creating a pcb for lcd touch screen free sample

Breadboards are great for prototyping circuits, but they aren’t so good for actually using the thing you’re building. At some point, you’ll probably want to make a project more permanent. The best way to do that is to put it on a PCB.

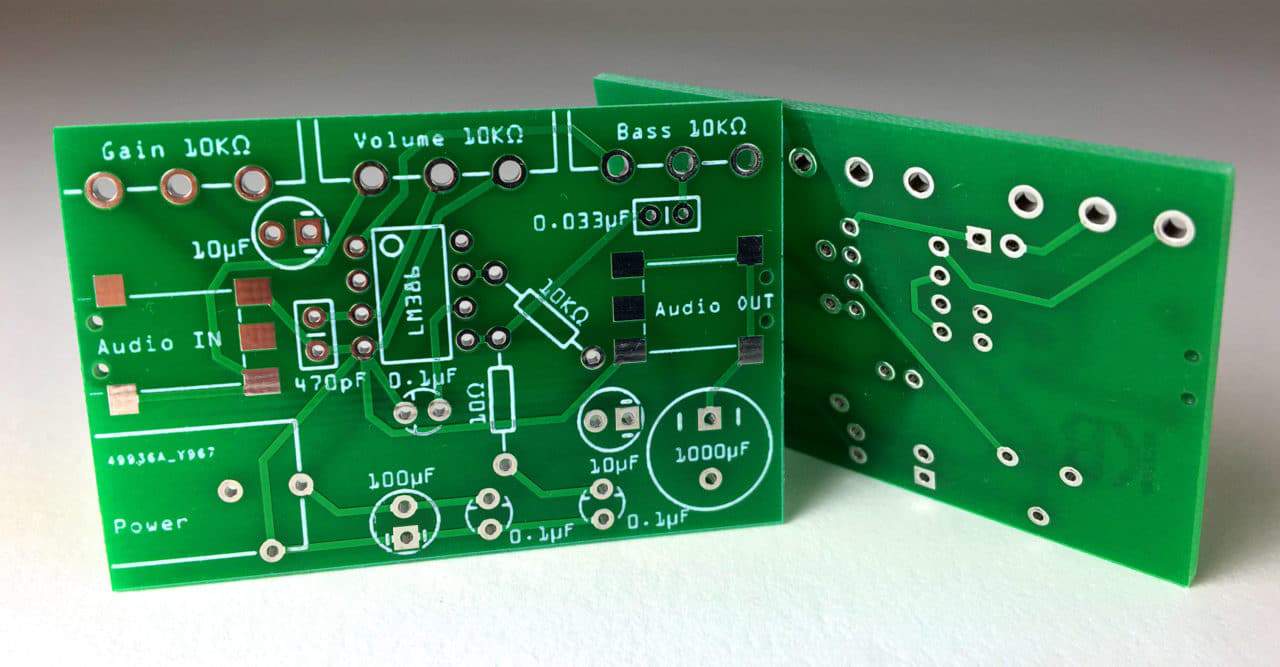

In this tutorial, I’ll walk you through the process of designing a PCB layout and getting it printed by a custom PCB manufacturer. The performance of your circuit will depend greatly on how it’s laid out on the PCB, so I’ll give you lots of tips on how to optimize your design.

You can always etch PCBs at home with a process that’s similar to developing prints from photographic film. But that method is messy and it uses a lot of chemicals. It’s much easier (and cheaper) to get your PCB made by a professional manufacturer. To demonstrate the process, I’ll use an online service called EasyEDA to design a PCB layout for an LM386 audio amplifier, then I’ll have it manufactured and show you the results. Their free online design software is easy to use and the rates are very affordable.

Before you start designing your PCB, it’s a good idea to make a schematic of your circuit. The schematic will serve as a blueprint for laying out the traces and placing the components on the PCB. Plus, the PCB editing software can import all of the components, footprints, and wires into the PCB file, which will make the design process easier (more on this later).

It’s best to place all of your schematic symbols on the canvas before drawing any wires. In EasyEDA, schematic symbols are located in “Libraries”. The default EasyEDA library has most of the common symbols, but there are also “User Generated Libraries” with lots of other symbols:

Each schematic symbol you use needs to have a PCB footprint associated with it. The PCB footprint will define the component’s physical dimensions and placement of the copper pads or through holes. Now is a good time to decide which components you’ll be using.

The schematic symbols in the EasyEDA library already have footprints associated with them, but they can be changed if your’re using a different size or style:

To change the footprint associated with a schematic symbol, search in the “User Generated” libraries for a footprint that matches the component you’re using. Once you find it, click on the heart icon to “Favorite” it:

Now click on the symbol in the schematic editor, and paste the name of the new footprint into the “package” field in the right sidebar menu (watch the video below for a demonstration):

Once all of your symbols are placed on the schematic and you’ve assigned footprints to each symbol, it’s time to start drawing the wires. Rather than explain the details of all that in this article, I’ve made a video so you can watch me draw the schematic for my LM386 audio amplifier:

After all the wiring is done, it’s a good idea to label the symbols. The labels will be transferred over to the PCB layout and eventually be printed on the finished PCB. Each symbol has a name (R1, R2, C1, C2 etc.) and value (10 μF, 100 Ω, etc.) that can be edited by clicking on the label.

The next step is to import the schematic into the PCB editor, but before we do that, let’s talk about some things to keep in mind when designing your PCB.

Identify what each part of your circuit does, and divide the circuit into sections according to function. For example, my LM386 audio amplifier circuit has four main sections: a power supply, an audio input, the LM386, and an audio output. It might help to draw some diagrams at this point to help you visualize the design before you start laying it out.

Keep the components in each section grouped together in the same area of the PCB to keep the conductive traces short. Long traces can pick up electromagnetic radiation from other sources, which can cause interference and noise.

The different sections of your circuit should be arranged so the path of electrical current is as linear as possible. The signals in your circuit should flow in a direct path from one section to another, which will keep the traces shorter.

Each section of the circuit should be supplied power with separate traces of equal length. This is called a star configuration, and it ensures that each section gets an equal supply voltage. If sections are connected in a daisy-chain configuration, the current drawn from sections closer to the supply will create a voltage drop and result in lower voltages at sections further from the supply:

It’s not uncommon to see round, triangular, or other interesting PCB shapes. Most PCBs are designed to be as small as possible, but that’s not necessary if your application doesn’t require it.

If you plan on putting the PCB into an enclosure, the dimensions may be limited by the size of the housing. In that case, you’ll need to know the enclosure’s dimensions before laying out the PCB so that everything fits inside.

The components you use will also have an effect on the size of the finished PCB. For instance, surface mounted components are small and have a low profile, so you’ll be able to make the PCB smaller. Through hole components are larger, but they’re often easier to find and easier to solder.

The location of components like power connections, potentiometers, LEDs, and audio jacks in your finished project will affect how your PCB is laid out. Do you need an LED near a power switch to indicate that it’s on? Or do you need to put a volume potentiometer next to a gain potentiometer? For the best user experience you might have to make some compromises and design the rest of your PCB around the locations of these components.

Larger circuits can be difficult to design on a single layer PCB because it’s hard to route the traces without intersecting one another. You might need to use two copper layers, with traces routed on both sides of the PCB.

The traces on one layer can be connected to the other layer with a via. A via is a copper plated hole in the PCB that electrically connects the top layer to the bottom layer. You can also connect top and bottom traces at a component’s through hole:

Some double layer PCBs have a ground layer, where the entire bottom layer is covered with a copper plane connected to ground. The positive traces are routed on top and connections to ground are made with through holes or vias. Ground layers are good for circuits that are prone to interference, because the large area of copper acts as a shield against electromagnetic fields. They also help dissipate the heat generated by the components.

Most PCB manufacturers will let you order different layer thicknesses. Copper weight is the term manufacturers use to describe the layer thickness, and it’s measured in ounces. The thickness of a layer will affect how much current can flow through the circuit without damaging the traces. Trace width is another factor that affects how much current can safely flow through the circuit (discussed below). To determine safe values for width and thickness, you need to know the amperage that will flow through the trace in question. Use an online trace width calculator to determine the ideal trace thickness and width for a given amperage.

If you look at a professionally designed PCB, you’ll probably notice that most of the copper traces bend at 45° angles. One reason for this is that 45° angles shorten the electrical path between components compared to 90° angles. Another reason is that high speed logic signals can get reflected off the back of the angle, causing interference:

If your project uses digital logic or high speed communication protocols above 200 MHz, you should probably avoid 90° angles and vias in your traces. For slower speed circuits, 90° traces won’t have much of an effect on the performance of your circuit.

The proximity of traces to components and adjacent traces will also determine how wide your traces can be. If you’re designing a small PCB with lots of traces and components, you might need to make the traces narrow for everything to fit.

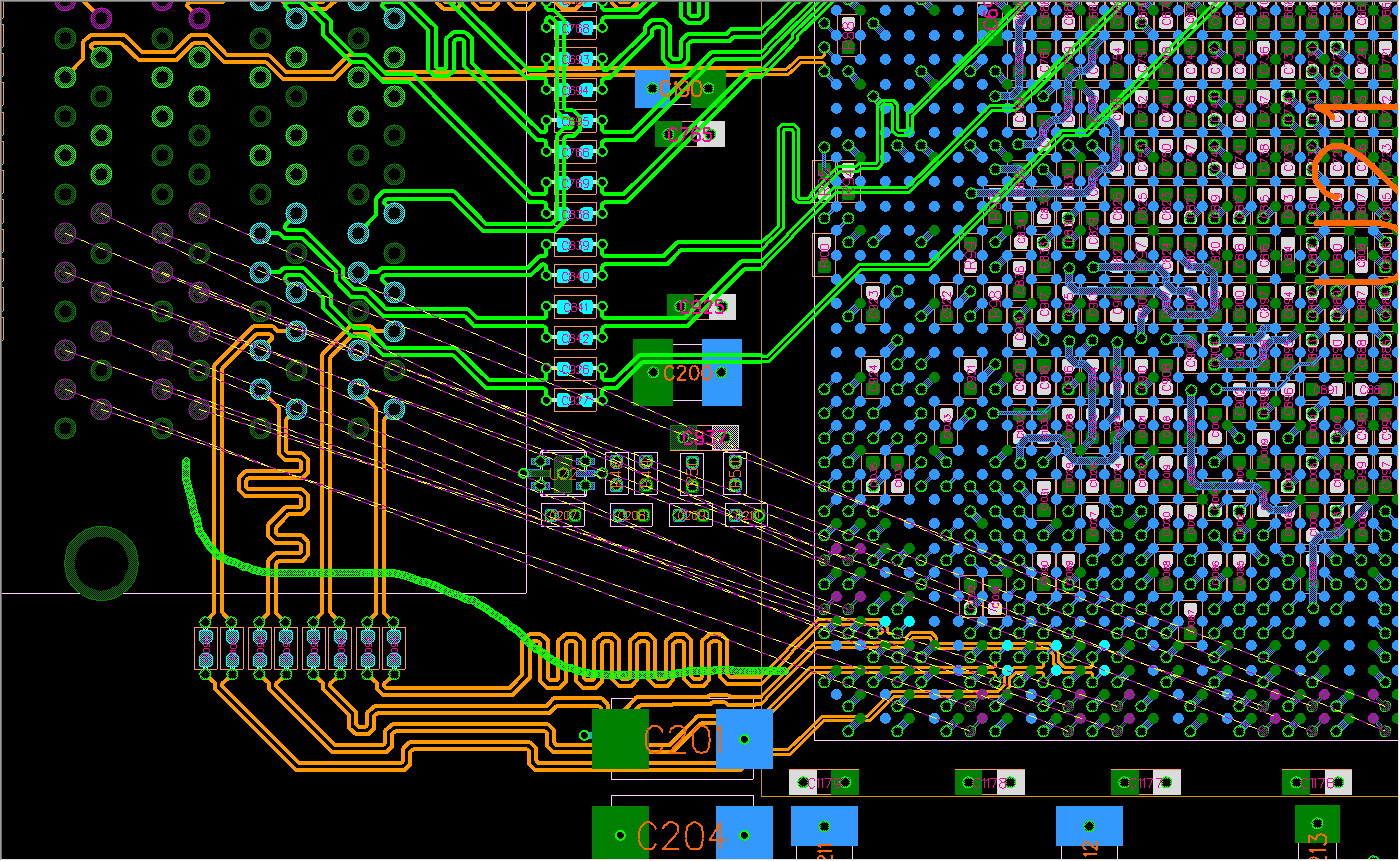

Notice the thin blue lines connecting the components. These are called ratsnest lines. Ratsnest lines are virtual wires that represent the connections between components. They show you where you need to route the traces according to the wiring connections you created in your schematic:

Now you can start arranging the components, keeping in mind the design tips mentioned above. You might want to do some research to find out if there are any special design requirements for your circuit. Some circuits perform better with certain components in specific locations. For example, in an LM386 amplifier circuit the power supply decoupling capacitors need to be placed close to the chip to reduce noise.

After you’ve arranged all of the components, it’s time to start drawing the traces. Use the ratsnest wires as a rough guide for routing each trace. However, they won’t always show you the best way to route the traces, so it’s a good idea to refer back to your schematic to verify the correct connections.

Traces can also be routed automatically using the software’s auto-router. For complicated circuits, it’s generally better to route traces manually, but try the auto-router on simpler designs and see what it comes up with. You can always adjust individual traces later.

The last thing to do before placing the order is to run a design rule check. A design rule check will tell you if any components overlap or if traces are routed too close together. The design rule check can be found by clicking the “Design Manager” button in the right side window:

Items that fail the design rule check will be listed below the “DRC Errors” folder. If you click on one of the errors, the problem trace or component will be highlighted in the PCB view:

You can specify your own settings for the design rule check by clicking the drop down menu in the upper right hand corner and going to Miscellaneous > Design Rule Settings:

At this point it’s a good idea to double check your PCB layout against your schematic to make sure that everything is connected properly. If you’re satisfied with the result, the next step is to order the PCB. EasyEDA makes this part really easy…

You can select the number of PCBs you want to order, the number of copper layers, the PCB thickness, copper weight, and even the PCB color. After you’ve made your selections, click “Save to Cart” and you’ll be taken to a page where you can enter your shipping address and billing information.

Gerber files are a set of image files that contain the patterns used to manufacture your PCB. All of the files are compressed into a single .zip file. There is a separate file for the copper traces, silk screen, and locations of drill holes and vias:

I ordered 15 PCBs for my LM386 audio amplifier circuit and the cost came out to about $15 USD. Manufacturing and shipping took about two weeks. The PCBs were well made, and I couldn’t find any defects. After I soldered on the components and tested the amplifier, it worked great. You can clone my LM386 amplifier schematic and PCB here if you want.

Making your own custom PCB is a lot of fun, and the results can be very rewarding. Hopefully this article will help you get your prototype circuit onto a PCB. Let us know in the comments if you have any questions, and let us know what PCB design projects you have planned. If you liked this tutorial and want to get more like it, be sure to subscribe!

A PCB is sort of like a layer cake or lasagna- there are alternating layers of different materials which are laminated together with heat and adhesive such that the result is a single object.

The base material, or substrate, is usually fiberglass. Historically, the most common designator for this fiberglass is "FR4". This solid core gives the PCB its rigidity and thickness. There are also flexible PCBs built on flexible high-temperature plastic (Kapton or the equivalent).

You will find many different thickness PCBs; the most common thickness for SparkFun products is 1.6mm (0.063"). Some of our products- LilyPad boards and Arudino Pro Micro boards- use a 0.8mm thick board.

Cheaper PCBs and perf boards (shown above) will be made with other materials such as epoxies or phenolics which lack the durability of FR4 but are much less expensive. You will know you are working with this type of PCB when you solder to it - they have a very distictive bad smell. These types of substrates are also typically found in low-end consumer electronics. Phenolics have a low thermal decomposition temperature which causes them to delaminate, smoke and char when the soldering iron is held too long on the board.

The next layer is a thin copper foil, which is laminated to the board with heat and adhesive. On common, double sided PCBs, copper is applied to both sides of the substrate. In lower cost electronic gadgets the PCB may have copper on only one side. When we refer to a double sided or 2-layer board we are referring to the number of copper layers (2) in our lasagna. This can be as few as 1 layer or as many as 16 layers or more.

The copper thickness can vary and is specified by weight, in ounces per square foot. The vast majority of PCBs have 1 ounce of copper per square foot but some PCBs that handle very high power may use 2 or 3 ounce copper. Each ounce per square translates to about 35 micrometers or 1.4 thousandths of an inch of thickness of copper.

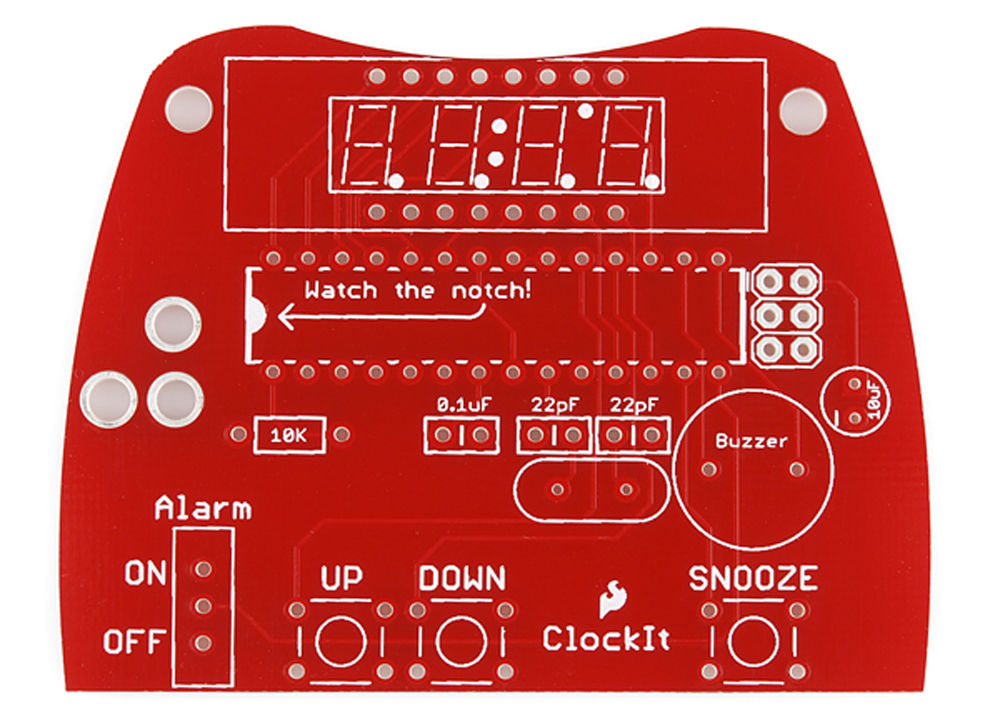

The layer on top of the copper foil is called the soldermask layer. This layer gives the PCB its green (or, at SparkFun, red) color. It is overlaid onto the copper layer to insulate the copper traces from accidental contact with other metal, solder, or conductive bits. This layer helps the user to solder to the correct places and prevent solder jumpers.

In the example below, the green solder mask is applied to the majority of the PCB, covering up the small traces but leaving the silver rings and SMD pads exposed so they can be soldered to.

Soldermask is most commonly green in color but nearly any color is possible. We use red for almost all the SparkFun boards, white for the IOIO board, and purple for the LilyPad boards.

The white silkscreen layer is applied on top of the soldermask layer. The silkscreen adds letters, numbers, and symbols to the PCB that allow for easier assembly and indicators for humans to better understand the board. We often use silkscreen labels to indicate what the function of each pin or LED.

Silkscreen is most commonly white but any ink color can be used. Black, gray, red, and even yellow silkscreen colors are widely available; it is, however, uncommon to see more than one color on a single board.

In this Arduino touch screen tutorial we will learn how to use TFT LCD Touch Screen with Arduino. You can watch the following video or read the written tutorial below.

For this tutorial I composed three examples. The first example is distance measurement using ultrasonic sensor. The output from the sensor, or the distance is printed on the screen and using the touch screen we can select the units, either centimeters or inches.

The next example is controlling an RGB LED using these three RGB sliders. For example if we start to slide the blue slider, the LED will light up in blue and increase the light as we would go to the maximum value. So the sliders can move from 0 to 255 and with their combination we can set any color to the RGB LED, but just keep in mind that the LED cannot represent the colors that much accurate.

The third example is a game. Actually it’s a replica of the popular Flappy Bird game for smartphones. We can play the game using the push button or even using the touch screen itself.

As an example I am using a 3.2” TFT Touch Screen in a combination with a TFT LCD Arduino Mega Shield. We need a shield because the TFT Touch screen works at 3.3V and the Arduino Mega outputs are 5 V. For the first example I have the HC-SR04 ultrasonic sensor, then for the second example an RGB LED with three resistors and a push button for the game example. Also I had to make a custom made pin header like this, by soldering pin headers and bend on of them so I could insert them in between the Arduino Board and the TFT Shield.

Here’s the circuit schematic. We will use the GND pin, the digital pins from 8 to 13, as well as the pin number 14. As the 5V pins are already used by the TFT Screen I will use the pin number 13 as VCC, by setting it right away high in the setup section of code.

As the code is a bit longer and for better understanding I will post the source code of the program in sections with description for each section. And at the end of this article I will post the complete source code.

I will use the UTFT and URTouch libraries made by Henning Karlsen. Here I would like to say thanks to him for the incredible work he has done. The libraries enable really easy use of the TFT Screens, and they work with many different TFT screens sizes, shields and controllers. You can download these libraries from his website, RinkyDinkElectronics.com and also find a lot of demo examples and detailed documentation of how to use them.

After we include the libraries we need to create UTFT and URTouch objects. The parameters of these objects depends on the model of the TFT Screen and Shield and these details can be also found in the documentation of the libraries.

Next we need to define the fonts that are coming with the libraries and also define some variables needed for the program. In the setup section we need to initiate the screen and the touch, define the pin modes for the connected sensor, the led and the button, and initially call the drawHomeSreen() custom function, which will draw the home screen of the program.

So now I will explain how we can make the home screen of the program. With the setBackColor() function we need to set the background color of the text, black one in our case. Then we need to set the color to white, set the big font and using the print() function, we will print the string “Arduino TFT Tutorial” at the center of the screen and 10 pixels down the Y – Axis of the screen. Next we will set the color to red and draw the red line below the text. After that we need to set the color back to white, and print the two other strings, “by HowToMechatronics.com” using the small font and “Select Example” using the big font.

Next is the distance sensor button. First we need to set the color and then using the fillRoundRect() function we will draw the rounded rectangle. Then we will set the color back to white and using the drawRoundRect() function we will draw another rounded rectangle on top of the previous one, but this one will be without a fill so the overall appearance of the button looks like it has a frame. On top of the button we will print the text using the big font and the same background color as the fill of the button. The same procedure goes for the two other buttons.

Now we need to make the buttons functional so that when we press them they would send us to the appropriate example. In the setup section we set the character ‘0’ to the currentPage variable, which will indicate that we are at the home screen. So if that’s true, and if we press on the screen this if statement would become true and using these lines here we will get the X and Y coordinates where the screen has been pressed. If that’s the area that covers the first button we will call the drawDistanceSensor() custom function which will activate the distance sensor example. Also we will set the character ‘1’ to the variable currentPage which will indicate that we are at the first example. The drawFrame() custom function is used for highlighting the button when it’s pressed. The same procedure goes for the two other buttons.

drawDistanceSensor(); // It is called only once, because in the next iteration of the loop, this above if statement will be false so this funtion won"t be called. This function will draw the graphics of the first example.

getDistance(); // Gets distance from the sensor and this function is repeatedly called while we are at the first example in order to print the lasest results from the distance sensor

So the drawDistanceSensor() custom function needs to be called only once when the button is pressed in order to draw all the graphics of this example in similar way as we described for the home screen. However, the getDistance() custom function needs to be called repeatedly in order to print the latest results of the distance measured by the sensor.

Here’s that function which uses the ultrasonic sensor to calculate the distance and print the values with SevenSegNum font in green color, either in centimeters or inches. If you need more details how the ultrasonic sensor works you can check my particular tutorialfor that. Back in the loop section we can see what happens when we press the select unit buttons as well as the back button.

Ok next is the RGB LED Control example. If we press the second button, the drawLedControl() custom function will be called only once for drawing the graphic of that example and the setLedColor() custom function will be repeatedly called. In this function we use the touch screen to set the values of the 3 sliders from 0 to 255. With the if statements we confine the area of each slider and get the X value of the slider. So the values of the X coordinate of each slider are from 38 to 310 pixels and we need to map these values into values from 0 to 255 which will be used as a PWM signal for lighting up the LED. If you need more details how the RGB LED works you can check my particular tutorialfor that. The rest of the code in this custom function is for drawing the sliders. Back in the loop section we only have the back button which also turns off the LED when pressed.

In order the code to work and compile you will have to include an addition “.c” file in the same directory with the Arduino sketch. This file is for the third game example and it’s a bitmap of the bird. For more details how this part of the code work you can check my particular tutorial. Here you can download that file:

drawDistanceSensor(); // It is called only once, because in the next iteration of the loop, this above if statement will be false so this funtion won"t be called. This function will draw the graphics of the first example.

getDistance(); // Gets distance from the sensor and this function is repeatedly called while we are at the first example in order to print the lasest results from the distance sensor

Displaying a custom image or graphic on a LCD display is a very useful task as displays are now a premium way of providing feedback to users on any project. With this functionality, we can build projects that display our own logo, or display images that help users better understand a particular task the project is performing, providing an all-round improved User Experience (UX) for your Arduino or ESP8266 based project. Today’s tutorial will focus on how you can display graphics on most Arduino compatible displays.

The procedure described in this tutorial works with all color displays supported by Adafruit’s GFX library and also works for displays supported by the TFTLCD library from Adafruit with little modification. Some of the displays on which this procedure works include:

While these are the displays we have, and on which this tutorial was tested, we are confident it will work perfectly fine with most of the other Arduino compatible displays.

For each of the displays mentioned above, we have covered in past how to program and connect them to Arduino. You should check those tutorials, as they will give you the necessary background knowledge on how each of these displays works.

For this tutorial, we will use the 2.8″ ILI9325 TFT Display which offers a resolution of 320 x 340 pixels and we will display a bitmap image of a car.

As usual, each of the components listed above can be bought from the links attached to them. While having all of the displays listed above may be useful, you can use just one of them for this tutorial.

To demonstrate how things work, we will use the 2.8″ TFT Display. The 2.8″ TFT display comes as a shield which plugs directly into the Arduino UNO as shown in the image below.

Not all Arduino displays are available as shields, so when working with any of them, connect the display as you would when displaying text (we recommend following the detailed tutorial for the display type you use of the above list). This means no special connection is required to display graphics.

Before an image is displayed on any of the Arduino screens, it needs to be converted to a C compatible hex file and that can only happen when the image is in bitmap form. Thus, our first task is to create a bitmap version of the graphics to be displayed or convert the existing image to a bitmap file. There are several tools that can be used for creation/conversion of bitmap images including, Corel Draw and Paint.net, but for this tutorial, we will use the Paint.net.

Our demo graphics today will be a car. We will create the car on a black background and use a white fill so it’s easy for us to change the color later on.

The resolution of the graphics created should be smaller than the resolution of your display to ensure the graphics fit properly on the display. For this example, the resolution of the display is 320 x 340, thus the resolution of the graphics was set to195 x 146 pixels.

Your graphics could also include some text. Just ensure the background is black and the fill color is white if you plan to change the color within your Arduino code.

With the graphics done, save both files as .bmp with 24bits color.It is important to keep in mind that large bitmaps use up a lot of memory and may prevent your code from running properly so always keep the bitmaps as small as possible.

Image2Code is an easy-to-use, small Java utility to convert images into a byte array that can be used as a bitmap on displays that are compatible with the Adafruit-GFX or Adafruit TFTLCD (with little modification) library.

All we have to do is to load the graphics into the software by clicking the “Choose file” button and it will automatically generate a byte array equivalent to the selected bitmap file.

Paste the bit array in the graphics.c file and save. Since we have two graphics (the car and the text), You can paste their data array in the same file. check the graphics.c file attached to the zip file, under the download section to understand how to do this. Don’t forget to declare the data type as “const unsigned char“, add PROGEM in front of it and include the avr/pgmspace.h header file as shown in the image below. This instructs the code to store the graphics data in the program memory of the Arduino.

With this done, we are now ready to write the code. Do note that this procedure is the same for all kind of displays and all kind of graphics. Convert the graphics to a bitmap file and use the Img2code utility to convert it into a hex file which can then be used in your Arduino code.

To reduce the amount of code, and stress involved in displaying the graphics, we will use two wonderful libraries; The GFX library and the TFTLCD library from Adafruit.

The GFX library, among several other useful functions, has a function called drawBitmap(), which enables the display of a monochrome bitmap image on the display. This function allows the upload of monochrome only (single color) graphics, but this can be overcome by changing the color of the bitmap using some code.

The Adafruit libraries do not support all of the displays but there are several modifications of the libraries on the internet for more displays. If you are unable to find a modified version of the library suitable for your the display, all you need do is copy the code of the drawBitmap() function from the GFX library and paste it in the Arduino sketch for your project such that it becomes a user-defined function.

The first two are thex and y coordinates of a point on the screen where we want the image to be displayed. The next argument is the array in which the bitmap is loaded in our code, in this case, it will be the name of the car and the text array located in the graphics.c file. The next two arguments are the width and height of the bitmap in pixels, in other words, the resolution of the image. The last argument is the color of the bitmap, we can use any color we like. The bitmap data must be located in program memory since Arduino has a limited amount of RAM memory available.

As usual, we start writing the sketch by including the libraries required. For this procedure, we will use the TFTLCD library alone, since we are assuming you are using a display that is not supported by the GFX library.

Next, we specify the name of the graphics to be displayed; car and title. At this stage, you should have added the bit array for these two bitmaps in the graphics.c file and the file should be placed in the same folder as the Arduino sketch.

With that done, we proceed to the void loop function, under the loop function, we call the drawbitmap() function to display the car and the text bitmap using different colors.

The last section of the code is the drawBitmap function itself, as earlier mentioned, to use the drawbitmap() function with the Adafruit TFTLCD library, we need to copy the function’s code and paste into the Arduino sketch.

Plug in your screen as shown above. If you are using any other display, connect it as shown in the corresponding linked tutorial. With the schematics in place, connect the Arduino board to your PC and upload the code. Don’t forget the graphics file needs to be in the same folder as the Arduino sketch.

That’s it for this tutorial guys. The procedure is the same for all kinds of Arduino compatible displays. If you get stuck while trying to replicate this using any other display, feel free to reach out to me via the comment sections below.

Arduino has always helped to build projects easily and make them look more attractive. Programming an LCD screen with touch screen option might sound as a complicated task, but the Arduino libraries and shields had made it really easy. In this project we will use a 2.4” Arduino TFT LCD screen to build our own Arduino Touch Screen calculator that could perform all basic calculations like Addition, Subtraction, Division and Multiplication.

Before we actually dive into the project it is important to know, how this 2.4” TFT LCD Module works and what are the types present in it. Let us take a look at the pinouts of this 2.4” TFT LCD screen module.

As you can see there are 28 pins which will perfectly fit into any Arduino Uno / Arduino Mega Board. A small classification of these pins is given in the table below.

As you can see the pins can be classified in to four main classifications such as LCD Command Pins, LCD Data Pins, SD Card Pins and Power Pins, We need not know much about the detailed working of these pins since they will be take care by our Arduino Library.

You can also find an SD card slot at the bottom of the module shown above, which can be used to load an SD card with bmp image files, and these images can be displayed in our TFT LCD screen using the Arduino Program.

Another important thing to note is your Interface IC. There are many types of TFT modules available in the market starting from the original Adafruit TFT LCD module to cheap Chinese clones. A program which works perfectly for your Adafruit shield might not work the same for Chinese breakout boards. So, it is very important to know which types of LCD display your are holding in hand. This detail has to be obtained from the vendor. If you are having a cheap clone like mine then it is most probably using the ili9341 driver IC.You can follow this TFT LCD interfacing with Arduino tutorial to try out some basic example programs and get comfortable with the LCD screen. Also check out our other TFT LCD projects with Arduino here:

If you planning to use the touch screen function of your TFT LCD module, then you have to calibrate it to make it work properly. A LCD screen without calibration might work unlikely, for instance you might touch at one place and the TFT might respond for a touch at some other place. These calibrations results will not be similar for all boards and hence you are left on your own to do this.

The best way to calibrate is to use the calibration example program (comes with library) or use the serial monitor to detect your error. However for this project since the size of buttons is large calibration should not be a big problem and I will also explain how you can calibrate your screen under the programming section below.

The 2.4” TFT LCD screen is a perfect Arduino Shield. You can directly push the LCD screen on top of the Arduino Uno and it will perfectly match with the pins and slid in through. However, as matters of safety cover the Programming terminal of your Arduino UNO with a small insulation tape, just in case if the terminal comes in contact with your TFT LCD screen. The LCD assembled on UNO will look something like this below.

We are using the SPFD5408 Library to get this arduino calculator code working. This is a modified library of Adafruit and can work seamlessly with our LCD TFT Module. You can check the complete program at the end of this Article.

To install this library, you can simply click on the link above which will take you to a Github page. There click on clone or download and select “Download ZIP”. A zip file will be downloaded.

Now, open Arduino IDE and select Sketch -> Include Librarey -> Add .ZIP library. A browser window will open navigate to the ZIP file and click “OK”. You should notice “Library added to your Libraries” on the bottom-left corner of Arduino, if successful. A detailed guide to do the same is given in the Interfacing Tutorial.

Now, you can use the code below in your Arduino IDE and upload it to your Arduino UNO for the Touch Screen Calculator to work. Further down, I have explained the code into small segments.

We need three libraries for this program to work; all these three libraries were given in the ZIP file you downloaded from the above provided link. I have simply included them in the code as shown below.

As said earlier we need to calibrate the LCD screen to make it work as expected, but don’t worry the values given here are almost universal. The variables TS_MINX, TS_MINY, TS_MAXX, and TS_MAXY decide the calibration of the Screen. You can toy around them if you feel the calibration is not satisfactory.

As we know the TFT LCD screen can display a lot of colours, all these colours have to be entered in hex value. To make it more human readable we assign these values to a variable as shown below.

Okay now, we can get into the programming part. There are three sections involved in this program. One is creating a UI of a calculator with buttons and display. Then, detecting the buttons based on the users touch and finally calculating the results and display them. Let us get through them one by one.

This is where you can use a lot of your creativity to design the User Interface of calculator. I have simply made a basic layout of a calculator with 16 Buttons and one display unit. You have to construct the design just like you will draw something on MS paint. The libraries added will allow you to draw Lines, Rectangle, Circles, Chars, Strings and lot more of any preferred colour. You can understand the available functions from this article.

I have used the line and box drawing abilities to design an UI which looks very similar to the 90’s calculator. Each box has a width and height of 60 pixels.

Another challenging task is detecting the user touch. Every time the user touches somewhere we will able to how where the X and Y position of the pixel he touched. This value can be displayed on the serial monitor using the println as shown below.

Since we have designed the box with width and height of 60 pixel each and have four Rows and for columns starting from (0,0). The position of each box can be predicted as shown in below picture.

But in practical case, this will not be the result. There will be a big difference between the expected and actual value, due to the calibration problem.

So, to predict the exact position of the box, you have to click on the line and check its corresponding position on the serial monitor. This might not be most professional way of doing it, but still it works perfectly. I measured the position of all the lines and obtained the below values.

Now, since we know the position of all the boxes. When a user touches anywhere we can predict where he has touched by comparing his (X,Y) values with the value for each box as shown below.

The final step is to calculate the result and display them on TFT LCD Screen. This arduino calculator can perform operation with 2 numbers only. These two numbers are named as variables “Num1” and “Num2”. The variable “Number” gives and takes value from Num1 and Num2 and also bears the result.

When a use presses a button, one digit is added to number. When another button is pressed, the previous one digit is multiplied with 10 and the new number is added with it. For example, if we press 8 and then press 5 and then press 7. Then first the variable will hold 8 then (8*10)+5=85 then (85*10)+7 = 857. So finally the variable will have the value 857 with it.

When we perform any operation like addition, when the users presses the addition button the value from Number will be transferred to Num1 and then Number will be made zero so that it gets ready to take the input for second number.

When Equal is pressed the value in Number will be sent to Num2 and then the respective calculation (in this case addition) will be made and the result will be again stored in the variable “Number”.

The working of this Arduino Touch Screen Calculator is simple. You have to upload the below given code on your Arduino and fire it up. You get the calculator displayed on your LCD screen.

Now, you can enter any number and perform your calculations. It is limited to only two operand and only operator for now. But, you can tweak the code to make it have lots of option.

You have to press the “C” to clear the value on screen each time after performing a calculation. Hope you understood the project and enjoyed building something similar. If you have any doubts feel free to post them on forums or on the comment section below. See you next time with another interesting project until then happy computing!!

First: There are several types of cheap touchscreens: resistive and capacitive (intro from 3m). And under touchscreen I mean touch panels (digitizers) - the thin multilayer panels which feels touches, but don"t display anything. Touchscreens can be combined with LCD/OLED screens to get display with touch capability. Resistive touchscreens are sensitive to pressure, and you can use any stick to press them, they also had problems with multitouch (sensing several touches at same time). Capacitive touchscreens are often used now in smartphones (since iPhone), and they sense capacitance of human body, working only with fingers or special conductive styli.

Resistive touchscreens usually have 4-wire or 5-wire analog interface (short description) to touchscreen controller. If you want to plug this directly into FPGA board, you need ADC (analog-to-digital converter, sometimes up to 10-12 bit precision) to measure coordinates of touch point.

Capacitive touchscreens usually have more complex interface with complex medium-frequency signals (25-200 kHz). Simplest panels still have 5 wires, but Cypress"s "Touchscreens 101" lists two more advanced panels with 11 and 20 pins. It will be very hard to implement (and calibrate) your own touch controller in FPGA even with good ADCs and DACs.

So, our second step is the touchscreen controller ASIC: the device between microcontroller or FPGA and the touchscreen. Controller will do all needed magic to detect touches and translate information about them into some digital protocol, like COM (RS-232) or USB in ancient controllers for PC, or simple SPI and I2C for microcontrollers and FPGAs (you should know how to implement SPI/I2C for FPGA; the fpga4fun site may help you: spi, i2c). Many small touchscreens sold now may include some controller, integrated into their PCB or flex wire.

Third step: if you want to make prototype with LCD display and touchscreen, especially with small size LCD (up to 6″), the touch panel may be already integrated into display. And because virtually all LCD have the controller to output some information to display (again, fpga4fun has some introduction into using LCD with FPGAs), they probably will have integrated touchscreen controller too.

Now we can start speak about your case: "what I could buy". If you already have FPGA board, you can search for some LCD+touchscreen for some popular hardware prototyping platform, e.g. for ardoino or raspberry pi. For example, adafruit shop has both separate touch panels, lines and buttons even without controller: http://www.adafruit.com/category/60. Also they have several LCD+touch like 2.8" TFT with STMPE610 touch controller (both SPI and I2C, selectable via pin). There are several on sparkfun.com too. Make sure that you understand how to connect the LCD to FPGA, both electrical and protocol requirements. Check is there touch controller, or you need to implement it in the FPGA with ADC (and there should be ADC on your FPGA board).

If you don"t have FPGA board or if you have no any FPGA experience, it can be better (and costly) to find FPGA kit with optional LCD+touch, but not from chinese vendors. There are lot of chinese kits in cheap section of ebay"s search "fpga touch", but they may have not so good tutorials and demo projects as right vendors. There are 7" kit from Terasic (2000 USD, VEEK-MT-C5SoC), or 7" 250USD LCD+touchpanel module for 1800 USD DE3 or 600USD DE2 FPGA boards. And for Digilent, there is 150 USD VmodTFT 4.3" TFT+touch (manual) compatible with Digilent boards with VHDCI connector, like 300 USD Nexys 3 board, 450 USD Atlys board, or 1100 USD Genesys superboard.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

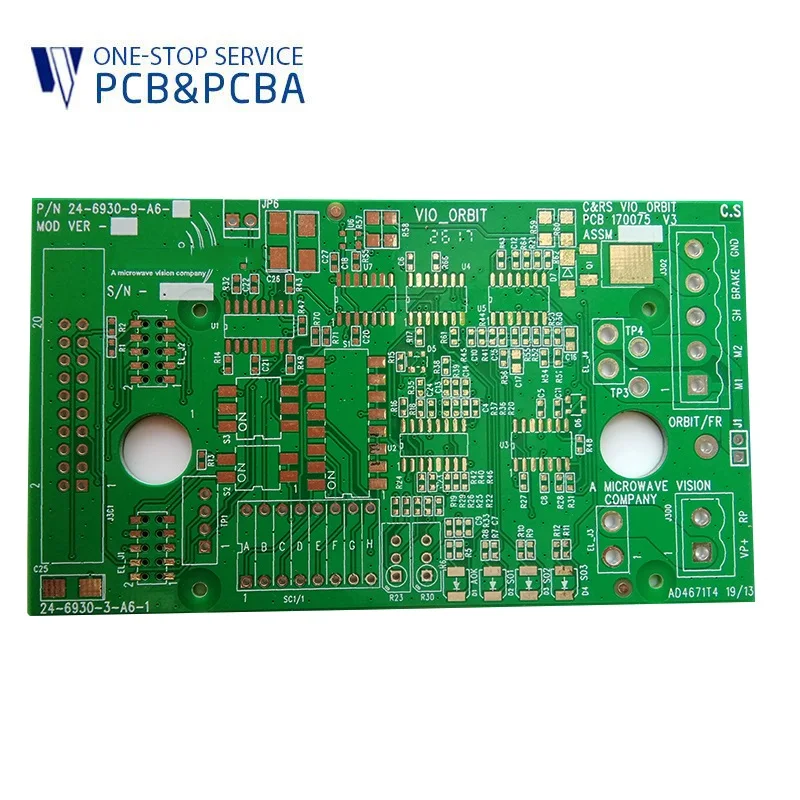

There are mainly two types of module PCB in our company: Internet of things (IoT)/ communication module PCB and vehicle-to-everything(V2X) module PCB.

As the most basic perception layer of the Internet, the IoT/communication module PCB has continued to grow rapidly. Both long-term evolution vehicle-to-everything (LTE-V2X) and new radio vehicle-to-everything (NR-V2X) are important parts of self-driving, the development of the corresponding module board market is increasingly prominent.

Special design features: max 3-time compression design, back drilling(including blind hole back drilling) & POFV, the impedance control tolerance≤ 5%, HDI system board, copper inlay, etc.

Antenna PCB is widely used in the telecom field to receive and transmit signals. With the development of the 5G network, antenna PCB is perfect for expanding wireless networks and enhancing the broadcasting or receiving stations.

Where there is fiber-optic communication, there is a demand for electro-optical switching modules. The optical module is the key component to realize electro-optical-electro transmission of the signal in fiber-optic communication. We mainly manufacture 100G & 400G high-end high-speed optical modules.

As the mounting density of SMT increases, the effective heat dissipation area of electronic equipment decreases. Especially when the PCB temperature is greater than 70 , the reliability of the PCB decreases by 5% for every 1 increase. There are three ways of heat transfer: heat conduction, convection and radiation, and all of which are included in the thermal PCB.

A PCB with a finished copper layer greater than 2oz is defined as a heavy copper PCB. Heavy copper PCB can achieve efficient and reliable power distribution. As a special type of PCB, heavy copper PCB is suitable for high-current capacity products. The significant benefits of heavy copper PCB are that it reduces the chance of circuit failure and enhances the heat transfer from the layer to an external source.

The auto anti-collision radar is the most important part of the developing trends of future automotive technology. MMW radar has advantages in auto-collision avoidance technology.

This project uses the SPIFFS (ESP32 flash memory) to store images used as background. You"ll need to upload these to the ESP32 before you upload the sketch to the ESP32. For this you"ll need the ESP32 Sketch Data Upload tool.

You can download this from Github: "https://github.com/me-no-dev/arduino-esp32fs-plugin". Follow the instructions on the Github to install the tool:Download the tool archive from releases page.

Before you upload the data folder to the ESP32, you"ll first have to select the right partitioning scheme.Go to Tools -> Board and select ESP32 Dev Module.

On Github you can find the full source code for this project. Go to the Bluetooth-System-Monitor Github repository and click "Code" and "Download .ZIP": https://github.com/DustinWatts/Bluetooth-System-M...

Extract and rename the extracted folder to "Bluetooth-System-Monitor". This is so the Arduino IDE does not complain that the folder and the sketch do not have the same name. If this happens, you will get a popup asking you if it should move the sketch. The dangerous thing here is, that it will only move the sketch and not the Data folder. This will result in errors when uploading!

Firstly, depending on the board you are using (with resistive touch, capacitive touch, or no touch) you will have to uncomment the correct one. For example, if you are using the ESP32 TouchDown uncomment: "#define ENABLE_CAP_TOUCH". If you are using a DevKitC with separate TFT, uncomment "#define ENABLE_RES_TOUCH".

In the sketch you can set some warning levels. This will make the text under the icons red. Scroll down until you see "// Define warning levels, change this as you like".Here you can set some warning levels.

You can also set the scale of the y-axis of the graphs. This is done under "// The scale of the Y-axis per graph". If these are to big or to small, the data will not be displayed correctly on the graph. You might have to experiment with these.

Go ahead and upload the Bluetooth-System-Monitor.ino sketch to the ESP32. The settings under tools besides the Partition Scheme can be left to the default (see image). Go to "Sketch" and select "Upload". This may take a while because it is a large sketch.

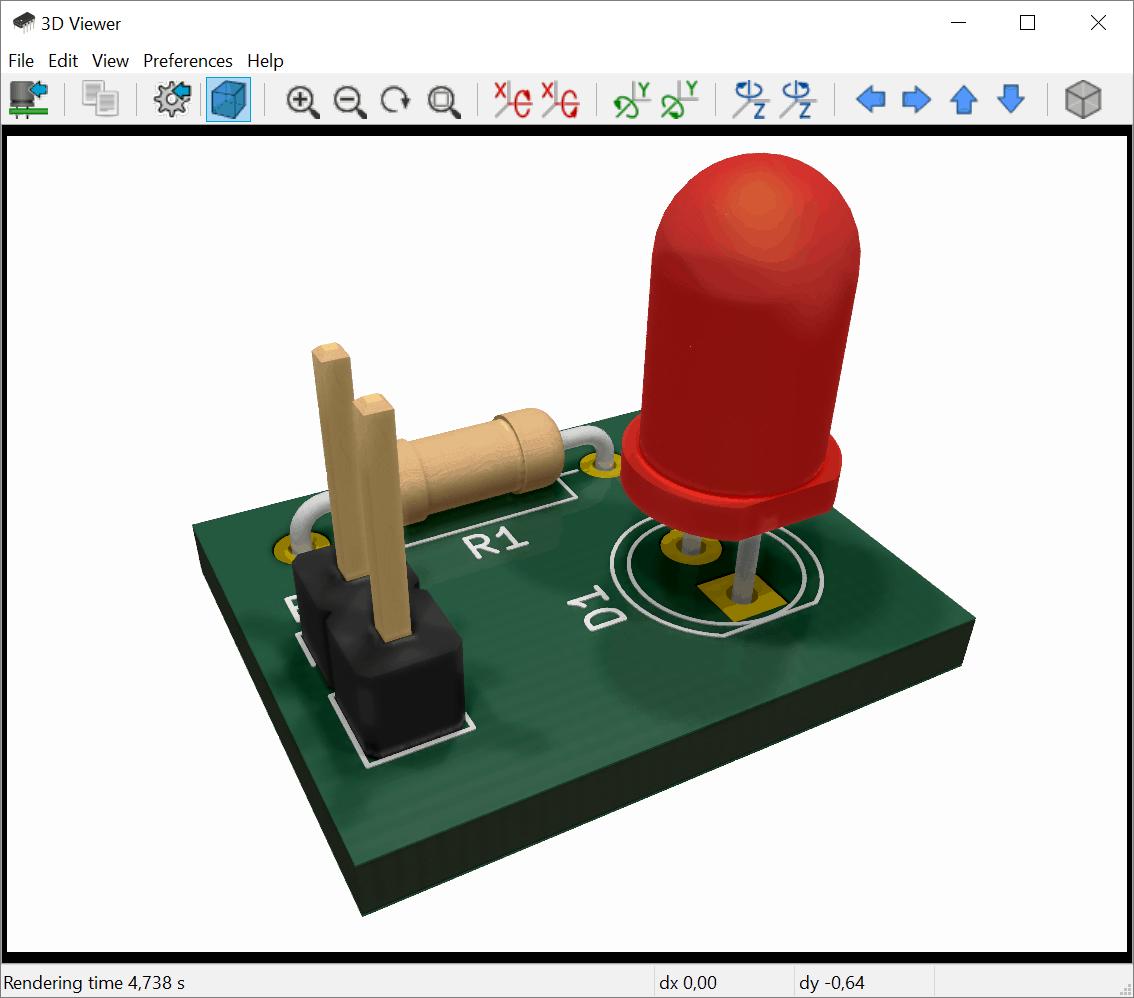

Welcome to the world of electronic product development in Altium"s world-class electronic design software. This tutorial will help you get started by taking you through the entire process of designing a simple PCB – from idea to output files.

The design for which you will be creating the schematic and designing a printed circuit board (PCB) is a simple astable multivibrator. The circuit is shown below; it uses two general-purpose NPN transistors configured as a self-running astable multivibrator.

Altium Designer can connect to a Workspace to provide a single, secure data source and storage while affording unparalleled collaboration. It could be an Altium 365 Workspace – a Workspace hosted on the Altium 365 cloud-based infrastructure platform, or an Enterprise Server Workspace – a Workspace provided through the Altium On-Prem Enterprise Server, installed and managed by your own IT department.

As its name suggests, the Altium On-Prem Enterprise Server is only available to those with Altium Designer and an active Altium Designer Enterprise Subscription.

This tutorial focuses on using Altium Designer with a connected Workspace – the most streamlined and empowered environment for your design needs. However, if you are not able to enjoy the benefits that a connected Workspace brings, you can store your design data, including projects, component libraries, and design outputs, locally on your hard drive or in a shared network resource.

To complete this tutorial, you will need to be connected to a Workspace. It is assumed that your Workspace has been activated/installed with the sample data.

An Arduino Uno shield-style display module which comprises a graphic LCD mounted on a carrier board. This module is specifically designed to simply presses onto a controller with the Arduino Uno form factor, making it easy to begin designing with this display.

This tutorial shows how to use the I2C LCD (Liquid Crystal Display) with the ESP32 using Arduino IDE. We’ll show you how to wire the display, install the library and try sample code to write text on the LCD: static text, and scroll long messages. You can also use this guide with the ESP8266.

Additionally, it comes with a built-in potentiometer you can use to adjust the contrast between the background and the characters on the LCD. On a “regular” LCD you need to add a potentiometer to the circuit to adjust the contrast.

Before displaying text on the LCD, you need to find the LCD I2C address. With the LCD properly wired to the ESP32, upload the following I2C Scanner sketch.

After uploading the code, open the Serial Monitor at a baud rate of 115200. Press the ESP32 EN button. The I2C address should be displayed in the Serial Monitor.

Displaying static text on the LCD is very simple. All you have to do is select where you want the characters to be displayed on the screen, and then send the message to the display.

In this simple sketch we show you the most useful and important functions from the LiquidCrystal_I2C library. So, let’s take a quick look at how the code works.

The next two lines set the number of columns and rows of your LCD display. If you’re using a display with another size, you should modify those variables.

Then, you need to set the display address, the number of columns and number of rows. You should use the display address you’ve found in the previous step.

To display a message on the screen, first you need to set the cursor to where you want your message to be written. The following line sets the cursor to the first column, first row.

Scrolling text on the LCD is specially useful when you want to display messages longer than 16 characters. The library comes with built-in functions that allows you to scroll text. However, many people experience problems with those functions because:

After reading the previous section, you should be familiar on how this sketch works, so we’ll just take a look at the newly created function: scrollText()

delayTime: delay between each character shifting. Higher delay times will result in slower text shifting, and lower delay times will result in faster text shifting.

The messageToScroll variable is displayed in the second row (1 corresponds to the second row), with a delay time of 250 ms (the GIF image is speed up 1.5x).

In a 16×2 LCD there are 32 blocks where you can display characters. Each block is made out of 5×8 tiny pixels. You can display custom characters by defining the state of each tiny pixel. For that, you can create a byte variable to hold the state of each pixel.

Then, in the setup(), create a custom character using the createChar() function. This function accepts as arguments a location to allocate the char and the char variable as follows:

In summary, in this tutorial we’ve shown you how to use an I2C LCD display with the ESP32/ESP8266 with Arduino IDE: how to display static text, scrolling text and custom characters. This tutorial also works with the Arduino board, you just need to change the pin assignment to use the Arduino I2C pins.

We hope you’ve found this tutorial useful. If you like ESP32 and you want to learn more, we recommend enrolling in Learn ESP32 with Arduino IDE course.

We worked with the client to determine what they wanted to have the touch-screen display do and what it should look like. We then picked an appropriate touch-screen based on the size, resolution, and availability.

As the electronics were being designed, we also started work on the software. This is where the software commands to control the display as well as the client"s graphical interface were created.

In addition to the previous steps, we also needed to create a mounting system for the display. Since the display we chose had no mounting holes of its own, we had to design in Solidworks a cradle that both held the display and the driver board to come. This cradle would then attach to the project case. Because we have two 3D printers in-house, we were able to quickly iterate plastic prototypes until we had the ideal cradle.

Once the cradle was designed, we then worked out what hardware was needed to mount everything together. Also, we needed to create a rubber gasket based on the design parameters of the cradle and the display. This was all done in Solidworks by creating a virtual assembly of the entire project.

The cradle design dictated the size of the circuit board driver for the display. With that information now determined, the circuit board was designed.

And lastly, the display was built in-house using our surface-mount machinery and skilled technicians. Once assembled, the driver board was programmed with the custom software and tested.

4) After the image has finished writing, open the config.txt file in the root directory of the TF card, add the following code at the end of config.txt, then save and quit the TF card safely.

7) Connect the HDMI interface of the LCD to the HDMI port of Raspberry Pi and then power on the Raspberry Pi, it can display normally after waiting for about a few seconds.

The screen is displayed vertically by default. For convenience, you can adjust the display orientation of the screen, see #Rotation(Working with Raspberry Pi).

After the display is rotated, the position of touch is incorrect because the touch doesn’t change with the display angle. So the touch also needs to be modified.

In some special systems, when you cannot rotate by modifying the software, you can press and hold the "Rotate Touch" button for 5 seconds to rotate touch. And you may need to test multi times for the correct orientation.

We recommend using the software modification method. Otherwise, when using the new system, it may cause touch reverse errors. At that time, you need to press and hold "Rotate Touch" to rotate.

Note: If you increase the brightness, it may cause the insufficient power of the LCD by getting power through the USB interface. To solve this problem, you can input 5V/2A power through the Power interface on the back of the LCD.

Since the first-generation Raspberry Pi released, Waveshare has been working on designing, developing, and producing various fantastic touch LCDs for the Pi. Unfortunately, there are quite a few pirated/knock-off products in the market. They"re usually some poor copies of our early hardware revisions, and comes with none support service.

Please note that we"ve found some poor copies of this item in the market. They are usually made of inferior materials and shipped without any testing.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey