thin-film transistor tft display made in china

Orient Display sunlight readable TFT displays can be categorized into high brightness TFT displays, high contrast IPS displays, transflective TFT displays, Blanview TFT displays etc.

The brightness of our standard high brightness TFT displays can be from 700 to 1000 nits. With proper adding brightness enhancement film (BEF) and double brightness enhancement film (DBEF) and adjustment of the LED chips, Orient Display high brightness TFT products can achieve 1,500 to 2,000 nits or even higher luminance. Orient Display have special thermal management design to reduce the heat release and largely extend LED life time and reduce energy consumption.

Our high contrast and wide viewing angle IPS displays can achieve contrast ratio higher than 1000:1 which can make readability under strong sunlight with lower backlight luminance. High brightness IPS displays have been widely accepted by our customers with its superb display quality and it has become one of the best sellers in all our display category.Transflective display is an old monochrome display technology but it has been utilized in our color TFT line for sunlight readable application. Orient Display has 2.4” and 3.5” to choose from.

Blanview TFT displays are the new technology developed by Ortustech in Japan. It can provide around 40% of energy consumption for TFT panels which can use smaller rechargeable or disposable batteries and generate less heat. The price is also lower than traditional transflective TFT displays. Orient Display is partnering with the technology inventor to provide 4.3” and 5.0”.

Orient Display can also provide full customized or part customized solutions for our customers to enhance the viewing experience. Orient Display can provide all the different kinds of surface treatments, such as AR (Anti-reflection); AG (Anti-glare), AF (Anti-finger print or Anti-smudge); AS (Anti-smashing); AM (Anti-microbial) etc. Orient Display can also provide both dry bonding (OCA, Optical Clear Adhesive), or wet bonding (OCR, Optical Clear Resin and OCG, Optical Clear Glue) to get rid of light reflective in air bonding products to make the products much more readable under sunlight and be more robust.

Touch panels have been a much better human machine interface which become widely popular. Orient Display has been investing heavy for capacitive touch screen sensor manufacturing capacity. Now, Orient Display factory is No.1 in the world for automotive capacitive touch screen which took around 18% market share in the world automotive market.

Based on the above three types of touch panel technology, Orient Display can also add different kinds of features like different material glove touch, water environment touch, salt water environment touch, hover touch, 3D (force) touch, haptic touch etc. Orient Display can also provide from very low cost fixed area button touch, single (one) finger touch, double finger (one finger+ one gesture) touch, 5 finger touch, 10 points touch or even 16 points touch.

Considering the different shapes of the touch surface requirements, Orient Display can produce different shapes of 2D touch panel (rectangle, round, octagon etc.), or 2.5D touch screen (round edge and flat surface) or 3D (totally curved surface) touch panel.

Considering different strength requirements, Orient Display can provide low cost chemical tampered soda-lime glass, Asahi (AGC) Dragontrail glass and Corning high end Gorilla glass. With different thickness requirement, Orient Display can provide the thinnest 0.5mm OGS touch panel, to thickness more than 10mm tempered glass to prevent vandalizing, or different kinds of plastic touch panel to provide glass piece free (fear) or flexible substrates need.

Of course, Orient Display can also offer traditional RTP (Resistive Touch Panel) of 4-wire, 5-wire, 8-wire through our partners, which Orient Display can do integration to resistive touch screen displays.

Engineers are always looking for lower cost, faster, more convenient interfaces to transmit signals and to accept data and commands. The numbers of available interfaces available in the market can be dazzling. Orient Display follows market trends to produce various kind of interfaces for our customers to choose.

Genetic Interfaces: Those are the interfaces which display or touch controller manufacturers provide, including parallel, MCU, SPI(,Serial Peripheral Interface), I2C, RGB (Red Green Blue), MIPI (Mobile Industry Processor Interface), LVDS (Low-Voltage Differential Signaling), eDP ( Embedded DisplayPort) etc. Orient Display has technologies to make the above interface exchangeable.

High Level Interfaces: Orient Display has technologies to make more advanced interfaces which are more convenient to non-display engineers, such as RS232, RS485, USB, VGA, HDMI etc. more information can be found in our serious products. TFT modules, Arduino TFT display, Raspberry Pi TFT display, Control Board.

Our organization promises all customers with the first-class products and solutions and the most satisfying post-sale service. We warmly welcome our regular and new clients to join us for Thin Film Transistor Monitor, Lcd Screen Panel, Marine Lcd Monitor, Interactive Screens,Touch Screen Display Module. We focus on for making superb top quality goods to provide support for our purchasers to ascertain long-term win-win romantic relationship. The product will supply to all over the world, such as Europe, America, Australia,Spain, Burundi,Mexico, Greek.The company attaches great importance to product quality and service quality, based on the business philosophy "good with people, genuine to whole world, your satisfaction is our pursuit". we design products, According to customer"s sample and requirements, to meet the needs of the market and offer different customers with personalized service. Our company warmly welcomes friends at home and abroad to visit, to discuss cooperation and seek common development!

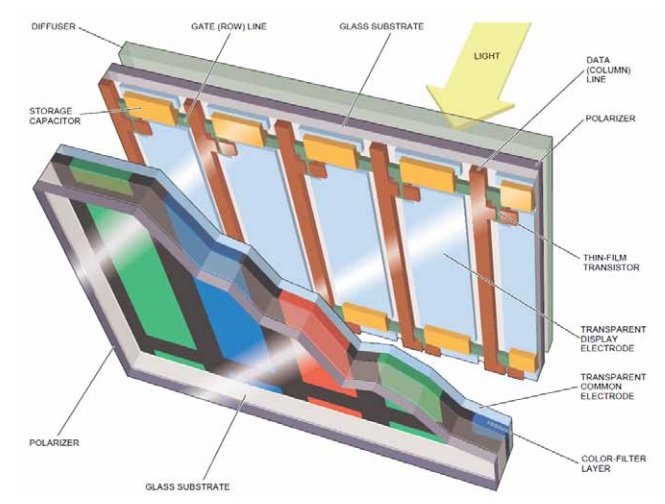

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

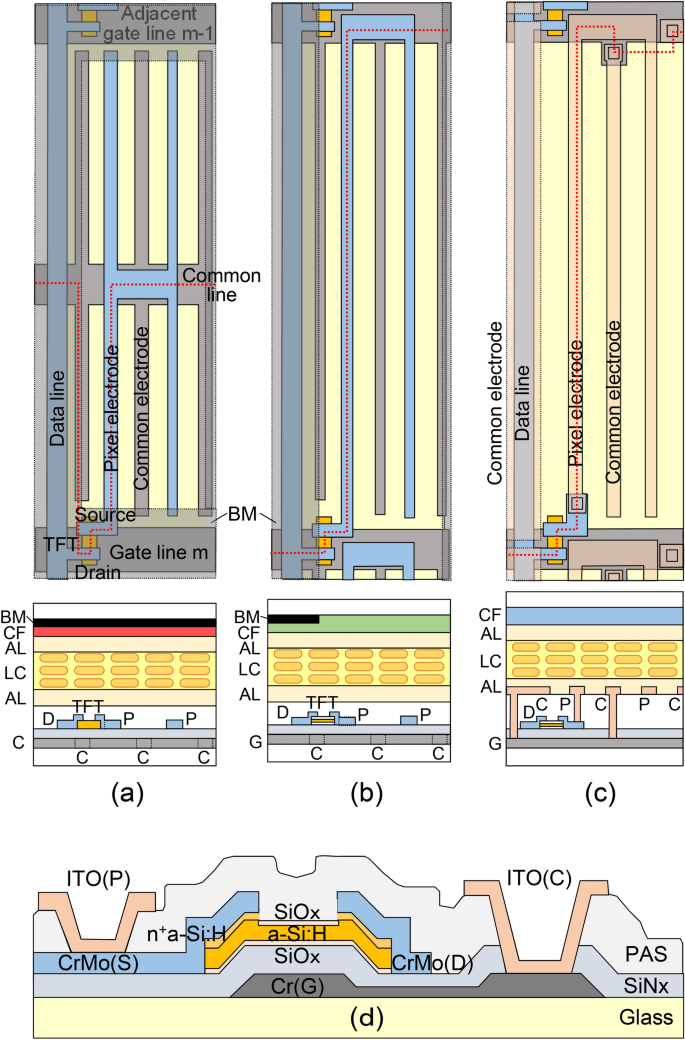

The liquid crystal displays used in calculators and other devices with similarly simple displays have direct-driven image elements, and therefore a voltage can be easily applied across just one segment of these types of displays without interfering with the other segments. This would be impractical for a large display, because it would have a large number of (color) picture elements (pixels), and thus it would require millions of connections, both top and bottom for each one of the three colors (red, green and blue) of every pixel. To avoid this issue, the pixels are addressed in rows and columns, reducing the connection count from millions down to thousands. The column and row wires attach to transistor switches, one for each pixel. The one-way current passing characteristic of the transistor prevents the charge that is being applied to each pixel from being drained between refreshes to a display"s image. Each pixel is a small capacitor with a layer of insulating liquid crystal sandwiched between transparent conductive ITO layers.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan"s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

With analogue signals like VGA, the display controller also needs to perform a high speed analog to digital conversion. With digital input signals like DVI or HDMI some simple reordering of the bits is needed before feeding it to the rescaler if the input resolution doesn"t match the display panel resolution.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Kim, Sae-Bom; Kim, Woong-Ki; Chounlamany, Vanseng; Seo, Jaehwan; Yoo, Jisu; Jo, Hun-Je; Jung, Jinho (15 August 2012). "Identification of multi-level toxicity of liquid crystal display wastewater toward Daphnia magna and Moina macrocopa". Journal of Hazardous Materials. Seoul, Korea; Laos, Lao. 227–228: 327–333. doi:10.1016/j.jhazmat.2012.05.059. PMID 22677053.

China"s first 8.5-generation TFT-LCD production line was launched in Bengbu, East China"s Anhui province, on June 18, 2019, representing a breakthrough in the production of high-definition LCD screen, Science and Technology Daily reported.

TFT-LCD, or Thin Film Transistor Liquid Crystal Display, is key strategic material of the electronic information display industry. The Gen 8.5 TFT-LCD production line, launched by the Bengbu Glass Industry Design and Research Institute of the China National Building Material Group, will produce high-definition LCD screens of 55 inches, the report said.

According to the Liquid Crystal Branch of the China Optics and Optoelectronics Manufactures Association, the demand for TFT-LCD in the Chinese mainland was about 260 million square meters in 2018, including 233 million square meters" Gen 8.5 TFT-LCD. However, the annual supply of domestically made TFT-LCD is less than 40 million square meters, with all of them Gen 6 or below, which cannot meet the demand in scale and quantity.

The association predicted that China"s market demand for Gen 8.5 TFT-LCD or above will exceed 300 million square meters by 2020, accounting for 49.6 percent of the total global demand.

The production and control precision of Gen 8.5 TFT-LCD is comparable to that of the semiconductor industry, representing a higher level of large-scale manufacturing of modern glass industry.

The institute in Bengbu, with 60 years of expertise in glass, has finally made a breakthrough in the production of Gen 8.5 TFT-LCD, and will provide key raw material guarantee for China"s LCD panel industry after it goes into mass production in September, the report said.

2.0TFT sunlight visible half penetration half anti RGB/color screen 240*320 Thin film transistor displays are a full color modules that can display graphics, characters and video and are great for adding an interesting user interface to any product. Thin Film Transistor Advantages: Since there is no fluid, thin film...

2.2 Visible semi-transparent semi-reflection color screen 240*320 under TFT sunlight Thin film transistor displays are a full color modules that can display graphics, characters and video and are great for adding an interesting user interface to any product. Thin Film Transistor Advantages: Since there is no fluid,...

A liquid crystal display or LCD draws its definition from its name itself. It is a combination of two states of matter, the solid and the liquid. LCD uses a liquid crystal to produce a visible image. Liquid crystal displays are super-thin technology display screens that are generally used in laptop computer screens,...

A liquid-crystal display (LCD) is a flat-panel display or other electronically modulated optical device that uses the light-modulating properties of liquid crystals combined with polarizers. Liquid crystals do not emit light directly, instead using a backlight or reflector to produce images in color or monochrome....

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple,...

Standard small to mid-size color TFT displays Increase your product’s appeal with a TFT LCD display from YeTai! TFT displays are liquid-crystal display modules with thin-film transistor technology. This TFT technology offers full RGB showcasing a range of colors and hues. Get rich colors, detailed images, and bright...

A liquid crystal display or LCD draws its definition from its name itself. It is a combination of two states of matter, the solid and the liquid. LCD uses a liquid crystal to produce a visible image. Liquid crystal displays are super-thin technology display screens that are generally used in laptop computer screens,...

TFT stands for "thin-film transistor." LCD stands for "liquid crystal display." Both terms refer to the flat-panel display, or screen, of a computer monitor or television set. TFT displays are made using large sheets of transistors, each one of which is controlled independently. A TFT screen is an "active-matrix"...

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple,...

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display (LCD) that uses thin-film transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active-matrix LCD, in contrast to passive-matrix LCDs or simple, direct-driven LCDs with...

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display (LCD) that uses thin-film transistor (TFT) technology. A TFT LCD is an active-matrix LCD, in contrast to passive-matrix LCDs or simple, direct-driven LCDs with a few segments.TFT LCDs are used in appliances including...

A thin-film-transistor liquid-crystal-display (TFT-LCD) is another form of LCD which uses TFT technology to improve image quality like contrast and addressability. thin film transistor-liquid crystal display are used widely in computer monitors, mobile phones, television screens, handheld video game systems,...

A thin-film-transistor liquid-crystal-display (TFT-LCD) is another form of LCD which uses TFT technology to improve image quality like contrast and addressability. The emergence of high performance Thin Film Transistor Liquid Crystal Display (TFT LCD) technology over the last decade heralds a new era in desktop...

Thin Film Transistor Liquid Crystal Displays or TFT LCD is an active matrix LCD as opposed to the non TFT variant which is passive. LCD came on the scene in the late sixties further to developments by RCA. Optel Corporation provided the first application of LCD in commercial/consumer items such as calculators and...

Stands for "Thin Film Transistor." These transistors are used in high-quality flat panel liquid-crystal displays (LCDs). TFT-based displays have a transistor for each pixel on the screen. This allows the electrical current that illuminates the display to be turned on and off at a faster rate, which makes the display...

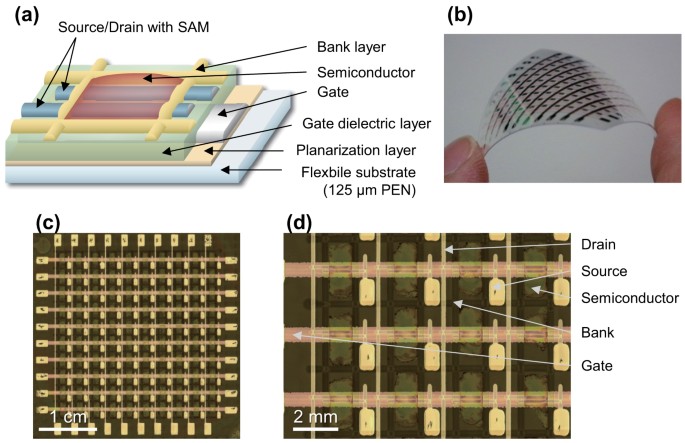

The development of a thin-film transistor (TFT) technology for use with plastic substrates is still in its infancy. There is significant room for improvement in ultra-low temperature fabricated poly-Si TFTs. High mobilities, low leakage currents and threshold voltages are desirable for high-performance active-matrix...

LCD’s became most popular in consumer devices. As the technology developed and progressed, TFT’s improved the LCD technology and the realm of possibility of uses grew. This became an active matrix technology allowing for the ability to address and electronically maintain the state of each pixel. Developments such as...

A TFT display is a form of Liquid Crystal Display with thin film transistors for controlling the image formation. The technology works by controlling brightness in red, green and blue sub-pixels through transistors for each pixel on the screen.The liquid-crystal behaviour is similar to that of a TN display, relying on...

An LCD consists of many pixels. A pixel consists of three sub-pixels (Red/Green/Blue, RGB). In the case of Full-HD resolution, which is widely used for smartphones, there are more than six million (1,080 x 1,920 x 3 = 6,220,800) sub-pixels. To activate these millions of sub-pixels a TFT is required in each sub-pixel....

A thin film transistor liquid crystal display (TFT-LCD) is a technology which is used in LCD monitor and television displays. TFT technology can be used to give one of the clearest pictures of any flat screen display and it uses much less electricity than older screens. Positive aspects of TFT displays: easy to...

Thin film transistor displays are a full color modules that can display graphics, characters and video and are great for adding an interesting user interface to any product. Thin Film Transistor Advantages: Can display up to 64 million colors Operates down to -30C Available sizes from 1.7” to 15” Larger and smaller...

Thin film transistor displays are a full color modules that can display graphics, characters and video and are great for adding an interesting user interface to any product. Thin Film Transistor Advantages: Can display up to 64 million colors Operates down to -30C Available sizes from 1.7” to 15” Larger and smaller...

(Yicai Global) June 19 -- China National Building Material has built the country"s first production line capable of producing 8.5th-generation TFT-LCD glass substrates, making China one of few nations to master the technology.

The central state-owned firm"s Bengbu Glass Industry Design and Research built the facility after three years of research, Science and Technology Daily reported. The plant aims to obtain certifications that will allow it to manufacture for domestic display makers.

TFT-LCD, or thin-film-transistor liquid-crystal displays, are classified by the size of their glass substrate. Sixth-generation displays are now widely considered out-dated while 8.5th-gen tech is the most advanced. The newer technologies use larger substrates, which are more efficient to make and can be used in larger screens.

In ruling NY N320557 (August 4, 2021), Customs and Border Protection (CBP) discussed the country of origin of five Thin Film Transistor – Liquid Crystal Display (TFT-LCD) modules. All five modules are virtually identical in composition, as they are all composed of a TFT-LCD cell, polarizers, a backlight, a driver and control printed circuit board (PCB), and a flexible PCB for connection. TFT display technology allows for the construction of high-resolution LCD displays, and the modules – once completed – can be incorporated into a variety of consumers display applications.

The manufacturing process for the five modules is also identical. The process begins in Japan where the TFT-LCD cell is manufactured. The TFT is created by depositing transistors onto a substrate through chemical vapor deposition, while the color filter is manufactured by building a color matrix on a glass substrate. The creation process of the cells is then completed when a layer of liquid crystal is deposited between the color filter and TFT as the two part are bonded together, creating a sheet of TFT-LCD cells. As next steps, the sheet of cells is delivered to China to be cut into individual cells. The cut-up cells are then bonded to the printed circuit board assembly (PCBA) – which contains the driver and control circuity – before the polarizers, backlight, and flexible connection PCBA are attached.

CBP also established that “substantial transformation” takes place when a particular product “emerges from a process with a new name, character or use different from that possessed by the article prior to processing.” The agency explained that the completed TFT-LCD cell is what imparts the essential function of the module and that the manufacturing process in Japan is what renders the end-use of the product. Despite the assembly that took place in China, the process did not substantially transform the cell into a new and different article. As such, CBP determined that the country of origin of the five modules is Japan.

SHANGHAI, Aug 26 (Reuters) - China"s BOE Technology Groupwill soon start building the country"s first eighth generation TFT-LCD (thin-film transistor liquid crystal display) production line with an investment of 28 billion yuan ($4.1 billion), a source close to the situation said on Wednesday.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT fabrication for immersive high-performance displays.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT fabrication for immersive high-performance displays.

The short name of TFT:Thin Film Transistor in Chinese. What is the difference between TFT and LCD? Our laptops and desktops now use relatively advanced TFT displays, which consist of LCD pixels and are powered by thin-film transistors integrated behind the pixels. Therefore, the TFT type display screen also belongs to a class of display devices with a source matrix.

TFT type display screen is currently a better LCD color display, TFT type display has many advantages: high responsiveness, high brightness, high contrast, and so on.TFT displays are closest to CRT displays. The TFT screen also often appears on the screen of each big mobile phone, there are 65536 colors, 160,000 colors, 16 million colors three, its display effect is also very good.

TFT means that every LCD pixel on an LCD is driven by a thin-film transistor integrated behind it. Thus can achieve high speed, high brightness, high contrast display screen information, TFT-LCD(thin-film transistor liquid crystal display) is one of the majority of LIQUID crystal displays.

Liquid Crystal Display (LCD). The structure of the LCD is placed in the middle of the two pieces of parallel glass liquid crystal box, the substrate glass set on TFT (thin-film transistor), set the color filter substrate glass on, on the TFT signal, and the voltage change to control the rotation direction of the liquid crystal molecules, so as to achieve control of each pixel display emergent polarized light or not and to achieve. Now THAT LCD has replaced CRT as the mainstream, the price has dropped a lot and become widely available.

The TFT(Thin Film Field-effect Transistor) is a video in which every single pixel in the liquid crystal display is actuated by a Thin Film Transistor embedded in the rear. Thus can achieve high speed, high brightness, high contrast display screen information.

Color screens of mobile phones vary depending on LCD quality and research and development technology. The types of color screens include STN (CSTN), TFT(LTPS), TFD, UFB, and OLED.

Liquid Crystal Display (LCD). Generally divided into monochrome and color LCD two kinds, the current monochrome LCD has almost out of the notebook computer market, and color LCD still continues to develop. The color LCD can be divided into two types: STN and TFT. The TFT(Thin Film Transistorized)LCD, also known as the active transistorized Transistor LIQUID crystal display (LCD), is the true-color LIQUID crystal display that many people describe as the Thin Film Transistor.DSTN (Dual Scan Twisted Nematic)LCD, namely double scan LIQUID crystal display. It is a display mode of STN LCD, which is no longer on the market.

What is the difference between TFT and LCD? Read here I believe you have a general understanding and cognition of TFT and LCD, LCD refers to liquid crystal display, TFT is a kind of LCD. The former is for laptops and the latter is for desktop computers. There are several different technologies for LCD, FED, PDP, OLED, TFT-LCD, they are all LCD. Only the desktop with several fronts more, lower cost, TFT technology cost is higher, generally used for notebook, or MOTO, etc., now most of the display is TFT type display, I believe we will pay more attention to the choice and purchase of digital goods.

RE:Country of origin; Thin Film Transistor (TFT); Liquid Crystal Display (LCD); TFT/LCD module; PCB; flat panel display computer monitor; marking; outermost container; ultimate purchaser; substantial transformation; Hitachi; Japan; China; HRL 560427; 19 CFR 134.1(a); 134.32(d).

This is in reply to your letter, dated April 8, 2002. In that letter, you requested a ruling on the country of origin marking requirements for TFT- LCD modules assembled in China of Japanese components and imported into the United States to be used to make notebook computer monitors and flat panel desktop computer monitors. Our response follows.

Hitachi will produce finished thin film transistor (TFT)/liquid crystal display (LCD) modules that will be imported into the United States. The two products at issue are: 1) TFT/LCD modules for use with notebook computers; and 2) a Super IPS (In Plane Switching) TFT-LCD module to make flat panel desktop computer monitors.

You state that although the Japanese-origin TFT-LCD Cell is the primary component, the Japanese components are substantially transformed in China when they are assembled into a TFT-LCD module in China. You contend that the components, which include the PCB, Back Light Unit (with CFL), tape, frame, cables, and the TFT-LCD Cell, when assembled result in a different commercial article, that is, a completed TFT-LCD module ready for use to manufacture notebook computer monitors or flat panel desktop computer monitors.

A representative of your company stated by telephone on April 24, 2002, that after importation of the finished TFT-LCD modules into the U.S., your company stores them in a warehouse as part of your company’s inventory. When a customer orders the modules, they are shipped to the customer. Your representative stated that because the imported articles are highly sensitive and fragile, your company does not normally repackage the imported articles. Your company’s customers then incorporate the TFT-LCD modules into a monitor when manufacturing their final computer product. In other words, the modules are not ready to be used as monitors when imported into the U.S. because they lack components such as the frame, power supply, driver, et cetera and must be further processed in the United States.

What are the country of origin marking requirements for finished TFT-LCD modules assembled in China from Japanese components and imported into the United States to be used for manufacturing notebook computer monitors and flat panel desktop computer monitors?

Based on the facts provided, it is our opinion that the assembly of various components used in producing the TFT/LCD module in China, including the Back Light Unit which is made in China from approximately 12 components, effects a substantial transformation of the individual components. The individual components, most of which are made in Japan, lose their identity and become integral part of the new article – TFT/LCD module. The assembly operations are also not minimal or simple. Thus, the TFT/LCD module as imported into the United States qualifies as a product of China and therefore should be marked as such.

In HRL 560427, the LCD module was made in Japan and imported into the U.S. The LCD module was then combined with nine other U.S. components to manufacture the final Flat Panel TFT/LCD monitor for personal computers. Customs ruled that the Japanese-origin LCD module was substantially transformed in the U.S. when incorporated into the monitor in the U.S. Similarly, in the instant case, the TFT/LCD module made in China will be incorporated in the United States into flat panel desktop computer monitors and notebook computer monitors manufactured by your customers.

In the instant case, unlike the case in 560247, the importer is not the manufacturer or the processor. However, subject to the terms of 19 C.F.R. § 134.35(a) and 19 C.F.R. § 134.1(d)(1), your company’s customers, who use the imported TFT/LCD modules to produce the flat panel desktop computer monitors and notebook computer monitors in the United States would be considered the ultimate purchasers. Therefore, as in HRL 560247, the imported article in the instant case qualifies for the marking exception provided in 19 C.F.R. § 134.35(a) and 19 C.F.R. § 134.32(d). Consequently, the country of origin marking requirements may be met in the instant case by having the imported articles’ containers (i.e. boxes or other containers that hold the modules) marked with the country of origin, assuming that those containers also reach your customers.

For the foregoing reasons and based on the facts provided, the TFT/LCD modules are products of China and therefore should be so marked. However, because the TFT/LCD modules will be used by your customers to manufacture flat panel desktop computer monitors and notebook computer monitors in the United States, your customers are the ultimate purchasers. Therefore, the marking requirements may be met by marking the containers of the imported articles with their country of origin, assuming that your customers receive the articles in those containers.

KING TECH is a TFT LCD IPS supplier solution specialist since 2003, we are the group company combined byAn Innolux authorized LCD panel&IC distribution company

We Provide Different Kinds of Custom TFT Display ServicesIf needed we can make custom size tft displays for customers, we have a good relationship with original TFT display module factories, and we can negotiate with them to tool up an LCD panel mask. The tooling cost will be very high and paid by the end customer, and MOQ is at least 25K/lot.

We are capable to change every structure of the TFT display module. To increase backlight brightness and make it sunlight readable, the highest brightness we’ve ever reached was 6500cd/m2.To change the display FPC shape and length. To customize a resistive touch panel(RTP) or capacitive touch panel(CTP/PCAP), we have a long-term cooperation supplier to work with us on such tooling, for CTP, we can also make different shapes and thicknesses of cover glass, single touch, and multi-touch, AG/AR/AF is also available.

With our own PCBA hardware& software design company, we can design different kinds of TFT display modules for our customers, from simple convert boards to complete motherboards, from HDMI driver boards to Android controller boards, from non-touch function boards to capacitive touch function boards, they are all part of our working.

We have our own TFT display module panel and driver distribution department, if you want to switch to another structure of display, we can also help, cause we know which TFT display module panel and the driver is more match, and which suit’s supply is more stable, which one we can get the lowest price.

In order to give the customer the best support, Kingtech, as one of the best TFT LCD IPS suppliers in China, also can provide industrial solutions such as developing a mother board, serial port UART board, T-CON board, HDMI board, and monitor according to the customer"s requirements.

Kingtech also has existing industrial solutions for the PV135 motherboard, PV901 Linux board, and PV804 motherboard. They can be connected between Raspberry pi and our TFT display module, which can make them work together.

For serial port UART board, Kingtech has a 2.8inch 240x320 LCD with serial port UART board, 3.5inch 320x480 module with serial port UART board, 4.3inch 480x272 display with a resistive touch with serial port UART board, 7inch 800x480/1024x600 TFT with capacitive touch with serial port UART board.

For the HDMI board, Kingtech has a 1.39inch 454x454 AMOLED round with HDMI board, 3.34inch 320x320 TFT round with HDMI board, 3.4inch 800x800 TFT round with HDMI board, 5inch 1080x1080 TFT with HDMI board, 4.3inch 800x480 TFT with HDMI board, 5inch 800x480 LCD with HDMI board, 7inch 800x480/1024x600 LCD display with HDMI board, 10.1inch 1280x800 LCD module with HDMI board.

Above all TFT display modules with board products can be used for industrial equipment, medical, smart-home, or others. Kingtech can also have industrial custom TFT display solutions according to the customer’s requirements. Ware is welcome to contact us. If you are interested in any tft display module products, we can negotiate with you at a reasonable TFT LCD display price. Thank you.

TFT display module is a Thin Film Transistor, and AMOLED is Active-matrix organic light-emitting Display. The TFT display module is backlight-on the liquid crystal panel; AMOLED is a panel that emits light on its own; TFT display module structure is more thick and strong, AMOLED is very thin and also weak, TFT display module is used widely than AMOLED, AMOLED is used in consumer products the most, like a smartwatch, mobile phone, and TV.

IPS is In-Plane Switching, It is also known as free viewing angle, which means the viewing angle of the display on 4 sides is the same, a normal display has its best viewing angle like 6 o’clock or 12 o’clock. While the TFT display module contains normal viewing angles and IPS display,IPS display is a kind of TFT display module.

TFT display module belongs to LCD, LCD is Liquid Crystal Display, it contains mono(single color) LCD and color LCD, single color LCD is barely used now, and color LCD has STN and TFT two types. Therefore, TFT display module is a kind of LCD display.

OLED is Organic Light Emitting Display, it is a display that emits light on its own, and it does not need an extra backlight, so it requests lower power consumption than TFT display module but its lifetime is shorter than TFT(5000 hours), AMOLED is a kind of OLED but it is more colorful. TFT display module requests a backlight to light on and power consumption are higher than OLED, but its lifetime is much longer(20000 hours).

The LED display is working by lighting up the LED lights, the TFT display module is lighted up by the backlight and the liquid crystal starts to work and shows contents. TFT display module has brighter and more true color, and lower price and LED display has lower power consumption, smaller heat, and longer lifetime.

Compares to other types of display, TFT display module is the more widely used, it can be made in different shapes and sizes, from very small sizes to big sizes. The resolution now is higher and higher, and the price of custom TFT display modules is more and more competitive. Its lifetime is longer than the OLED display, and its color is brighter than OLED.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey