tft lcd glass substrate price

"TFT-LCD Glass Substrate Market" report presents a comprehensive overview, market shares, and growth opportunities of TFT-LCD Glass Substrate market by product type, application, key manufacturers and key regions and countries. The global TFT-LCD Glass Substrate market size is projected to reach Multimillion USD by 2028, in comparision to 2021, at unexpected CAGR during 2022-2028.

TFT-LCD Glass SubstrateMarket Research Report is spread across 85 Pages with 130 Number of Tables and Figures that provides exclusive data, information, vital statistics, trends, and competitive landscape details in this niche sector.

The Global TFT-LCD Glass Substrate market is anticipated to rise at a considerable rate during the forecast period, between 2022 and 2028. In 2020, the market is growing at a steady rate and with the rising adoption of strategies by key players, the market is expected to rise over the projected horizon.

Due to the COVID-19 pandemic, the global TFT-LCD Glass Substrate market size is estimated to be worth USD million in 2022 and is forecast to a readjusted size of USD million by 2028 with a CAGR of % during the forecast period 2022-2028. Fully considering the economic change by this health crisis, Gen. 5 accounting for % of the TFT-LCD Glass Substrate global market in 2021, is projected to value USD million by 2028, growing at a revised % CAGR from 2022 to 2028. While Television segment is altered to an % CAGR throughout this forecast period.

North America TFT-LCD Glass Substrate market is estimated at USD million in 2021, while Europe is forecast to reach USD million by 2028. The proportion of the North America is % in 2021, while Europe percentage is %, and it is predicted that Europe share will reach % in 2028, trailing a CAGR of % through the analysis period 2022-2028. As for the Asia, the notable markets are Japan and South Korea, CAGR is % and % respectively for the next 6-year period.

The global major manufacturers of TFT-LCD Glass Substrate include Corning, AGC, NEG, Tunghsu Optoelectronic, AvanStrate, IRICO and LG Chem, etc. In terms of revenue, the global 3 largest players have a % market share of TFT-LCD Glass Substrate in 2021.

Report further studies the market development status and future TFT-LCD Glass Substrate Market trend across the world. Also, it splits TFT-LCD Glass Substrate market Segmentation by Type and by Applications to fully and deeply research and reveal market profile and prospects.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of TFT-LCD Glass Substrate in these regions, from 2015 to 2027, covering ● North America (United States, Canada and Mexico)

Some of the key questions answered in this report: ● What is the global (North America, Europe, Asia-Pacific, South America, Middle East and Africa) sales value, production value, consumption value, import and export of TFT-LCD Glass Substrate?

● Who are the global key manufacturers of the TFT-LCD Glass Substrate Industry? How is their operating situation (capacity, production, sales, price, cost, gross, and revenue)?

● What are the upstream raw materials and manufacturing equipment of TFT-LCD Glass Substrate along with the manufacturing process of TFT-LCD Glass Substrate?

● What are the key drivers, restraints, opportunities, and challenges of the TFT-LCD Glass Substrate market, and how they are expected to impact the market?

This report presents an extensive outline, pieces of the overall industry, and development chances of Glass Substrates for TFT-LCD market by item type, application, key makers and key locales and nations.

Glass Substrate is a special glass used for thin-film-transistor (TFT) liquid crystal displays (LCD) and OLEDs, which form the display area of products including LCD televisions, personal computers and mobile phones. An LCD panel consists of various components stacked in a number of layers. These components include a polarizer, a color filter and a liquid crystal layer, with the glass substrate being the most important.

According to our latest study, the global Glass Substrates for TFT-LCD market size was valued at USD 7271.6 million in 2021 and is forecast to a readjusted size of USD 11450 million by 2028 with a CAGR of 6.7% during review period. The influence of COVID-19 and the Russia-Ukraine War were considered while estimating market sizes.

This report is a detailed and comprehensive analysis for global Glass Substrates for TFT-LCD market. Both quantitative and qualitative analyses are presented by manufacturers, by region and country, by Type and by Application. As the market is constantly changing, this report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets. Company profiles and product examples of selected competitors, along with market share estimates of some of the selected leaders for the year 2022, are provided.

Additionally, the Glass Substrates for TFT-LCD market trend provides a comprehensive study of prime players at intervals the market by lightness their product description, business outline, and business strategy. It conjointly endows with the amount of production, Glass Substrates for TFT-LCD"s future demand, needed staple, and also the cash health of the organization.

The Glass Substrates for TFT-LCD Market report purposefully analyses every sub-segment regarding the individual growth trends, contribution to the total market, and the upcoming forecasts.

For the end users/applications, this report focuses on the status and outlook for major applications/end users, consumption (sales), market share and growth rate of Glass Substrates for TFT-LCD market for each application, including: -

This report studies the global market size of Glass Substrates for TFT-LCD in key regions like North America, Europe, China and Japan, focuses on the consumption of Glass Substrates for TFT-LCD in these regions.

Key questions answered in the report: ● What are the Glass Substrates for TFT-LCD market opportunities and threats faced by the vendors in the Global Glass Substrates for TFT-LCD industries?

3) Focuses on the key Glass Substrates for TFT-LCD manufacturers, to study the capacity, production, value, market share and development plans in the future.

Global Glass Substrates for TFT-LCD Industry 2023 Market Research Report provides exclusive vital statistics, data, information, trends and competitive landscape details in this niche sector.

For its transparency, flat and smooth surface, and excellent heat resistance, this product is used as a substrate for various types of displays such as televisions, personal computers, smart phones, tablet devices, and in-vehicle infotainment. It is an alkali-free aluminosilicate glass that was developed by using the float process.

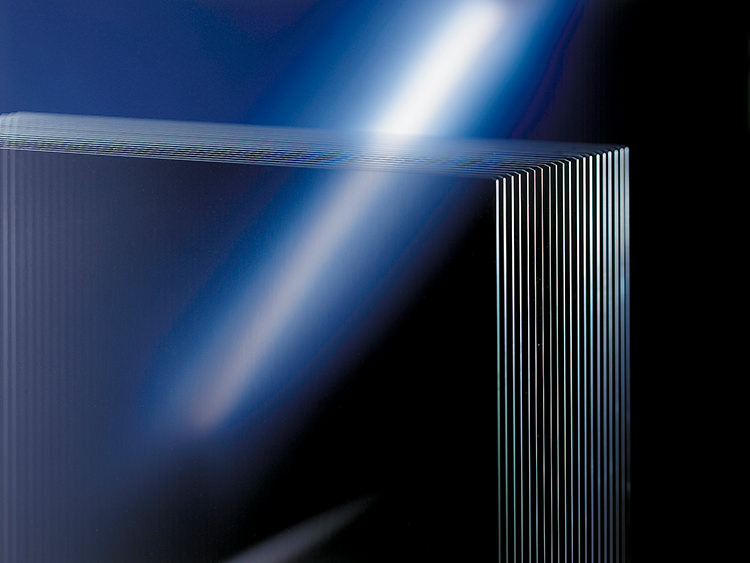

Recently, screen sizes of LCD TVs have become wider and larger. The glass substrates from AGC enable this trend of larger LCD TV sizes. Glass substrates also play a key role to reproduce clear and beautiful screen images as one of the core components of LCDs.

It is necessary for TFT-LCD glass to meet many strict quality requirements. Unlike window pane glass, glass for TFT-LCDs is not allowed to contain alkalis. This is because alkali-ions contaminate liquid crystal materials and even adversely affect the characteristics of the TFT. Additionally, the glass should not exhibit large sagging even though its thickness is just 0.3 to 0.7 mm and should have excellent heat resistance while assuring dimensional stability even after being heated at high temperature. The glass also should have properties that its composition does not dissolve during the fabrication process using chemicals. "AN100", non-alkali glass developed by us, is the one that has fulfilled those various requirements. Furthermore, since "AN100" does not contain hazardous materials such as arsenic or antimony, it has high reputation for being an environment-friendly glass. Our technologies are supporting the design of thin, large, and environmentally friendly LCD TVs.

An LCD has a layer of liquid crystal sandwiched between two sheets of glass. The most remarkable feature of liquid crystal is its optical characteristics of being both a liquid and a solid. Applying voltage to the layer of liquid crystal causes the orientation of the molecules in the liquid crystal to change relative to each other. This molecule rearrangement controls the light transmission from the backlight; the light passes through color filters of red, blue, and green, and eventually rich images appear on the screen.

Majority of LCDs in wide use now are TFT-LCDs. In a TFT-LCD, a layer of thin film that forms transistors is used as a device that applies voltage to the liquid crystal layer, and those transistors control the voltage supplied to each pixel. The advantages of a TFT-LCD are high resolution and quick response time that enables motion image to be fine and clear.

It is AGC’s display glass substrates, developed using its distinctive precision glass processing technologies, that support these higher resolution TVs.

Smartphones and tablets can now be considered life necessities, and the LCD screen is the most frequently used interface whenever such devices are used. Without the LCD display, it is not possible to send email or view pictures taken by the camera function.

Furthermore, LCDs play an important role in a variety of applications such as in-vehicle displays, e.g. navigation systems and center information displays, and digital signage.

Through production and supply of LCD glass substrates, which is a key material of LCDs, AGC helps create a more convenient and comfortable life through integrating various technologies within the Group.

In its display business, AGC holds the number-two global market share in glass substrates used for thin-film-transistor (TFT) liquid crystal displays (LCD) and OLEDs.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

The glass substrate is one of the core layers of TFT LCD. It influences fundamental features of the display in the resolution, light transmittance, thickness, weight, and viewing angle.

The glass substrate is the core component of the TFT LCD and plays a significant role in the upstream of the TFT LCD industry, similar to the silicon wafer in the semiconductor industry.

Since the quality of the glass substrate decides the features of the display in the resolution, light transmittance, thickness, weight, viewing angle, and other important parameters.

The fundamental structure of the TFT LCD is similar to a sandwich, two layers of “bread” (TFT substrate and color filter) sandwiched with “jam” (liquid crystal).

Considering the unique environment in the manufacturing process of TFT-LCD, such as high temperature, high pressure, and environment switching among acidic-neutral-alkaline, the following characteristics of the glass must meet the challenge and quality requirement.

In the manufacturing process, the maximum temperature can reach above 600 ℃, which requires the glass substrate to remain rigid without any sticking even at such a high temperature.

After the etching process, the glass substrate needs to remain with minimal changes, and can’t be left with visible residue and interference with film deposition.

In the process the mother glass is cut into pieces in the required size, with a thickness of only 0.5-0.7mm, the glass needs to have high mechanical strength and elastic modulus >70GPa.

Usually, the size has doubled with each successive generation. From the initial generation 4 (G4) to the current G11, the size of the substrate has grown to 3000*3320mm.

In the global market of glass substrates for TFT-LCD, more than 90% are concentrated in several major manufacturers, such as Corning (America), Asahi Glass (Japan), Nippon Electric Glass (Japan), and AvanStrate (Taiwan).

However, there is still a gap and need for breakthroughs in the glass for high-generation LCD panel production lines and AMOLED alkali-free glass technology. It is hard to achieve high localization in a short time.

AGC has now decided to relocate a cutting-edge glass substrate production facility from within the AGC Group. This investment will significantly reduce the need for capital investment while maintaining the group"s total production capacity.

There has been a large increase in production of TFT-LCD panels in China in recent years which has resulted in an abrupt increase in demand for glass substrates. To accommodate demand growth, the AGC Group has established a supply system by setting up a processing facility in Kunshan, Jiangsu Province, and Shenzhen, Guangdong Province, and a furnace in Huizhou,Guangdong Province.

AGC has also decided to build an 11th generation dedicated glass substrate* furnace in order to address the anticipated growth in demand of TFT-LCD panels that will use similar-sized TFT-LCD glass substrates.

Display glass substrate is a special glass used for supporting TFT (Thin Film Transistor), LCD (Liquid Crystal Display) and OLED panels forming display units for products including televisions, personal computers and mobile phones. Ever display panel consists of various components stacked in a number of layers, which includes a color filter, a polarizer and a liquid crystal display with the glass substrate being the most important.

In 2016, the display glass substrate market was valued at US$ 1.42 Billion and is projected to reach US$ 1.97 Billion by 2028, growing at a CAGR of 5.7%. With the expanding demand for consumer grade electronic devices such as smartphones, laptops and personal computers, the global display glass substrate market is expected to grow during the forecast period.

The expanding use of LCD’s in smart handheld devices, consumer durables, and other automotive applications is one of the most powerful factors projected to drive the growth of the display glass substrate market. Moreover, the advancements in the electronics and semiconductor industries are further projected to drive the increasing demand for display glass substrates.

The electronics industry is the largest end-using commerce segment that suitably utilizes display glass substrates and the general growth for the display glass substrate market is heavily dependent on it. Increasing in manufacturing of display devices, electronic components, semiconductor devices, MEMS (Microelectronic Mechanical System) devices, and computing & telecommunication devices is expected to drive the growth of the display glass substrate market.

However, the immense manufacturing cost of display glass substrates acts as a restraint to the expansion of the display glass substrate market. Manufacturers of display glass substrates are focusing on directing their earnings through several process control techniques with the aim of optimizing production costs to a certain level.

Asia Pacific is accredited to be the largest market for display glass substrates. The display glass substrate market in the Asia Pacific region is estimated to grow at the highest CAGR during the forecast period owing to the occupancy of numerous electronics manufacturers in this region.

China, Hong Kong and South Korea are expected to account for the largest share of the glass substrate market in the Asia Pacific region in 2028 as most of the major producers of display glass substrates such as Nippon Sheet Glass (Japan) and The Tungshu Group (China) are located in the Asia Pacific region. The Asia Pacific region accounts for over 37% of the total display glass substrate market. Other regions include North America and Europe with a market share of 8% and 3% in the global display glass substrate market.

Some of the key players in the global display glass substrate market are Corning Incorporated, LG Chem, AGC Incorporated, AvanStrate Incorporated, SCHOTT Ag, Tungshu Optoelectronics, IRICO Group New Energy Company Limited and CGC Glass.

The research report presents a comprehensive assessment of the display glass substrate market and contains thoughtful insights, facts, historical data and statistically supported and industry validated market data. It also includes projections using a suitable set of assumptions and methodologies. The research report of display glass substrate market provides analysis and information according to the different market segments such as geographies, grade type and application.

The display glass substrate market report is a compilation of first-hand information, qualitative and competitive assessment industry analysts, inputs from industry experts and industry participants across the value chain. The report for display glass substrate market provides an in depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

“LCD glass substrate” is a generic term for the special glass used for thin-film transistor (TFT) LCDs which form the display area of products including LCD televisions, personal computers and mobile phones. An LCD panel consists of various components stacked in a number of layers. These components include a polarizer, a color filter and a liquid crystal layer, with the glass substrate being the most important. Glass substrates are extremely thin – typically about 0.3-0.7 mm – and 8th-generation glass substrates (2,200 x 2,500 mm) are as large as three tatami mats in size.

In order to accurately display beautiful, high-definition images, LCD glass substrates must have super-smooth surfaces with irregularities reduced to the nano-level. It is also necessary to avoid the formation of internal bubbles and the intrusion of foreign matter (dust) too minute for the naked eye. Smooth and scratch-free glass substrates with the ultimate precision represent the maximum quality AvanStrate aims for.

Abstract The visual appearance of manufactured products is often one of the important quality attributes for certain types of products, which are mainly used for display purposes or used as the exterior part of other products. TFT-LCD (thin film transistor – liquid crystal display) glass substrates can be one of the representative cases. In such cases, visual quality (i.e., visual appearance) as well as the physical or mechanical quality attributes has to be controlled or maintained. This paper…Expand

Be described the composition that can contain in glass formula of the present invention below, the containing ratio of each composition represents with weight percent.

2content is higher, and chemical resistant properties and physical strength can increase, and strain point increases, and the high temperature viscosity of glass increases, SiO

2content is lower not easily forms glass, and strain point declines, and the coefficient of expansion increases, and acid resistance declines, and alkali resistance declines.SiO

3chemical durability of glass can be improved and reduce devitrification of glass tendency, improve the composition of Young"s modulus simultaneously.Al

3content is lower, the easy crystallization of glass, physical strength is lower be unfavorable for shaping.The present invention introduces the Al of 14-22wt%

3being found performance for improving, reducing glass viscosity.On the other hand reduce proportion, improve resistance to BHF, improve glass meltability, make glass not easily devitrification and low expansion composition can be subtracted, be required composition.The present invention introduces the B of 3-12wt%

MgO is conducive to founding of glass, improves the stability of glass, suppresses devitrification of glass tendency, and MgO has when not reducing strain point and reduces high temperature viscosity, makes glass be easy to the feature melted.The present invention have chosen 5-10wt%MgO, preferred 6-9wt%MgO.

The molar content of SrO is 0-5%, and as fusing assistant and prevent glass from occurring crystallization, improve the specific refractory power of glass, if content is too much, glass density can be too high, causes the quality of product overweight.So the content of SrO is defined as 1-3%.

3, or yttrium oxide or cerium oxide or Samarium trioxide or Erbium trioxide can significantly improve Young"s modulus and the strain point of glass, the temperature of fusion of glass can be reduced simultaneously.With lanthanum trioxide La

Concrete steps: weigh each oxide compound according to each embodiment listed in table 1, table 2, fully mix, make it even, are poured into by compound in crucible, be incubated 8-12h at lower 1610 DEG C-1640 DEG C of High Temperature Furnaces Heating Apparatus.In order to make glass ingredient even, platinum rod under high temperature, is used to stir.The glass metal melted is cooled to shaping required temperature range, produces the thickness of the glass substrate that flat-panel screens needs, simpler cold work is carried out to shaping glass substrate, finally the Basic Physical Properties of glass substrate is tested.The characteristic datas such as the boron-containing quantity of glass, glass yield, thermal expansivity, strain point, liquidus temperature, high temperature viscosity, Young"s modulus, density, optical transmittance can be obtained respectively.

The technical measurement that glass property listed by embodiment in table 1, table 2 is commonly used according to glass art.Thermal linear expansion coefficient adopts horizontal expander instrument to measure, and the thermal linear expansion coefficient (CTE) within the scope of 50-350 DEG C is with × 10

3; High temperature viscosity adopts drum type brake to rotate high temperature viscosimeter and measures, and utilizes VFT formulae discovery temperature of fusion, and unit is DEG C (temperature when temperature of fusion refers to that glass melt viscosity reaches 200 pool); Liquidus temperature adopts normal gradients stove to measure, and unit is DEG C; Young"s modulus adopts resonant method test; Transmitance adopts ultraviolet-visible spectrophotometer test, and unit is %.

As can be seen from table 1, table 2, can be proved again by each embodiment: the glass substrate produced by means of glass ingredient principle provided by the invention can reach following technical indicator after testing: the thermal linear expansion coefficient (CTE) within the scope of 50-350 DEG C is 30-37 × 10

3; High temperature viscosity adopts drum type brake to rotate high temperature viscosimeter and measures, and utilizes VFT formulae discovery temperature of fusion for being greater than 1619 DEG C (temperature when temperature of fusion refers to that glass melt viscosity reaches 200 pool); Young"s modulus adopts resonant method test for being greater than 83 GPa; Light transmission rate adopts ultraviolet-visible spectrophotometer test for being greater than 92%.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey