cut lcd panel free sample

[1] The present invention relates to a cutting method of a large size TFT-LCD panel and a liquid crystal display unit to enhance a simplicity of process facility and a speediness through solving a problem of an increase of facilities due to manufacturing TFT-LCD panels of respective sizes and reducing a subsequently increased cost by enabling a mass production of a various size of TFT-LCD panels in one manufacturing line through using a TFT-LCD panel cut in a desired size that is manufactured in large size. Background Art

[2] Generally, it is well known that various flat panel display units replacing a cathode ray tube (CRT) which has been used so far are developed and being distributed as many interests are concentrated on a display unit of larger size and better quality as a medium for screen image information.

[3] It is also well known that a liquid crystal display unit, one of these flat panel display units, has developed in a level equal or better than CRT in screen color tone quality aspect.

[5] Most of all as an outline, one pixel (composed of R. G. B. three sub-pixels) in the thin film transistor (TFT) - LCD is approximately as fine as 0.3 mm wide.

TFT process, a color filter (CF) process, a cell process and a module process. The cell process makes one panel with two glasses undergone the TFT process and the CF process. Then, the module process completes the manufacturing process by mounting the one TFT-LCD panel undergone the cell process in a real monitor or TV.

process in the processes of manufacturing the TFT-LCD panel is necessary in the TFT process but also a similar pattern process is necessary in the CF process.

TFT-LCD panel formed as hereinabove, the TFT-LCD panel is completed by providing a polarized plate on a surface of the TFT substrate and the CF substrate.

[11] The TFT-LCD panel of size demanded by a user may be produced in a large amount but the other TFT-LCD panel of less demand may be produced in only a limited amount since various sizes of the TFT-LCD panels completed as hereinabove require a difference in production line and in each process of the production line dependent on the sizes of the TFT-LCD panels. Disclosure of Invention Technical Problem

[13] The cutting method of a large size TFT-LCD panel of the present invention, provided to solve the hereinabove problems, has an object of enhancing a simplicity of process facility and speediness through solving a problem of an increase of facilities due to manufacturing TFT-LCD panels of different sizes and reducing a subsequently increased cost by enabling a mass production of a various size of TFT-LCD panels in one manufacturing line through using a TFT-LCD panel cut in a desired size that is manufactured in large size.

[14] The cutting method of a large size TFT-LCD panel formed as hereinabove can devise a simplicity in process and a profitability through solving a spatial enlargement and other costs increase due to an increase of facilities by equipping a facility"s process dependent on a size according to a production of TFT-LCD panels in various sizes, having an advantage of possibly producing a various size of the TFT-LCD panel asked by a user purpose or a user taste in a simple and convenient way, and solving an abandonment and reduction of the facilities due to a change in consumption dependent

[18] FIG. 4 illustrates a state of a scribe line set into a mid-depth of a color filter substrate and a thin film transistor substrate by diamond wheel in the cutting method of a large size TFT-LCD panel of the present invention.

[20] FIG. 6 illustrates a state completed after processing sealing a cut portion in the cutting method of a large size TFT-LCD panel of the present invention.

[21] FIG. 7 is a cross sectional view illustrating a state of a light blocking tape attached on a surface above the cut portion of the color filter substrate and the thin film transistor substrate.

[22] FIG. 8 is a cross sectional view different from FIG. 7 illustrating a state of a light blocking tape attached on outer surfaces of the polarized plate bonded above the color filter substrate and the polarized plate bonded below the thin film transistor substrate at the respective cut portions.

[27] In a completed large size TFT-LCD panel formed in a sequentially coupled configuration of a polarized plate, a color filter (CF) substrate, a liquid crystal layer, a thin film transistor (TFT) substrate and a polarized plate below the TFT substrate, a polarized plate stripping step that removes a portion of a predetermined width to be cut from the each polarized plate provided on a surface and an opposite surface of the large size TFT-LCD panel, a cutting location setting step that sets a portion not damaging a gate line and a data line of the TFT substrate through investigating a portion stripped in the polarized plate stripping step by microscope, a scribe line setting step that sets a first scribe line cutting the CF substrate into its mid-depth along the portion set in the cutting location setting step using a diamond wheel, a turning

over step that turns over the large size TFT-LCD panel to a side opposite from a side where a portion of the first scribe line is set after chucking one end of the large size TFT-LCD panel, a scribe line setting step that sets a second scribe line cutting the TFT substrate into its mid-depth in the stripped polarized plate portion along the portion set in the cutting location setting step which precisely corresponds with the set first scribe line using a diamond wheel after turning over the large size TFT-LCD panel, a tempering step that tempers for 30 minutes to form a natural crack in the scribe lines formed on the CF substrate and the TFT substrate of the large size TFT-LCD panel, a cutting step that cuts the CF substrate and the TFT substrate naturally cracked after the 30 minutes tempering step, and a sealing process step that sealing a cut portion formed in the cutting step, and

[28] In a completed large size TFT-LCD panel formed in a sequentially coupled configuration of a polarized plate, a color filter (CF) substrate, a liquid crystal layer, a thin film transistor (TFT) substrate and a polarized plate, a cutting location setting step that sets a portion to be cut, a scribe line setting step that sets a first scribe line cutting the CF substrate into its mid-depth along the portion set in the cutting location setting step using a diamond wheel, a turning over step that turns over the large size TFT-LCD panel to a side opposite from a side where a portion of the first scribe line is set after chucking one end of the large size TFT-LCD panel, a scribe line setting step that sets a second scribe line cutting the TFT substrate into its mid-depth along the portion set in the cutting line setting step which precisely corresponds with the set first scribe line, using a diamond wheel after turning over the large size TFT-LCD panel, a tempering step that tempers for 30 minutes to form a natural crack in the scribe lines formed on the CF substrate and the TFT substrate of the large size TFT-LCD panel, a cutting step that cuts the CF substrate and the TFT substrate naturally cracked after the 30 minutes tempering step, and a sealing process step that sealing a cut portion formed in the cutting step may accomplish the present invention object.

[29] Further, the present invention comprises a scribe line setting step that sets scribe lines simultaneously cutting the CF substrate and the TFT substrate into their mid-depths along the portions set in the cutting location setting step using a diamond wheel.

[30] The cutting method of a large size TFT-LCD panel further comprises a blocking off a light illuminated from a backlight through attaching a light blocking tape along a cut portion selected between the CF substrate and the TFT substrate or the both substrates or between the polarized plates located above the CF substrate and below the TFT substrate or the both polarized plates.

[31] Further, the present invention comprising the cutting performed by using any one among a diamond needle, laser, and a diamond wheel in the first and second scribe line setting step or in the simultaneous scribe line setting step may accomplish the

LCD panel 100 is formed in structure sequentially coupled of, a polarized plate 10, a color filter (CF) substrate 11, a liquid crystal layer 12, a thin film transistor (TFT) substrate 13 and a polarized plate 14.

[36] In order to cut the large size TFT-LCD panel 100 completed as hereinabove, a polarized plate stripping step is initially performed that removes a portion of a predetermined width to be cut from the each polarized plate 10 provided on a surface above the CF substrate 11 and an opposite surface below the TFT substrate 13.

[38] The TFT substrate 13 is exposed if the polarized plates 10 and 14 around the cutting portion are removed by its lengthwise direction. Since gate lines transferring a scanning signal and data line transferring a screen image signal are configured by innumerably crossing with each other and difficult to perceive by naked eyes, a cutting location setting step sets a portion not damaging the gate line and the data line of the TFT substrate through investigating a portion stripped on the polarized plate stripping step by microscope.

[40] 1st scribe line setting step refers to a step of cutting the CF substrate 11 into its mid- depth along the portion set in the cutting location setting step using a diamond wheel. This step is very difficult and requires a skill of high precision determined by an experience of a technician.

[43] To process a side opposite from a side where a portion of the first scribe line is set, the present step turns over the large size TFT-LCD panel 100 after chucking one end of the large size TFT-LCD panel 100.

[45] The present step sets a 2nd scribe line setting step cutting the TFT substrate 13 into its mid-depth in the portion of the stripped polarized plate 14 bonded with the TFT substrate 13 below along the portion set in the cutting location setting step which

precisely corresponds with the set first scribe line, using a diamond wheel after turning over the large size TFT-LCD panel 100. This step is also difficult and requires a skill of high precision to correspond with the set first scribe line.

[48] A natural crack is made if tempered for 30 minutes to form a natural crack in the scribe lines formed on the CF substrate 11 and the TFT substrate 13 of the large size TFT-LCD panel 100. Then, the air flows into a liquid crystal layer 12. If there is the air flow into the liquid crystal layer 12, the liquid crystal layer 12 is temporarily restricted from flowing out by the flowed in air.

[50] After the 30 minutes tempering step, the CF substrate 11 and the TFT substrate 13 are naturally cracked along the first scribe line and the second scribe line and the present step externally applies a certain amount of force in order to cut the large size TFT-LCD panel 100 along the scribe lines.

[52] The present step is the last step that applies a sealant 30 on a cut portion in the large size TFT-LCD panel 100 and the present invention is completed by applying the sealant 30.

[53] Through undergoing the process hereinabove, the large size TFT-LCD panel 100 is possible to be cut into a plural or multiple numbers without a many numbers of equipment and to meet a desired size of a demander or an operator.

[56] That is, in a large size TFT-LCD panel 100 completed of forming sequentially coupled, a polarized plate 10, a color filter (CF) substrate 11, a liquid crystal layer 12, a thin film transistor (TFT) substrate 13 and a polarized plate 14 below the TFT substrate 13, a cutting location setting step that sets a portion to be cut, a scribe line setting step that sets a first scribe line cutting the CF substrate 11 into its mid-depth along the portion set in the cutting location setting step using a diamond wheel, a turning over step that turns over the large size TFT-LCD panel 100 to a side opposite from a side where a portion of the first scribe line is set after chucking one end of the large size TFT-LCD panel 100, a scribe line setting step that sets a second scribe line cutting the TFT substrate 13 into its mid-depth along the portion set in the cutting location setting step corresponds with the set first scribe line, using a diamond wheel after turning over the large size TFT-LCD panel 100, a tempering step that tempers for

30 minutes to form a natural crack in the scribe lines formed on the CF substrate 11 and the TFT substrate 13 of the large size TFT-LCD panel 100, a cutting step that cuts the CF substrate 11 and the TFT 13 substrate naturally cracked after the 30 minutes tempering step, and a sealing process step that sealing a cut portion formed in the cutting step may configure the present invention.

[59] For example, after undergoing the sequentially processed cutting location setting steps of the first or the second exemplary embodiments through the polarized plate stripping step that removes a corresponding portion of a predetermined width to be cut from the polarized plates 10 and 14 provided on a surface of the CF substrate 11 and an opposite surface of the TFT substrate 13 like the first exemplary embodiment or without the polarized plate stripping step like the second exemplary embodiment, a scribe line setting step sets scribe lines simultaneously cutting the CF substrate 11 and the TFT substrate 13 into their mid-depths along the portion set in the cutting location setting step using a diamond wheel.

[61] The present exemplary embodiment may or may not include the polarized plate stripping step like the first or second exemplary embodiment, and the subsequent steps may proceed in the same sequence as tempering step for the natural crack, cutting step cutting the CF substrate 11 and the TFT substrate 13 and sealing process step .

[62] Meanwhile, when a light from the backlight unit through the TFT-LCD panel 100 processed by the respective exemplary embodiments is illuminated to display a corresponding image, the image may be displayed with an image quality relatively unclear at a portion corresponding to the cutting portion.

[63] Considering this, a light blocking tape 20 may be provided to accomplish the object of the present invention by covering a certain region including the cutting portion against the light illuminated from the back light unit and realizing a clear screen quality at the display region corresponding to the cutting portion.

[64] Here, the light blocking tape 20 may be attached in a range covering any cut portions of the CF substrate 11 and the TFT substrate 13 or the both substrates 11 and 13 as shown in FIG. 7.

10 bonded above with the CF substrate 11 or at a periphery of the polarized plate 14 bonded below with the TFT substrate 14 which are removed with the set cutting portion, may maximize a clearness of the screen quality when the light from the back light unit is illuminated on the cut portion of the TFT-LCD panel 100 completed by cutting into a desirable size.

[70] Further, FIG. 10 and FIG. 11 illustrate an application of the TFT-LCD panel according to the cutting method provided by the present invention. FIG. 10 is a brief exploded perspective view of a liquid crystal display unit. FIG. 11 is a brief cross sectional view of FIG. 10.

[71] As shown in FIG. 10 and FIG. 11, the cut processed TFT-LCD panel 100 equipped with the backlight unit (not shown in drawing) below undergoes a series of course coupling a top sash 2 corresponding to an upper frame with an accommodating frame 3 accommodating the TFT-LCD panel 100 and the backlight unit to be used for the liquid crystal display unit.

[72] Here, when the TFT-LCD panel 100 cut processed in a desired size according to the present invention is received in the top sash 2 and the accommodating frame 3, a realization of a clear screen may be difficult since a slight difference may be produced, not accurately fixing the TFT-LCD panel 100, and producing a flowing phenomena because of the internal difference.

[74] Accordingly, in order to prevent the flowing phenomena, that is the flowing phenomena of the received TFT-LCD panel 100, attaching a plurality of both-faces tape 4 at the outer peripheral edge on the top sash 2 surface and attaching a plurality of both-faces tape 4 at the outer peripheral edge on the accommodating frame 3 surface as well is preferable to completely prevent the flowing phenomena.

[76] Therefore, since a large size TFT-LCD panel may be miniaturized for an application to various video games, monitors or cell phone liquid crystal displays through cut processing the large size TFT-LCD panel without a separate manufacturing line for manufacturing process according to present invention, an industrial applicability expecting an effective reduction of manufacturing facility and its value may be recognized.

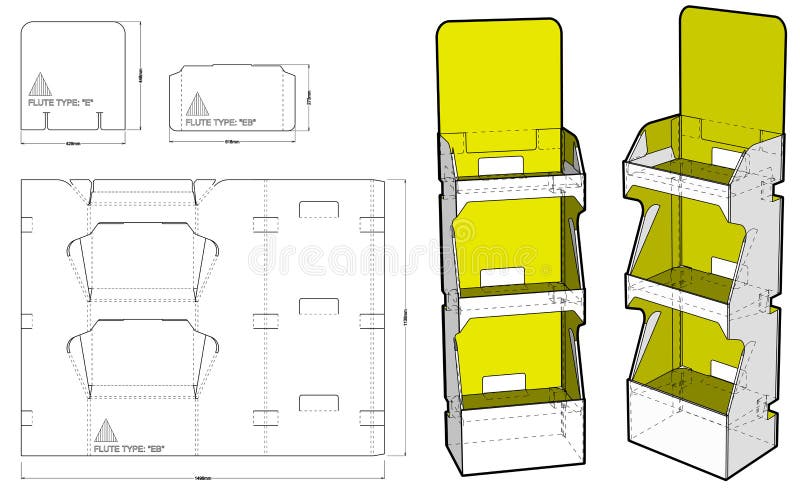

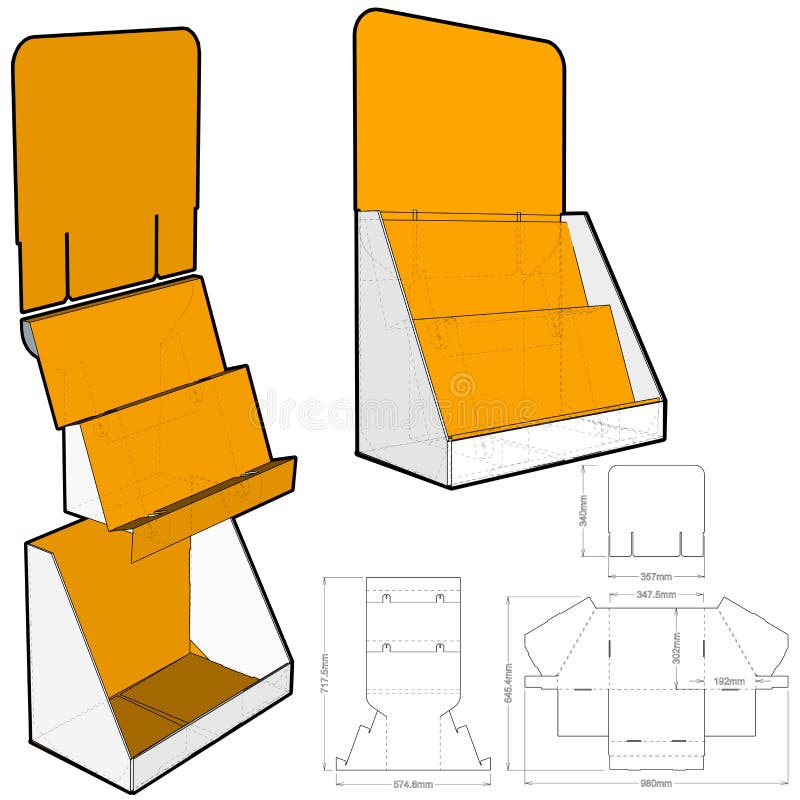

Laser Cut Display Stands template files are in file formats which are recommended for laser cutting DXF, DWG, CDR (CorelDRAW), AI (Adobe Illustrator), EPS (Adobe Illustrator), SVG, PDF. We have 127 Laser Cut Display Stands templates for laser cutting, all laser cut Display Stands files are free to download.

Every single member from our large efficiency revenue team values customers" wants and company communication for Small Lcd Module, Graphic Display Module, Custom Tn Lcd Module, Our customers mainly distributed in the North America, Africa and Eastern Europe. we will source top quality goods using the really aggressive selling price.

Usually customer-oriented, and it"s our ultimate focus on to be not only by far the most reliable, trustable and honest provider, but also the partner for our customers for Factory Free sample Monitor Lcd Panel - 11.6inch TFT LCD Display for notebook and advertising machine system – DISEN , The product will supply to all over the world, such as: Russia, Atlanta, UK, Our products are produced with the best raw materials. Every moment, we constantly improve the production programme. In order to ensure better quality and service, we have been focusing on the production process. We have got high praise by partner. We are looking forward to establishing business relationship with you.

As a TFT LCD manufacturer, we import mother glass from brands including BOE, INNOLUX, and HANSTAR, Century etc., then cut into small size in house, to assemble with in house produced LCD backlight by semi-automatic and fully-automatic equipment. Those processes contain COF(chip-on-glass), FOG(Flex on Glass) assembling, Backlight design and production, FPC design and production. So our experienced engineers have ability to custom the characters of the TFT LCD screen according to customer demands, LCD panel shape also can custom if you can pay glass mask fee, we can custom high brightness TFT LCD, Flex cable, Interface, with touch and control board are all available.

Our pursuit and enterprise aim would be to "Always fulfill our buyer requirements". We carry on to acquire and layout excellent quality items for the two our old and new clients and realize a win-win prospect for our shoppers in addition as us for Lcd Panel And Controller, Touchscreen Display Module, Tft Mobile Color Monitor, As a result of our hard perform, we have always been around the forefront of clean technology merchandise innovation. We"ve been a eco-friendly partner you can rely on. Get hold of us today for additional data!

We emphasize progress and introduce new merchandise into the market each and every year for Factory Free sample Tft Color Display - 8.0 inch 800×600 / 1280×720 / 8.8 inch BOE Industrial TFT LCD Display – DISEN , The product will supply to all over the world, such as: Rome, Germany, Swaziland, As an experienced group we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of our company is to build up a satisfactory memory to all customers, and establish a long term win-win business relationship. Choose us, we always wait for your appearance!

As a TFT LCD manufacturer, we import mother glass from brands including BOE, INNOLUX, and HANSTAR, Century etc., then cut into small size in house, to assemble with in house produced LCD backlight by semi-automatic and fully-automatic equipment. Those processes contain COF(chip-on-glass), FOG(Flex on Glass) assembling, Backlight design and production, FPC design and production. So our experienced engineers have ability to custom the characters of the TFT LCD screen according to customer demands, LCD panel shape also can custom if you can pay glass mask fee, we can custom high brightness TFT LCD, Flex cable, Interface, with touch and control board are all available.

If a respondent endorses a trauma exposure, they can score a 0-5 on the PC-PTSD-5, which is a count of "yes" responses to the 5 questions about how the trauma has affected them in the past month. Research in a large sample of VA primary care patients found that a cut-point of 4 ideally balanced false negatives and false positives for the overall sample and for men. However, for women, a cut-point of 4 resulted in high numbers of false negatives. Practitioners may consider a lower cut-point for women in some settings if evaluation resources are available. In contrast, a higher cut-point may be preferable if resources are such that false positives will substantially decrease clinician availability. Because performance parameters will change according to sample, clinicians should consider sample characteristics and screening purposes when selecting a cut-point.

If you have a clip that contains both audio and video, you can choose to insert only the audio portion of the clip. See Add only a clip’s video or audio in Final Cut Pro.

To find the music or sound you want to use, do any of the following:Search and filter the collection:Use the pop-up menu at the top of the browser to filter the items shown in the browser. For example, you could select Sound Effects, then choose Final Cut Pro Sound Effects > Impacts & Crashes.

Note:To use a song you purchased from the iTunes Store in your project, you must be the copyright holder of the song or have express permission from the copyright holder. For more information, see the Final Cut Pro software license agreement (choose Final Cut Pro > About Final Cut Pro, then click License Agreement).

For better import and playback performance, Final Cut Pro automatically transcodes all MP3 audio files to MOV audio files and retains the original MP3 files for future use. For information about where to find original and transcoded media files, see Locate source media files in Final Cut Pro.

Note:If you add a clip with mono audio to a stereo project, Final Cut Pro plays the single mono audio in both left and right channels, visible in the stereo audio meters for the project.

They also use integrated driver chips which tend to support a handful of different resolutions; I guess that if you cut off the half which did not have any driver circuitry, LED backlights, display bias voltage drivers, etc, you might be able to just tell the controller it has a different-sized screen. E.g., take a 128x64 SSD1306 OLED display and cut it into a 128x32 one.

I don"t think it would be very likely to work; there"s probably a lot of very fine connections that you might accidentally bodge or short, even with a high-powered laser cut which maybe re-seals the top/bottom layers along the edge. But in that example, if nothing important broke, I think the SSD1306 driver does support a 128x32-pixel resolution and you might be able to just operate it normally.

DaVinci Resolve is divided into "pages", each of which gives you a dedicated workspace and tools for a specific task. Editing is done on the cut and edit pages, visual effects and motion graphics on the Fusion page, color correction on the color page, audio on the Fairlight page, and media organization and output on the media and deliver pages. All it takes is a single click to switch between tasks!

The edit page is the world’s most advanced professional non-linear editor. The familiar track layout, dual monitor design and traditional workflow makes it easy for new users to learn while still being powerful enough for professional editors. It’s perfect for larger projects such as feature films, television shows, streaming, commercials, documentaries and more. The edit page features drag and drop editing, context sensitive automatic trimming tools, fully customizable keyboard shortcuts so you can work faster, and a library full of hundreds of titles, transitions, and effects that you can add and animate. You also get complete media management, organization and timeline management tools. Learn More

The cut page is perfect for projects with tight deadlines that you have to turn around quickly. It’s also great for documentary work. The cut page has a streamlined interface that’s fast to learn and designed for speed. Features such as source tape, dual timelines, fast review, and smart editing tools help you work faster than ever. The sync bin and source overwrite tools are the fastest way to edit multicam programs, making it easy to create perfectly synchronized cut aways! Everything on the cut page is action based so every click does something. That means you’ll spend more time editing and less time hunting for commands. Plus, the scalable interface is great for portable editing! Learn More

DaVinci Resolve Studio 18 features over 100 GPU and CPU accelerated Resolve FX such as blurs, light effects, noise, image restoration, beauty enhancement, stylize and more! Version 18 adds even more plugins for depth map generation, surface tracking, fast noise, and despilling. There’s even improvements to the beauty effect, edge detection and lens reflections. Automatically generate a 3D matte of a scene with the depth map FX to grade or add effects to a background or foreground. Track the movement of textured surfaces with the surface tracker effect to apply images to t-shirts, flags and faces! All Resolve FX effects can be applied and animated in the cut, edit, Fusion and color pages!

With all the different workflows and systems available, you need a post production solution that’s compatible and open enough to handle anything! DaVinci Resolve can be used with any type of storage ranging from direct attached hard drives to NAS and SAN systems. You can extend DaVinci Resolve with third party Open FX and audio plugins, or add third party title and motion graphics templates. New workflow integration and encoding APIs let developers integrate workflow and asset management systems with DaVinci Resolve. Plus, it works with all major file formats and post production software, making it easy to move files between DaVinci Resolve, Final Cut Pro, Media Composer, and Premiere Pro.

DaVinci Resolve keyboards have been designed as an alternative way to edit that’s much faster than a mouse because you can use both hands at the same time! The DaVinci Speed Editor features dedicated edit function keys on the left and a high quality search dial with electronic clutch and transport controls on the right. You can use the search dial and source tape buttons with your right hand to locate shots, while simultaneously marking in and out points, performing edits and live trimming with your left hand. All without touching the mouse! The DaVinci Resolve Editor Keyboard adds a QWERTY keyboard with color coded shortcut keycaps, designed for editors who spend hours each day editing. Learn More

DaVinci Resolve color panels let you adjust multiple parameters at once so you can create unique looks that are impossible with a mouse and keyboard. The incredibly small DaVinci Resolve Micro Panel is great for new colorists just getting started or anyone that needs a portable panel. It features 3 high quality trackballs, knobs for primary adjustment controls and buttons for playback and navigation. The DaVinci Resolve Mini Panel features additional controls and screens for accessing virtually all palettes and tools. For the ultimate in control, the DaVinci Resolve Advanced Panel gives high end professional colorists access to every single feature and command mapped to a specific button! Learn More

The best creative tools shouldn’t be limited to Hollywood. That’s why there’s a free version of DaVinci Resolve, so you can learn how to use the same tools that professional Hollywood artists use. DaVinci Resolve is designed to inspire creativity so you can focus on doing your best work. Once you learn the software and start using it for more work, you can purchase DaVinci Resolve Studio which adds tons of additional effects, 3D and more. Adding an editor keyboard, color control panel, or audio console lets you work even faster because you can use both hands at the same time, allowing you to be more creative and do things that are impossible with a mouse!

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey