flexible lcd displays factory

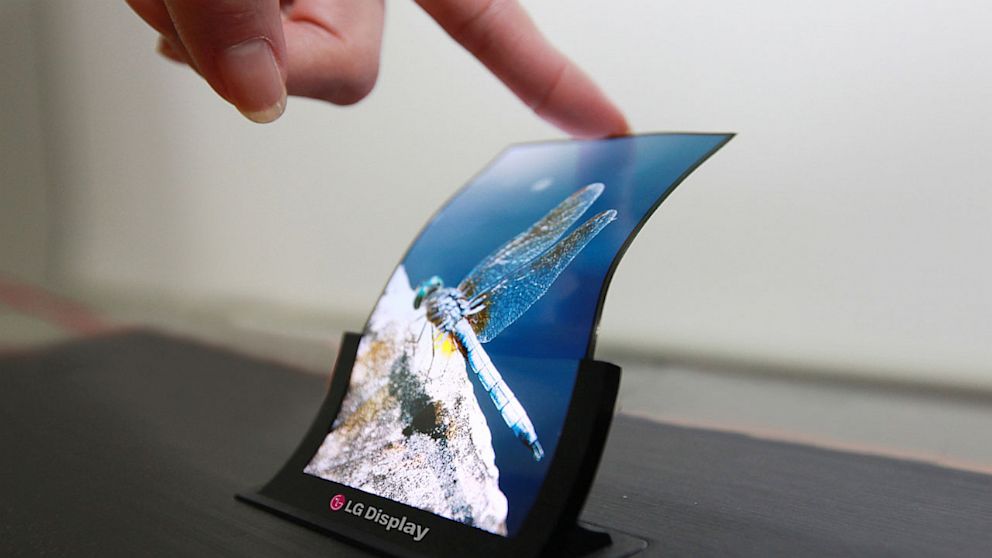

FlexEnable’s glass-free organic LCD (OLCD) delivers high-brightness, long lifetime flexible displays that are low cost and scalable to large areas, while also being thin, lightweight and shatterproof.

OLCD is a plastic display technology with full colour and video-rate capability. It enables product companies to create striking designs and realise novel use cases by merging the display into the product design rather than accommodating it by the design.

Unlike flexible OLED displays, which are predominantly adopted in flagship smartphones and smartwatches, OLCD opens up the use of flexible displays to a wider range of mass-market applications. It has several attributes that make it better suited than flexible OLED to applications across large-area consumer electronics, smart home appliances, automotive, notebooks and tablets, and digital signage.

OLCD can be conformed and wrapped around surfaces and cut into non-rectangular shapes during the production process. Holes can be also added to fit around the functional design of the system – for example around knobs and switches.

As with glass-based LCD, the lifetime of OLCD is independent of the display brightness, because it is achieved through transmission of a separate light source (the backlight), rather than emission of its own light. For example OLCD can be made ultra-bright for viewing in daylight conditions without affecting the display lifetime – an important requirement for vehicle surface-integrated displays.

OLCD is the lowest cost flexible display technology – it is three to four times lower cost that flexible OLED today. This is because it makes use of existing display factories and supply chain and deploys a low temperature process that results in low manufacturing costs and high yield.

Unlike other flexible display approaches, OLCD is naturally scalable to large sizes. It can be made as small or as large as the manufacturing equipment used for flat panel displays allows.

The flexibility of OLCD allows an ultra-narrow bezel to be implemented by folding down the borders behind the display. This brings huge value in applications like notebooks and tablets where borderless means bigger displays for the same sized device. The bezel size allowed by OLCD is independent of the display size or resolution. In addition, OLCD can make a notebook up to 100g lighter and 0.5mm thinner.

OLCD is the key to the fabrication of ultra-high contrast dual cell displays with true pixel level dimming, offering OLED-like performance at a fraction of the cost. The extremely thin OLCD substrate brings advantages in cost, viewing angle and module thickness compared to glass displays. At the same time OLCD retains the flexibility required for applications such as surface-integrated automotive displays.

Due to its unique properties, OLCD has the potential to transform how and where displays are used in products. The videos below give a glimpse into this innovative technology.

OLCD brings the benefits of being thin, light, shatterproof and conformable, while offering the same quality and performance as traditional glass LCDs. The mechanical advantages of plastic OLCD over glass LCD are further enhanced by the technology’s excellent optical performance, much of which originates from the extreme thinness of plastic TAC substrates compared to glass.

A flexible display has longevity, which allows it to be used in many ways. For example, a flexible LED display can be used in indoor and outdoor, as well as other indoor and outdoor displays.

Stocking a range of flexible display options for your customers will be able to find more information at the same time. LED displays are programmable and can be programmable to allows different users to enhance a brand experience.

This type of signage allows businesses to display more information and is at the right time. For your customers, there are flexible options such as flexible digital signage, which allows businesses to display products and services.

It ’ s easy to set up and allows the customers to display customized products. For your owners who own bars, restaurants or beauty salons, have a flexible range of flexible display options at Alibaba.com.

The Global Flexible Displays Market size is expected to reach $31.5 billion by 2025, rising at a market growth of 25.9% CAGR during the forecast period. Flexible displays are mainly OLED and AMOLED displays that are curved, bended, or fully foldable. Consumer electronics manufacturers have offered numerous smartphones, TV sets and other display devices in a rigid curved form factor in the current market scenario. Although these displays are curved in comparison to traditional rigid flat displays, these displays do not give the end-users true versatility.

Growth is driven by increased demand for display-based consumer electronics coupled with consumer inclination towards energy-efficient, flexible gadgets. Technological advances in display technology have resulted in the introduction of advanced flexible displays, creating opportunities for growth for the market"s key players. In terms of portability, non-fragility and weight, the superior features offered by flexible displays make them an attractive option for consumer electronics manufacturers. In addition, the adoption of flexible displays based on Organic Light Emitting Diode (OLED) is experiencing exponential growth in high-definition content and high-performance applications. In addition, market demand is propelled by high growth in the smart wearable market.

Based on Type, the market is segmented into OLED and Others. Based on Application, the market is segmented into Smartphone, Smart Wearbles, TV, E-reader, Automotive & Transportation and Others. The segment of smartphones and tablets was the largest market share in 2018. Smartphones have LED-LCD and OLED-based display panels, tablets are extended shape of smartphone and are mainly equipped with LED-LCD display panels. Due to the high demand on the consumer market, various smartphone and laptop manufacturers and suppliers have reached the tablet market. These are made more durable by using flexible displays in smartphones and tablets, as they provide sleek designs and better ergonomics to operate these devices. Based on Material Type, the market is segmented into Plastic, Glass and Others.

Based on Regions, the market is segmented into North America, Europe, Asia Pacific, and Latin America, Middle East & Africa. The presence of a large number of consumer electronics manufacturers and massive customer base is boosting the regional demand for flexible displays. Countries like Japan, South Korea, China, and India are the leaders in flexible display growth. China is the world"s largest producer of flexible OLED displays.

The major strategies followed by the market participants are Product launches and Partnerships & Collaborations. Based on the Analysis presented in the Cardinal matrix, Samsung Electronics Co., Ltd. (Samsung Group) and LG Corporation are some of the forerunners in the Flexible Display Market. The market research report covers the analysis of key stake holders of the market. Key companies profiled in the report include LG Display Co., Ltd. (LG Corporation), Samsung Electronics Co., Ltd. (Samsung Group), AU Optronics Corporation, Corning, Inc., Sharp Corporation, Kateeva, Inc., BOE Technology Group Co., Ltd., Royole Corporation, E Ink Holdings, Inc. and Visionox Technology, Inc.

Nov-2019: Sharp introduced a 30-inch 4K flexible organic LED (OLED) display in cooperation with Japan Broadcasting Corporation (NHK). This display has world’s largest color-filter-less (RGB light emission method), high-definition 4K flexible OLED display, and flexibility of film substrate that allows the display to be stored as a compact roll.

Oct-2019: Visionox Technology announced that it has collaborated with Peratech. In this, both the companies have started working on different integrations of Visionox’s AMOLED displays and Visionox’s AMOLED displays for fulfilling the needs of users for display-based interactive interfaces.

May-2019: BOE Technology announced its collaboration with Himax Technologies in which Himax launched flexible OLED automotive display driver and timing controller for BOE Technology Group. This technology of Himax has been adopted by BOE in its 12.3-inch three-unit curved flexible OLED automotive displays for cockpit areas with only 0.99 mm bezels.

Dec-2018: Royole partnered with Airbus in order to develop aircraft-cabin applications. In this partnership, both the companies will investigate the commercial opportunities and use of sensors and flexible displays on passenger aircraft.

Dec-2018: Visionox Technology and IDEX Biometrics collaborated on exploring the development of next-generation IDEX’s unique off-chip biometric sensors for smart cards that uses Visionox’s flexible LTPS TFT backplane technology. The collaboration is focused towards the development of feature-rich and cost-effective smart card systems supporting both biometric and display technologies.

Oct-2018: Visionox Technology teamed up with Hefei municipal government for constructing the factory that can produce 30,000 substrates per month. These substrates will be used in sixth-generation active matrix organic light emitting diode displays. Both are thinking of establishing a Joint Venture for building and operating the plant.

Apr-2019: LG Display acquired DuPont"s OLED business as well as its R&D and production facilities. The OLED technology uses an inkjet printing method for adding a soluble material to a panel, thus producing the high-performing displays in an economical manner and reducing the material waste.

May-2019: Corning announced the launch of Corning® Astra(TM) Glass, a new glass substrate optimized for mid-to-large size; immersive displays in notebooks, high-performance tablets, and 8K TVs. This glass has been engineered to enable the higher-pixel density of high-performance displays, which are required by panel makers in order to meet the customer demand for faster, brighter, and more lifelike images.

Feb-2019: Sharp introduced four new models of its 4K Ultra-HD resolution commercial LCD display line. These displays will be ideal for business, retail, and hospitality sectors. This helps the customers to see subtler textures and finer details in photos and videos.

Jan-2019: Samsung Display introduced its first 15.6-inch OLED panel for the notebook market. This panel delivers brighter colors and deeper blacks over 4K LCD-based screens.

Oct-2018: Royole introduced the Royole FlexPai, a commercial foldable smartphone, a combination of tablet and mobile phone with flexible screen. This smartphone is based upon Royole"s Flexible+ platform; this can be easily combined into a number of products and applications across different industries.

We will make just about every exertion for being excellent and perfect, and speed up our actions for standing during the rank of worldwide top-grade and high-tech enterprises for Flexible Lcd Screen, Tft Flat Screen Monitor, Lcd Display Module, Lcd Blackout Panel,Lcd Frame. We look forward to supplying you with our products in the near future, and you will find our quotation is very reasonable and the quality of our products is very excellent! The product will supply to all over the world, such as Europe, America, Australia,Lesotho, Nigeria,Egypt, Madras.They"re durable modeling and promoting effectively all over the world. Under no circumstances disappearing major functions in a quick time, it"s a should for you of excellent good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the company make a terrific efforts to expand its international trade, raise its company profit and raise its export scale. We"re confident that we are going to possess a vibrant prospect and to be distributed all over the world within the years to come.

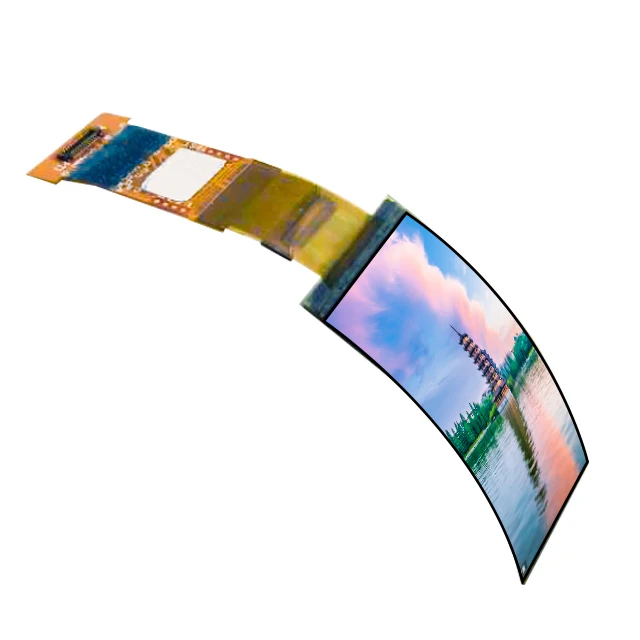

Since OLEDs are self-emissive displays, they don"t require backlight units like LCD displays. OLEDs have many outstanding characteristics such as thin and flexible form factor, lightweight, high image quality.

In particular, flexible OLED displays, which use flexible substrates such as polyimide instead of glass, are foldable or rollable, so demand is increasing mainly for mobile devices.

A backplane consisting of TFTs (thin film transistor circuit) and banks (partition wall for an organic light emitting layer) is formed on a flexible substrate.

A flexible display or rollable display is an electronic visual display which is flexible in nature, as opposed to the traditional flat screen displays used in most electronic devices.e-readers, mobile phones and other consumer electronics. Such screens can be rolled up like a scroll without the image or text being distorted.electronic ink, Gyricon, Organic LCD, and OLED.

Electronic paper displays which can be rolled up have been developed by E Ink. At CES 2006, Philips showed a rollable display prototype, with a screen capable of retaining an image for several months without electricity.pixel rollable display based on E Ink’s electrophoretic technology.flexible organic light-emitting diode displays have been demonstrated.electronic paper wristwatch. A rollable display is an important part of the development of the roll-away computer.

With the flat panel display having already been widely used more than 40 years, there have been many desired changes in the display technology, focusing on developing a lighter, thinner product that was easier to carry and store. Through the development of rollable displays in recent years, scientists and engineers agree that flexible flat panel display technology has huge market potential in the future.

Flexible electronic paper (e-paper) based displays were the first flexible displays conceptualized and prototyped. Though this form of flexible displays has a long history and were attempted by many companies, it is only recently that this technology began to see commercial implementations slated for mass production to be used in consumer electronic devices.

The concept of developing a flexible display was first put forth by Xerox PARC (Palo Alto Research Company). In 1974, Nicholas K. Sheridon, a PARC employee, made a major breakthrough in flexible display technology and produced the first flexible e-paper display. Dubbed Gyricon, this new display technology was designed to mimic the properties of paper, but married with the capacity to display dynamic digital images. Sheridon envisioned the advent of paperless offices and sought commercial applications for Gyricon.

In 2005, Arizona State University opened a 250,000 square foot facility dedicated to flexible display research named the ASU Flexible Display Center (FDC). ASU received $43.7 million from the U.S. Army Research Laboratory (ARL) towards the development of this research facility in February 2004.demonstration later that year.Hewlett Packard demonstrated a prototype flexible e-paper from the Flexible Display Center at the university.

Between 2004–2008, ASU developed its first small-scale flexible displays.U.S. Army funds ASU’s development of the flexible display, the center’s focus is on commercial applications.

This company develops and manufactures monochrome plastic flexible displays in various sizes based on its proprietary organic thin film transistor (OTFT) technology. They have also demonstrated their ability to produce colour displays with this technology, however they are currently not capable of manufacturing them on a large scale.Dresden, Germany, which was the first factory of its kind to be built – dedicated to the high volume manufacture of organic electronics.plastic and do not contain glass. They are also lighter and thinner than glass-based displays and low-power. Applications of this flexible display technology include signage,wristwatches and wearable devices

In 2004, a team led by Prof. Roel Vertegaal at Queen"s University"s Human Media Lab in Canada developed PaperWindows,Organic User Interface. Since full-colour, US Letter-sized displays were not available at the time, PaperWindows deployed a form of active projection mapping of computer windows on real paper documents that worked together as one computer through 3D tracking. At a lecture to the Gyricon and Human-Computer Interaction teams at Xerox PARC on 4 May 2007, Prof. Vertegaal publicly introduced the term Organic User Interface (OUI) as a means of describing the implications of non-flat display technologies on user interfaces of the future: paper computers, flexible form factors for computing devices, but also encompassing rigid display objects of any shape, with wrap-around, skin-like displays. The lecture was published a year later as part of a special issue on Organic User InterfacesCommunications of the ACM. In May 2010, the Human Media Lab partnered with ASU"s Flexible Display Center to produce PaperPhone,MorePhone

Research and development into flexible OLED displays largely began in the late 2000s with the main intentions of implementing this technology in mobile devices. However, this technology has recently made an appearance, to a moderate extent, in consumer television displays as well.

Nokia first conceptualized the application of flexible OLED displays in mobile phone with the Nokia Morph concept mobile phone. Released to the press in February 2008, the Morph concept was project Nokia had co-developed with the University of Cambridge.nanotechnology, it pioneered the concept of utilizing a flexible video display in a consumer electronics device.London, alongside Nokia’s new range of Windows Phone 7 devices.

Sony Electronics expressed interest for research and development towards a flexible display video display since 2005.RIKEN (the Institute of Physical and Chemical Research), Sony promised to commercialize this technology in TVs and cellphones sometime around 2010.TFT-driven OLED display.

In January 2013, Samsung exposed its brand new, unnamed product during the company"s keynote address at CES in Las Vegas. Brian Berkeley, the senior vice president of Samsung"s display lab in San Jose, California had announced the development of flexible displays. He said "the technology will let the company"s partners make bendable, rollable, and foldable displays," and he demonstrated how the new phone can be rollable and flexible during his speech.

During Samsung"s CES 2013 keynote presentation, two prototype mobile devices codenamed "Youm" that incorporated the flexible AMOLED display technology were shown to the public.OLED screen giving this phone deeper blacks and a higher overall contrast ratio with better power efficiency than traditional LCD displays.LCD displays. Samsung stated that "Youm" panels will be seen in the market in a short time and production will commence in 2013.

The Flexible Display Center (FDC) at Arizona State University announced a continued effort in forwarding flexible displays in 2012.Army Research Lab scientists, ASU announced that it has successfully manufactured the world"s largest flexible OLED display using thin-film transistor (TFTs) technology.

Flexible displays have many advantages over glass: better durability, lighter weight, thinner as plastic, and can be perfectly curved and used in many devices.glass and rollable display is that the display area of a rollable display can be bigger than the device itself; If a flexible device measuring, for example, 5 inches in diagonal and a roll of 7.5mm, it can be stored in a device smaller than the screen itself and close to 15mm in thickness.

Flexible screens can open the doors to novel and alternative authentication schemes by emphasizing the interaction between the user and the touch screen. In “Bend Passwords: Using Gestures to Authenticate on Flexible Devices,” the authors introduce a new method called Bend Passwords where users perform bending gestures and deform the touch screen to unlock the phone. Their work and research points to Bend Passwords possibly becoming a new way to keep smartphones secure alongside the popularization of flexible displays.

Flexible displays using electronic paper technology commonly use Electrophoretic or Electrowetting technologies. However, each type of flexible electronic paper vary in specification due to different implementation techniques by different companies.

The flexible electronic paper display technology co-developed by Arizona State University and HP employs a manufacturing process developed by HP Labs called Self-Aligned Imprint Lithography (SAIL).

The flexible electronic paper display announced by AUO is unique as it is the only solar powered variant. A separate rechargeable battery is also attached when solar charging is unavailable.

Many of the e-paper based flexible displays are based on OLED technology and its variants. Though this technology is relatively new in comparison with e-paper based flexible displays, implementation of OLED flexible displays saw considerable growth in the last few years.

In May 2011, Human Media Lab at Queen"s University in Canada introduced PaperPhone, the first flexible smartphone, in partnership with the Arizona State University Flexible Display Center.

At CES 2013, Samsung showcased the two handsets which incorporates AMOLED flexible display technology during its keynote presentation, the Youm and an unnamed Windows Phone 8 prototype device.Galaxy Note Edge,Samsung Galaxy S series devices.

Crawford, Gregory P., ed. (2005). Flexible flat panel displays (Reprinted with corrections. ed.). Chichester, West Sussex, England: John Wiley & Sons. p. 2. ISBN 978-0470870488.

Thryft, Ann R. (7 June 2012). "All-Plastic Electronics Power Flexible Color Display". Design News. Archived from the original on 31 March 2019. Retrieved 24 April 2013.

Lahey, Byron; Girouard, Audrey; Burleson, Winslow and Vertegaal, Roel (May 2011). PaperPhone: Understanding the Use of Bend Gestures in Mobile Devices with Flexible Electronic Paper Displays, Proceedings of the SIGCHI Conference on Human Factors in Computing Systems, Pages 1303–1312.

Gomes, A., Nesbitt, A., and Vertegaal, R. (2013) MorePhone: A Study Of Actuated Shape Deformations for Flexible Thin-Film Smartphone Notifications. In Proceedings of ACM CHI’13 Conference on Human Factors in Computing. ACM Press, 2013, pp. 583–592.

Lee, Reuben (10 January 2013). "Samsung shows off flexible display phones at CES keynote". CNET. Archived from the original on 17 February 2013. Retrieved 12 February 2013.

Lowensohn, Josh (9 January 2013). "Eyes-on: Samsung"s Youm flexible-display tech at CES 2013". CNET. Archived from the original on 26 November 2013. Retrieved 12 February 2013.

Electronics on Plastic by Laser Release (EPLaR) is a method for manufacturing flexible electrophoretic displays using conventional AM-LCD manufacturing equipment, avoiding the need to build new factories. The technology can also be used to manufacture flexible OLED displays using standard OLED fabrication facilities.

The technology was developed by Philips Research and uses standard display glass as used in TFT-LCD processing plants. It is coated with a layer of polyimide using a standard spin-coating procedure used in the production of AM-LCD displays. This polyimide coating can now have a regular TFT matrix formed on top of it in a standard TFT processing plant to form the plastic display, which can then be removed using a laser to finish the display and the glass reused, thus lowering the total cost of manufacture.

The EPLaR process is licensed by Philips for use by Taiwan"s Prime View International in its TFT manufacturing plants for manufacture of flexible plastic displays.

Dublin, Jan. 23, 2020 (GLOBE NEWSWIRE) -- The "Global Flexible Display Market (2019-2025)" report has been added to ResearchAndMarkets.com"s offering.

The Global Flexible Displays Market size is expected to reach $31.5 billion by 2025, rising at a market growth of 25.9% CAGR during the forecast period.

Growth is driven by increased demand for display-based consumer electronics coupled with consumer inclination towards energy-efficient, flexible gadgets. Technological advances in display technology have resulted in the introduction of advanced flexible displays, creating opportunities for growth for the market"s key players.

In terms of portability, non-fragility and weight, the superior features offered by flexible displays make them an attractive option for consumer electronics manufacturers. In addition, the adoption of flexible displays based on Organic Light Emitting Diode (OLED) is experiencing exponential growth in high-definition content and high-performance applications. In addition, market demand is propelled by high growth in the smart wearable market.

Smartphones have LED-LCD and OLED-based display panels, tablets are extended shape of smartphone and are mainly equipped with LED-LCD display panels. Due to the high demand on the consumer market, various smartphone and laptop manufacturers and suppliers have reached the tablet market. These are made more durable by using flexible displays in smartphones and tablets, as they provide sleek designs and better ergonomics to operate these devices.

Based on Regions, the market is segmented into North America, Europe, Asia Pacific, and Latin America, Middle East & Africa. The presence of a large number of consumer electronics manufacturers and massive customer base is boosting the regional demand for flexible displays. Countries like Japan, South Korea, China, and India are the leaders in flexible display growth. China is the world"s largest producer of flexible OLED displays.

The major strategies followed by the market participants are Product launches and Partnerships & Collaborations. Based on the Analysis presented in the Cardinal matrix, Samsung Electronics Co., Ltd. (Samsung Group) and LG Corporation are some of the forerunners in the Flexible Display Market.

Partnerships, Collaborations & Agreements Nov-2019: Sharp introduced a 30-inch 4K flexible organic LED (OLED) display in cooperation with Japan Broadcasting Corporation (NHK). This display has world"s largest color-filter-less (RGB light emission method), high-definition 4K flexible OLED display, and flexibility of film substrate that allows the display to be stored as a compact roll.

Oct-2019: Visionox Technology announced that it has collaborated with Peratech. In this, both the companies have started working on different integrations of Visionox"s AMOLED displays and Visionox"s AMOLED displays for fulfilling the needs of users for display-based interactive interfaces.

May-2019: BOE Technology announced its collaboration with Himax Technologies in which Himax launched flexible OLED automotive display driver and timing controller for BOE Technology Group. This technology of Himax has been adopted by BOE in its 12.3-inch three-unit curved flexible OLED automotive displays for cockpit areas with only 0.99 mm bezels.

Acquisition & Mergers Apr-2019: LG Display acquired DuPont"s OLED business as well as its R&D and production facilities. The OLED technology uses an inkjet printing method for adding a soluble material to a panel, thus producing the high-performing displays in an economical manner and reducing the material waste.

May-2019: Corning announced the launch of Corning Astra(TM) Glass, a new glass substrate optimized for mid-to-large size; immersive displays in notebooks, high-performance tablets, and 8K TVs. This glass has been engineered to enable the higher-pixel density of high-performance displays, which are required by panel makers in order to meet the customer demand for faster, brighter, and more lifelike images.

Feb-2019: Sharp introduced four new models of its 4K Ultra-HD resolution commercial LCD display line. These displays will be ideal for business, retail, and hospitality sectors. This helps the customers to see subtler textures and finer details in photos and videos.

Jan-2019: Samsung Display introduced its first 15.6-inch OLED panel for the notebook market. This panel delivers brighter colors and deeper blacks over 4K LCD-based screens.

The present disclosure relates to liquid crystal display technology, and more particularly to a manufacturing method of flexible display panels, a flexible glass substrate, and a flexible display panel.

Flexible display devices are also called as roll-up displays, which are display devices that may be arbitrarily bent and deformed and are made by flexible materials. The flexible displays may include e-paper, flexible liquid crystal devices, and Organic Light-Emitting Diode (OLED) displays, and are characterized by attributes such as light, small, thin, portable, anti-high and low temperature, anti-vibration, and may be well adapted to environment.

The OLED devices include the attributes such as self-luminescent, high brightness, wide viewing angle, high brightness, flexible and low power consumption, and are widely adopted by panels of cellular phones, computer, and televisions. The OLED display technology adopts very thin organic material emitting layer and flexible substrate. When current passes by, the organic material may emit lights. However, as the organic material may react with water and oxygen, water vapors and oxygen may damage the organic materials and the luminescent performance may be affected. Thus, flexible OLED displays are demanded to include good flexible and barrier property subject to the water and the oxygen.

Currently, the manufacturing method of flexible OLED devices may adopt the plastic substrate of polymer to form an organic film on the plastic substrate and to form a TFT and OLED device layer. In the end, the organic/inorganic materials are stacked to form a thin film package. However, most of the plastic substrate of polymer material are fragile to the high-temperature process. In addition, the requirement of forming the inorganic thin film having enough water-blocking capability increases the difficulty of the manufacturing process. Another solution is to adopt the flexible glass substrate. The flexible glass substrate owns a better surface characteristics and has excellent high temperature performance. In addition, the water-blocking capability of the flexible glass substrate is good, and thus the inorganic thin film is not needed, which simplifies the manufacturing process. However, the flexible glass substrate is fragile. Not only the quality of the product is affected, but also the yield rate and the application of the products are limited. SUMMARY

The object of the invention is to provide a manufacturing method of flexible display panels, a flexible glass substrate, and a flexible display panel to avoid the performance issue caused by the fragile flexible glass substrate.

In one aspect, a manufacturing method of flexible display panels includes: forming a TFT layer at one side of a flexible glass substrate; forming a polymer enhanced layer at the other side of the flexible glass substrate; curing the polymer enhanced layer; forming a display layer on the TFT layer; and forming an encapsulation layer on the side of the flexible glass substrate where the TFT layer is located.

In another aspect, a flexible display panel includes: a TFT layer, a display layer, an encapsulation layer and a flexible glass substrate; and wherein a polymer enhanced layer is formed at one side of the flexible glass substrate, and the TFT layer is arranged at the other side of the flexible glass substrate opposite to the polymer enhanced layer, the display layer is arranged on the TFT layer, and an encapsulation layer is arranged on the side of the flexible glass substrate where the TFT layer is located.

In view of the above, the polymer enhanced layer at one side of the flexible glass substrate. As the polymer material owns the attributes such as strong flexibility, high compressive resistance, and high mechanical strength, these prevent the stress from being centralized so as to overcome the fragile issue of flexible glass substrate. In addition, the compressive strength of the flexible glass substrate is enhanced. As such, the attributes of the flexible glass including anti-high-temperature, good surface characteristics, and good water blocking capability are achieved. At the same time, the flexibility and high pressure resistance are obtained. Further, the encapsulation efficiency and the display performance of the flexible display panel are enhanced. Also, by configuring the polymer enhanced layer at one side of the flexible glass substrate, there are a variety of methods may be selected in the subsequent process. BRIEF DESCRIPTION OF THE DRAWINGS

FIGS. 1 and 2 illustrate the manufacturing method of the flexible display panel in accordance with one embodiment. The method includes the following steps.

The flexible glass substrate 10 may be a thin and transparent glass, which may be bent easily by human. The thin film transistor (TFTs) are configured for driving liquid crystal pixels on the panel.

The glass is a typical brittle material. Although the flexible glass may be bent, but the compression strength of the flexible glass is still low. Defects exist in the surface and the internal of the flexible glass, and crack may expand when being subject to external forces and environmental media.

Thus, by forming the polymer enhanced layer 12 at one side of the flexible glass substrate 10, the polymer enhanced layer 12 may be adhered to the 10 may be adhered to the flexible glass substrate 10. In this way, the flexibility of the polymer may enhance the performance of the flexible glass by increasing the anti-pressure capability.

In the present disclosure, the TFT layer 11 is formed at one side of the flexible glass substrate 10, and the polymer enhanced layer 12 is formed at the other side of the flexible glass substrate 10. This prevents the polymer enhanced layer 12 from being damaged by the TFT high-temperature manufacturing process. In addition, as no high-temperature manufacturing process is needed in the following process, the glass substrate and the polymer layer are prevented from being detached from each other due to different coefficients of expansion.

For instance, the polymer enhanced layer 12 may be PET, PI, or epoxy resin. For instance, PET may be polyethylene terephthalate, which owns attributes such as great mechanical property, high impact strength, good folding resistance, anti-high and low temperature, and low penetration rate with respect to gas and vapors. That is, the PET owns great performance with respect to oxygen, water, oil, and smell. In addition, the transparency of PET is high, which may block ultraviolet rays. Thus, by adopting the PET to be the polymer enhanced layer 12, not only the anti-pressure capability of the flexible glass may be enhanced, but also the performance of the flexible glass substrate 10 subject to water, high and low temperature may also be enhanced. In addition, the transparency and gloss of the flexible glass are not affected. Polyimide (PI) owns the attributes such as anti-abrasion, anti-high-temperature, and high impact resistance. Epoxy resin owns good physical and chemical performance. For instance, epoxy resin owns great bonding strength toward metal or nonmetal. In addition, epoxy resin owns good flexibility. It can be understood that the polymer enhanced layer 12 may be other polymer materials having good flexibility, high adhesivity, and high compressive resistance.

The polymer enhanced layer 12 may be cured by, such as, backing or by radiation via UV rays. In the embodiment, the polymer enhanced layer 12 may be PET on the flexible glass substrate 10, and is cured by UV rays

In the embodiment, the display layer 13 is the OLED layer. In particular, the OLED layer may include an anode metal layer, an organic layer and a cathode metal layer. OLED may be formed by ink-jet printing or vacuum evaporation, and the OLED layer is formed on the TFT layer 11 by film formation. The ink-jet printer may include system controller, inkjet controller, spray nozzle, and driving mechanism of print substrate. The organic objects are ejected out, when being controlled by the inkjet controller, and then are printed on the print substrate. It can be understood the display layer 13 may be the corresponding display panel for the flexible display e-paper or flexible display panel.

In block S104, an encapsulation layer 14 is formed at one side of the flexible glass substrate 10 where the TFT layer 11 is located. As the blocking capability of the flexible glass substrate 10 subject to the water and oxygen is relatively low when being compared with the rigid glass substrate, the flexible glass substrate 10 has to be effectively encapsulated. In particular, the encapsulation layer 14 may be formed by surface encapsulation or thin-film encapsulation, wherein the thin-film encapsulation may include stacking the inorganic or organic materials. The packing material may be SiNx/SiOC/SiNx. The method is accomplished by depositing the thin film having the blocking capability with respect to water and oxygen when the temperature is low. Regarding the surface encapsulation, solid glue having high water-blocking capability is adhered to the encapsulation cover, and then is bonded with the substrate to accomplish the encapsulation.

In view of the above, the polymer enhanced layer at one side of the flexible glass substrate. As the polymer material owns the attributes such as strong flexibility, high compressive resistance, and high mechanical strength, these prevent the stress from being centralized so as to overcome the fragile issue of flexible glass substrate. In addition, the compressive strength of the flexible glass substrate is enhanced. As such, the attributes of the flexible glass including anti-high-temperature, good surface characteristics, and good water blocking capability are achieved. At the same time, the flexibility and high pressure resistance are obtained. Further, the encapsulation efficiency and the display performance of the flexible display panel are enhanced. Also, by configuring the polymer enhanced layer at one side of the flexible glass substrate, there are a variety of methods may be selected in the subsequent process.

FIGS. 2 and 3 are flowcharts illustrating the manufacturing method of the flexible display panels in accordance with another embodiment. The method includes the following steps.

In block S201, a PI enhanced layer is formed at the other side of the flexible glass substrate. In particular, the PI enhanced layer is formed by sputtering.

In block S204, an encapsulation layer is formed at one side of the flexible glass substrate where the TFT layer is located. In the embodiment, the encapsulation is formed by SiNx/SiOC/SiNx via the thin-film encapsulation.

In one embodiment, a flexible glass substrate, as shown in FIG. 4, is provided. A polymer enhanced layer 32 is formed at one side of the flexible glass substrate 30.

Specifically, the polymer enhanced layer 32 may be PET, PI, or epoxy resin. The polymer enhanced layer 32 may be formed on the flexible glass substrate 30 by one of the spin-coating, sputtering, spray coating and screen printing.

In one embodiment, a flexible display panel, as shown in FIG. 5, includes a TFT layer 41, a display layer 43, an encapsulation layer 44 and a flexible glass substrate 40, wherein one side of the flexible glass substrate 40 includes a polymer enhanced layer 42.

The TFT layer 41 is arranged on one side of the flexible glass substrate 40 that is opposite to the side where the polymer enhanced layer 42 is located. The display layer 43 is arranged on the TFT layer 41. The encapsulation layer 44 is arranged at one side of the flexible glass substrate 40 where the TFT layer 41 is located.

Specifically, the polymer enhanced layer 42 may be PET, PI, or epoxy resin. The polymer enhanced layer 42 may be formed on the flexible glass substrate 40 by one of the spin-coating, sputtering, spray coating and screen printing. The display layer 43 may be the OLED layer.

Flat panel displays use different backplane technologies. Small and medium OLEDs for mobile phones use a low temperature polysilicon (LTPS) backplane which is created by laser annealing amorphous silicon (a-Si). OLED TVs use a metal oxide backplane. Both backplanes use deposited thin films which must be highly uniform and contamination free to maximize electrical performance. The OLEDs are evaporated or deposited and encapsulated to reduce degradation caused by water vapor and oxygen exposure. Encapsulation uses either strengthened glass or thin films, depending on whether the OLED is rigid or flexible. Dissimilarity of materials within the rigid and flexible stacks make cutting and singulation of individual display devices a challenge. The highly complex nature of this process can induce defects, decreasing throughput and yield.

Our industrial femtosecond and picosecond display manufacturing lasers are excellent for glass and film cutting. For cover glass and rigid OLED, they provide flexible pulse and burst control with precision, resulting in a micro-crack, chip-free edge, making the glass stronger and less likely to break if dropped. This reduces the need for post-cut polishing, increasing throughput by reducing the number of manufacturing process steps. For flexible OLEDs, Spectra-Physics lasers with short pulse widths create a minimal heat affected zone and provide a clean cut through layers of dissimilar materials including various thin films, PET, and adhesives. Increased throughput is achieved from higher output power that speeds up the cutting process. The narrow kerf or cut and the low heat affected zone means more parts can be cut out of the same material.

Flexible LED displays panels are made of premium PCB and rubber material. Extremely soft, suitable for creative installations in any size and shape. Features compact design, 5 mm thickness, and magnetic connections. Easily fixed anywhere, including shopping centers, hotels, stadiums, etc. Viewpointec is devoted to providing the best flexible LED screen solutions.

We are professionalflexible LED screen manufacturerswith over 25 years of experience. No design is too complex and no project is too large for us to implement. Our team will work closely in consultation with you and other relevant project consultants to deliver stunningflexible LED screen displays.

Further, Viewpointec flexible LED displays are produced from our very ownflexible video wall factory.This gives us full control over production and enables us to maintain high quality standards. We also have the capacity to produce flexible LED screens in bulk and in any size that your display may require.

A flexible LED screen is made up of LED pixels pitched on a pliable material like rubber or PCB. It is insulated using a flexible transparent material on both sides to protect the LED circuit from getting damaged. This structure makes flexible LED screens highly resilient. They can be contorted during installation and still deliver crisp images.

A flexible video wall consists of manyfoldable LED screensmounted together. It can take different shapes depending on how the individual screens are arranged. The flexible LED screen display panels are joined using magnets along their borderlines to create a seamless video wall display.

We offer flexible LED displays that are tailor-made to fit in your space and captivate audiences. Whether it’s a 3D gaming lounge or a conference, you can rely on our flexible LED screens to deliver high-resolution images at all times. They are available in different dimensions and pixel pitch options depending on your needs.

Viewpointec flex LED screen modules are made of durable lightweight rubber. They are easy to install and can be mounted as far as 15 meters from a remote power source to provide you with more installation options. Additionally, we can create customized flex tiles for you that are trimmed and tilted in special angles for even more adventurous displays.

A giant curved LED advertising screen is a great choice when you need to reach a wide audience from a focal point. We can help you achieve this by custom-making one to your preferred size and design. It would comprise several standard-sized flexible LED screens mounted together to form a seamless giant curved LED display.

Our giant curved LED advertising screens are lightweight and display dynamic images in true Viewpointec style. They can be mounted on their own or supported by a custom frame. Further, all the flexible screens that make up the giant curved advertising screen have internal thermal management. This makes the giant advertising screen more durable as the LEDs would not overheat even with long durations of use.

Our flexible LED screens thrive in indoor setups of different kinds. They display bright, high-contrast images with distinct clarity. Moreover, they are versatile enough and can be installed in hallways, meeting rooms,display windows, or even hanging from a ceiling. If you are looking to catch your customers’ attention, this would certainly be an effective solution for you.

Viewpointec supplies flexible LED displays in China and to clients across the world. Our indoor LED advertising displays are affordable and customizable to suit any premises. We also guarantee you impeccable service and timely delivery on all the projects that you entrust us with.

When it comes to boosting your business, one of the best tools to invest in is a flexible LED display. These LED displays are designed to feature LED pixels on a rubber or PCB material and are used to display eye-catching images.

You also have the option of investing in a flexible video wall that makes it easier to run ads and other materials. These LED displays come in handy when attracting new clients to your business and are designed to communicate what you offer. Investing in these displays proves to be beneficial in a variety of ways that you should take advantage of.

Flexible LED displays are designed in such a way that they offer the best images and videos. The quality featured on these displays allows you to let your creativity shine through. You get to easily work on designs that are aligned with your business and the products or services you offer.

These displays provide the perfect platform for you to showcase the designs and let others into your business. Given that you can easily customize the pixel pitch and brightness on these displays, creating great designs is quite easy. They give you great flexibility and allow you to experiment with different designs to see what works for you.

Flexible LEDs panels come in handy when you are looking to attract new customers to your business. They offer you a great opportunity to showcase your products and services to let people know more about you. For this, the best way to capture the attention of the viewers is by crafting an irresistible offer.

Alongside the incredible images and designs, tell your prospective clients what they stand to gain once they visit your business. This is a great way to advertise your business and reach out to a whole new group of potential clients. Your displays will offer the perfect platform for you to do this and attract more people and business to you.

As a business, finding cost-effective solutions is always number one on the list. This is where flexible displays come in. They are designed to be budget-friendly and great investments overall.

They offer great returns on investment when used right by attracting potential customers to your business. Given that all the Viewpointec LED displays are manufactured in-house, we can offer more competitive prices. Our LED displays will offer great quality images and videos for a friendly price allowing you to implement them in your business.

Flexible LED displays come with a straightforward implementation that does not require you to jump through the hoops. They are very easy to install which means that you can set them up yourself. They come mounted on a solid substrate that allows them to take up the desired space you are working with.

Different displays have different characteristics, just tell Panox Display your application, and operating environment, Panox Display will suggest a suitable display for you.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey