lcd panel timing controller manufacturer

The timing controller (“TCON”) receives image data and converts the format for the source drivers’ input and also generates controlling signals for gate and source drivers.

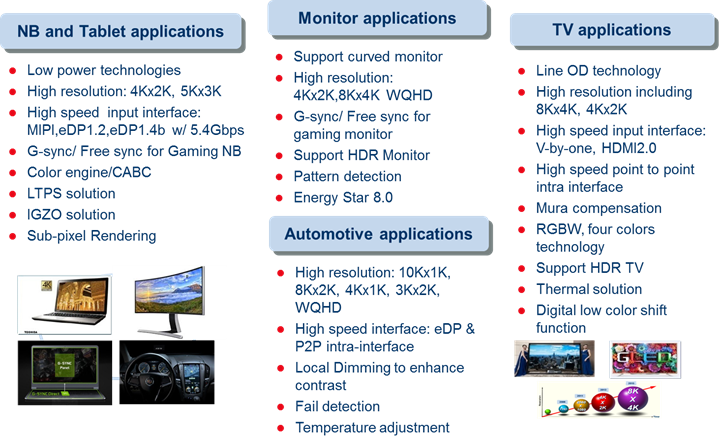

Himax have a complete product line and leading technology on Tcon panel for Automotive, Tablet, NB, Monitor, TV, public or industrial displays. We also provide high resolution, high frame rate, low power consumption, high speed transmitter interface technology that help improve image quality. In addition, we are dedicated to new display technology for OLED and uLED, which continue to provide customers with innovative and forward-looking solutions.

Different displays use different types of TCONs. In this article we will be talking about TCONs for the IT market: LCD (Liquid Crystal Display) notebook PCs and monitors.

An LCD panel has millions of Red, Green, and Blue (RGB) liquid crystals that are used to block a white backlight when electrical voltage is applied to them. High voltage signals to each individual pixel control how much of the backlight to block. A white display means nothing is being blocked. A black display means all three colors are blocked at maximum effort.

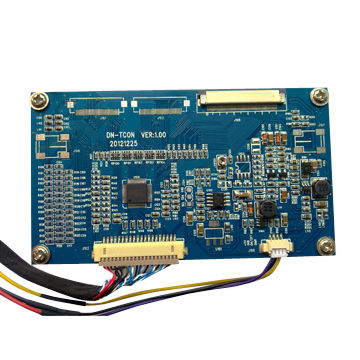

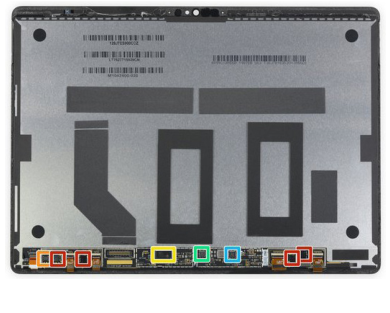

TCONS direct the high voltage driver chips that move the color filters and are usually found on a circuit board that sits below the glass panel (Fig. 1).

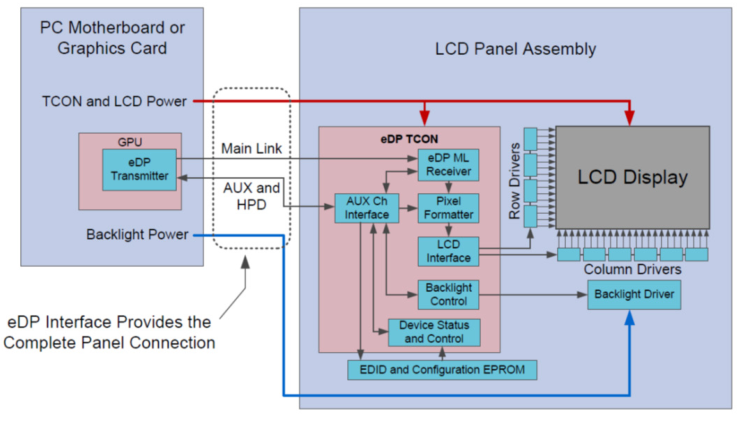

eDP connections are fast, use few wires, and are flexible for size, bandwidth and adding features eDP provides all panel connections in one plug, including power, data, and control signals. This is Analogix’s specialty.

While the GPU is responsible for transforming mathematical equations into individual pixels and frames, a TCON takes the individual frames generated by the GPU, corrects for color and brightness, then sends out parts of the image to each individual driver at the panel’s specific timing.

The human eye has an incredible dynamic range. That means we can see both very dark images and very bright images, at the same time. However, neither camera sensors nor display panels can display that range. Your camera generates HDR images by using images from multiple exposures to combine the brightest and darkest parts of the picture. This increases the contrast (dynamic range) between light and dark, pulling out details from darkened or washed out areas.

HDR accurately maps real world color and luminance to a display panel. VESA DisplayHDR™ standard specifies HDR quality, including luminance, color gamut, bit depth, and rise time.

Display panels have difficulty displaying a wide range of brightness. Normal sunlight can reach 10,000 nits, but the backlight on most notebooks today is around 250 nits

VESA DisplayHDR requires the panel to meet minimum brightness, contrast, and color. No panel can reach 10,000nits of natural light. The brightest a 250nit notebook panel can produce is 250nits and any image above 250nits is washed out. Also, no details from 250 nits to 10,000nits can be seen.

The HDR400 specifications require a dimmable backlight which helps with both producing darker blacks and lowering the power consumption. Tone mapping is used to map the whole range of 10,000 nits down to what the panel can handle, so the details can be seen. Tone mapping does not increase the brightness of the panel; it only makes the details visible.

VESA DisplayHDR600 Requires local dimming. No LCD panel can reach the VESA DisplayHDR600 requirement of 6000:1 contrast ratio. However, this can be overcome with local dimming.

For example, a 750:1 contrast panel requires 8 different backlight power settings to reach 6000:1 contrast ratio. However, unless there are thousands of separate regions, local dimming always produces halos around the bright areas. In order to reduce the halos, the following are recommended:

Monitors can use a direct backlight with many regions. An extra layer of liquid crystal can be used to dim the backlight at a specific location but this often results in a panel that is too thick for a notebook.

Notebook backlights use LEDs on the edge of the panel to reduce panel thickness. These can be on 1 side, 2 sides, or all 4 sides. Each edge adds to cost and bezel size.

Global Dimming Power Savings - Figure 6 shows a 15.6” UHD panel with 400nit maximum brightness. Figure 7 shows a comparison of backlight power consumption values between 400nit, 50nit and, respectively 5nit.

The primary goal of color management is to obtain a good match across color devices; for example, the colors of one frame of a video should appear the same on a computer LCD monitor, on a TV screen, and as a printed poster. Color management helps to achieve the same appearance on all of these devices, provided the devices are capable of delivering the needed color intensities. Color management cannot guarantee identical color reproduction, as this is rarely possible, but it can at least give more control over any changes which may occur.

A PC in HDR and SDR modes use different color gamut but the same screen. Dual-panel phones and notebooks need the color of the two sides to match perfectly. Graphic artists for web sites, movies, video games, etc., need to know what they are creating looks the same on their screen as on their customers’ screens.

As panels improve, the color space of new panels may exceed the color space from Windows. This results in displays which look oversaturated. There is a trend towards low blue light or “night shift” panels, while still retaining color accuracy for the other colors. Today, low blue light panels are created by measuring each individual panel, then hoping that the yield is high enough.

Analogix’s Advanced Color Blocking (ACB) technology is used to create consistent image quality across different panels and change color space for different usage modes (Fig. 8). It allows for 3D color gamut rotation in the optical color domain rather than the RGB domain and color space change on the fly, such as color mapping of BT.2020 source to sRGB or DCI-P3 panels. It includes LUT shadow registers and hardware transition calculations (to smooth changes).

Color conversion in the TCON can dynamically and continuously adjust the incoming signal from the GPU for a low blue light color space. This way, no individual panel measurement is needed and yields should increase. While this can also be done by the GPU itself, that takes GPU bandwidth and 500x more power.

Panel Self-Refresh (PSR) – frame buffer in a TCON can maintain a display image without receiving video data from the CPU. For a still image, this allows the GPU to enter a low-power state and the eDP main link to turn off. Allowing the GPU to power down between display updates will save significant power and extend battery life.

Panel Self-Refresh with Selective Update (PSR2) is a superset of the panel self-refresh feature and it allows the transmission of modified areas within a video frame with obvious benefits when watching a movie or playing a game. PSR2 identifies when only a portion of the screen is static, which is a selective update. In PSR2, when the full screen is static, the refresh rate can be lowered for further power savings as done by Intel Low Refresh Rate (LRR). Intel LRR lowers the refresh rate by changing pixel clock or by changing vertical blank depending on the scenario such as idle, playing video, browsing, etc. All Analogix TCONs support Intel LRR.

In-Cell Touch embeds the touch function in the display itself, the panel including all the touch sensors, controllers, and needed processing. This simplifies the production process and reduces weight and reflection by removing the cover glass. It also allows for thinner bezels as there is no need for daughter cards and no separate wires for touch, as well as lighter devices as the cover glass is removed.

Analogix has pioneered the in-cell touch notebook panel TCONs. About 15% of notebooks support touch and we expect the touch attach rate to increase as more active pen support is introduced.

Digital View’s SVX-1920v3 is a full featured LCD controller that is a suitable fit for an extensive range of professional display applications. This is an advanced LCD controller that is ideal for use with high resolution

Digital View"s ALR-1400v2 is a multi-purpose LCD controller that was designed for industrial LCD monitors and can be used for a number of industrial and commercial display applications. Features: ∙ Compact Design ∙

Digital View’s ALR-1920-120 is a multi-purpose LCD controller board with a comprehensive selection of built-in features and control options. This solution is compatible with 120Hz panels with up to 1920x1200 resolution.

The 4169900XX-3 / SP-1600 Controller is end of life (EOL) as of September 15, 2017. The last time buy (LTB) date is/was October 1, 2017. The suggested replacement is the SP-1920. Features: ∙ 10-bit ∙ LVDS

Digital View’s SVH-1920v2 LCD controller is the updated replacement for the SVH-1920. This newer version includes the same signal inputs and mountings as the original with the addition of an eDP panel connection and increased

The 4171400XX-3 / DVS-1600 Controller is end of life (EOL) as of September 15, 2017. The last time buy (LTB) date is/was October 1, 2017. The suggested replacement is the SP-1920. Features: ∙ 10-bit ∙ LVDS

The 4169901XX-3 / HE-1600 Controller is end of life (EOL) as of September 15, 2017. The last time buy (LTB) date is/was October 1, 2017. The suggested replacement is the SP-1920. Features: ∙ 10-bit ∙ LVDS

Digital View’s HE-1920v2 is the replacement for the HE-1920. It is a harsh environment LCD controller with ceramic capacitors and unmatched durability. The HE-1920v2 has a conformal coating layer that preserves the components

The HLR-1920 by Digital View is a compact, wide temperature LCD controller great for general purpose solutions. It is compatible with LCD panels up to 1920x1200 resolution. The HLR-1920 features low signal latency from input

The 4172200XX-3 / AVP-1600 Controller is end of life (EOL) as of September 15, 2017. The last time buy (LTB) date is/was October 1, 2017. The suggested replacement is the SP-1920. Features: ∙ 10-bit ∙ LVDS

Digital View’s SVX-2560 is an advanced LVDS and eDP panel LCD controller. It works with LCD panel resolutions up to 2560x1600 and 1920x1920 and is compatible with video signals up to 2560x1600. Features: ∙ LCD

Digital View"s SVX-4096 is an advanced LCD controller ideal for 4K LCDs. It is compatible with LCD and OLED panel resolutions up to 4096x2160 and video signals up to 4096x2160. Because it is a 4K LCD controller, it is an ideal

The Digital View HX-4096 is a harsh environment 4k LCD controller. It supports video signals up to 4096 x 2160 and LCD panel resolutions up to 4096 x 2160. Because of its conformal coating and extended temperature range,

Digital View’s HSP-1920 is the durable, harsh environment version of the SP-1920 LCD controller. It is supports input and panel activity for video signals up to 1920x1200. The built-in H.246 failover media player makes

Digital View’s ALT-1920 is a compact, general solution LCD controller that covers three popular input formats including HDMI, Analog RGB (VGA), and DisplayPort. It is equipped with ceramic capacitors for improved reliability

The Digital View SP-4096 is an easy-to-use controller board for 4k LCDs. It supports LCD panels and video output of up to 4096 x 2160 resolution. Because of its high resolution and excellent reliability, this 4k LCD controller

The Digital View HSP-4096 is the harsh environment version of the SP-4096 and includes a conformal coating that provides increased resistance to the elements. It supports video signals up to 4096 x 2160 and LCD panel resolutions

The Digital View SVX-4096-120 is an advanced controller board that can support both LCD and OLED panels up to 4096 x 2160 resolution. Because of its super high resolution, this 4k controller board is ideal for commercial

The Digital View DT-4096 is a compact and easy-to-use controller board that supports LCD panels up to 4096 x 2160 resolution. Because of its extensive image control options and super high resolution, this 4k controller

(Hong Kong – 30 June 2006) Solomon Systech Limited is proud to launch their TFT LCD timing controller, SSD2900, which supports high resolution – SXGA (1280 x 1024) and UXGA (1600 x 1200) TFT-LCD monitors. This simple but specific IC specializes in its integrated dual LVDS (Low-Voltage Differential Signaling) receivers and RSDS (Reduced Swing Differential Signaling) transmitter.

SSD2900 supports 18/24 bit-per-pixel LVDS input and transmits 18/24 bit-per-pixel RSDS data. The LVDS and RSDS are low voltage swing interfaces for low EMI solution. SSD2900 has on-chip spread spectrum controller which provides total solution to EMI. It reduces EMI by tolerating spread spectrum interface at LVDS input, whereas the spread spectrum controller at RSDS output varies the clock to wider the spectrum in frequency domain with center spread +/- 0.25% of nominal frequency at 2kHz. In addition, the embedded timing controller operates in DE-only mode which provides accurate timing control signals for source/gate drivers. Bandwidth of one channel LVDS is 25-85MHz, whereas maximum output RSDS bandwidth is 85MHz. Moreover, SSD2900 supports virtual 8-bit color depth in FRC mode. Its low power core operates from 3.0V to 3.6V. The usage of SSD2900 is simply hardware, no application software and command required.

The DP627 is a panel timing controller (Tcon) developed specifically for a PC Direct Drive Monitor (DDM). It includes a DisplayPortTM receiver and supports display resolutions up to 1920 x 1200 (Full HD) with up to 30 bit color. It is designed to be mounted on the LCD panel, elliminating the seperate monitor controller board within the monitor to reduce monitor size and cost.

The DP627 provides pixel data through a mini-LVDS interface with programmable timing to support a variety of LCD panel designs. The device includes audio support through both I2S and S/PDIF digital outputs. The DP627 de-spreads the DisplayPort SSC Link clock, and can also add SSC on the mini-LVDS output.

Himax Technologies, Inc. launched its flexible OLED automotive display driver and timing controller for BOE Technology Group Co., Ltd., China’s largest display manufacturer.

Compared to traditional TFT LCD displays, OLED displays’ superior image quality, lightweight, slim design and form factor advantage, have contributed to its increasing penetration in the smartphone market over the past few years.

Leveraging its chip-on-film (COF) packaging, Himax’s flexible OLED display driver technology was adopted by BOE in its 12.3-inch three-unit curved flexible OLED automotive displays for cockpit areas with only 0.99 mm bezels. This brand-new in-vehicle display application aims to provide better audiovisual experience for car users. In addition to its OLED driver, Himax has also developed a customized timing controller for BOE to manufacture its curved flexible OLED automotive displays thinner and lighter.

“Himax’s automotive display driver IC grew 44% year-over-year in 2018, and we now command more than 30% of the global automotive display driver IC market,” said Jordan Wu, president and CEO of Himax Technologies. “We are the leader in all key technologies including TDDI, AMOLED and local dimming timing controllers. The collaboration with BOE on flexible OLED automotive displays not only represents a new growth opportunity but also a clear conviction of our technology leadership. We expect shipments to start 2H 2019 for customers’ new product launches in 2020.”

Hantronix TFT LCDs will deliver a vibrant, high contrast user interface to any application. Our TFT displays are available in a wide range of sizes, and are easy to incorporate into any design. We offer the most popular and cost-effective Amorphous Silicon Thin Film Transistor or a-SiTFT panels. This application note discusses how to drive a TFT LCD using widely available microprocessors.

Note that some small, lower end panels may not have all of the electronics included with them because of size or cost restraints. Some panels have a simple row and column interface. Some may need an external timing controller. Some have a processor bus type Interface.

Depending on internal circuitry demands, some panels may include a few other signals, such as a reset line. Determining how to drive such simple signals is usually straightforward.

Many LCD controllers, including those integrated into microcontrollers, will directly drive the signals shown in Figure 1. This means that the biggest obstacle to quickly getting an image on the screen is generating the appropriate signal timing. The LCD controller is responsible for generating the timing; however software must be written to correctly program the controller for the specific LCD model.

An LCD panel comprises a matrix of pixels (picture elements), divided into red, green, and blue "sub-pix-els". Each sub-pixel is driven by a small transistor. Typically, LCD panels have internal row and column drivers, much like DRAM. A row is selected by the row driver, then the column driver sequences through each of the columns. After each of the columns has been written, the row driver selects the next row and the process repeats. The VSYNC signal resets both row and column drivers to the upper left pixel. The HSYNC causes the row driver to step to the new row. The clock sequences the column driver through each of the pixels, with each clock edge latching data values for the red, green, and blue sub-pixels. These values drive a form of D/A converter to store an electrical charge in a capacitor in each sub-pixel which controls the drive of the transistor; this in turn controls the brightness of the sub-pixel. A red-green-blue color mask is used to filter the light from each sub-pixel to form its corresponding color.

Like a DRAM, an LCD panel must be constantly refreshed or the image will fade. Most TFT LCD panels work when refreshed around 60 Hz. The imagedata is usually held in a section of main memory called a frame Buffer.

Each location in the frame buffer corresponds to a pixel on the LCD. The value in the location determines the color displayed for that pixel. See Figure 2. The size of the frame buffer depends on two things: the number of locations needed, and the size of each location.

The total number of locations needed is determined by the panel resolution. For instance, the resolution of the Hantronix HDA350-2G panel is 320 × 240 pixels. Therefore 320 × 240 = 76,800 memory locations will be needed in the frame buffer „ one for each pixel.

TFT panels typically have an input of at least 6 bits of red data, 6 bits of green data, and 6 bits of blue data. A panel with 6 red, 6 green, and 6 blue data lines is termed a 6-bit panel. If the processor or LCD controller doesn"t drive as many data lines as the panel requires, use the data line configuration shown in Figure 3 or Figure 5.

The Valid Data time (THd) is equal to the number of pixels in the horizontal direction, in this case 320. From the Timing Table we see that the typical value for the HSYNC pulse (THp) is 12, and the typical number of total clocks per line is 400.

CDS is renowned as one of the foremost specialist distributors and suppliers of LCD TFTs and value added services for these products, many of which can be found at the 2 links below. But we wanted just to highlight some of the interfacing points for LCDs including the controllers, timings, picture elements etc. as such information is not always easy to find. We hope you find it interesting or if you know this already it acts as a refresher to your already in-depth LCD knowledge and the driving of these displays.

CDS’s wide range of TFT LCDs will deliver a vibrant, high contrast user interface to any application. Our TFT displays are available in a wide range of sizes, designs, and formats and are easy to incorporate into any design. CDS offers the most popular and cost-effective Amorphous Silicon Thin Film Transistor or a-SiTFT panels. This BLOG POST is an application note that discusses how to drive a TFT LCD using widely available microprocessors.

Some small, lower end panels may not have all of the electronics included with them because of size or cost restraints. Some panels have a simple row and column driver interfaces. Some may need an external timing controller. Some have a processor bus type Interface.

Depending on internal circuitry demands, some panels may include a few other signals, such as a reset line. Determining how to drive such simple signals is usually straightforward.

Many LCD controllers, including those integrated into microcontrollers, will directly drive the signals shown in Figure 1. This means that the biggest obstacle to quickly getting an image on the screen is generating the appropriate signal timing. The LCD controller is responsible for generating the timing; however software must be written to correctly program the controller for the specific LCD model.

An LCD panel comprises a matrix of pixels (picture elements), divided into red, green, and blue “sub-pixels”. Each sub-pixel is driven by a small transistor. Typically, LCD panels have internal row and column drivers, much like DRAM. A row is selected by the row driver, then the column driver sequences through each of the columns. After each of the columns has been written, the row driver selects the next row and the process repeats. The VSYNC signal resets both row and column drivers to the upper left pixel. The HSYNC causes the row driver to step to the new row. The clock sequences the column driver through each of the pixels, with each clock edge latching data values for the red, green, and blue sub-pixels. These values drive a form of D/A converter to store an electrical charge in a capacitor in each sub-pixel which controls the drive of the transistor; this in turn controls the brightness of the sub-pixel. A red-green-blue colour mask is used to filter the light from each sub-pixel to form its corresponding colour.

Like a DRAM, an LCD panel must be constantly refreshed or the image will fade. Most TFT LCD panels work when refreshed around 60 Hz. The image data is usually held in a section of main memory called a frame Buffer.

Each location in the frame buffer corresponds to a pixel on the LCD. The value in the location determines the colour displayed for that pixel. See Figure 2. The size of the frame buffer depends on two things; 1. the number of locations needed, and 2. the size of each location.

The total number of locations needed is determined by the panel resolution. For instance, let’s take the resolution of a panel is 320 × 240 pixels. 320 × 240 = 76,800 memory locations will be needed in the frame buffer „ one for each pixel.

TFT panels typically have an input of at least 6 bits of red data, 6 bits of green data, and 6 bits of blue data. A panel with 6 red, 6 green, and 6 blue data lines is termed a 6-bit panel. If the processor or LCD controller doesn’t drive as many data lines as the panel requires, use the data line configuration shown in Figure 3 or Figure 5.

The Valid Data time (THd) is equal to the number of pixels in the horizontal direction, in this case 320. From the Timing Table we see that the typical value for the HSYNC pulse (THp) is 12, and the typical number of total clocks per line is 400.

The vertical timing is split into the same four areas as the horizontal timing. The formula is: TOTAL LINES(TV) = VSYNC WIDTH(TVp) + BACK PORCH(TVs) + VALID DATA(TVd) + FRONT PORCH

We hope the above information has been of use and please check out our wide range of LCDs, TFTs, and OLED Products as we are sure we will have a display that would be ideal for your application.

1. Panel timings and compatibility vary by controller model, not all LCD panels are supported and custom engineering services may be required, contact us for details.

The TW8836 is designed to sync to a composite video source, scale and de-interlace the video, and display the image on the LCD panel in less than 500 milliseconds, far exceeding the fast boot requirements outlined in the new U.S. law. Because the TW8836 does not require any external memory, the video is latency free and thus ultra responsive to help increase the backup safety of vehicles. Since the TW8366 is a hardware-based solution, many automotive manufacturers view the LCD video processor as more reliable in terms of fast boot capability and as a more stable video path for the rear camera than competing software-based solutions supported by the main processor. Because the main processors require time for the operating system (OS) to boot up, there is risk to routing the rear camera video through SoCs as any glitch in the software could compromise the reliability and integrity of the backup camera video, resulting in a violation of the new U.S. safety regulation.

The TW8836 provides a special BT.656 output path that is independent of the primary LCD scaler path, enabling ultimate system architecture flexibility—the chip can drive the panel directly and show rear camera video while the SoC is booting up. Once the SoC boots up, it can then route the source video to the SoC via the BT.656 path to support overlay of graphics (GUI) on top of the video. The combined video can then be sent back to the TW8836 for display on the LCD via the Open LDI (LVDS) or digital RGB input port. Such features allow the TW8836 to be used in conjunction with the most popular infotainment SoCs in the market.

The TW8836 LCD video processor can take virtually any type of video input—including analog composite, S-video, analog RGB, digital RGB and Open LDI (LVDS)—and drive almost any digital LCD panel up to WXGA+ (1366×768) resolution—including transistor-transistor logic (TTL), 1 CH Open LDI (LVDS) and timing controller-less (TCON-less) panels—making it an ideal solution for rear camera display or multiple video source infotainment applications. Due to the extreme flexibility and extensive input and output video support, the TW8836 can be used by automotive OEMs to support a wider variety of both analog and digital video sources, as well as offload the video processing workload from the main processor, allowing the processor to support additional system functionality or the manufacturer may simply use a lower cost processor.

The TW8836 helps optimize the system design and overall cost as it supports differential composite inputs, eliminating the need for an external op amp. In addition, the device does not need external DRAM, helping to keep the bill of material (BOM) cost of implementing the LCD video processor relatively low.

“Intersil is continuing to break new ground in the automotive space by serving the market with an extremely flexible and reliable LCD video processor solution that can be used to increase the safety of vehicles as well as enhance an infotainment system’s ability to support a wide variety video sources at the highest grade quality,” said Philip Chesley, vice president of Precision Products at Intersil. “Intersil has been the leader in automotive LCD controller technology for over 10 years, which enables us to best serve our long-standing OEM partners’ design requirements and deliver a safer, best-in-class experience for consumers.”

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey