enhance lcd displays quotation

Most off-the-shelf displays are not designed to operate in extreme environments although the use of TFT LCD displays is now common in many outdoor, rugged and/or public access applications. Concerns for high performance viewability, protection against damage and functionality in EMI/RFI sensitive applications can be addressed with combinations of a Display Logic LED Backlight Enhancement and the following solutions.

At TeleTraders, we want to buy your used LCD Displays from you in bulk. If you’re older LCD Displays are still usable, consider selling them to TeleTraders to help offset your equipment upgrade costs. Give TeleTraders a call at

When it comes time to update your office, offset your expenses and sell used LCD Displays. We will make you a competitive offer for your old monitors, LCDs, computers, modems, and laptops.

Our company is happy to purchase your old used, outdated LCD displays and monitors to free your business from the sometimes complicated electronics disposal processes. Please give us a call at 770-864-9179 or get a Free Online Quote to get started.

Our team utilizes industry experience to provide you with a fair and competitive price quote for your old used LCD displays and computer devices. We continue to upgrade our knowledge base as office equipment quickly becomes outdated in the constantly changing world of electronics. We team up with many companies around the world to quickly resell, repurpose, or recycle the LCD displays sent our way. Our efforts ensure the electronics remain in operation well beyond their initial run with your company.

When you sell your LCD displays and other office equipment to TeleTraders, we can also handle all of the packing, removal and transporting for the equipment, helping free up both your space and your time.

We understand that office technology needs change over time. The LCD displays and monitors that worked for your office a year or two ago may not be keeping pace anymore with your needs. We can help by offering you the best rates possible for your bulk LCD displays. Contact TeleTraders to get started right now.

When it’s time to upgrade your computer and LCD displays, you shouldn’t have to spend lots of time trying to figure out how to dispose of, sell or recycle your used LCD displays and office equipment – that’s where TeleTraders will be able to help you.

We request a detailed list of your used office LCD displays, including make, model, and quantity of units. Please, also include a photo of your equipment so we can gauge the current quality of the hardware.

TeleTraders is happy to accept most major and minor brands of common IT office LCD displays, office LCD display systems, and also other IT office equipment. If there is any question about whether we will accept your brand of equipment, feel free to contact us by phone or email at any time and we will respond to your inquiry as quickly as possible.

We are always looking to help businesses, small and large, offset the costs of upgrading their IT office LCD displays and IT office LCD display systems. In order to make an inquiry about a possible trade-in valuation, please Contact Us so we can work with you to evaluate used IT office LCD display gear. You may also Call Us directly for immediate assistance.

Parker Chomerics offers a wide variety of touchscreen, window and LCD solutions for military, medical, aerospace, and industrial display applications. Providing turnkey solutions with integrated assemblies aids in fast design cycles and fast to market product development cycles.

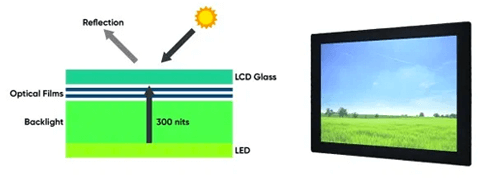

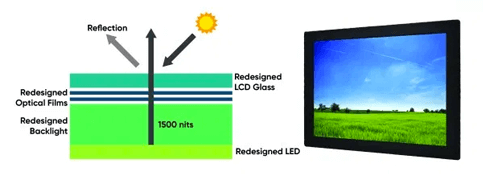

Problem: The LCD market continues to develop more efficient, higher resolution and lower cost displays using lower power single light bar LED backlights. They are also getting thinner and less robust. This makes enhancement to true Sunlight Readability (1000 nits or greater) increasingly difficult using the factory backlight arrangement.

Solution: Q-Vio has developed a new ultra-rugged high bright family of sunlight readable displays that is based upon completely custom robust aluminum frame along with special light guide design that allows Q-Vio to control all aspects of the backlight. Single rail, dual rail or even 4 sided are all achievable with Q-Vio’s custom ruggedization. These panels have exceptional thermal management with the entire frame acting as a large heatsink. Because these ultra-bright sunlight readable displays are more rigid and robust for mission-critical applications that need high shock and vibration resistance, they are a perfect fit for rugged Military display systems, Maritime LCDs or Panel Mount LCD applications. Night Vision (NVIS) is also an option with this family.

We use our expertise and technology to assist our customer to design the LCD into the specification at the most economical cost in the shortest amount of time.

DisplayBoost has been serving the IPC industry for over a decade, providing professional, custom, 1000+ nits sunlight readable LCDs that integrate seamlessly with your company’s existing system. From assembly to delivery, we’re with you every step of the way. We’ll test your finished LCD before sending it to you, troubleshoot it for problems, and ensure everything is working as it should be for the environment in which it will be operating.

We’re happy to work with both domestic and international customers, providing creative solutions that meet your company’s specific demands. Combining premium materials, cutting-edge technology, and experienced professionals, we’ll deliver an LCD that exceeds your expectations along with industry standards.

Liquid crystal display (LCD) is a flat panel display that uses the light modulating properties of liquid crystals. Liquid crystals do not produce light directly, instead using a backlight or reflector to produce images in colour or monochrome.

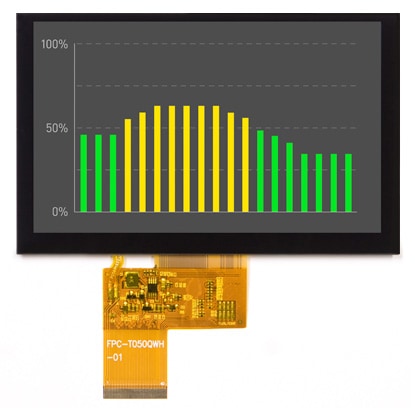

Have your product stand out with the DT050ATFT display - our 5” TFT LCD module with full viewing angle. The full viewing angle feature allows the display contents of the LCD to be visible from practically any angle. It"s a cost-effective enhancement compared to using an IPS display. The 5" TFT has 800 x 480 RGB resolution and supports 24-bit parallel RGB input mode. The LCD uses two driver ICs to drive the display: a source driver with TCON (Ilitek ILI6122) and a gate driver (Ilitek ILI5960). It also is available with either a resistive touchscreen or capacitive touchscreen panel. This 5 inch LCD is an ideal option for a variety of digital devices including video or POS systems.

Liquid Crystal Display (LCD) is the only display technology available today. Response time is an issue of concern. Other display technologies, such as organic light-emitting diodes (OLEDs), cathode ray tubes (CRTs), plasma, vacuum fluorescent displays (VFDs), and the latest Samsung micro-LED displays, do not have response time issues.

The reason why the response time of LCD S is slower is that the liquid crystal material is a fluid of organic matter sandwiched between two glass substrate electrodes. When power is applied, the liquid crystal molecules are twisted parallel between the electrodes and the liquid crystal molecules are forced to be perpendicular to the electrodes. This process takes time, hence the response time, because the liquid crystal fluid has viscosity. The higher the viscosity, the longer the response time. This explains why the lower the temperature, the slower the response of the LCD. If you read the lcd display data sheet, you will find that the lcd display has a storage and operating temperature range. The response speed of the LCD display should depend on the application.

A normal monitor has a response time of 10 ms. If you want a monitor for gaming or a TV for watching sports, the required response time should be quite fast (about 1ms). The most extreme example is an LCD welding helmet, which requires a very fast response time (“0.1ms) to prevent UV damage to the eyes of welders. However, some applications require slower response times for LCD displays, such as avalanche transceivers with very low refresh rates in order to save power, which require very slow LCD response times in order to avoid flicker. In the next work, we will mainly try to increase the response time of LCD as the goal.

The response time of an LCD screen is the time it takes to change from one color to another. Typically, it is measured from black to white back to black again. But more accurately, it should be gray to gray, because LCDs display grayscale followed by color shading (gradients), not pure black and simultaneous or RGB (red, green, and blue) colors.

As we know, high viscosity is the main reason for slowing down LCD distortion. Chemists have invented methods to reduce the viscosity. There are many patents on this issue.、

Typically, the liquid crystal material is sandwiched between two electrodes with a gap of about 6 to 7 microns (microns), and the LCD is around 25 ms at room temperature. For a TV, the response time is not good enough. As the cell gap decreases, the electric field becomes larger, forcing the LCD module to change with more power. But closing the gap has the negative effect of decreasing yield, which pushes up the price of LCDs.

There is a calculated response time versus viscosity and LCD cell gap as follows. From here, it can be seen that the cell gap has the greatest effect on the response speed.

Although all LCDs include liquid crystal materials and need to struggle with viscosity. The structure inside the cell may be different. Considering the most popular types of LCDs, TN (Twist Nematic) LCDs are faster than STN (SuperTwist Nematic) LCDs; active matrix (including TFT: thin film transistors (LCDS) are faster than passive matrix LCDs, and IPS (In-Plane Switching) LCDs are faster than TN-type LCDs.

This is the same principle to reduce the gap of the LCD unit. The goal is to use higher voltages to increase the electric field and force the liquid crystal molecules to rotate faster. By using over drive circuitry, the mid-level response time is close to that of a black and white screen, regardless of which system drives the LCD panel.

However, there is a downside to using overdrive circuitry, as it will alter the color balance and skew it away from the original video source. This is because applying additional voltage to the LCD cell will cause it to exceed the target tone. For example, when changing from a gray tint of “50” to “100”, a tone above “100” is immediately displayed on the screen. This is called overshoot/downshift.

This is a technique to reduce blur and after-image. Usually LCDs are refreshed at 60 Hz. This means that the screen (frame) changes 60 times in a second. Inserting a pitch-black screen between frames reduces the appearance of blurred images and after-images. This technique has been widely used in home LCD TVs with good results. But the disadvantage of black insertion is that it reduces brightness and causes flicker. To overcome this problem, some LCD panels have increased the refresh frequency to 120 Hz.

The use of liquid crystal displays (LCDs) in user interface assemblies is widespread across nearly all industries, locations, and operating environments. Over the last 20 years, the cost of LCD displays has significantly dropped, allowing for this technology to be incorporated into many of the everyday devices we rely on.

The odds are high you are reading this blog post on a laptop or tablet, and it’s likely the actual screen uses LCD technology to render the image onto a low-profile pane of glass. Reach into your pocket. Yes, that smartphone likely uses LCD technology for the screen. As you enter your car, does your dashboard come alive with a complex user interface? What about the menu at your favorite local drive-thru restaurant? These are some everyday examples of the widespread use of LCD technology.

But did you know that the U.S. military is using LCD displays to improve the ability of our warfighters to interact with their equipment? In hospitals around the world, lifesaving medical devices are monitored and controlled by an LCD touchscreen interface. Maritime GPS and navigation systems provide real-time location, heading, and speed information to captains while on the high seas. It’s clear that people’s lives depend on these devices operating in a range of environments.

As the use of LCDs continues to expand, and larger screen sizes become even less expensive, one inherent flaw of LCDs remains: LCD pixels behave poorly at low temperatures. For some applications, LCD displays will not operate whatsoever at low temperatures. This is important because for mil-aero applications, outdoor consumer products, automobiles, or anywhere the temperature is below freezing, the LCD crystal’s performance will begin to deteriorate. If the LCD display exhibits poor color viewing, sluggish resolution, or even worse, permanently damaged pixels, this will limit the ability to use LCD technologies in frigid environments. To address this, there are several design measures that can be explored to minimize the impact of low temperatures on LCDs.

Most LCD displays utilize pixels known as TFT (Thin-Film-Transistor) Color Liquid Crystals, which are the backbone to the billions of LCD screens in use today. Since the individual pixels utilize a fluid-like crystal material as the ambient temperature is reduced, this fluid will become more viscous compromising performance. For many LCD displays, temperatures below 0°C represent the point where performance degrades.

Have you tried to use your smartphone while skiing or ice fishing? What about those of you living in the northern latitudes - have you accidently left your phone in your car overnight where the temperatures drop well below freezing? You may have noticed a sluggish screen response, poor contrast with certain colors, or even worse permanent damage to your screen. While this is normal, it’s certainly a nuisance. As a design engineer, the goal is to select an LCD technology that offers the best performance at the desired temperature range. If your LCD display is required to operate at temperatures below freezing, review the manufacturer’s data sheets for both the operating and storage temperature ranges. Listed below are two different off-the-shelf LCD displays, each with different temperature ratings. It should be noted that there are limited options for off-the-shelf displays with resilience to extreme low temperatures.

For many military applications, in order to comply with the various mil standards a product must be rated for -30°C operational temperature and -51°C storage temperature. The question remains: how can you operate an LCD display at -30°C if the product is only rated for -20°C operating temperature? The answer is to use a heat source to raise the display temperature to an acceptable range. If there is an adjacent motor or another device that generates heat, this alone may be enough to warm the display. If not, a dedicated low-profile heater is an excellent option to consider.

Made of an etched layer of steel and enveloped in an electrically insulating material, a flat flexible polyimide heater is an excellent option where space and power are limited. These devices behave as resistive heaters and can operate off a wide range of voltages all the way up to 120V. These heaters can also function with both AC and DC power sources. Their heat output is typically characterized by watts per unit area and must be sized to the product specifications. These heaters can also be affixed with a pressure sensitive adhesive on the rear, allowing them to be “glued” to any surface. The flying leads off the heater can be further customized to support any type of custom interconnect. A full-service manufacturing partner like Epec can help develop a custom solution for any LCD application that requires a custom low-profile heater.

With no thermal mass to dissipate the heat, polyimide heaters can reach temperatures in excess of 100°C in less than a few minutes of operation. Incorporating a heater by itself is not enough to manage the low temperature effects on an LCD display. What if the heater is improperly sized and damages the LCD display? What happens if the heater remains on too long and damages other components in your system? Just like the thermostat in your home, it’s important to incorporate a real-temp temperature sensing feedback loop to control the on/off function of the heater.

Another important consideration when selecting a temperature sensor is how to mount the individual sensors onto the display. Most LCD displays are designed with a sheet metal backer that serves as an ideal surface to mount the temperature sensors. There are several types of thermally conductive epoxies that provide a robust and cost-effective way to affix the delicate items onto the display. Since there are several types of epoxies to choose from, it’s important to use a compound with the appropriate working life and cure time.

For example, if you are kitting 20 LCD displays and the working life of the thermal epoxy is 8 minutes, you may find yourself struggling to complete the project before the epoxy begins to harden.

Before building any type of prototype LCD heater assembly, it’s important to carefully study the heat transfer of the system. Heat will be generated by the flexible polyimide heater and then will transfer to the LCD display and other parts of the system. Although heat will radiate, convect, and be conducted away from the heater, the primary type of heat transfer will be through conduction. This is important because if your heater is touching a large heat sink (ex. aluminum chassis), this will impact the ability of the heater to warm your LCD display as heat will be drawn toward the heat sink.

Before freezing the design (no pun intended) on any project that requires an LCD display to operate at low temperatures, it’s critical to perform low temperature first. This type of testing usually involves a thermal chamber, a way to operate the system, and a means to measure the temperature vs time. Most thermal chambers provide an access port or other means to snake wires into the chamber without compromising performance. This way, power can be supplied to the heater and display, while data can be captured from the temperature sensors.

The first objective of the low-temperature testing is to determine the actual effects of cold exposure on the LCD display itself. Does the LCD display function at cold? Are certain colors more impacted by the cold than others? How sluggish is the screen? Does the LCD display performance improve once the system is returned to ambient conditions? These are all significant and appropriate questions and nearly impossible to answer without actual testing.

As LCD displays continue to be a critical part of our society, their use will become even more widespread. Costs will continue to decrease with larger and larger screens being launched into production every year. This means there will be more applications that require their operation in extreme environments, including the low-temperature regions of the world. By incorporating design measures to mitigate the effects of cold on LCD displays, they can be used virtually anywhere. But this doesn’t come easy. Engineers must understand the design limitations and ways to address the overarching design challenges.

A full-service manufacturing partner like Epec offers a high-value solution to be able to design, develop, and manufacture systems that push the limits of off-the-shelf hardware like LCD displays. This fact helps lower the effective program cost and decreases the time to market for any high-risk development project.

To receive a quotation for a Dynamic Displays industrial LCD monitor, please provide within the quote form below, as much of the requested information as possible. This information will be used to determine the best LCD monitor replacement for your specific equipment, and to log and track your request. You will receive a response to your inquiry on the same day it was submitted.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey