lcd panel schematic diagram factory

Abstract: laptop LCD SCHEMATIC laptop inverter board schematic laptop lcd inverter board schematic laptop lcd board schematic schematic of laptop inverter lcd inverter board schematic lcd laptop schematic lcd qvga 320x240 YLCDRSK2378

Text: Advanced Direct Drive LCD Advanced Direct Drive LCD Description: Using the Renesas API to create real world LCD products Objectives 1. Compile the Demo Project. 2. Change the background image , XP or Vista E10A Debugger Renesas H8S/2378 LCD Kit and LCD Panel HEW Version 4.06 or newer , knowledge of Renesas MCU"s and Basic understanding of LCD Displays Time to Complete Lab1: 30 Minutes , using the LCD Kit for the H8S/2378(part number YLCDRSK2378) before you begin a hardware design it is

Abstract: schematic diagram lcd laptop inverter schematic diagram online UPS circuit diagram of 5kva online ups inverter ups pcb service manual schematic diagram mge UPS tyco igbt module 25A aic 2565 schematic diagram UPS 5 KVA 5kva schematic diagram UPS

Text: . . .page MBPS Schematic Diagram 6421M-S/6410M-S. . . . . . . . . . . . . . . . . . . . . . . . .A - 1 ACDP Schematic Diagram D6421P-S. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A - 2 Line to Neutral Inverter Plant Schematic Diagram . . . . . . . . . . . . . . . . . .A - 3 Line to Line Inverter Plant Schematic Diagram . . . . . . . . . . . . . . . . . . . . .A - 4 Static , Single-Line Diagram . AlphatranTM Inverter Plant Schematic . . . . . . . . . . . . . . . . . . .

Abstract: laptop display lcd connector pins lcd monitor inverter board schematic converted display port HDMI laptop lcd display interface LCX06 HDMI CONNECTOR SMT laptop inverter board schematic laptop inverter lcd schematic hdmi 1.4 pcb layout

Text: Intel"s Eaglelake/Cantiga chipset with an integrated graphics controller · A built-in laptop LCD screen or an external monitor with a VGA interface as the primary display · Another LCD monitor with a , Low-voltage open-drain inverter (14 SO) Fairchild 74LCX06M(Top Mark: LCX06) U8 1 DisplayPort , kit into an available PCIe bus slot. Connect an LCD monitor with an HDMI interface to the HDMI plug on the MAX9406 EV kit using an HDMI cable. Or, connect an LCD monitor with a DVI interface using a

Abstract: s1d13517 laptop inverter backlight schematic schematic diagram lcd laptop inverter schematic diagram of laptop inverter laptop CCFL inverter SCHEMATIC S5U13517P00C100 HK-2-S inverter display pinout 10pin SEIKO TP10

Text: : S5U13517P00C100 Schematic Diagram (1 of 3) S5U13517P00C100 Evaluation Board User Manual (Rev. 1.0 , : S5U13517P00C100 Schematic Diagram (2 of 3) 19 A B C R59 0 3.3VDD PCLK PDE PHS PVS GPO , Controller Figure 6-3: S5U13517P00C100 Schematic Diagram (3 of 3) S5U13517P00C100 Evaluation Board User , . . . . . . . . . . . 4.4.2 Connecting to the Epson S5U13U00P00C100 USB Adapter Board 4.5 LCD , Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 Chapter 6 Schematic

Abstract: laptop lcd inverter board schematic lcd inverter board schematic lcd qvga 320x240 320x240 YLCDRSK2378 schematic of laptop inverter 2.4 lcd qvga 320x240 2378 graphic lcd module 320x240

Text: LifeLine TFT-LCD Direct Drive H8S/2378 LIFELINE: H8S/2378 TFT- LCD Direct Drive Rev 1.2 12/2/2009 Who is this Document Written for? Anyone who has received an H8S/2378 LCD Demo kit and wants , step by step guide to make sure you can make it through the procedure. Note: If you are using the LCD , be aware that this board has an obsolete schematic that should be used only after noting the annotations in the updated schematic . One of the primary reasons the schematic is obsolete centers around how

Abstract: FAN7317B tv lcd Schematic Power Supply schematic diagram inverter lcd monitor backlight inverter circuit diagram SOIC127P1030X265-20L schematic diagram lcd monitor EFD2126 lcd monitor circuit diagram 21 inch Lcd tv circuit schematic diagram

Text: FAN7317B - LCD Backlight Inverter Drive IC January 2010 FAN7317B LCD Backlight Inverter , The FAN7317B is a LCD backlight inverter drive IC that controls P-N full-bridge topology using a new , Inverter Drive IC Typical Application Circuit ( LCD Backlight Inverter ) Application 22-Inch LCD Monitor , . Transformer Schematic Diagram Figure 56. Transformer Schematic Diagram 3. Core & Bobbin Core , FAN7317B - LCD Backlight Inverter Drive IC Physical Dimensions 13.00 12.60 11.43 20 B 11 A

Text: FAN7317B LCD Backlight Inverter Drive IC Features Description ï§ ï§ ï§ ï§ ï§ ï§ ï§ ï§ ï§ ï§ ï§ ï§ ï§ ï§ ï§ ï§ The FAN7317B is a LCD backlight inverter drive , FAN7317Bâ LCD Backlight Inverter Drive IC April 2011 Application Device Input Voltage Range , . Transformer Schematic Diagram Figure 56. Transformer Schematic Diagram 3. Core & Bobbin ï§ ï§ ï , ⢠1.0.2 www.fairchildsemi.com 19 FAN7317Bâ LCD Backlight Inverter Drive IC Typical

Abstract: schematic diagram inverter lcd monitor tv lcd Schematic Power Supply LCD 20pin LCD INVERTER SERVICE INFORMATION lcd inverter SCHEMATIC schematic diagram lcd monitor schematic diagram ac inverter backlight inverter circuit diagram schematic diagram ac to ac inverter

Text: FAN7317B LCD Backlight Inverter Drive IC Features Description The FAN7317B is a LCD backlight , through Protection Functions Figure 55. Typical Application Circuit 2. Transformer Schematic Diagram Figure 56. Transformer Schematic Diagram 3. Core & Bobbin Core: EFD2126 Material: PL7 Bobbin , FAN7317B - LCD Backlight Inverter Drive IC Typical Application Circuit ( LCD Backlight Inverter , Semiconductor Corporation FAN7317B· 1.0.1 www.fairchildsemi.com 21 FAN7317B - LCD Backlight Inverter

Abstract: tdk schematic diagram lcd laptop inverter schematic 20 pin lcd laptop s1d13748 schematic diagram of laptop inverter LED backlight schematic laptop laptop LCD inverter SCHEMATIC LED-0603 40 pin laptop lcd connector S5U13748P00C100

Text: section 6, for Schematic diagram 3 of 3, updated the part used for F1 to a a TDK ACH32C-333-T X80A-G, 4.4.2 Connecting to the Epson S5U13U00P00C100 USB Adapter Board 4.5 LCD Panel Interface . . . . . . . . , . . . . . . . . . . . . . . . . . . . . . . . . 18 Chapter 6 Schematic Diagrams . . . . . . . . . , S5U13U00P00C100 USB Adapter board so that it can be used with a laptop or desktop computer, via USB 2.0. This , S5U13U00P00C100 USB Adapter board · Headers for connecting to LCD panels · Header for S1D13748 GPIO pins

Text: 2). The following diagram shows the location of connectors H2, H3, and H4. H3 ( LCD Panel , Adapter Board 4.5 LCD Panel Interface . . . . . . . . . . . . . . . . . . . . . 4.6 GPIO Connections . . , 18 Chapter 6 Schematic Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 , laptop or desktop computer, via USB 2.0. This user manual is updated as appropriate. Please check the , ¢ Headers for connecting to LCD panels ⢠Header for S1D13748 GPIO pins (optional) ⢠On-board 4MHz

Abstract: CRT MONITOR SCHEMATIC DIAGRAM monochrome schematic diagram vga to LCD SCHEMATIC mda VGA cga ega to vga SCHEMATIC mda VGA board cga monochrome monitor schematic cga to vga schematic 20 pin lcd laptop schematic diagram vga to tv

Text: to drive flat-panel and CRT displays tor laptop and notebook applications. Set I supports up to 16 shades of gray on LCD "s and PDP"s (plasma display panels). Set II supports 64 shades of gray on LCD "s. Set III supports 64 colors on multi-color LCD "s. All three sets are fully compatible with software , board Schematic of evaluation/demo board Parts list Installation guide Cabling and power supply , , SPC8010FOA, and SEA6461J35 Drives CRT monitors and grayscale LCD or PDP (16 shades) Set II SPC8000FOB

Abstract: schematic diagram inverter lcd monitor lcd inverter board schematic lcd tv inverter board schematic ccfl lcd inverter schematic lcd monitor inverter board schematic lcd tv inverter schematic lcd inverter schematic LCD TV backlight power inverter lcd backlight inverter 7 pin

Text: FAN7313 LCD Backlight Inverter Drive IC Features Description High-Efficiency Single-Stage , Reel www.fairchildsemi.com FAN7313 LCD Backlight Inverter Drive IC September 2006 Application Lamps Input Voltage 19-inch LCD Monitor 4 13V 1. Schematic F1 FUSE C1 220u , Schematic Diagram Supported by Namyang electronics (http://www.namyangelec.co.kr). FAN7313 Rev. 00 , Semiconductor Corporation FAN7313 Rev. 1.0.0 www.fairchildsemi.com 8 FAN7313 LCD Backlight Inverter

Abstract: schematic diagram lcd monitor advance 17 schematic diagram tv monitor advance 17 lcd tv inverter board schematic CFL inverter circuit schematic diagram lcd monitor inverter board schematic schematic diagram tv monitor advance CFL 12v inverter circuit schematic schematic diagram of lcd inverter board 2 lamps lcd inverter schematic

Text: FAN7311B LCD Backlight Inverter Drive IC Features Description High-Efficiency Single-Stage , FAN7311B Rev. 1.0.0 www.fairchildsemi.com FAN7311B LCD Backlight Inverter Drive IC January 2007 Application Lamps Input Voltage 19-inch LCD Monitor 4 13V 1. Schematic F1 FUSE C22 220u , . Transformer Schematic Diagram - Supported by Namyang electronics (http://www.namyangelec.co.kr) FAN7311, FAN7311B LCD Backlight Inverter Drive IC Typical Application Circuits The following are registered

Abstract: LTM190EX schematic diagram tv monitor advance 17 FDS8958A schematic diagram e FDS8958A ccfl lcd inverter schematic inverter circuit schematic diagram four lcd backlight lcd inverter board schematic fds8958 2012 SMD resistor

Text: FAN7311 LCD Backlight Inverter Drive IC Internal Block Diagram FAN7311 LCD Backlight Inverter Drive , FAN7311 LCD Backlight Inverter Drive IC Features Description High-Efficiency Single-Stage , www.fairchildsemi.com FAN7311 LCD Backlight Inverter Drive IC January 2007 RT max. 2V CT OUTA , . 1.0.6 www.fairchildsemi.com 4 FAN7311 LCD Backlight Inverter Drive IC Absolute Maximum Ratings , Corporation FAN7311 Rev. 1.0.6 www.fairchildsemi.com 5 FAN7311 LCD Backlight Inverter Drive IC

Abstract: FAIRCHILD SMD MARKING SMD IC MARKING GP smd diode marking code 15h lcd tv inverter board schematic VA07 smd marking QT SMD MARKING CODE C17 SMD MARKING CODE d8 power supply of LCD TV backlight schematic

Text: 8 www.fairchildsemi.com FAN7311B LCD Backlight Inverter Drive IC Timing Diagram The , FAN7311B LCD Backlight Inverter Drive IC January 2007 FAN7311B LCD Backlight Inverter Drive , Semiconductor Corporation FAN7311B Rev. 1.0.0 www.fairchildsemi.com FAN7311B LCD Backlight Inverter Drive , LCD Backlight Inverter Drive IC Absolute Maximum Ratings Stresses exceeding the absolute maximum , LCD Backlight Inverter Drive IC Electrical Characteristics For typical values, TA=25°C and VIN

Abstract: circuit diagram of wireless door BELL car laptop charger schematic D link schematic circuit diagram adsl modem board circuit diagram of car central lock system circuit diagram of wireless door BELL with remote schematic diagram 48v dc motor speed controller dc motor 9v charging ic laptop motherboard DVD player with usb port circuit diagram

Text: surrounding controller logic are powered from the 5V bus. The LCD inverter and the electronics on the board , surrounding controller logic are powered from the 5V bus. The LCD inverter and the electronics on the board , · · LCD Controller 1-3A CL 0.25 0.75A CL 1-2A Power Electronics LCD Inverter , Customer Convenience Port (Passenger) Powered 6 Pin IEEE 1394b bilingual connector LCD Display · , 85-240AC Power In Communication Link 2 LCD or OLED Display Wireless RF Transmitter Blue

Text: on-board voltage regulator. The following diagram shows the location of the LCD panel connectors H4 and H5 , Adapter Board 4.5 LCD Panel Interface . . . . . . . . . . . . . . . . . . . . . 4.6 Camera Interface . . , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 Chapter 6 Schematic , can connect to the S5U13U00P00C100 USB Adapter board so that it can be used with a laptop or desktop , for connecting to various Host Bus Interfaces ⢠Headers for connecting to LCD panels ⢠Headers

Abstract: schematic diagram tv monitor lcd advance 22 CFL inverter circuit schematic diagram lcd inverter board schematic 32 inch LCD TV SCHEMATIC schematic diagram inverter lcd monitor schematic diagram lcd monitor advance 17 lcd tv inverter board schematic lcd tv inverter schematic CFL 12v inverter circuit schematic

Text: Backlight Inverter Drive IC Internal Block Diagram FAN7311B LCD Backlight Inverter Drive IC Pin , www.fairchildsemi.com 9 FAN7311B LCD Backlight Inverter Drive IC Timing Diagram Application Lamps Input , FAN7311B LCD Backlight Inverter Drive IC Features Description High-Efficiency Single-Stage , FAN7311B Rev. 1.0.0 www.fairchildsemi.com FAN7311B LCD Backlight Inverter Drive IC January 2007 , Semiconductor Corporation FAN7311B Rev. 1.0.0 www.fairchildsemi.com 4 FAN7311B LCD Backlight Inverter

Abstract: M 3kv 18k lcd tv inverter board schematic lcd monitor inverter board schematic 22k 3kv inverter circuit schematic diagram four lcd backlight lcd ccfl driver schematic inverter circuit schematic diagram for lcd backlight schematic diagram inverter 12v to 5v 8 pin ic on lcd power board schematic

Text: www.fairchildsemi.com FAN7311 - LCD Backlight Inverter Drive IC Internal Block Diagram RT max. 2V min. 0.5V 6 , Rev. 1.0.7 8 www.fairchildsemi.com FAN7311 - LCD Backlight Inverter Drive IC Timing Diagram , FAN7311 - LCD Backlight Inverter Drive IC December 2007 FAN7311 LCD Backlight Inverter Drive , www.fairchildsemi.com FAN7311 - LCD Backlight Inverter Drive IC Pin Assignments RT1 20 OUTB OUTA 19 18 VIN 17 , www.fairchildsemi.com FAN7311 - LCD Backlight Inverter Drive IC Absolute Maximum Ratings Stresses exceeding the

Abstract: schematic diagram cga to vga SCHEMATIC mda VGA board CRT MONITOR SCHEMATIC DIAGRAM monochrome monochrome crt schematic schematic diagram tv to vga cga ega to vga SCHEMATIC mda VGA CRT MONITOR SCHEMATIC DIAGRAM schematic diagram vga

Text: have been optimized to drive flat-panel and CRT displays (or laptop and notebook applications. Set I supports up to 16 shades of gray on LCD "s and PDP"s (plasma display panels). Set II supports 64 shades of gray on LCD "s. Set III supports 64 colors on multi-color LCD "s, All three sets are fully compatible , graphic adapter board Schematic of evaluation/demo board Parts list Installation guide Cabling and power , SPC8000FOB, SPC8010FOA, and SEA6461J35 Drives CRT monitors and grayscale LCD or PDP (16 shades) Set II

Abstract: schematic diagram lcd monitor advance 17 27k 3kv 32 inch LCD TV SCHEMATIC efd2124 circuit diagram tv monitor lcd advance capacitor 27k 3kv capacitor c1 220uF 3kv fuse lcd inverter board schematic

Text: FAN7313 LCD Backlight Inverter Drive IC Internal Block Diagram FAN7313 LCD Backlight Inverter Drive , ) FAN7313 LCD Backlight Inverter Drive IC Timing Diagram CMP CT CLK T OUTH OUTL , FAN7313 LCD Backlight Inverter Drive IC Features Description High-Efficiency Single-Stage , Reel www.fairchildsemi.com FAN7313 LCD Backlight Inverter Drive IC September 2006 + , www.fairchildsemi.com 4 FAN7313 LCD Backlight Inverter Drive IC Absolute Maximum Ratings For typical values

Abstract: schematic 20 pin lcd laptop 14 schematic diagram of laptop inverter laptop inverter backlight schematic schematic 20 pin lcd laptop laptop CCFL inverter SCHEMATIC laptop LCD inverter SCHEMATIC 20X2 LCD DISPLAY PINOUT laptop backlight inverter pinout schematic diagram lcd laptop inverter

Text: . . . . . . . . . . . 4.5.2 Connecting to the Epson S5U13U00P00C100 USB Adapter Board 4.6 LCD , . . . . . . . . 18 6 Schematic Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . , the S5U13U00P00C100 USB Adapter board so that it can be used with a laptop or desktop computer, via , S5U13U00P00C100 USB Adapter board · Headers for connecting to LCD panels · Header for S1D13742 GPIO pins , adjustable 6~24V output, 40mA max., to provide power for LED backlight of LCD panels. S1D13742 X63A-G

Abstract: 3 phase charger inverter schematic diagram AVP-1280 led lcd inverter schematic usb support video player circuit diagram MBRS340T3G usb video player circuit diagram panel mount banana plug esr meter wall wart schematic

Text: Backlight for the LCD Display, connect the Microsemi LXMG1623-05-44 Inverter Module to the B 11 and B 12 , 2 Video Interface ( LCD ) Controller other6 FIGURE 23. Typical LCD Based Display System Diagram , System Block Diagram with Video Interface Controller and LCD Display 29 www.national.com RD , . Provides charging current for PMP device when docked in docking station connector. Detachable LCD , provides lighting to LCD Display. High Efficiency Portable Media Player (PMP) Docking Station High

Text: Advanced Direct Drive LCD Advanced Direct Drive LCD Description: Using the Renesas API to create real world LCD products Objectives 1. Compile the Demo Project. 2. Change the background image. Lab Materials: Please verify you have the following materials at your lab station. · Laptop · E10A Debugger · Renesas H8SX/1668 LCD Kit and LCD Panel · HEW Version 4.06 or newer · H8S Tools Version , "s and Basic understanding of LCD Displays Time to Complete Lab1: 30 Minutes Time to Complete Lab2

Abstract: schematic diagram inverter lcd monitor inverter circuit schematic diagram four lcd backlight schematic diagram tv monitor lcd advance 22 32 inch LCD TV SCHEMATIC lcd tv inverter board schematic efd2124 schematic diagram lcd monitor advance 17 1K 1608 schematic diagram e FDS8958a

Text: FAN7311 LCD Backlight Inverter Drive IC Internal Block Diagram FAN7311 LCD Backlight Inverter Drive , FAN7311 LCD Backlight Inverter Drive IC Features Description High-Efficiency Single-Stage , FAN7311 LCD Backlight Inverter Drive IC September 2006 RT CT OUTA OSCILLATOR max. 2V , www.fairchildsemi.com 4 FAN7311 LCD Backlight Inverter Drive IC Absolute Maximum Ratings For typical values , www.fairchildsemi.com 5 FAN7311 LCD Backlight Inverter Drive IC Electrical Characteristics For typical values

Important technical improvements of LCD, such as LED backlighting and wide viewing Angle, are directly related to LCD. And account for an LCD display 80% of the cost of the LCD panel, enough to show that the LCD panel is the core part of the entire display, the quality of the LCD panel, can be said to directly determine the quality of an LCD display.

The production of civil LCD displays is just an assembly process. The LCD panel, the main control circuit, shell, and other parts of the main assembly, basically will not have too complex technical problems.

Does this mean that LCDS are low-tech products? In fact, it is not. The production and manufacturing process of the LCD panels is very complicated, requiring at least 300 process processes. The whole process needs to be carried out in a dust-free environment and with precise technology.

The general structure of the LCD panel is not very complex, now the structure of the LCD panel is divided into two parts: the LCD panel and the backlight system.

Due to the LCD does not shine, so you need to use another light source to illuminate, the function of the backlight system is to this, but currently used CCFL lamp or LED backlight, don’t have the characteristics of the surface light source, so you need to guide plate, spreadsheet components, such as linear or point sources of light evenly across the surface, in order to make the entire LCD panel on the differences of luminous intensity is the same, but it is very difficult, to achieve the ideal state can be to try to reduce brightness non-uniformity, the backlight system has a lot to the test of design and workmanship.

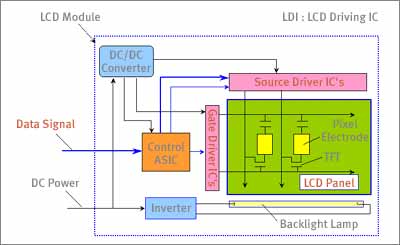

In addition, there is a driving IC and printed circuit board beside the LCD panel, which is mainly used to control the rotation of LCD molecules in the LCD panel and the transmission of display signals. The LCD plate is thin and translucent without electricity. It is roughly shaped like a sandwich, with an LCD sandwiched between a layer of TFT glass and a layer of colored filters.

LCD with light refraction properties of solid crystals, with fluid flow characteristics at the same time, under the drive of the electrode, can be arranged in a way that, in accordance with the master want to control the strength of the light through, and then on the color filter, through the red, green, blue three colors of each pixel toning, eventually get the full-screen image.

According to the functional division, the LCD panel can be divided into the LCD panel and the backlight system. However, to produce an LCD panel, it needs to go through three complicated processes, namely, the manufacturing process of the front segment Array,the manufacturing process of the middle segment Cell, and the assembly of the rear segment module. Today we will be here, for you in detail to introduce the production of the LCD panel manufacturing process.

The manufacturing process of the LCD panel Array is mainly composed of four parts: film, yellow light, etch and peel film. If we just look at it in this way, many netizens do not understand the specific meaning of these four steps and why they do so.

First of all, the motion and arrangement of LCD molecules need electrons to drive them. Therefore, on the TFT glass, the carrier of LCD, there must be conductive parts to control the motion of LCD. In this case, we use ITO (Indium Tin Oxide) to do this.ITO is transparent and also acts as a thin-film conductive crystal so that it doesn’t block the backlight.

The different arrangement of LCD molecules and the rapid motion change can ensure that each pixel displays the corresponding color accurately and the image changes accurately and quickly, which requires the precision of LCD molecule control.ITO film needs special treatment, just like printing the circuit on the PCB board, drawing the conductive circuit on the whole LCD board.

This completes the previous Array process. It is not difficult to see from the whole process that ITO film is deposited, photoresist coated, exposed, developed, and etched on TFT glass, and finally, ITO electrode pattern designed in the early stage is formed on TFT glass to control the movement of LCD molecules on the glass. The general steps of the whole production process are not complicated, but the technical details and precautions are very complicated, so we will not introduce them here. Interested friends can consult relevant materials by themselves.

The glass that the LCD board uses makes a craft also very exquisite. (The manufacturing process flow of the LCD display screen)At present, the world’s largest LCD panel glass, mainly by the United States Corning, Japan Asahi glass manufacturers, located in the upstream of the production of LCD panel, these manufacturers have mastered the glass production technology patents. A few months ago, the earthquake caused a corning glass furnace shutdown incident, which has caused a certain impact on the LCD panel industry, you can see its position in the industry.

As mentioned earlier, the LCD panel is structured like a sandwich, with an LCD sandwiched between the lower TFT glass and the upper color filter. The terminal Cell process in LCD panel manufacturing involves the TFT glass being glued to the top and bottom of a colored filter, but this is not a simple bonding process that requires a lot of technical detail.

As you can see from the figure above, the glass is divided into 6 pieces of the same size. In other words, the LCD made from this glass is finally cut into 6 pieces, and the size of each piece is the final size. When the glass is cast, the specifications and sizes of each glass have been designed in advance.

Directional friction:Flannelette material is used to rub the surface of the layer in a specific direction so that the LCD molecules can be arranged along the friction direction of the aligned layer in the future to ensure the consistency of the arrangement of LCD molecules. After the alignment friction, there will be some contaminants such as flannelette thread, which need to be washed away through a special cleaning process.

After the TFT glass substrate is cleaned, a sealant coating is applied to allow the TFT glass substrate to be bonded to the color filter and to prevent LCD outflow.

Finally, the conductive adhesive is applied to the frame in the bonding direction of the glass of the color filter to ensure that external electrons can flow into the LCD layer. Then, according to the bonding mark on the TFT glass substrate and the color filter, two pieces of glass are bonded together, and the bonding material is solidified at high temperatures to make the upper and lower glasses fit statically.

Color filters are very important components of LCD panels. Manufacturers of color filters, like glass substrate manufacturers, are upstream of LCD panel manufacturers. Their oversupply or undersupply can directly affect the production schedule of LCD panels and indirectly affect the end market.

As can be seen from the above figure, each LCD panel is left with two edges after cutting. What is it used for? You can find the answer in the later module process

Finally, a polarizer is placed on both sides of each LCD substrate, with the horizontal polarizer facing outwards and the vertical polarizer facing inwards.

When making LCD panel, must up and down each use one, and presents the alternating direction, when has the electric field and does not have the electric field, causes the light to produce the phase difference and to present the light and dark state, uses in the display subtitle or the pattern.

The rear Module manufacturing process is mainly the integration of the drive IC pressing of the LCD substrate and the printed circuit board. This part can transmit the display signal received from the main control circuit to the drive IC to drive the LCD molecules to rotate and display the image. In addition, the backlight part will be integrated with the LCD substrate at this stage, and the complete LCD panel is completed.

Firstly, the heteroconductive adhesive is pressed on the two edges, which allows external electrons to enter the LCD substrate layer and acts as a bridge for electronic transmission

Next is the drive IC press. The main function of the drive IC is to output the required voltage to each pixel and control the degree of torsion of the LCD molecules. The drive IC is divided into two types. The source drive IC located in the X-axis is responsible for the input of data. It is characterized by high frequency and has an image function. The gate drive IC located in the Y-axis is responsible for the degree and speed of torsion of LCD molecules, which directly affects the response time of the LCD display. However, there are already many LCD panels that only have driving IC in the X-axis direction, perhaps because the Y-axis drive IC function has been integrated and simplified.

The press of the flexible circuit board can transmit data signals and act as the bridge between the external printed circuit and LCD. It can be bent and thus becomes a flexible or flexible circuit board

The manufacturing process of the LCD substrate still has a lot of details and matters needing attention, for example, rinse with clean, dry, dry, dry, ultrasonic cleaning, exposure, development and so on and so on, all have very strict technical details and requirements, so as to produce qualified eyes panel, interested friends can consult relevant technical information by a search engine.

LCD (LC) is a kind of LCD, which has the properties of light transmission and refraction of solid Crystal, as well as the flow property of Liquid. It is because of this property that it will be applied to the display field.

However, LCD does not emit light autonomously, so the display equipment using LCD as the display medium needs to be equipped with another backlight system.

First, a backplate is needed as the carrier of the light source. The common light source for LCD display equipment is CCFL cold cathode backlight, but it has started to switch to an LED backlight, but either one needs a backplate as the carrier.

CCFL backlight has been with LCD for a long time. Compared with LED backlight, CCFL backlight has many defects. However, it has gradually evolved to save 50% of the lamp and enhance the transmittance of the LCD panel, so as to achieve the purpose of energy-saving.

With the rapid development of LED in the field of lighting, the cost has been greatly reduced.LCD panels have also started to use LED as the backlight on a large scale. Currently, in order to control costs, an LED backlight is placed on the side rather than on the backplate, which can reduce the number of LED grains.

At the top of the diffusion plate, there will be 3~4 diffuser pieces, constantly uniform light to the whole surface, improve the uniformity of light, which is directly related to the LCD panel display effect. Professional LCD in order to better control the brightness uniformity of the screen, panel procurement, the later backlight control circuit, will make great efforts to ensure the quality of the panel.

Since the LCD substrate and the backlight system are not fixed by bonding, a metal or rubber frame is needed to be added to the outer layer to fix the LCD substrate and the backlight system.

After the period of the Module, the process is completed in LCM (LCDModule) factory, the core of this part of the basic does not involve the use of LCD manufacturing technology, mainly is some assembly work, so some machine panel factories such as chi mei, Korea department such as Samsung panel factory, all set with LCM factories in mainland China, Duan Mo group after the LCD panel assembly, so that we can convenient mainland area each big monitor procurement contract with LCD TV manufacturers, can reduce the human in the whole manufacturing and transportation costs.

However, neither Taiwan nor Korea has any intention to set up factories in mainland China for the LCD panel front and middle manufacturing process involving core technologies. Therefore, there is still a long way to go for China to have its own LCD panel industry.

Electrical panel wiring diagrams are used to outline each device, as well as the connection between the devices found within an electrical panel. As electrical panels are what will contain control systems, panel wiring diagrams are commonly encountered by PLC technicians and engineers. Although electrical panels may not be overly complex from the first glance, a lot of engineering goes into selecting proper devices, sizing wiring and designing the layout of the panel that is documented by the electrical panel wiring diagrams.

It is important to note that electrical panel wiring diagrams must follow local authorities that dictate the standards that must be respected within the panel. In the United States, this authority is the National Fire Protection Association (NFPA) and the code is called the National Electrical Code (NEC). Furthermore, each state may choose to adopt a different version of the code based on the release. It is important to be familiar with the code that applies in your area before designing a panel.

The electrical panel above includes a MicroLogix PLC, protection devices (fuses), connection devices (unmanaged switch, EtherNet to RS232 converter), terminal blocks and a power supply.

Power devices within an electrical panel are used to deliver the current required to each device and to protect them from overcurrent situations.Electrical Panel Circuit Breaker | Typically the entry-point for external current into the panel. An electrical panel breaker is similar to what you may found in household applications, but with much higher ratings. This device is used to cut-off all power from the electrical panel and will automatically trip when a certain current level (based on the breaker rating) is exceeded.

The electrical panel wiring diagram above displays an example of a circuit breaker as well as multiple fuses that protect variable frequency drives. Notice that the drawing of the circuit breaker incorporates an icon that indicates that the circuit will open during a current surge.

The diagram above contains a transformer that takes a 575VAC voltage and translates it into 115VAC. 115VAC is a standard voltage in North America and is utilized for many devices including PLCs, HMIs, switches and more.

The electrical drawing will split each card onto a page. In other words, the external modules we saw in the panel will have a separate page on which the components connected to each point are shown.

We haven’t covered all the major components in the section above. However, since we dove into Input and Output points tied to external devices, it is important to cover those before we proceed. In this section, we will present a device symbol that you may find in an electrical panel wiring diagram and give a brief description of the device, as well as a few examples for reference.

In the diagram above, we are shown a connection between an unmanaged switch and a series of peripheral devices that utilize the EtherNet protocol. As mentioned above, for simplicity purposes, it is assumed that the reader understands the use of the RJ45 standard EtherNet cable for this purpose.

Note that this page only describes network connections to these devices. The same devices will be listed on a different page as they require additional signals. Example: The “030-SC01 Conveyor Bed” Variable Frequency Drive (VFD) will be connected to power, a motor, the PLC and safety circuits. These will be covered in a separate page of the electrical panel wiring diagram.

The electrical wiring diagram above contains an example of a safety circuit one may find in an industrial environment. The following components are shown here:The MSR304 is an Allen Bradley Safety Relay. It sends a signal through a series of safety switches and E-Stops and reads the signal it receives at the end of the chain. If all the switches are closed, the relay confirms that the safety circuit is good and energizes the load it is tied to.

The 090-ZSS11 is a safety switch that is part of the safety chain of devices. As shown in the diagram, the safety devices are wired one after the other.

In this section, we"ll outline different tools engineers and technicians use to create electrical panel wiring diagrams. Some of these tools are expensive and are sold through distributors only. However, most of these vendors provide trial versions that you can utilize with limited capabilities in order to assess if their solution is right for you.

EPLAN - This tool specializes in design software for panel and industrial design. You won"t find the extensive list of features you may see in AutoCAD, but the features you will find are exceptionally well designed and maintained by the team. EPLAN has gained in popularity in the recent years and has become the tool of choice for many engineers and electricians.

Electrical Drawings are mandatory by the National Electrical Code (NEC) in the US and other authorities in different regions of the world. They provide a specification list to which electricians and engineers will design and assemble the control panel used in manufacturing and the industry.

Each page of the drawing will display a circuit that will contain some of the elements of the panel along with references to other pages. By using the schematic, it’s possible to identify elements within the panel, validate the connections and troubleshoot field issues when they occur.

Smart OLED/LCD/LED TV Repair Guide. Learn how to troubleshooting & repairing Smart OLED/LCD/LED TV the right way. Most of the TV problem symptom like no display, tv not power on…

In this work, we design and optimize a new amorphous silicon gate (ASG) driver circuit for GOP (gate-on-panel) application in medium size LCD. The circuit is composed of sixteen TFTs and one capacitor with distinct pre-charge nodes and dual low voltage levels. The design of distinct pre-charge nodes is conducive to the decrease of the charge time, and the dual low voltage level will stabilize the output waveform in off-duty periods. Biology-inspired global optimization technique is thus…Expand

Hi, I have upgraded to a Hisense smart tv.I want to repair my old Hisense 32v77 LCD tv. Where can I access a schematic drawing of the main logic control board. unable to find a replacement board.The

Hi Guys - I would like to get Service Manual for LCDN47T36R3D television especially in regard to backlight devices and circuit diagram. - pm45@mweb.co.za

I am looking for the service manual for a hisence 65k5500uw or 65k5500uw/s1z1 with circuit diagrams. My email address is shawnmould56@gmail.com thank you.

As the designer, you have the choice of individually configuring and generating the outputs via the schematic and PCB editor"s File and Reports menus, or alternatively, you can add all of the required outputs into an OutputJob and generate them from there.

Multiple outputs can be streamed into a single output file if required - for example, schematic prints and PCB layout prints can be output into the same PDF.

To use the BOM Report feature, add a Bill of Materials to the OutputJob and set the Data Source to [Project], which means the schematic project. For a pick and place file, the Data Source would be set to the [

If you are generating output via the schematic or PCB editor menus, then the outputs are generated directly when you click OK in the relevant dialog. Use the links in the previous section to access the setup dialog for a specific output type.

Schematic component parameters can also be included in the PDF, click on the component symbol in the PDF to display them. HelpURL and ComponentLinks can become links in the PDF, if they are defined in the Device Independent Path format, as described below.

In this module, we will introduce you to the schematic diagram. We will cover: The diagram, The notes, The legend, and How to read a schematic diagram. Skip to quiz!

A schematic diagram is a blueprint of the electrical components within a system. Schematic diagrams include a diagram, notes, and a legend. See the picture to the right for an example of schematic diagram.

A schematic diagram shows the wiring of each component in the circuit. Schematic diagrams are very useful when you are troubleshooting or wiring a circuit.

For example, look at the schematic diagram to the right. You can see that there are abbreviations on the diagram like CONT, CAP, and CH. Without reading the legend, you cannot understand the abbreviations and the components of the circuit.

After you read the legend, it is important to read the notes section of the diagram. The notes section can have important information about the circuit.

For example, the notes section may have a note about the crankcase heater (CH) on a schematic diagram. The notes may say something like “CH not used on all diagrams”. If you did not read the notes, you may have an incorrect understanding of the circuit. The CH may not be present.

The next step is to look at the diagram on the schematic. Each symbol on the diagram represents a component within the circuit. The lines running between each component represent a wire.

L1 and L2 power the line side of the circuit. L1 and L2 represent the two poles on an AC power supply. The picture to the right shows L1 and L2 on a schematic diagram. Note that the line voltage is labeled above L1 and L2.

The line side of the circuit will have bolder wiring connections than the control side. The line side will also have L1 and L2 nearby. The picture to the right shows the line side of the circuit. Note that the wiring lines are bolder than the bottom half of the diagram.

The control side of the circuit will have thinner wiring lines than the line side of the circuit. Note that the wiring lines are thinner than the top part of the diagram.

Recall that factory wiring is done by the manufacturer. Field wiring is done by the technician. Factory wiring is represented by a solid line on the diagram. Field wiring is represented by a dashed line on the diagram.

Most schematic diagrams will also tell you the color of wires. On each line in the diagram, you will see a symbol. For example, BLK or BLU. BLK stands for black wiring and BLU stands for blue wiring. Some legends will define the color symbols.

Recall that a schematic diagram represents components with symbols. On a diagram, some symbols will have a black border around them. You can see an example in the picture to the right.

A black border around a group of symbols indicates the internals of a single component. For example, the image to the right shows a contactor on a schematic diagram. You can see that the contactor is labeled CONT, and it has a black box around several internal components.

The diagram shows the internal components so that you can determine the type of contactor. In the picture, you can see that this is a single pole contactor since there is only one contactor switch. There is one contactor switch between 11 and 12, a wire running beneath the switch, and a coil underneath the wire.

A schematic diagram can also be used to determine how components are wired to each other. For example, view the image to the right. You can see that this image shows a dual run capacitor, start capacitor, start relay, and a start thermistor.

In this module, you learned how to read a schematic diagram. Always read the notes and legend before looking at the diagram. Schematic diagrams display the components and wiring within a circuit.

A ladder diagram is a blueprint of the electrical components within a system. Ladder diagrams will have a diagram and a legend. See the picture to the right for an example of a ladder diagram.

Ladder diagrams specialize in displaying the logic of a circuit. Recall that circuit logic explains what happens to the circuit when a component switches its position. For example, circuit logic would explain which components gain or lose power when a switch opens.

For example, look at the legend to the right. You can see that the legend explains abbreviations like CC, EFR, and HR. Without reading the legend, you cannot understand the abbreviations on the diagram.

Recall that each symbol on a diagram represents a component within the circuit. Ladder diagrams place each component in the circuit between two vertical power lines called L1 and L2. Each symbol is on a horizontal line between L1 and L2.

The horizontal lines are called rungs. Each rung represents one circuit within the electrical system. Recall that electrical systems have multiple circuits. Since systems have multiple circuits, the ladder diagram will have multiple rungs.

Components that receive less voltage, like a 24V coil, will be placed on the control side of the diagram. Components that receive higher voltage, like a 240V compressor, will be placed on the line side of the diagram.

A ladder diagram will have all components on the line side of the circuit between two vertical lines labeled L1 and L2. L1 and L2 represent the two poles on an AC power supply. L1 and L2 provide power to the components on the line side of the circuit.

The control side of the circuit will not have lines for L1 and L2. The control side of the circuit will be below the line side on a diagram. A transformer usually marks the separation between the line and the control side. The picture to the right shows the control side of a ladder diagram.

For example, in the diagram to the right, the compressor contactor (CC) has components on the line and control side. You can see that there are contactor switches labeled CC on the line side, and coils labeled CC on the control side. Both symbols are a part of the same CC but receive different voltages.

Once L1 is energized, the current flows across each rung of the ladder diagram. This assumes that the rung is a closed connection. If the rung has an open switch, the current will not flow across the rung.

Recall that symbols on the same rung of the ladder diagram are part of the same circuit. For example, look at the ladder diagram in the image to the right. You can see that the compressor and compressor contactor are on the same rung of the line side of the diagram.

Recall that components in a circuit can be wired in series or parallel. Ladder diagrams make it easier to see if components are in parallel or series.

You can tell components are in parallel if there is more than one path for current to flow through a rung. In the diagram, the current could go from L1 through the EFR and then through the evaporator fan. The current could also go from L1 through the HR and then through the evaporator fan.

In this module, you learned how to read a ladder diagram. Always read the legend before looking at the diagram. Remember that a ladder diagram places the components between L1 and L2.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey