tft lcd glass substrate for sale

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

For its transparency, flat and smooth surface, and excellent heat resistance, this product is used as a substrate for various types of displays such as televisions, personal computers, smart phones, tablet devices, and in-vehicle infotainment. It is an alkali-free aluminosilicate glass that was developed by using the float process.

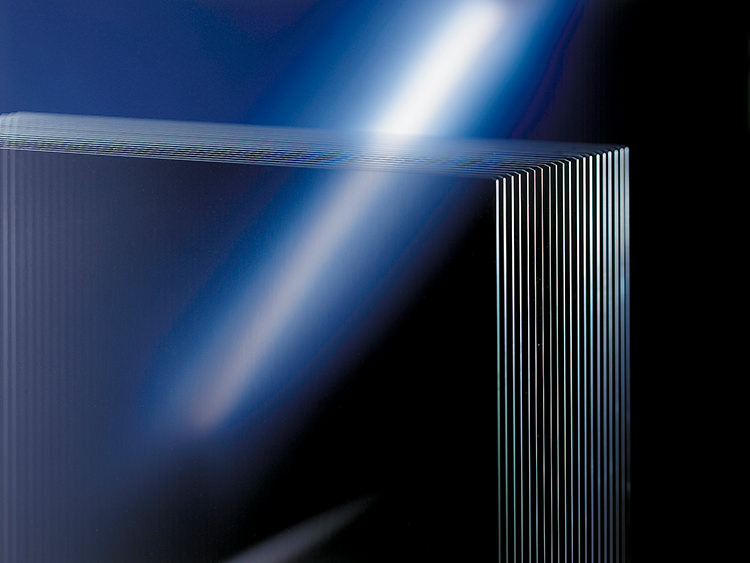

Recently, screen sizes of LCD TVs have become wider and larger. The glass substrates from AGC enable this trend of larger LCD TV sizes. Glass substrates also play a key role to reproduce clear and beautiful screen images as one of the core components of LCDs.

It is necessary for TFT-LCD glass to meet many strict quality requirements. Unlike window pane glass, glass for TFT-LCDs is not allowed to contain alkalis. This is because alkali-ions contaminate liquid crystal materials and even adversely affect the characteristics of the TFT. Additionally, the glass should not exhibit large sagging even though its thickness is just 0.3 to 0.7 mm and should have excellent heat resistance while assuring dimensional stability even after being heated at high temperature. The glass also should have properties that its composition does not dissolve during the fabrication process using chemicals. "AN100", non-alkali glass developed by us, is the one that has fulfilled those various requirements. Furthermore, since "AN100" does not contain hazardous materials such as arsenic or antimony, it has high reputation for being an environment-friendly glass. Our technologies are supporting the design of thin, large, and environmentally friendly LCD TVs.

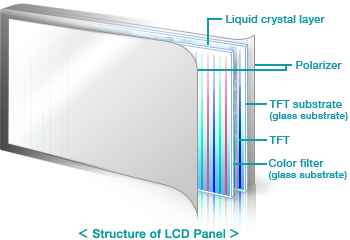

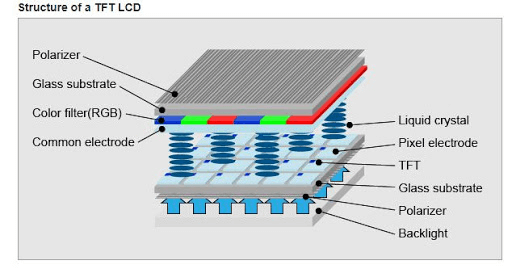

An LCD has a layer of liquid crystal sandwiched between two sheets of glass. The most remarkable feature of liquid crystal is its optical characteristics of being both a liquid and a solid. Applying voltage to the layer of liquid crystal causes the orientation of the molecules in the liquid crystal to change relative to each other. This molecule rearrangement controls the light transmission from the backlight; the light passes through color filters of red, blue, and green, and eventually rich images appear on the screen.

Majority of LCDs in wide use now are TFT-LCDs. In a TFT-LCD, a layer of thin film that forms transistors is used as a device that applies voltage to the liquid crystal layer, and those transistors control the voltage supplied to each pixel. The advantages of a TFT-LCD are high resolution and quick response time that enables motion image to be fine and clear.

It is AGC’s display glass substrates, developed using its distinctive precision glass processing technologies, that support these higher resolution TVs.

Smartphones and tablets can now be considered life necessities, and the LCD screen is the most frequently used interface whenever such devices are used. Without the LCD display, it is not possible to send email or view pictures taken by the camera function.

Furthermore, LCDs play an important role in a variety of applications such as in-vehicle displays, e.g. navigation systems and center information displays, and digital signage.

Through production and supply of LCD glass substrates, which is a key material of LCDs, AGC helps create a more convenient and comfortable life through integrating various technologies within the Group.

This report presents an extensive outline, pieces of the overall industry, and development chances of Glass Substrates for TFT-LCD market by item type, application, key makers and key locales and nations.

Glass Substrate is a special glass used for thin-film-transistor (TFT) liquid crystal displays (LCD) and OLEDs, which form the display area of products including LCD televisions, personal computers and mobile phones. An LCD panel consists of various components stacked in a number of layers. These components include a polarizer, a color filter and a liquid crystal layer, with the glass substrate being the most important.

According to our latest study, the global Glass Substrates for TFT-LCD market size was valued at USD 7271.6 million in 2021 and is forecast to a readjusted size of USD 11450 million by 2028 with a CAGR of 6.7% during review period. The influence of COVID-19 and the Russia-Ukraine War were considered while estimating market sizes.

This report is a detailed and comprehensive analysis for global Glass Substrates for TFT-LCD market. Both quantitative and qualitative analyses are presented by manufacturers, by region and country, by Type and by Application. As the market is constantly changing, this report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets. Company profiles and product examples of selected competitors, along with market share estimates of some of the selected leaders for the year 2022, are provided.

Additionally, the Glass Substrates for TFT-LCD market trend provides a comprehensive study of prime players at intervals the market by lightness their product description, business outline, and business strategy. It conjointly endows with the amount of production, Glass Substrates for TFT-LCD"s future demand, needed staple, and also the cash health of the organization.

The Glass Substrates for TFT-LCD Market report purposefully analyses every sub-segment regarding the individual growth trends, contribution to the total market, and the upcoming forecasts.

For the end users/applications, this report focuses on the status and outlook for major applications/end users, consumption (sales), market share and growth rate of Glass Substrates for TFT-LCD market for each application, including: -

This report studies the global market size of Glass Substrates for TFT-LCD in key regions like North America, Europe, China and Japan, focuses on the consumption of Glass Substrates for TFT-LCD in these regions.

Key questions answered in the report: ● What are the Glass Substrates for TFT-LCD market opportunities and threats faced by the vendors in the Global Glass Substrates for TFT-LCD industries?

3) Focuses on the key Glass Substrates for TFT-LCD manufacturers, to study the capacity, production, value, market share and development plans in the future.

Global Glass Substrates for TFT-LCD Industry 2023 Market Research Report provides exclusive vital statistics, data, information, trends and competitive landscape details in this niche sector.

The global TFT LCD Glass Substrate market size is projected to reach multi million by 2028, in comparision to 2021, at unexpected CAGR during 2022-2028 (Ask for Sample Report).

The TFT LCD Glass Substrate has several applications, including: Television,Laptop & Tablet,Desktop Monitor,Automotive,Mobilphone,Other. Based on types these are segmented in Gen. 5,Gen. 6,Gen. 7,Gen. 8. The market for TFT LCD Glass Substrate is highly competitive. There are several major market players in the market, including Corning,AGC,NEG,Tunghsu Optoelectronic,AvanStrate,IRICO,LG Chem. The report provides an expansive market geographical regions analysis by covering areas like North America: United States, Canada, Europe: GermanyFrance, U.K., Italy, Russia,Asia-Pacific: China, Japan, South, India, Australia, China, Indonesia, Thailand, Malaysia, Latin America:Mexico, Brazil, Argentina, Colombia, Middle East & Africa:Turkey, Saudi, Arabia, UAE, Korea.

Key Benefits for Industry Participants & StakeholdersThis TFT LCD Glass Substrate research report provides an expansive market analysis of the desired sector by wrapping areas like growth drivers, trends persisting in the endeavor, regulatory framework prevalent in the sector as well as a comprehensive SWOT analysis.

The TFT LCD Glass Substrate Research Report focuses heavily on analyzing various segments of the market. The TFT LCD Glass Substrate Market is categorized by type, region, and Application.

Sections in TFT LCD Glass Substrate Market Report:Section 1 mainly consists of an overview and an introduction of the TFT LCD Glass Substrate company focusing on the important figures and statistics of the market.

Section 2 comprises multiple marketing transactions, sales generation, consistency key factors, and the overall growth of the TFT LCD Glass Substrate company.

Section 4 includes a key driver analysis for satisfaction and loyalty along with SWOT Analysis, considering the potential strengths, weaknesses, growth opportunities, and threats put forth by the TFT LCD Glass Substrate company..

Section 5 enlists the benefits of the TFT LCD Glass Substrate company, by providing a full overview of the feasible company verdicts which include an in-depth analysis of the product profiles, and corporate growth.

Section 6 chiefly covers the analysis of the effect of the impact of the TFT LCD Glass Substrate industry on the development and growth factors of the market across the globe.

Section 9 is the final section of the TFT LCD Glass Substrate market report that recaps and puts a full stop to all arguments and wrong interpretations by providing the right outcomes to the reader end.

The TFT LCD Glass Substrate Market Industry Research Report contains:The TFT LCD Glass Substrate market research report covers all topics of the company including marketing methodologies, analysis of the growth and performance, and interaction with real-time consumers.

It contains all the components of numerous market ideas, prototypes, product profiles, trends, and figures a user needs to evaluate the growth of the TFT LCD Glass Substrate company.

Another significant subject of this market report is the necessity to grade and evaluate the effectiveness of the TFT LCD Glass Substrate company in the global development of the firm.

In addition to this TFT LCD Glass Substrate research study, it aids in business marketing, business analysis, and overall performance concerning the competitive field.

The TFT LCD Glass Substrate Market Research Report says that the covid 19 pandemic has severely damaged not only human lives but also the global economy and global markets. Data information and statistics of the TFT LCD Glass Substrate report remained in flux, and government policies fluctuate to extremes, as the killer virus swept through nations, affecting production, disrupting supply chains, and unsettling the financial markets. The TFT LCD Glass Substrate Market Research Report aims to analyze the actions of competition authorities to support small and medium-sized enterprises (SMEs) during the coronavirus (COVID-19) pandemic and facilitate their recovery.

The TFT LCD Glass Substrate report gives insightful data about the TFT LCD Glass Substrate Market Share and the challenges within the industry. It discusses in detail theTFT LCD Glass Substrate Market Share to help businesses understand the areas of growth and the reasons slowing down the progress. The TFT LCD Glass Substrate Market Research also analyzes the future of the company and what are the challenges and risks that a company may face in the future.

This report helps to find information on how to boost sales of TFT LCD Glass Substrate in the overseas markets.The report offers detailed coverage of the TFT LCD Glass Substrate industry’s progress and main market trends with the impact of coronavirus.

The opportunities and threats that are ought to arise in the future for the key market players have also been emphasized in the TFT LCD Glass Substrate research report publication.

The research report also mentions the innovations, profound inventions, latest developments, marketing strategies, and branding techniques, present in the TFT LCD Glass Substrate market.

This TFT LCD Glass Substrate report additionally states import/export consumption, supply and demand figures, demographics, revenue, and gross margins alongside the features of different methodologies to upskill the company’s development.

AGC has now decided to relocate a cutting-edge glass substrate production facility from within the AGC Group. This investment will significantly reduce the need for capital investment while maintaining the group"s total production capacity.

There has been a large increase in production of TFT-LCD panels in China in recent years which has resulted in an abrupt increase in demand for glass substrates. To accommodate demand growth, the AGC Group has established a supply system by setting up a processing facility in Kunshan, Jiangsu Province, and Shenzhen, Guangdong Province, and a furnace in Huizhou,Guangdong Province.

AGC has also decided to build an 11th generation dedicated glass substrate* furnace in order to address the anticipated growth in demand of TFT-LCD panels that will use similar-sized TFT-LCD glass substrates.

Silk-sreened glass, also called silk printing or screened printing glass, is custom-made by transferring a silk-screen image to the glass and then processing it through a horizontal tempering furnace. Each individual lite is screen-printed with the desired pattern and ceramic enamel frit color. The ceramic frit can be silk-screened onto the glass substrate in one of three standard patterns–dots, lines, holes–or in a full-coverage application. In addition, custom patterns can be easily duplicated on the glass. Depending on the pattern and the color, the glass lite can be made transparent, translucent or opaque.

Chemically strengthened glass is a type of glass that has increased strength as a result of a post-production chemical process. When broken, it still shatters in long pointed splinters similar to float glass. For this reason, it is not considered a safety glass and must be laminated if a safety glass is required. However, chemically strengthened glass is typically six to eight times the strength of float glass.

The glass is chemically strengthened by a surface finishing process. Glass is submersed in a bath containing a potassium salt (typically potassium nitrate) at 300 °C (572 °F). This causes sodium ions in the glass surface to be replaced by potassium ions from the bath solution.

These potassium ions are larger than the sodium ions and therefore wedge into the gaps left by the smaller sodium ions when they migrate to the potassium nitrate solution. This replacement of ions causes the surface of the glass to be in a state of compression and the core in compensating tension. The surface compression of chemically strengthened glass may reach up to 690 MPa.

Recently, China’s first 8.5 generation TFT-LCD glass substrate independently developed by Triumph Technology, a company affiliated with the China Building Materials Group, successfully rolled off the production line in Anhui, marking the breakthrough in China’s high-generation TFT-LCD glass substrate. China has now become the third country in the world to master the production technology of high-generation TFT-LCD glass substrates, after the United States and Japan.

TFT-LCD glass substrate (i.e. a glass substrate for the thin-film-transistor liquid-crystal displays), is one of the key strategic materials for the electronic information display industry. Its production control precision is comparable to that of the semiconductor industry, representing the highest level in the field of modern large-scale glass manufacturing in the world. In order to promote the high-quality development of China’s information display industry, the Ministry of Science and Technology has launched a project focusing on “The Development and Industrialization Demonstration of the Core Technology in High-generation Electronic Glass Substrate and Cover Plate” under the key national R&D plan “The Technology Upgrading and Industrialization of Key Basic Materials”, aiming at enhancing the initiative and voice of China’s electronic glass industry in the international market.

We TFT screen manufacturers generally buy back the glass panel belongs to the big board, and the big board glass needs to be cut into the corresponding size to be cut into the substrate, cut into 5-inch TFT screen, 7-inch TFT screen, 8-inch TFT screen, and so on. And the cut TFT screen panel will be cleaned. After cleaning on the Cell Test test, speaking of poor TFT screen panel selected out, this step is very critical.

Put the two glass substrates according to the fixed interval, seal the two glass edges with frame glue and conductive glue and leave one or two notches, put the liquid crystal panel into the vacuum chamber, pump out the air from the liquid crystal panel through the notches reserved, then fill the liquid crystal with the help of atmospheric pressure (liquid crystal is a kind of compound material between solid and liquid), and then use UV glue to close the mouth of the crystal filling to complete the liquid crystal filling process.

Polarizer lamination is also called POL, which refers to the TFT screen panel on both sides of the polarizer, the angle of the two polarizers and color filters, TFT"s PI directional film friction angle parallel, stick polarizer production completed. TFT screen imaging to use polarized light. TFT screen panel before and after each a polarized light film affixed to the LCD glass above and below, the composition of the total thickness of about 1mm LCD film. If any of the polarizers is missing, the liquid crystal sheet is unable to display images.

The chip on glass is directly bonded to the glass by the COG (Chip on Glass). and then this pressure. Use ACF to crimp the endpoints together as required, and then seal with sealing glue.

The wiring also called the flex circuit, is mainly responsible for connecting the circuits and is responsible for energizing them. Through ACF bonding, hot pressing at a certain temperature, pressure, and time, the FPC flexible circuit board is connected to the TFT screen panel to achieve the connection of the external driver circuit. The manufacturing process mainly includes ACF pre-paste, pre-bonding, main bonding, testing, and other steps. After assembly and wiring are called FOG.

The last step is missing the backlight, with the backlight can be driven to light, the previous process has been assembled to FOG, and then the LED backlight module and iron frame or plastic frame for fixed, to complete the LCM LCD module finished assembly process.

This is the complete TFT screen production process, although it is relatively simple, the details of this all test the production level of TFT screen manufacturers.

A TFT LCD, or a thin film transistor liquid crystal display, is one of the fastest growing forms of display technology today. The thin film transistor (TFT) is a type of semiconductor device used in display technology to enhance efficiency, compactness, and cost of the product. In conjunction with its semiconductor properties, the TFT LCD is an active matrix display, controlling pixels individually and actively rather than passively, furthering the benefits of this semiconductor device.

The TFT LCD is built with three key layers. Two sandwiching layers consist of glass substrates, though one includes TFTs while the other has an RGB, or red green blue, color filter. The layer between the glass layers is a liquid crystal layer.

The Architecture of a TFT Pixelbelow) from the other substrate layer of the device and control the amount of voltage applied to their respective sub-pixels. This layer also has pixel electrodes between the substrate and the liquid crystal layer. Electrodes are conductors that channel electricity into or out of something, in this case, pixels.

On the surface level is the other glass substrate. Just beneath this glass substrate is where the actual pixels and sub-pixels reside, forming the RGB color filter. In order to counteract the electrodes of the previously mentioned layer, this surface layer has counter (or common) electrodes on the side closer to the liquid crystals that close off the circuit that travels between the two layers. In both these substrate layers, the electrodes are most frequently made of indium tin oxide (ITO) because they allow for transparency and have good conductive properties.

The outer sides of the glass substrates (closest to the surface or closest to the back) have filter layers called polarizers. These filters allow only certain beams of light to pass through if they are polarized in a specific manner, meaning that the geometric waves of the light are appropriate for the filter. If not polarized correctly, the light does not pass through the polarizer which creates an opaque LCD screen.

Between the two substrate layers lie liquid crystals. Together, the liquid crystal molecules may behave as a liquid in terms of movement, but it holds its structure as a crystal. There are a variety of chemical formulas available for use in this layer. Typically, liquid crystals are aligned to position the molecules in a certain way to induce specific behaviors of passing light through the polarization of the light waves. To do this, either a magnetic or electric field must be used; however, with displays, for a magnetic field to be usable, it will be too strong for the display itself, and thus electric fields, using very low power and requiring no current, are used.

The twisted nematic effect is one of the cheapest options for LCD technology, and it also allows for fast pixel response time. There are still some limits, though; color reproduction quality may not be great, and viewing angles, or the direction at which the screen is looked at, are more limited.

The light that passes through the device is sourced from the backlight which can shine light from the back or the side of the display. Because the LCD does not produce its own light, it needs to use the backlight in the OLED) have come into use as well. Typically white, this light, if polarized correctly, will pass through the RGB color filter of the surface substrate layer, displaying the color signaled for by the TFT device.

Within an LCD, each pixel can be characterized by its three sub-pixels. These three sub-pixels create the RGB colorization of that overall pixel. These sub-pixels act as capacitors, or electrical storage units within a device, each with their own independent structural and functional layers as described earlier. With the three sub-pixels per pixel, colors of almost any kind can be mixed from the light passing through the filters and polarizer at different brightness based on the liquid crystal alignment.

HONG KONG (Reuters) - China’s IRICO Display Devices plans to invest 23 billion yuan ($3.56 billion) in glass substrate and TFT-LCD projects funded through a private placement of shares, it said on Tuesday.

The proceeds of the share placing will be divided into three parts, it said, with 14 billion yuan invested in a 8.6 generation TFT-LCD project and 6 billion yuan going to a 8.5 generation LCD glass substrate project. The remaining 3 billion yuan will be used for the company’s working capital.

There has been a large increase in production of TFT-LCD panels in China in recent years which has resulted in an abrupt increase in demand for glass substrates. To accommodate demand growth, the AGC Group has established a supply system by setting up a processing facility in Kunshan, Jiangsu Province, and Shenzhen, Guangdong Province, and a furnace in Huizhou,Guangdong Province.

AGC has also decided to build an 11th generation dedicated glass substrate* furnace in order to address the anticipated growth in demand of TFT-LCD panels that will use similar-sized TFT-LCD glass substrates.

AGC Asahi Glass (or also called AGC, Registered Company name: Asahi Glass Co., Ltd., Headquarters: Tokyo, President & CEO: Takuya Shimamura) is the parent company of the AGC Group, a world-leading glass solution provider and supplier of flat, automotive and display glass, chemicals, ceramics and other high-tech materials and components. Based on more than a century of technical innovation, the AGC Group has developed a wide range of cutting-edge products. The AGC Group employs some 50,000 people worldwide and generates annual sales of approximately 1.3 trillion Japanese yen through business in about 30 countries.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey