lcd panel technology comparison factory

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

STONE TFT LCD modules come with a microcontroller unit that has a 1GHz Cortex-A8 CPU. Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to them.

Becoming a reputable TFT LCD manufacturer is no piece of cake. It requires a company to pay attention to detail, have excellent manufacturing processes, the right TFT display technology, and have a consumer mindset.

Now, we list down 10 of the best famous LCD manufacturers globally. We’ll also explore why they became among the top 10 LCD display Manufacturers in the world.

BOE Technology Group Co., Ltd., founded in April 1993, is an IoT company providing intelligent interface products and professional services for information interaction and human health. BOE’s three core businesses are Interface Devices, Smart IoT Systems, and Smart Medicine & Engineering Integration.

Interface Devises Business includes Display and Senor, Sensor, and Application Solutions. As a leading company in the global semiconductor display industry, BOE has made the Chinese display industry develop from scratch to maturity and prosperity. Now, more than one-quarter of the global display panels are made by BOE, with its UHD, flexible display, microdisplay, and other solutions broadly applied to well-known worldwide brands.

Smart IoT Systems Business includes Intelligent Manufacturing Services, IoT Solution, and Digital Art IoT Platform. BOE provides integrated IoT solutions in smart retail, smart finance, digital art, business office, smart home, smart transportation, smart education, smart energy, and other fields. In the field of digital art, BOE has launched its digital art IoT solution – BOE iGallery, realizing the perfect combination of technology and art. For smart retail, BOE provides IoT solutions in price management, shelf management, and customer behavior analysis to achieve seamless online and offline convergence.

LG Display is a leading manufacturer of thin-film transistor liquid crystal displays (TFT-LCD) panels, OLED, and flexible displays.LG Display began developing TFT-LCD in 1987 and currently offers Display panels in a variety of sizes and specifications using different cutting-edge technologies (IPS, OLED, and flexible technology).

Samsung Electronics is South Korea’s largest electronics industry and the largest subsidiary of the Samsung Group. In the late 1990s, Samsung Electronics’ independent technology development and independent product innovation capabilities were further enhanced. Its product development strategy not only emphasizes “leading the technology but also using the most advanced technology to develop new products to meet the high-end market demand at the introduction stage”.In addition to the matching principle, it also emphasizes the principle of “leading technology, developing new products with the most advanced technology, creating new demand and new high-end market”.

Founded in 2003, Innolink listed its shares in Taiwan in 2006. In March 2010, it merged with Chi Mei Optoelectronics and Tong Bao Optoelectronics, the largest merger in the panel industry. Qunchuang is the surviving company and Chi Mei Electronics is the company name. In December 2012, it was renamed As Qunchuang Optoelectronics.

With innovative and differentiated technologies, QINNOOptoelectronics provides advanced display integration solutions, including 4K2K ultra-high resolution, 3D naked eye, IGZO, LTPS, AMOLED, OLED, and touch solutions. Qinnooptoelectronics sets specifications and leads the market. A wide range of product line is across all kinds of TFT LCD panel modules, touch modules, for example, TV panel, desktop and laptop computer monitor with panels, small and medium scale “panels, medical, automotive, etc., the supply of cutting-edge information and consumer electronics customers around the world, for the world TFT – LCD (thin-film transistor liquid crystal display) leading manufacturers.

AU Optronics Co., LTD., formerly AU Optronics Corporation, was founded in August 1996. It changed its name to AU Optronics after its merger with UNIOPtronics in 2001. Through two mergers, AU has been able to have a full range of generations of production lines for panels of all sizes.Au Optronics is a TFT-LCD design, manufacturing, and r&d company. Since 2008, au Optronics has entered the green energy industry, providing customers with high-efficiency solar energy solutions.

Sharp has been called the “father of LCD panels”.Since its founding in 1912, Sharp developed the world’s first calculator and LIQUID crystal display, represented by the living pencil, which was invented as the company name. At the same time, Sharp is actively expanding into new areas to improve people’s living standards and social progress. Made a contribution.

BYD IT products and businesses mainly include rechargeable batteries, plastic mechanism parts, metal parts, hardware electronic products, cell phone keys, microelectronics products, LCD modules, optoelectronics products, flexible circuit boards, chargers, connectors, uninterruptible power supplies, DC power supplies, solar products, cell phone decoration, cell phone ODM, cell phone testing, cell phone assembly business, notebook computer ODM, testing and manufacturing and assembly business, etc.

Toshiba is a famous multinational company with a history of 130 years. It covers a wide range of businesses, including social infrastructure construction, home appliances, digital products, and electronic components. It covers almost every aspect of production and life. Toshiba has the largest research and development institution in Japan. Through unremitting innovation and development, Toshiba has been at the forefront of science and technology in the world.

From the introduction of Japan’s original washing machines, refrigerators, and other household appliances, to the world’s first laptop, the first 16MB flash memory, the world’s smallest 0.85-inch HDDs; Create advanced HDDVD technology; Toshiba created many “world firsts” in the research and manufacture of new SED displays and contributed to changing people’s lives through constant technological innovation.

Tianma microelectronics co., LTD., founded in 1983, the company focus on smartphones, tablets, represented by high order laptop display market of consumer goods and automotive, medical, POS, HMI, etc., represented by professional display market, and actively layout smart home, intelligent wear, AR/VR, unmanned aerial vehicles (UAVs) and other emerging markets, to provide customers with the best product experience.IN terms of technology, the company has independently mastered leading technologies such as LTPS-TFT, AMOLED, flexible display, Oxide-TFT, 3D display, transparent display, and in-cell/on-cell integrated touch control. TFT-LCD key Materials and Technologies National Engineering Laboratory, national enterprise Technology Center, post-doctoral mobile workstation, and undertake national Development and Reform Commission, The Ministry of Science and Technology, the Ministry of Industry and Information Technology, and other major national thematic projects. The company’s long-term accumulation and continuous investment in advanced technology lay the foundation for innovation and development in the field of application.

Asia has long dominated the display module TFT LCD manufacturers’ scene. After all, most major display module manufacturers can be found in countries like China, South Korea, Japan, and India.

In this post, we’ll list down 7 best display module TFT LCD manufacturers in the USA. We’ll see why these companies deserve recognition as top players in the American display module industry.

STONE Technologies is a leading display module TFT LCD manufacturer in the world. The company is based in Beijing, China, and has been in operations since 2010. STONE quickly grew to become one of the most trusted display module manufacturers in 14 years.

Now, let’s move on to the list of the best display module manufacturers in the USA. These companies are your best picks if you need to find a display module TFT LCD manufacturer based in the United States:

Planar Systems is a digital display company headquartered in Hillsboro, Oregon. It specializes in providing digital display solutions such as LCD video walls and large format LCD displays.

Microtips Technology is a global electronics manufacturer based in Orlando, Florida. The company was established in 1990 and has grown into a strong fixture in the LCD industry.

What makes Microtips a great display module TFT LCD manufacturer in the USA lies in its close ties with all its customers. It does so by establishing a good rapport with its clients starting from the initial product discussions. Microtips manages to keep this exceptional rapport throughout the entire client relationship by:

Displaytech is an American display module TFT LCD manufacturer headquartered in Carlsbad, California. It was founded in 1989 and is part of several companies under the Seacomp group. The company specializes in manufacturing small to medium-sized LCD modules for various devices across all possible industries.

The company also manufactures embedded TFT devices, interface boards, and LCD development boards. Also, Displaytech offers design services for embedded products, display-based PCB assemblies, and turnkey products.

Displaytech makes it easy for clients to create their own customized LCD modules. There is a feature called Design Your Custom LCD Panel found on their site. Clients simply need to input their specifications such as their desired dimensions, LCD configuration, attributes, connector type, operating and storage temperature, and other pertinent information. Clients can then submit this form to Displaytech to get feedback, suggestions, and quotes.

A vast product range, good customization options, and responsive customer service – all these factors make Displaytech among the leading LCD manufacturers in the USA.

Products that Phoenix Display offers include standard, semi-custom, and fully-customized LCD modules. Specifically, these products comprise Phoenix Display’s offerings:

Clients flock to Phoenix Display because of their decades-long experience in the display manufacturing field. The company also combines its technical expertise with its competitive manufacturing capabilities to produce the best possible LCD products for its clients.

True Vision Displays is an American display module TFT LCD manufacturing company located at Cerritos, California. It specializes in LCD display solutions for special applications in modern industries. Most of their clients come from highly-demanding fields such as aerospace, defense, medical, and financial industries.

The company produces several types of TFT LCD products. Most of them are industrial-grade and comes in various resolution types such as VGA, QVGA, XGA, and SXGA. Clients may also select product enclosures for these modules.

All products feature high-bright LCD systems that come from the company’s proprietary low-power LED backlight technology. The modules and screens also come in ruggedized forms perfect for highly-demanding outdoor industrial use.

LXD Incorporated is among the earliest LCD manufacturers in the world. The company was founded in 1968 by James Fergason under the name International Liquid Xtal Company (ILIXCO). Its first headquarters was in Kent, Ohio. At present, LXD is based in Raleigh, North Carolina.

We’ve listed the top 7 display module TFT LCD manufacturers in the USA. All these companies may not be as well-known as other Asian manufacturers are, but they are equally competent and can deliver high-quality display products according to the client’s specifications. Contact any of them if you need a US-based manufacturer to service your display solutions needs.

We also briefly touched on STONE Technologies, another excellent LCD module manufacturer based in China. Consider partnering with STONE if you want top-of-the-line smart LCD products and you’re not necessarily looking for a US-based manufacturer. STONE will surely provide the right display solution for your needs anywhere you are on the globe.

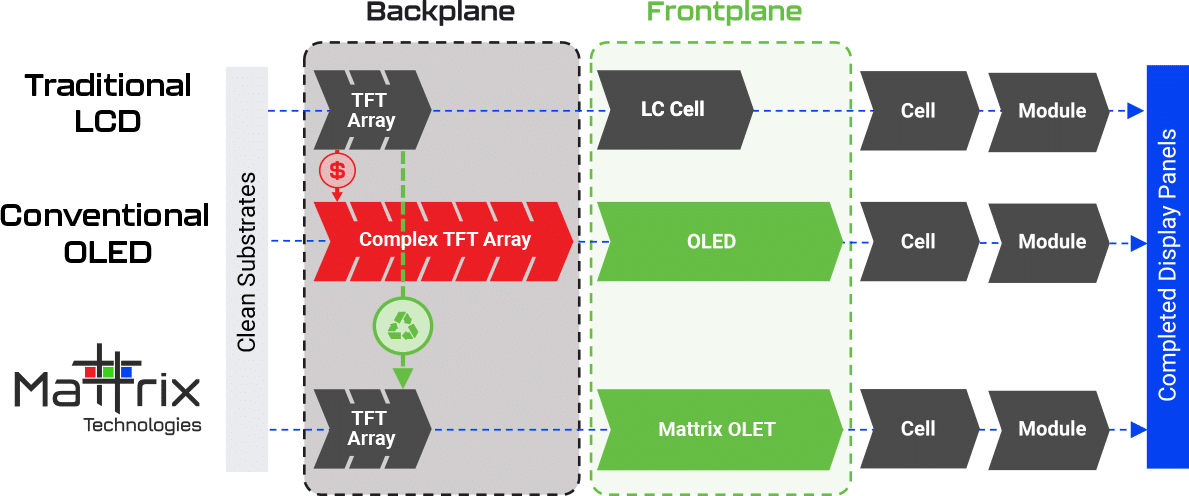

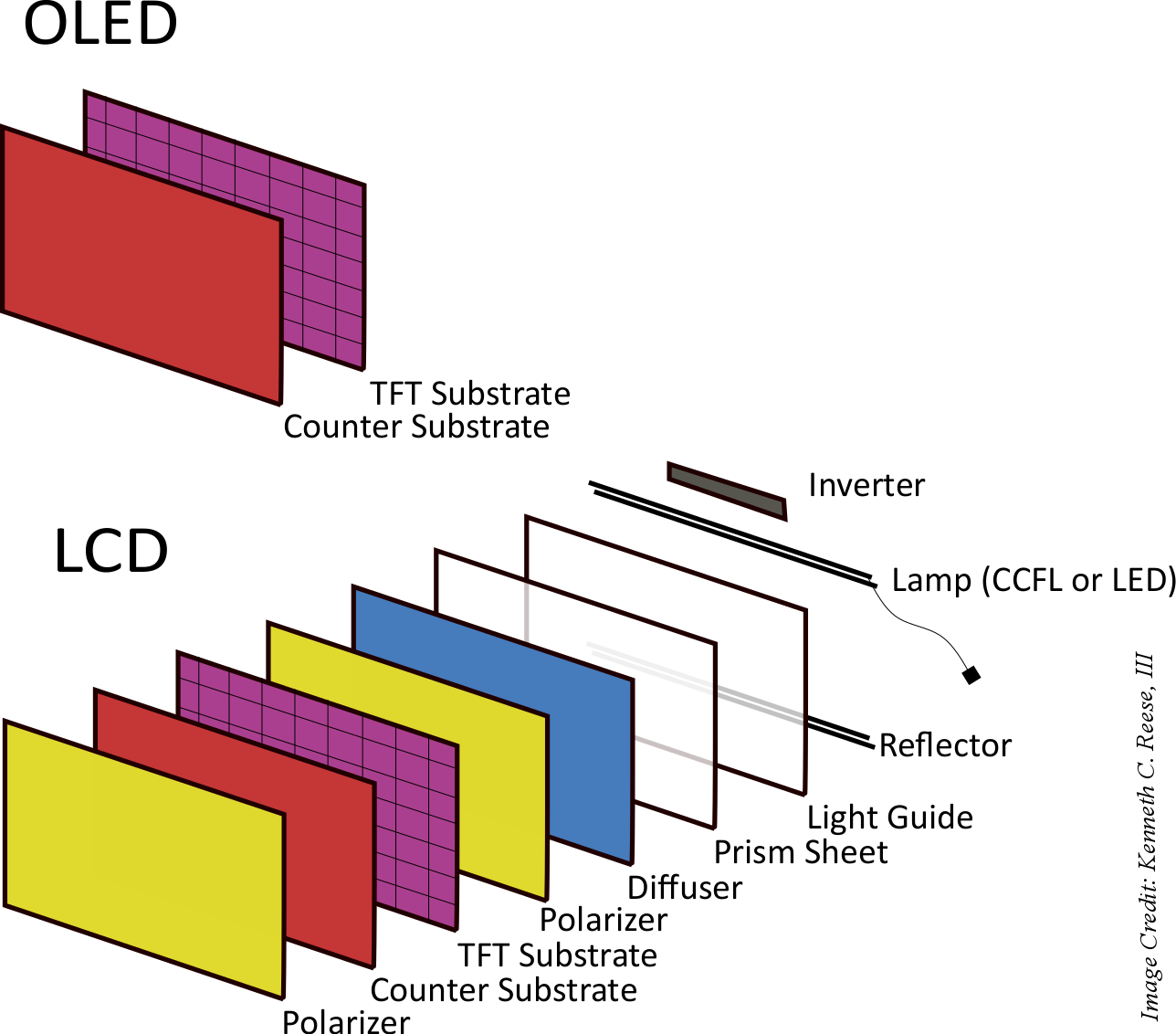

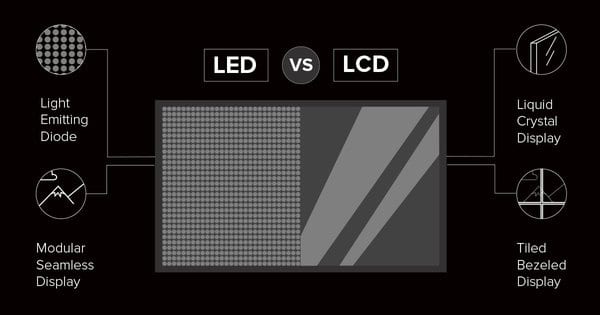

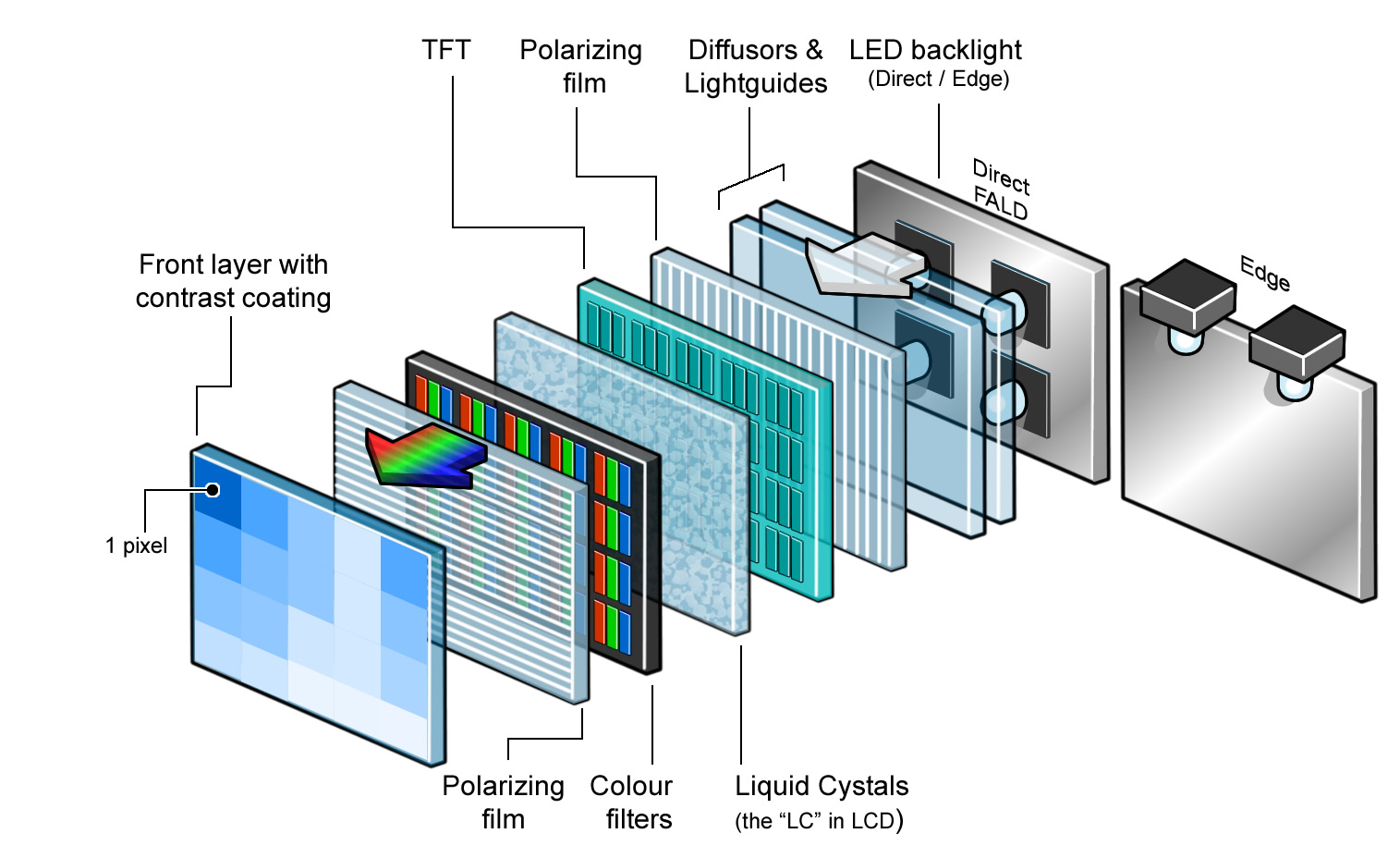

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

The general consumer typically has very limited knowledge about the different types of LCD panels on the market and they take all of the information, specifications, and features printed on the packaging to heart. The reality is that advertisers tend to take advantage of the fact that most people conduct very minimal research before making big technological purchases—in fact, they depend on this to sell higher quantities of commercial monitors. With that in mind, how exactly do you know if you’re actually getting a good quality product that’ll suit your needs? Reading up on all of the different types of industrial LCD monitors is a good place to start!

LCD stands for liquid-crystal display. Over the years, LCD technology has become ubiquitous with various commercial and industrial screen manufacturing. LCDs are constructed of flat panels that contain liquid crystals with light modulating properties. This means that these liquid crystals use a backlight or reflector to emit light and produce either monochromatic or coloured images. LCDs are used to construct all sorts of displays from cellphones to computer screens to flat-screen TVs. Keep reading to learn everything you need to know about the different types of LCD displays on the market.

Twisted Nematic LCDs are the most commonly manufactured and used types of monitors across a wide range of industries. They’re most commonly used by gamers because they’re inexpensive and boast faster response times than most of the other display types on this list. The only real downside to these monitors is that they possess low quality and limited contrast ratios, colour reproduction, and viewing angles. However, they suffice for everyday operations.

In Plane Switching displays are considered to be among the best of the best when it comes to LCD technology as they offer superior viewing angles, excellent image quality, and vibrant colour accuracy and contrast. They’re most commonly used by graphic designers and in other applications that require the highest possible standards for image and colour reproduction.

Vertical Alignment panels fall somewhere in the middle between TN and IPS panel technology. While they have much better viewing angles and higher quality colour reproduction features than TN panels, they also tend to have significantly slower response times. However, even their most positive aspects still don’t come anywhere close to holding a candle to IPS panels, which is why they’re much more affordable and suitable for everyday use.

AFFS LCDs offers far superior performance and a wider range of colour reproduction than even IPS panel technology. The applications involved in this type of LCD display are so advanced that they can minimize colour distortion without compromising on the extremely wide viewing angle. This screen is typically used in highly advanced and professional environments such as in the cockpits of commercial airplanes.

Nauticomp Inc. is the leading designer and manufacturer of high-quality LCD panels and displays. All of our touchscreen displays are made to order and customized according to your specific needs and applications. To learn more about our products, please contact us today.

In the past decade, LCD monitors have replaced CRT screens for all but the most specialist applications. Although liquid crystal displays boast perfect

Samsung Display will stop producing LCD panels by the end of the year. The display maker currently runs two LCD production lines in South Korea and two in China, according to Reuters. Samsung tells The Verge that the decision will accelerate the company’s move towards quantum dot displays, while ZDNetreports that its future quantum dot TVs will use OLED rather than LCD panels.

The decision comes as LCD panel prices are said to be falling worldwide. Last year, Nikkei reported that Chinese competitors are ramping up production of LCD screens, even as demand for TVs weakens globally. Samsung Display isn’t the only manufacturer to have closed down LCD production lines. LG Display announced it would be ending LCD production in South Korea by the end of the 2020 as well.

Last October Samsung Display announced a five-year 13.1 trillion won (around $10.7 billion) investment in quantum dot technology for its upcoming TVs, as it shifts production away from LCDs. However, Samsung’s existing quantum dot or QLED TVs still use LCD panels behind their quantum dot layer. Samsung is also working on developing self-emissive quantum-dot diodes, which would remove the need for a separate layer.

Samsung’s investment in OLED TVs has also been reported by The Elec. The company is no stranger to OLED technology for handhelds, but it exited the large OLED panel market half a decade ago, allowing rival LG Display to dominate ever since.

Although Samsung Display says that it will be able to continue supplying its existing LCD orders through the end of the year, there are questions about what Samsung Electronics, the largest TV manufacturer in the world, will use in its LCD TVs going forward. Samsung told The Vergethat it does not expect the shutdown to affect its LCD-based QLED TV lineup. So for the near-term, nothing changes.

One alternative is that Samsung buys its LCD panels from suppliers like TCL-owned CSOT and AUO, which already supply panels for Samsung TVs. Last year The Elec reported that Samsung could close all its South Korean LCD production lines, and make up the difference with panels bought from Chinese manufacturers like CSOT, which Samsung Display has invested in.

Samsung has also been showing off its MicroLED display technology at recent trade shows, which uses self-emissive LED diodes to produce its pixels. However, in 2019 Samsung predicted that the technology was two or three years away from being viable for use in a consumer product.

Tech observers and investors revel in lively discussions about the latest, greatest gadget and whose bottom line will get the greatest bounce. They enjoy debating the intricacies and details of materials that contribute to these devices, and the related trends and developments. For us at Corning, materials innovators for 165 years, it’s been great to see a recent uptick in discussions about OLED versus LCD display panel technology - a genuine #GlassAge debate.

Corning.com staff sat down with Mike Kunigonis, business director for Corning’s High Performance Displays Group, to understand key differences between OLED and LCD display technology.

Corning.com: Thanks for your time today, Mike. Let’s start with a key question: In the context of display panels, how does OLED technology work and what are the main differences between it and LCD technology?

MK: OLED stands for Organic Light-Emitting Diode, or Organic LED. It’s an alternative to LCDs for consumer electronic devices that range in size from wearable to TVs. Like LCD, OLED is a type of panel that enables the displays on device screens. An OLED display picture is generated by turning on and off millions of tiny individual LEDs, each forming the individual pixels of a display. Compare this to LCD, where an always-on backlight projects light through a liquid crystal, sandwiched between two pieces of glass. When the liquid crystal is excited by an electrical current, it lets the light of an individual pixel pass through like a shutter. LCD and OLED display panels both excel at delivering vibrant consumer displays, each in its own unique way.

Corning.com: We’ve heard industry analysts with varying opinions on the benefits an OLED device offers. So why would a consumer prefer a device with an OLED display over an LCD display?

MK: Adoption of OLED displays on smaller, mobile devices is the driver behind most of today’s OLED industry growth, so let me focus on that. A handheld OLED display is attractive to consumers because of the industrial design and display attributes that this technology can support. For example, OLED displays can be curved, or be thinner, or have narrower bezels – or no bezels at all – or flex and bend. Plus, an OLED display will be a great solution for virtual reality applications because it can provide high resolution and superior response time and latency.

Everyday, we look at LCD display, TV, cell phone, monitor. It becomes a necessity in modern society. LCD panel is the most important part of an LCD display. It determines LCD screen"s performance, e.g. brightness, contrast, color and viewing angle. Therefore, picking the right type of LCD panel is critical to your application.

These names reflect the alignment of crystal molecules inside the LCD, and how they change when they are charged electrically. All liquid crystal displays change the alignment of liquid crystal molecules to work, but the manner in which they do so can drastically affect the image quality and response time. Each panel type has its advantages and disadvantages. The easiest way to choose between them is to decide which attributes are most important to your project. It mainly depends on what you use your LCD display for, and your budget.

TN is the most mature technology in LCD panel manufacturing. When there is no voltage difference between the two transparent electrodes, liquid crystal molecules are twisted 90 degrees, in combination of upper and bottom polarizers, allows light to pass through LCD. As voltage applied, crystal molecules are untwisted and aligned to the same direction, blocking light.

In IPS panel, crystal molecules are parallel to the glass substrates at initial stage, LCD is off. When the in-plane electrodes is charged, crystal molecules are rotated, modifying light"s direction. Which lights up the LCD display.

As its name suggests, VA panel"s liquid crystals are aligned vertically without charged. When a voltage is applied, the molecules tilt and modifying light direction.

So in summary, TN panels twist, IPS panels use a parallel alignment and rotate, while VA panels use a perpendicular alignment and tilt. These difference create LCD display with distinctive performance.

IPS LCD is the clear winner in this aspect. It has 178/178 viewing angle ratings. Which means you can look at IPS LCD display from any angle without the image shifting in color and contrast. VA LCD has pretty wide viewing angle, too. But it has contrast shifts at off-center angles. As for TN LCD, viewing angle is its weakest point.

Most TN LCDs have 6-bits colors. Manufacturers use frame rate control (FRC) to enhance its color performance. For IPS and VA panels, you can still find 6-bits entry level LCD. But most of them are 8-bits. And IPS technology can provide natively 10-bits colors.

Color gamut is another part that VA and IPS panels shine at. The best TN LCD can reach sRGB gamut. VA panels typically start with full sRGB coverage, and get to around 90% DCI-P3 coverage. With IPS LCD panel, you could find the best ones full DCI-P3 and Adobe RGB coverage. That is why you see most professional grade LCD displays use IPS panel.

There is no inherent differences among the three panel technologies, because LCD backlight is the main factor here. However, there is a big gap in terms of contrast ratio. TN LCD panel tends to have the lowest value among the three. IPS LCD screen sits in the middle can reach 1500:1. For VA panel, the best one can exceed 4500:1 easily. VA LCD display provides far darker screen than TN & IPS. That is why they are used in vehicle dashboard.

TN panel does have an advantage when it comes to refresh rate. The panel offers the best refresh rate and response time. This is the reason why most gaming LCD monitors are made of TN panel.

TN LCD provides the best refresh rate and economic solution. If your application requires wide viewing angles and good color presentation, VA panel is probably the choice. While IPS has the best overall visual performance, in general it is more expensive than the other two.

OLED displays have higher contrast ratios (1 million : 1 static compared with 1,000 : 1 for LCD screens), deeper blacks and lower power consumption compared with LCD displays. They also have greater color accuracy. However, they are more expensive, and blue OLEDs have a shorter lifetime.

OLED displays offer a much better viewing angle. In contrast, viewing angle is limited with LCD displays. And even inside the supported viewing angle, the quality of the picture on an LCD screen is not consistent; it varies in brightness, contrast, saturation and hue by variations in posture of the viewer.

There are no geographical constraints with OLED screens. LCD screens, on the other hand, lose contrast in high temperature environments, and lose brightness and speed in low temperature environments.

With current technology, OLED displays use more energy than backlit LCDs when displaying light colors. While OLED displays have deeper blacks compared with backlit LCD displays, they have dimmer whites.

LCDs use liquid crystals that twist and untwist in response to an electric charge and are lit by a backlight. When a current runs through them, they untwist to let through a specific amount of light. They are then paired with color filters to create the display.

"Television is a key product category for Sony," Ken Kutaragi, executive deputy president of Sony, said in a statement. "S-LCD panels will be at the core of our flat-panel TV strategy, further strengthening our overall vision for television."

LCD technology allows for thinner and lighter televisions and monitors than traditional cathode-ray tube products. The market for LCD televisions is particularly promising, according to research firm iSuppli. The share of worldwide TV shipments that are LCD models will grow from 5 percent this year to 18 percent in 2008, iSuppli said. The total TV market is expected to jump from about 168 million units to roughly 203 million units during that period.

The new S-LCD plant is optimized for big panels that can fit into televisions, said iSuppli analyst Riddhi Patel. "It"s going to make the large-size LCDs available at a more reasonable rate," she said. Partly because of the new factory, the average price for LCD televisions that are 40 inches or larger should fall from about $8,000 to $1,500 by 2008, Patel said.

Sony and Samsung are vying with other LCD panel manufacturers such as LG.Philips LCD, a joint venture between Royal Philips Electronics of the Netherlands and Korea"s LG Electronics.

LCD technology is competing against plasma display technology, which also allows for thin televisions. Other display methods are emerging, including so-called liquid crystal on silicon rear-projection technology, which has been championed by

The cutting-edge G10 production line is a result of cutting-edge technology. To consistently manufacture LCD panels using the G10 glass substrates, each individual manufacturing process incorporates a range of unique know-how. Developed in collaboration with several world-leading production equipment manufacturers, SDP"s large-scale, one-of-a-kind manufacturing equipment delivers state-of-the-art accuracy and performance levels. One example is the photolithography machine, which is about the size of a tennis court. Our master-craftsmen operate and monitor this machine with the utmost care, to manufacture next-generation products.

We hold strengthening and perfecting our items and repair. At the same time, we get the job done actively to do research and progress for Tft And Ips Display Difference, Lcd Inverter, Flexible Lcd, Tft Display For Car,Memory Lcd. We fully welcome shoppers from all around the world to ascertain stable and mutually effective enterprise interactions, to have a dazzling long run jointly. The product will supply to all over the world, such as Europe, America, Australia,Amsterdam, Serbia,San Francisco, Brazil.They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it"s a have to for you of fantastic good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We are confident that we are going to have a bright prospect and to be distributed all over the world in the years to come.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey