lcd panel manufacturer pricelist

Prices for all TV panel sizes fluctuated and are forecast to fluctuate between 2020 and 2022. The period from March 2020 to July 2021 saw the biggest price increases, when a 65" UHD panel cost between 171 and 288 U.S. dollars. In the fourth quarter of 2021, such prices fell and are expected to drop to an even lower amount by March 2022.Read moreLCD TV panel prices worldwide from January 2020 to March 2022, by size(in U.S. dollars)Characteristic32" HD43" FHD49"/50" UHD55" UHD65" UHD------

DSCC. (January 10, 2022). LCD TV panel prices worldwide from January 2020 to March 2022, by size (in U.S. dollars) [Graph]. In Statista. Retrieved November 26, 2022, from https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/

DSCC. "LCD TV panel prices worldwide from January 2020 to March 2022, by size (in U.S. dollars)." Chart. January 10, 2022. Statista. Accessed November 26, 2022. https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/

DSCC. (2022). LCD TV panel prices worldwide from January 2020 to March 2022, by size (in U.S. dollars). Statista. Statista Inc.. Accessed: November 26, 2022. https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/

DSCC. "Lcd Tv Panel Prices Worldwide from January 2020 to March 2022, by Size (in U.S. Dollars)." Statista, Statista Inc., 10 Jan 2022, https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/

DSCC, LCD TV panel prices worldwide from January 2020 to March 2022, by size (in U.S. dollars) Statista, https://www.statista.com/statistics/1288400/lcd-tv-panel-price-by-size/ (last visited November 26, 2022)

(Yicai Global) June 7 -- HKC Optoelectronics Technology has completed its pre-listing tutoring and is ready for an initial public offering, sources at China"s third-largest maker of liquid crystal display panels told Yicai Global.

HKC has LCD panel production bases in Chongqing and Mianyang in southwest China and Chuzhou in the east, and has formed a vertical industrial chain including LCD panels, light-emitting diode backlights, LCD modules and whole machine production.

The Shenzhen-based firm ranked third among Chinese companies for global display panel shipments last year, after BOE Technology Group and TCL China Star Optoelectronics Technology, according to data from Sigmaintell Consulting. HKC also accounted for 10.1 percent of the global television screen market, and 6.5 percent of the global display panel market.

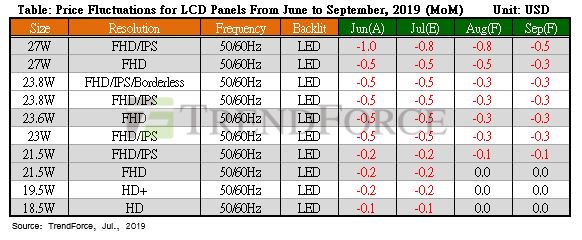

But global LCD panel prices have been falling, posing a challenge for HKC"s short-term business outlook. According to research firm Omdia, since last September the average price of 43-inch LCD panels has dropped 46 percent, and for 55- and 65-inch panels prices are down 34 percent.

“Current prices pose a big challenge for all panel makers,” Zhang Hong, director of TV research at Sigmaintell, told Yicai Global, adding that losses are growing at some manufacturers of LCD TV panels.

Cinno Research’s Chief Analyst Zhou Hua told Yicai Global that HKC"s LCD panel production line has had a lot of support from the local government, but in the current economic environment it is harder to secure such high subsidies.

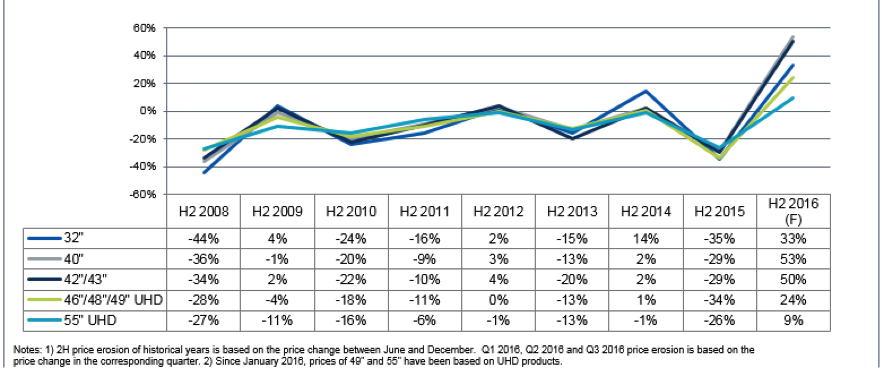

After the two months with the fastest price declines in the history of the industry in September and October, LCD TV panel prices continued to fall in November, but the pace of price decreases is slowing, and we expect that pattern to continue into 2022. After two months where the average decline in LCD TV panel prices exceeded 15%, the average decline in November among the seven TV sizes we track was “only” 6.4%. LCD TV panel prices have now lost most of the gains that they achieved in the long up-cycle from May 2020 to June 2021.

Continuing strong demand and concerns about a glass shortage resulting from NEG’s power outage have led to a continuing increase in LCD TV panel prices in Q1. Announcements by the Korean panel makers that they will maintain production of LCDs and delay their planned shutdown of LCD lines has not prevented prices from continuing to rise. Panel prices increased more than 20% for selected TV sizes in Q3 2020 compared to Q2, and by 27% in Q4 2020 compared to Q3, and we now expect that average LCD TV panel prices in Q1 2021 will increase by another 9%.

Samsung Display (SDC) shipped 86.3 million OLED panels for smartphones and smart wearable devices globally in third-quarter 2022, taking a worldwide market share of 62.9%, down 5.9pp sequentially, iNews 24 cited Stone Partners statistics as indicating.

Channel retailers are launching significant price competition to stimulate TV sales during the Black Friday shopping season in the US, optimizing the availability of affordable TV panel prices, according to market sources.

China-based display panel maker BOE Technology recently made an investment in Chinese smartphone vendor Honor, a partnership that industry observers say will allow the former to increase handset-use OLED panel shipments and the latter to secure panel supply.

Display panel makers, with demand and product prices dropping, have temporarily stopped placing manufacturing equipment since mid-2022, according to panel inspection equipment maker Favite.

AU Optronics (AUO) shipped LCD panels totaling 1.281 million square meters in October, increasing 3.1% sequentially, while Innolux shipped 8.77 million large-size panels and 21.9 million small- to medium-size ones in the month, respectively decreasing 4.9% and 6.7% sequentially, according to the companies.

China-based display panel maker BOE Technology has become the largest shareholder of China-based LED epitaxial wafer and chip maker HC SemiTek via the latter"s private placement, according to industry sources.

Considering that the US has launched a tech war against China by prohibiting the exports of advanced semiconductors involving US-developed technologies and related manufacturing equipment to China, if the conflict spills over to display panels, the US is also able to take measures to stall OLED panel production in China.

Samsung Electronics plans to increase its purchases of LCD panels in 2023 from non-China suppliers, such as Taiwan-based AU Optronics and Innolux, according to industry sources.

Panel maker Innolux has begun providing e-paper module products to clients for multiple applications, according to company president James Yang, as the company transforms itself into a system integrator.

After falling for 15 consecutive months, TV panel prices have recently begun picking up, with the rally likely continuing into November, according to industry sources.

Producers of raw materials for the solar sector are the key beneficiaries of rising demand this year, outpacing profit growth posted by the largest panel manufacturers.

Panel maker Innolux saw its net loss widen to NT$12.7 billion (US$395.5 million) in the third quarter of 2022, compared to a net loss of NT$4.7 billion in the previous quarter.

Corning has reported its sales went down 4% in the third quarter of 2022, but believes that panel makers" utilization rates have declined to a "correction low point," with display glass prices remaining consistent.

Panel maker AU Optronics (AUO) has reported a net loss of NT$10.43 billion (US$323.33 million) attributable to company owners for the third quarter of 2022. EPS for the quarter was minus NT$1.23.

LCD TV panel prices have stopped falling after sliding below suppliers" cash-cost levels, according to industry sources. Additionally, aggressive production cuts by panel makers also have helped bring a stop to falling prices.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Our company specializes in developing solutions that arerenowned across the globe and meet expectations of the most demanding customers. Orient Display can boast incredibly fast order processing - usually it takes us only 4-5 weeks to produce LCD panels and we do our best to deliver your custom display modules, touch screens or TFT and IPS LCD displays within 5-8 weeks. Thanks to being in the business for such a noteworthy period of time, experts working at our display store have gained valuable experience in the automotive, appliances, industrial, marine, medical and consumer electronics industries. We’ve been able to create top-notch, specialized factories that allow us to manufacture quality custom display solutions at attractive prices. Our products comply with standards such as ISO 9001, ISO 14001, QC 080000, ISO/TS 16949 and PPM Process Control. All of this makes us the finest display manufacturer in the market.

Without a shadow of a doubt, Orient Display stands out from other custom display manufacturers. Why? Because we employ 3600 specialists, includingmore than 720 engineers that constantly research available solutions in order to refine strategies that allow us to keep up with the latest technologiesand manufacture the finest displays showing our innovative and creative approach. We continuously strive to improve our skills and stay up to date with the changing world of displays so that we can provide our customers with supreme, cutting-edge solutions that make their lives easier and more enjoyable.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey