lcd panel meter free sample

This panel meter features a 4½ digit LCD with 12.5mm (0.5") digit height and a low-profile bezel for mounting. With 200mV and 2V d.c. full scale readings, digital hold, auto-zero, and auto-polarity, this meter plugs directly into a single-in-line (SIL) socket or can be panel mounted using the snap-in bezel and window supplied.

This compact, 4-20mA loop powered panel meter features a 3½ digit LCD with 11mm (0.43") digit height, LED backlighting and one-piece snap-in housing. Calibration is by two multi-turn potentiometers and connection to the current loop is via two screw terminals.

The EMV1200-40 two-wire panel meter features a 3 digit LCD with 12.5mm (0.5″) digit height in a low profile housing and a measurement range up to 40V.

Fitted with a threaded stud that allows mounting of the product through a 5.5mm (7/32”) drill hole, this unique enclosure provides quick and easy mounting. A rubber seal provides splashproof protection when fitted between the meter and mounting panel. Connection is via wires.

* I am only talking about the "AC 100A Meter(Split Core Transformer)" style; the other 3 styles you can order from this page look dramatically different and no doubt have extremely different functionality, so don"t rely on customer reviews or answers that do not specify which style they bought; also, it is probably a good idea to specify the style you are considering purchasing if you are asking a question on here. (Or not, you decide.)

* NEGATIVE: This meter does not keep track of the amount of time that has passed since the watt-hours were reset, so you will have to mark down the time somehow if you intend to calculate daily/monthly energy costs.

* POSITIVE: This meter survives power outages without losing track of watt-hours used, which every power meter should do and is a huge benefit in areas like mine where the power goes out frequently and I cannot monitor the power daily.

* I saw conflicting answers regarding the measurement of 220-volt (or 240-volt... whatever, I get it) in places like the United States where there is a neutral wire that divides the voltage in half. My use case is a main panel that supplies power to a sub-panel in my workshop where some circuits are 110-volt and some are 220-volt. (NOTE: The voltage between the red and black wires is 220 volts, and the white wire is the neutral that is halfway in between. Thus, red to white is 110 volts and black to white is 110 volts, albeit at opposite phases but what the heck the appliances are stupid and don"t really care about phases.)

* I have 3 of these devices, so I am able to show my results in real time. Ignore the watt-hour numbers in my photos, because the meters were reset at different times. Pay attention only to the volts, amps, and watts. (I"ll look it up later so I become a supposed expert, but right now I really do not understand what power factor even means. I am pretty smart and was literally at the top of my class in my 300-level college electronics course, so I know what I know and I know that I don"t know everything.)

* Of course, if you have an appliance (like my air conditioner or my well pump) that only uses 220 and doesn"t use the neutral line at all, you could simply span the red and black wires and ignore the white wire. But for subpanels where there is a mix of these appliances and circuits, this is not so simple.

* Results when the coil was on the white side (and the #3 meter power leads were spanning the red and black)... what the heck, this sort of answers the question of whether current flows on the neutral or not (SPOILER ALERT, it does, why else would it be made of copper):

* CONCLUSION: It is unpossible to accurately measure a split voltage system with a single meter. If you put the coil on one end (black) or the other (red) you will get the correct amperage for that side but it will inaccurately multiply that by the total voltage and overstate the watts. If you put the coil in the middle, you will get the larger of the two amperages from either side multiplied by the total voltage and (IMO) overstate the watts (maybe?).

The N1540 meter was designed with advanced technology for highest performance and reliability in the most demanding applications. Based on an advanced and robust hardware platform, the N1540 can be fully programmed via its front keypad or via a USB interface. The unique USB interface makes the programming task a simple one step fool proof operation. It allows, for example, the set up of several instruments with the same programming parameters with extreme ease while saving precious time.

This powerful but attractively priced panel meter contains two alarms (six functions), sensor offset, configuration of parameters protected by password, serial communication, indication in degrees Celsius (°C) or Fahrenheit (°F), among others.

With a very short 35 mm (1.34 inches) depth enclosure, the N1540 can be easily installed in panels and enclosures where space is at a premium. Dual alarm relays and a convenient 24 V auxiliary power supply are also available in this competitively priced process meter.

The meter configuration can be performed directly on the meters key panel or through the USB interface. We offer a free downloadable software, NConfig software, for configuration and monitoring through the USB port of a Windows computer.

The USB interface is used for CONFIGURING or MONITORING the panel meter. We offer NConfig software as a free download that must be used for the configuration. It makes it possible to create, view, save and open configurations from the meter or files in your computer. The software can be used for saving and opening configurations in files and makes it possible to transfer configurations between meters and to make backup copies.

A common application of a panel meter is motor current monitoring. A motor that runs fans or pumps in an industrial setting will have certain line parameters. For instance, the resistance of the fan may increase due to filter blockage, which if not treated, can lead to a cascade of problems, most notably halt in operations. Alternatively, a broken belt can lead to a drop-in motor output current, which must be dealt with immediately to regain productivity. A potential or current transformer can be used to measure the voltage and currents respectively, which can then be displayed on a panel meter.

Digital panel meters typically read an input signal, displaying it within a panel, examples being that of voltage, current and resistance. The signal comes from a sensor, whose input is converted into digital form and then displayed as a variable, e.g. temperature, pressure, etc. Depending on the functionalities, the meters can also act as controllers, generating a control signal that drives an actuator, relay, safety gate, etc.

Analog: the panel meter provides an analog output, i.e. variable current or voltage, proportional to the input signal, which can then be amplified to control output devices.

Numeric: this means that the panel displays only numbers; most products have this type of construction as the values that need to be displayed are mostly numbers.

Either LCD or LED is used as the display of a panel meter. An LED display consist of diodes that light up, usually following a N-segment algorithm. The benefit of an LED display is its visibility in the dark.

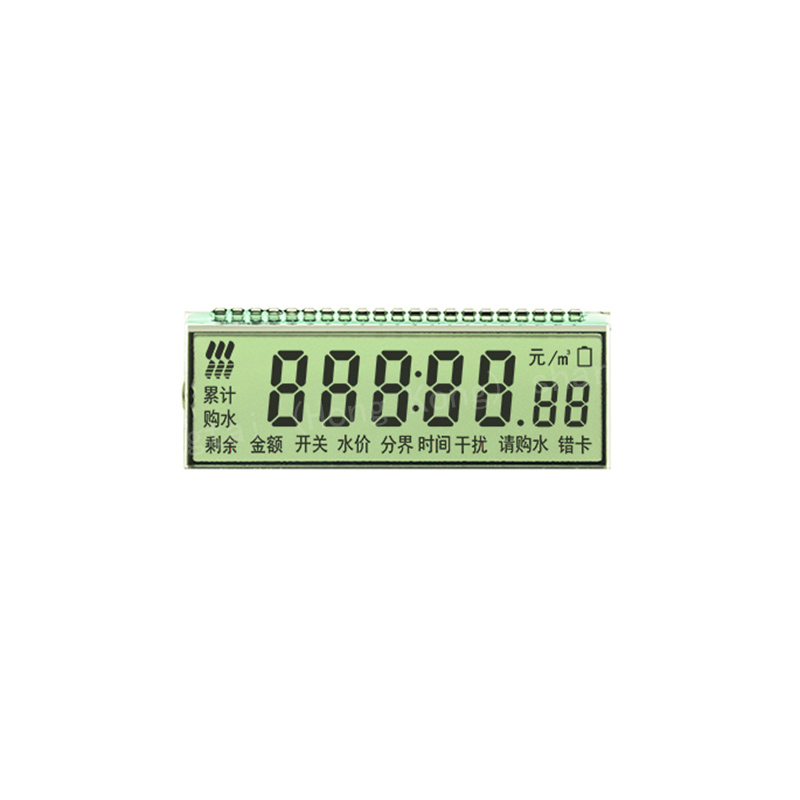

On the other hand, an LCD displays black digits over a gray/green screen. LCDs are less power consuming compared to LEDs but require a backlight for visibility in the dark.

The device’s physical compatibility with the panel is determined by the size of its panel face. Typically rated in millimeters or inches, the size is specified by both length and width, sometimes even depth. The display to be selected should have dimensions that can fit inside the control panel. Furthermore, the display should be large enough for operators to see, depending on the distance they would be standing at.

These are devices that measure analog signals and display them directly without any intermediate conversion. The values are displayed on a dial, usually with a scale, pointer and needle. Generally, an analog panel meter accepts a signal input, but based on the model can also accept multiple signals, such as pulsating frequencies. These are known as multiple channel analog panel meters. The introduction of digital panel meters has pushed out analog products, however, they are still used in some applications. Modern analog meters usually feature anti-glare and illuminated face displays.

Pivot & jewels: These can withstand shocks but are not as accurate as taut band panel meters. The operation method involves a coil & pointer being suspended by steel, fitted into two jewel bearings.

Furthermore, analog panel meters are available in more than one channels, having the capability to measure multiple variables in different units. They are commonly used to measure three phase power. Devices are also available that can measure radio frequency signals.

Most analog panel meters usually have a range of measurements that fall between 0 – 4 mA or 0 – 10 VDC. Face type, depth behind panel and dimensions are common specifications for an analog panel meter. The most common face types used are either round or rectangular. Round devices vary by front face diameter while rectangular devices vary in terms of front face height. For devices that have zero as a reference point, scaling methods that are commonly used are zero-right, zero-left and zero-center.

Totalizers:these panel meters take the sum of an input signal over a specified period of time. Totalizers are generally used to count pulse inputs or in flow measurement applications.

Temperature and process panel meters:this is the most common type of panel meter, and accepts a single channel input, displaying it digitally on the screen. Common inputs are those taken from temperature sensors such as RTDs and thermocouples.

Multi-input indicators:a type of digital panel meters, it can accept more than one input. Most meters have a switching button that displays the output of the subsequent channel, while there are others that can scan all channels automatically, switching its output periodically.

Besides the above four CGMs, other meters are being developed that do not require blood samples. One such CGM is called GlucoTrack by Integrity Applications, which measures blood glucose via your earlobe. However, it hasn’t yet been FDA approved.

Throw out damaged or outdated test strips. Store strips in their sealed container; keep them away from moisture and humidity. Be sure the strips are meant for your specific glucose meter.

Use liquid control solutions every time you open a new container of test strips, and then use the solutions occasionally as you use the strips. You generally should also use liquid control solutions if you drop your blood glucose meter, or whenever you get unusual results.

Match your reading with lab results. Take the blood glucose monitor along when you visit your health care provider or have an appointment for lab work. Check your blood sugar level with your meter at the same time that blood is drawn for lab tests, being sure to use a fingerstick sample, not blood from the blood draw. Then compare your meter"s reading with the lab results. Results that are within 15% of the lab reading are considered accurate.

Although the meter may show more Display Numbers than listed, UI only needs a few for billing. If your meter does not show all of these Display Numbers, don’t worry. The missing Display Numbers won’t be needed for your bill.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey