs the discovered defective products.

After all products are produced, they are packaged and shipped according to customer needs. PCBA electronic product processing is a relatively complicated process. In the process of production, each employee needs to work together and strictly follow the production process to control the quality, meet the customer’s quality requirements, and deliver the perfect product.

All touch screen PCB is available in the wide range of sizes and capacities. For those in large commercialities, the touchscreen PCB is available in different sizes and won ’ t leave any customer interested in the matter of they are looking for the new touch in PCB or for other industrial. touchscreen PCb is available in a wide range of colors, and functionality. No matter the touch of PCB is for use, businesses in large commercialities and such places are need to have more options.

The touchscreen PCb assembly is one of the most popular types. It is scratch-resistant and easy to install in a variety of settings, and for the best performance, Alibaba.com has a wide range of touchscreen PCb assembly and types, touchscreen PCb assembly is also available. scratch-resistant and easy to repair without the degradable quality of the components, being one of the most popular types.

Most people who have dabbled in the world of electronic construction will be familiar in some form with the process of producing a printed circuit board by exposing a UV sensitive coating through a transparent mask, before moving on to etching. Older readers will have created their masks by hand with crêpe paper tape on acetate, while perhaps younger ones started by laser-printing from their CAD package.

How about a refinement of the process, one which does away with the acetate mask entirely? [Ionel Ciobanuc] may have the answer, in the form of an exposure through an LCD screen. The video below the break shows how it’s done, starting with a (probably a bit too lengthy) sequence on applying the photo-resist coating to the board, and then sitting LCD on top of UV lamp with the board positioned at the top of the pile.

It’s an interesting demonstration, and one that certainly removes a step in the process of PCB creation as it brings the pattern direct from computer to board without an intermediate. Whether or not it’s worth the expenditure on an LCD is up to you, after all a sheet of acetate is pretty cheap and if you already have a laser printer you’re good to go. We’re curious to know whether or not any plastic components in the LCD itself might be damaged by long-term exposure to intense UV light.

Electronics ranging from mobile devices to large-scale interactive displays rely on PCB membrane switches to create an intuitive user interface. The printed circuit boards used in these assemblies can be rigid, semi-rigid or flexible and either single-sided, double-sided or multi-layered. The overlay is the final touch, giving a PCB membrane switch the look, texture, and functionality needed for its intended application.

We have the technology and expertise to produce custom, state-of-the-art PCB membrane switches and overlays for printed circuit boards that meet your unique requirements. Our engineers work with customer-supplied printed circuit boards to design and manufacture a pcb membrane switch assembly to meet your specific requirements.

Our custom PCB assemblies may utilize fewer pieces of hardware than other designs require. With fewer components and no metal panel, PCB assembly installation time is reduced, and there are fewer inventory items that are part of the printed circuit board assembly procedure. Using fewer components and eliminating the metal panel allows the PCB assembly and LEDs to be installed closer to the back of the display lens, resulting in better visual clarity for the user.

We can provide PCB overlay membrane switch assemblies with added components on the PCB in addition to the membrane switch circuitry. This layout results in extra space on other printed circuit boards in the total assembly when space is at a premium.

Our manufacturing capabilities enable us to create full control panel assemblies in complete, ready-to-use form. Build in a few or several layers to meet your design and functionality needs. Select from a non-tactile, tactile, or mixed panel PCB membrane switch, then complete the look with your preferred material, texturing, and window size. Our team is here to assist you through each step of the design process.

Add graphics to your custom membrane switch PCB assembly using our in-house screen printed or digital printing services. Digital printing can produce many special graphic effects such as color cross-fading, halftones, and near photo quality images. We also provide services for circuit layout, CAD design, proofing, prototyping, and more.

Dyna-Graphics offers unique hybrid PCB membrane switches that, with proper design, give your products an interface offering both touch screen and membrane switch inputs in an integrated environmentally sealed package.

We laminate touch screens directly to the back side of the membrane switches or graphic overlays. These assemblies can be applied directly onto your product to provide a custom sealed interface for your display. From new product designs to retrofitting existing devices, our hybrid touch screen/membrane switches provide the capabilities, performance, and functionality you need. The applications for these hybrid switches are practically limitless!

No matter what sort of custom design you need, from the simplest to the most complex, Dyna-Graphics can build a PCB membrane switch assembly to meet your unique requirements. Our team will work with you to develop the perfect custom control module solution.

Dyna-Graphics is an ISO 9001:2015 certified HMI (Human Machine Interface) solutions company. Additionally, all manufactured membrane switches and overlays are RoHS Compliant.

To improve the protection of human health and the environment posed by chemicals, Dyna-Graphics is proud to be REACH compliant and conflict minerals certified.

Dyna-Graphics is an ISO 9001:2015 certified HMI (Human Machine Interface) solutions company. Additionally, all manufactured membrane switches and overlays are RoHS Compliant.

To improve the protection of human health and the environment posed by chemicals, Dyna-Graphics is proud to be REACH compliant and conflict minerals certified.

Dyna-Graphics is an ISO 9001:2015 certified HMI (Human Machine Interface) solutions company. Additionally, all manufactured membrane switches and overlays are RoHS Compliant.

To improve the protection of human health and the environment posed by chemicals, Dyna-Graphics is proud to be REACH compliant and conflict minerals certified.

Responsible for performing installations and repairs (motors, starters, fuses, electrical power to machine etc.) for industrial equipment and machines in order to support the achievement of Nelson-Miller’s business goals and objectives:

• Perform highly diversified duties to install and maintain electrical apparatus on production machines and any other facility equipment (Screen Print, Punch Press, Steel Rule Die, Automated Machines, Turret, Laser Cutting Machines, etc.).

• Provide electrical emergency/unscheduled diagnostics, repairs of production equipment during production and performs scheduled electrical maintenance repairs of production equipment during machine service.

Important technical improvements of LCD, such as LED backlighting and wide viewing Angle, are directly related to LCD. And account for an LCD display 80% of the cost of the LCD panel, enough to show that the LCD panel is the core part of the entire display, the quality of the LCD panel, can be said to directly determine the quality of an LCD display.

The production of civil LCD displays is just an assembly process. The LCD panel, the main control circuit, shell, and other parts of the main assembly, basically will not have too complex technical problems.

Does this mean that LCDS are low-tech products? In fact, it is not. The production and manufacturing process of the LCD panels is very complicated, requiring at least 300 process processes. The whole process needs to be carried out in a dust-free environment and with precise technology.

The general structure of the LCD panel is not very complex, now the structure of the LCD panel is divided into two parts: the LCD panel and the backlight system.

Due to the LCD does not shine, so you need to use another light source to illuminate, the function of the backlight system is to this, but currently used CCFL lamp or LED backlight, don’t have the characteristics of the surface light source, so you need to guide plate, spreadsheet components, such as linear or point sources of light evenly across the surface, in order to make the entire LCD panel on the differences of luminous intensity is the same, but it is very difficult, to achieve the ideal state can be to try to reduce brightness non-uniformity, the backlight system has a lot to the test of design and workmanship.

In addition, there is a driving IC and printed circuit board beside the LCD panel, which is mainly used to control the rotation of LCD molecules in the LCD panel and the transmission of display signals. The LCD plate is thin and translucent without electricity. It is roughly shaped like a sandwich, with an LCD sandwiched between a layer of TFT glass and a layer of colored filters.

LCD with light refraction properties of solid crystals, with fluid flow characteristics at the same time, under the drive of the electrode, can be arranged in a way that, in accordance with the master want to control the strength of the light through, and then on the color filter, through the red, green, blue three colors of each pixel toning, eventually get the full-screen image.

According to the functional division, the LCD panel can be divided into the LCD panel and the backlight system. However, to produce an LCD panel, it needs to go through three complicated processes, namely, the manufacturing process of the front segment Array,the manufacturing process of the middle segment Cell, and the assembly of the rear segment module. Today we will be here, for you in detail to introduce the production of the LCD panel manufacturing process.

The manufacturing process of the LCD panel Array is mainly composed of four parts: film, yellow light, etch and peel film. If we just look at it in this way, many netizens do not understand the specific meaning of these four steps and why they do so.

First of all, the motion and arrangement of LCD molecules need electrons to drive them. Therefore, on the TFT glass, the carrier of LCD, there must be conductive parts to control the motion of LCD. In this case, we use ITO (Indium Tin Oxide) to do this.ITO is transparent and also acts as a thin-film conductive crystal so that it doesn’t block the backlight.

The different arrangement of LCD molecules and the rapid motion change can ensure that each pixel displays the corresponding color accurately and the image changes accurately and quickly, which requires the precision of LCD molecule control.ITO film needs special treatment, just like printing the circuit on the PCB board, drawing the conductive circuit on the whole LCD board.

First, the ITO film layer needs to be deposited on the TFT glass, so that there is a smooth and uniform ITO film on the whole TFT glass. Then, using ionized water, the ITO glass is cleaned and ready for the next step.

Next, a photoresist is applied to the glass on which ITO film is deposited, and a uniform photoresist layer is formed on the ITO glass. After baking for a period of time, the solvent of the photoresist was partially volatilized to increase the adhesion of the photoresist material to the ITO glass.

Ultraviolet light (UV) is used to illuminate the surface of the photoresist through a pre-made electrode pattern mask, which causes the photoresist layer to react. The photoresist is selectively exposed under ultraviolet light by covering the photoresist on the glass coated with the photoresist.

The exposed part of the photoresist is then washed away with the developer, leaving only the unexposed part, and the dissolved photoresist is then washed away with deionized water.

Then etch off the ITO film without photoresist covering with appropriate acid etching solution, and only retain the ITO film under the photoresist. ITO glass is conductive glass (In2O3 and SnO2). The ITO film not covered by photoresist is easy to react with acid, while the ITO film covered by photoresist can be retained to obtain the corresponding wire electrode.

Stripping: High concentration of alkali solution (NaOH solution) is used as a stripping solution to peel off the remaining photoresist on the glass so that ITO glass can form ITO graphics exactly consistent with the photolithography mask.

Rinse the basic label of glass with an organic solution and remove the photolithographic tape after reaction to keep the glass clean. This completes the first thin-film conductive crystal process, which generally requires at least five identical processes to form a complex and sophisticated pattern of electrodes on the glass.

This completes the previous Array process. It is not difficult to see from the whole process that ITO film is deposited, photoresist coated, exposed, developed, and etched on TFT glass, and finally, ITO electrode pattern designed in the early stage is formed on TFT glass to control the movement of LCD molecules on the glass. The general steps of the whole production process are not complicated, but the technical details and precautions are very complicated, so we will not introduce them here. Interested friends can consult relevant materials by themselves.

The glass that the LCD board uses makes a craft also very exquisite. (The manufacturing process flow of the LCD display screen)At present, the world’s largest LCD panel glass, mainly by the United States Corning, Japan Asahi glass manufacturers, located in the upstream of the production of LCD panel, these manufacturers have mastered the glass production technology patents. A few months ago, the earthquake caused a corning glass furnace shutdown incident, which has caused a certain impact on the LCD panel industry, you can see its position in the industry.

As mentioned earlier, the LCD panel is structured like a sandwich, with an LCD sandwiched between the lower TFT glass and the upper color filter. The terminal Cell process in LCD panel manufacturing involves the TFT glass being glued to the top and bottom of a colored filter, but this is not a simple bonding process that requires a lot of technical detail.

As you can see from the figure above, the glass is divided into 6 pieces of the same size. In other words, the LCD made from this glass is finally cut into 6 pieces, and the size of each piece is the final size. When the glass is cast, the specifications and sizes of each glass have been designed in advance.

Then, the organic polymer directional material is coated on the surface of the glass, that is, a uniform directional layer is applied to the appropriate position of ITO glass by the method of selective coating. Meanwhile, the directional layer is cured.

Directional friction:Flannelette material is used to rub the surface of the layer in a specific direction so that the LCD molecules can be arranged along the friction direction of the aligned layer in the future to ensure the consistency of the arrangement of LCD molecules. After the alignment friction, there will be some contaminants such as flannelette thread, which need to be washed away through a special cleaning process.

After the TFT glass substrate is cleaned, a sealant coating is applied to allow the TFT glass substrate to be bonded to the color filter and to prevent LCD outflow.

Finally, the conductive adhesive is applied to the frame in the bonding direction of the glass of the color filter to ensure that external electrons can flow into the LCD layer. Then, according to the bonding mark on the TFT glass substrate and the color filter, two pieces of glass are bonded together, and the bonding material is solidified at high temperatures to make the upper and lower glasses fit statically.

Color filters are very important components of LCD panels. Manufacturers of color filters, like glass substrate manufacturers, are upstream of LCD panel manufacturers. Their oversupply or undersupply can directly affect the production schedule of LCD panels and indirectly affect the end market.

As can be seen from the above figure, each LCD panel is left with two edges after cutting. What is it used for? You can find the answer in the later module process

Finally, a polarizer is placed on both sides of each LCD substrate, with the horizontal polarizer facing outwards and the vertical polarizer facing inwards.

A polarizer is an optical plate that allows only light from a certain direction to pass through. It is an optical element that converts natural light into straight polarized light. The mechanism of action is to make the vertical direction light pass through the straight incident light after passing through the vertical polarizer, and the other horizontal direction light is absorbed, or use reflection and scattering and other effects to make its shade.

When making LCD panel, must up and down each use one, and presents the alternating direction, when has the electric field and does not have the electric field, causes the light to produce the phase difference and to present the light and dark state, uses in the display subtitle or the pattern.

The rear Module manufacturing process is mainly the integration of the drive IC pressing of the LCD substrate and the printed circuit board. This part can transmit the display signal received from the main control circuit to the drive IC to drive the LCD molecules to rotate and display the image. In addition, the backlight part will be integrated with the LCD substrate at this stage, and the complete LCD panel is completed.

Firstly, the heteroconductive adhesive is pressed on the two edges, which allows external electrons to enter the LCD substrate layer and acts as a bridge for electronic transmission

Next is the drive IC press. The main function of the drive IC is to output the required voltage to each pixel and control the degree of torsion of the LCD molecules. The drive IC is divided into two types. The source drive IC located in the X-axis is responsible for the input of data. It is characterized by high frequency and has an image function. The gate drive IC located in the Y-axis is responsible for the degree and speed of torsion of LCD molecules, which directly affects the response time of the LCD display. However, there are already many LCD panels that only have driving IC in the X-axis direction, perhaps because the Y-axis drive IC function has been integrated and simplified.

The press of the flexible circuit board can transmit data signals and act as the bridge between the external printed circuit and LCD. It can be bent and thus becomes a flexible or flexible circuit board

The manufacturing process of the LCD substrate still has a lot of details and matters needing attention, for example, rinse with clean, dry, dry, dry, ultrasonic cleaning, exposure, development and so on and so on, all have very strict technical details and requirements, so as to produce qualified eyes panel, interested friends can consult relevant technical information by a search engine.

LCD (LC) is a kind of LCD, which has the properties of light transmission and refraction of solid Crystal, as well as the flow property of Liquid. It is because of this property that it will be applied to the display field.

However, LCD does not emit light autonomously, so the display equipment using LCD as the display medium needs to be equipped with another backlight system.

First, a backplate is needed as the carrier of the light source. The common light source for LCD display equipment is CCFL cold cathode backlight, but it has started to switch to an LED backlight, but either one needs a backplate as the carrier.

CCFL backlight has been with LCD for a long time. Compared with LED backlight, CCFL backlight has many defects. However, it has gradually evolved to save 50% of the lamp and enhance the transmittance of the LCD panel, so as to achieve the purpose of energy-saving.

With the rapid development of LED in the field of lighting, the cost has been greatly reduced.LCD panels have also started to use LED as the backlight on a large scale. Currently, in order to control costs, an LED backlight is placed on the side rather than on the backplate, which can reduce the number of LED grains.

However, no matter CCFL backlight or LED backlight is placed in various ways, the nature of the backlight source cannot be a surface light source, but a linear light source or point light source. Therefore, other components are needed to evenly distribute the light to the whole surface. This task is accomplished by the diffuser plate and diffuser plate.

On the transparent diffuser plate, point-like printing can block part of the light. The LED backlight on the side drives the light from the side of the diffuser plate, and the light reflects and refracts back and forth in the diffuser plate, distributing the light evenly to the whole surface. Point-like printing blocks part of the light, screening the light evenly like a sieve.

At the top of the diffusion plate, there will be 3~4 diffuser pieces, constantly uniform light to the whole surface, improve the uniformity of light, which is directly related to the LCD panel display effect. Professional LCD in order to better control the brightness uniformity of the screen, panel procurement, the later backlight control circuit, will make great efforts to ensure the quality of the panel.

The backlight system also includes a backlight module laminator, located behind the backplane. In the CCFL backlight era, you can often see the long strip laminator like the one above, with each coil responsible for a set of tubes.

However, it is much simpler to use a side white LED as a backlight. The small circuit board on the far left of the figure above is the backlight of the LED.

This is the general structure of the backlight system. Since I have never seen the backlight mode of R.G.B LED, I cannot tell you what the backlight mode is like. I will share it with you when I see it in the future.

Since the LCD substrate and the backlight system are not fixed by bonding, a metal or rubber frame is needed to be added to the outer layer to fix the LCD substrate and the backlight system.

After the period of the Module, the process is completed in LCM (LCDModule) factory, the core of this part of the basic does not involve the use of LCD manufacturing technology, mainly is some assembly work, so some machine panel factories such as chi mei, Korea department such as Samsung panel factory, all set with LCM factories in mainland China, Duan Mo group after the LCD panel assembly, so that we can convenient mainland area each big monitor procurement contract with LCD TV manufacturers, can reduce the human in the whole manufacturing and transportation costs.

However, neither Taiwan nor Korea has any intention to set up factories in mainland China for the LCD panel front and middle manufacturing process involving core technologies. Therefore, there is still a long way to go for China to have its own LCD panel industry.

The double-sided PCB (or 2-layer PCB) is the printed circuit board with copper coated on both sides, top and bottom. There is an insulating layer in the middle. To use circuits on both sides, there must be a proper circuit connection between the two sides. The “bridges” between such circuits are call vias. A via is a small hole on the PCB board coated with metal, which can be connected with circuits on both sides.

The following section describes the steps involved in producing a double-sided board with solder mask over bare copper (SMOBC), plated through-holes (PTH), and gold-plated contacts and the component legend.

Using the information on the traveler- including the numbers and sizes of the panels, as well as any special instructions, the manufacturer prepares the materials necessary to process the order. PCBs start with copper-clad epoxy glass as the raw material. There are a lot of materials used in PCB manufacturing for users and PCB manufacturers to choose from. Different brands and materials have different characteristics, and different materials also provide different benefits, such as FR4, a ceramic substrate, iron substrate, aluminum substrate, etc.

Fr-4, one of the flame retardant materials widely used in PCB base substrates. FR4 board is economical and affordable and can maintain the stability and safety of the PCB board under extreme temperature conditions.

However, FR4 is not suitable for high-frequency and high-speed PCBs. At this time, we need to choose high-frequency materials, such as Rogers’ RO4000 series, RT5000/6000 series, Tacanic’s TLX series, and so on. Aluminum, metal, or copper as the substrate for LED PCB or aluminum PCB are used in the LED lighting industry.

The next step is to cut the board according to the requirement. The raw PCB board is quite large. There are various sizes available, such as 37 x 49 inches, 41 x 49 inches, and 43 x 49 inches. Therefore, it is cut in the required sizes that can be used in the machines. The board size obtained after cutting is not according to your circuit size; it is much larger. Your PCB size could be small, so multiple circuits on the board can make the process economical.

The circuit board goes to an automatic drilling machine that creates holes in the board quickly. The machine changes the drill bits on its own; everything is automated.

As drilling processes improves, burr-free holes can be produced. But most manufacturers process drilled panels through a deburring machine. The panels pass through brushes or abrasive wheels what mechanically remove any copper burns at he rims of the holes. Deburring also removes any fingerprints and oxides to create a smooth, shiny surface.

Electroless deposition of Cu through the holes as holes are composed of epoxy initially. After Cu deposition, panel is dipped in acid dip and anti-tarnish solution to prevent against oxidation. It is of two types- horizontal and vertical. Horizontal PTH is for carbon deposition and vertical PTH is for Cu deposition. Electroless copper is one of the most important steps in double-sided PCB and multilayer PCB manufacturing processes. Because all PCBs with 2 or more layers use plated through holes to connect the conductors between the layers.

In photo imaging, a negative image circuitry pattern is transferred to the PCB panel. First, the panel is covered with a layer of photoresist. The most common photoresist material is dry film plating resist is an ultraviolet (UV) light sensitive photo polymer. It’s supplied on a roll and applied by processing the panel through heated rollers on a hot roll laminator. Once the film is applied, the board is ready to be exposed to UV light for circuit printing.

The whole process is carried out in a room where there are only yellow lights. It is because photo-resistive films are sensitive to other lights. The film that has the circuit design is applied over the board; it is applied on both sides. Then, the board passes through a UV light chamber. When the board is exposed to UV light, the circuit part is hardened, while the excessive part remains the same.

First the panels are clamped in plating racks and immersed in a series of chemical bath that clean the copper pattern that makes up the circuitry. Next, the panels are immersed in a copper plating solution. The solution and panels have opposite electrolytical charges. These opposite polarities cause copper ions to migrate to the un coated copper areas on the panel, depositing the desired thickness of copper on the plates surface and in the holes. After copper plating the panels are moved from bath to bath. The circuitry pattern is covered with extra copper, is further electroplated with tin or tin/lead solder.

The panels are placed in a tank or spray machine to remove the imaging material. Theis step is also called resist stripping. After the resist is stripped off, the panels are placed in the conveyorized spray etcher or batch tank, where a chemical etchant (an ammonia-based compound) removes the uncovered copper but doesn’t’ attack the tin or tin/lead plating, which protects the copper underneath. The tin or tin/lead plating is called the etch resist. Then the tin or tin/lead is chemically stripped from the copper, revealing the copper circuitry pattern.

Green, white, blue, and other colors of solder mask on the circuit is a thin layer of polymer that works as an insulator between two conducting lines. It prevents the formation of short circuits. The mask is applied all over the board, and then it is dried. Remove the excess solder mask that is over the circuit. A film that contains circuit patterns is applied over the board. Then the board goes through a UV chamber. The solder other than the circuit is hardened while the solder mask over the circuit remains the same. Finally, the solder mask over the circuit is cleaned.

The copper on the board can undergo oxidation. It cannot last for a long time. Therefore, it is necessary to apply a surface finish over copper to protect it from oxidation. There are many types of surface finishes available, and customers can pick according to their needs. You can choose HASL, OSP, ENIG, ENEG, ENEPIG, Immersion tin, Immersion silver, etc.

Other plating finishes are used, most commonly gold. However, copper and gold tend to undergo solid state diffusion into each other (with copper doing so at a faster rate); the process is accelerated by increased temperature. Copper on a trace surface oxidizes, resulting in increased contact resistance (copper migrating into the gold can cause the gold to tarnish and corrode). This can be minimized by plating a barrier layer between the copper and gold. Nickel is commonly used as a barrier layer to prevent the gold migrating into the copper on the tracks. (The nickel barrier helps to reduce both the number and the effect of pores compared with plating gold directly over the copper base.) The nickel protective coating provides several benefits. It serves as a backing to the gold for extra hardness as well as providing an effective diffusion barrier layer between gold and copper. The nickel/gold provides a finish that is heat and corrosion resistant, environmentally stable, wire solderable and durable (the nickel underplate enhances the wear characteristics of gold) albeit at a higher cost than simple solder finishes. Traditionally, nickel/gold plating has been applied over copper tracks used for keyboard contacts or edge fingers to provide the conductive, corrosion resistant coating. This approach provides benefits for soldering,

The labels on the PCB are called silkscreens. These can be used to mark components and insert the logo. In this step, the PCB board enters into a giant printer that prints the labels on the board. Silkscreens are available in various colors, such as red, blue, yellow, and black, but the standard color is white.

For this purpose, the Flying Probe Test is used. It is a simple test in which there are multiple probes. The probes are placed over the connections, and the current is passed through them. It checks whether the circuit is working as expected or not. For instance, if there is no connection between two paths, then the current should not pass if the probes are connected to them.

If you have any questions about Orient Display PCB (Printed Circuit Board). Please feel free to contact: Sales Inquiries, Customer Service or Technical Support.

<

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey