are lcd monitors hazardous factory

-“These chemicals are semi-liquid and can get into the environment at any time during manufacturing and recycling, and they are vaporized during burning,” said University of Saskatchewan environmental toxicologist and lead author John Giesy in a press release. “Now we also know that these chemicals are being released by products just by using them.”

-The researchers found the specific monomers isolated from the smartphones were potentially hazardous to animals and the environment. In lab testing, the chemicals were found to have properties known to inhibit animals’ ability to digest nutrients and to disrupt the proper functioning of the gallbladder and thyroid–similar to dioxins and flame retardants which are known to cause toxic effects in humans and wildlife.

-To be clear, the researchers didn’t observe any adverse health effects from the accumulation of liquid crystals in the human body; they only found that these crystals do in fact leak from devices, and that they have the potential to be toxic. “We don’t know yet whether this a problem, but we do know that people are being exposed, and these chemicals have the potential to cause adverse effects,” said Giesy.

-If you crack LCD screens and find the liquid crystal leakage, don’t panic. Just remember that the liquid crystal materials might not be more toxic than your detergents for stove or washroom. Just wash your hands with soup throughout. Never try to play with it or even worse to taste it. The liquid of the cracked computer screen will not evaporate, no emissions worries.

-Any electronics has environment impact and can’t be used landfills. If you want to get rid of old LCD monitors or LCD TVs, give them to electronic collection stations. Let’s the professionals to handle them. They will extract some precious metals/parts and make them into something useful or at least not hazard. FYI, liquid crystal materials are retrievable.

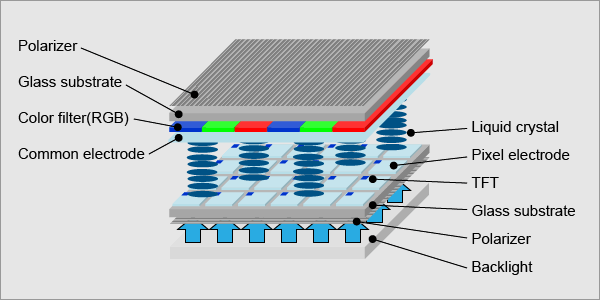

Scientists have discovered that LCD screens leak chemicals into just about every environment where they are found, according to a new study, and these particles have the potential to be toxic over time.As described in a study published last week in Proceedings of the National Academy of Sciences, researchers collected dust samples from seven buildings in China: a cafeteria, student dorm, classroom, hotel, home, lab, and an electronics repair shop. Nearly half of the 53 samples tested positive for liquid crystal particles—which are supposed to stay sealed in the screen after manufacturing—even in places where there were no LCD devices at the time of collection.AdvertisementThe international research team analyzed 362 chemicals used in LCD screens and found that nearly 100 have the potential to be toxic. These particles don’t break down quickly and have "high mobility" in the environment. When inhaled or ingested, according to the study, these particles can build up in the body over time with toxic effects, potentially causing digestive problems and other health issues.“These chemicals are semi-liquid and can get into the environment at any time during manufacturing and recycling, and they are vaporized during burning,” said University of Saskatchewan environmental toxicologist and lead author John Giesy in a press release. “Now we also know that these chemicals are being released by products just by using them.”According to the study, these chemicals are "simply filled" into the space between polarizers (light filters) during manufacturing and are not chemically bonded to any base material. This means that "they can be released during production; through wastewater; or during active use, disposal, or recycling."To be clear, the researchers didn"t observe any adverse health effects from the accumulation of liquid crystals in the human body; they only found that these crystals do in fact leak from devices, and that they have the potential to be toxic.

“We don’t know yet whether this a problem, but we do know that people are being exposed, and these chemicals have the potential to cause adverse effects,” said Giesy.AdvertisementLab testing showed that the hazardous substances found in phones were similar to flame retardants, which have proven to be toxic to living creatures, creating problems with animals’ digestive systems and hindering their ability to absorb nutrients. They also disrupted their gallbladders and thyroids.The team says the next step is to understand the effect of these chemicals on humans, animals, and the environment. “Since there are more and more of these devices being made, there’s a higher chance of them getting into the environment,” said Giesy.Right now, there are no standards for measuring them and no regulations limiting exposure to them. “We are at ground zero,” he said.Giesy’s previous work was the first to shed a spotlight on toxic perfluorinated and polyfluorinated chemicals (PFCs). PFCs used to be in all kinds of oil and water-resistant products such as raincoats and non-stick pans. His findings led to a global ban of PFCs.

Despite the magical appearance of modern screens, these marvels use very real resources. Monitors have long been the most resource-heavy parts of a modern computer, due in no small part to their size. Because of their size, a monitor manufacturers’ usage of certain compounds creates greater environmental concerns than the computer to which the monitor is attached.

Cathode Ray Tube Basics The first monitors were built off of much of the same technology as televisions. Known as Cathode Ray Tube, or CRT, monitors, these behemoths use a single, large vacuum tube with an electron gun at one end which fires light through a mask. The mask is charged in such a way to block certain wavelengths at specified locations, creating images. These monitors have been largely replaced by Liquid Crystal Displays, or LCDs.

Liquid Crystal Displays Liquid crystal displays are significantly thinner, lighter and higher image quality than CRT monitors. LCDs use a layer of specially made crystals mounted to an electrical grid. Small charges at different coordinates of the grid can change the color of each reactive crystal. A small fluorescent or LED bulb is then mounted along the long edge of the monitor to light it up.

Chemicals of CRT The biggest chemical concern in a CRT comes from the tube itself. The glass vacuum tube is lined with a significant amount of lead – as much as 4 pounds by some estimates. Cadmium is another highly toxic mineral found in CRT monitors which threatens workers who dispose of these electronics. To a lesser degree, CRTs also contain arsenic.

Chemicals of an LCD LCDs made great strides towards eliminating the chemicals used by its predecessor, the CRT. However, LCDs still contains small amounts of lead as well as mercury in fluorescently-lit models. In addition to the chemicals actually contained within the LCD, the manufacturing process of the liquid crystals uses nitrogen trifluoride, a chemical known to have an impact 17,000 times greater than carbon dioxide on global warming.

The components in computers and monitors contain many different toxic materials. This may not affect the average user working on one PC, but it does cause problems when equipment is recycled or discarded in bulk. If you are considering upgrading your office computers, you may not give much thought to how you"ll dispose of your old equipment, but when the time comes, you should know what is in the box and behind the screen.

Toxic Components in Computers The central processing unit in a computer contains toxic substances, and lead is found in circuit boards. Metal plates and housings may contain chromium, which is used to harden and protect metal plates from corrosion. Motherboards and connectors often contain beryllium. Cadmium is commonly found in chip resistors, semi-conductors, infrared detectors, stabilizers, cables and wires. Circuit boards, switches and relays contain mercury as well chromium. Brominated flame retardants are used in many components, including circuit boards and plastic casings.

Toxic Components in Monitors Older cathode-ray tube monitors may contain up to eight pounds of lead. Newer LCD and flat-panel monitors typically don"t have this much lead, but they do contain some and copper, too. The lamp used to illuminate the screen is likely to contain mercury, and the coating inside the screen may be made from cadmium. Brominated flame retardants are commonly found in many monitor components.

E-Waste According to the Electronics TakeBack Coalition (ETBC), the U.S. disposed of 423,000 computers and 595,000 monitors in 2010. Just 40 percent of computers and 33 percent of monitors were recycled; the rest were trashed. E-Waste is a serious environmental concern. Toxic materials in computer components can harm the environment and, if they enter food chains, they can harm humans too.

Recycling Businesses don"t typically buy new computers or systems because current hardware isn"t suitable for a purpose. Instead, they upgrade to improve performance, and old equipment may still have some value. These computers can be refurbished or sent for recycling -- even a broken PC contains components that are valuable and can be reused. Most major manufacturers offer businesses some form of recycling service. Some also offer trade-in discounts or cash for old equipment that could help cover some costs of a new system.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Technology is constantly evolving, bringing us new and better devices that leave us questioning what we ever thought was so great about those old ones in the first place. Last year’s mobile phones, TVs, and computers that use LCD screens are now dated by ever-improving models and a better grade of LCD – so replacing and upgrading the technology is important.

So, what should we do with these old devices and LCD hardware with a lifespan of 10-20 years that we now have lying sad and forgotten in the corner, in the attic, or out on the curb? Recycle them, of course! LCDs have their own regulations for recycling, so here are some tips on how to recycle your old LCD screens and devices.

LCDs that were manufactured before 2009 use cold cathode fluorescent lamps (CCFLs) to backlight the display. These CCFL displays contain mercury, which makes them hazardous to dispose of or incinerate. Other electronic products can contain hazardous chemicals, such as heavy metals and brominated flame retardants. These materials can leak out of landfills and into groundwater, streams, etc., or can be transformed into “super toxicants” while being incinerated. Throwing away these types of devices can clearly be harmful, even today. There are still some harmful chemicals and materials inside electronic devices that will damage the environment if they aren’t disposed of properly—and many times, they aren’t.

Another big problem is that because of the turn-over rate of these electronic devices, LCD screens are just left sitting in landfills. Since they need to be disposed of in certain ways, they’re left to sit and waste away, taking up space in the landfills. Many states have laws prohibiting the disposal of electronic waste in landfills. Because of that, LCDs are likely to sit and rot, or be incinerated in large quantities. They also could be shipped off to other countries that don’t have these prohibiting laws, which is definitely not the best solution to the problem.

Many times, we get new and better gadgets before the current one even needs replacing. That old TV still works, still shows the picture clearly and there’s not a scratch on it. But this new one…well, it’s bigger. It has the Internet capabilities built right in and it can do backflips! Okay, not really, but the point is that we tend to get something new while we still have a perfectly functioning, but slightly older, model. Instead of keeping it in the attic, you can donate it or recycle it to companies and stores in your area that will take it. These places can resell it to people who don’t have the latest backflipping TV, mobile phone or tablet.

Since the issue was raised, there has been much research performed on the best method for recycling LCD screens. Different facilities have different ideas, practices and processes. Some of these processes include removing the hazardous waste materials from the screens/monitors; others believe in completely taking apart the device/screen piece by piece and seeing what can be resold or refurbished, then disposing of the rest in environmentally friendly ways.

Almost 98% of an LCD monitor can be recycled. All plastics are removed to be recycled into new products. Printed circuit boards can be recovered from LCD recycling and smelted to recover valuable metals, while cabling is stripped to reclaim copper and other metals.

Considering how frequently we get new electronic devices, being smart about LCD recycling can make a huge difference. General Digital encourages all of its customers to recycle their used computer monitors and televisions. Learn more about e-cycling from Maryland’s Department of the Environment, and Maine’s Department of Environmental Protection.

It might come off as a surprise but about 98% of an LCD/monitor can be recycled to extract useful material including plastic, copper, and other metals. The plastic removed from an LCD monitor is used for manufacturing new products while the circuit boards are smelted to extract metals. The wiring in the monitor can also be stripped to extract copper and rubber. All these materials can be recycled instead of getting wasted and polluting the environment. Moreover, some LCDs and monitors can be refurbished to be used again by extending their lifecycle. Only an expert in electronic recycling can do this through a meticulous process. Trust our team at Hummingbird International to do this for you, be it commercial waste disposal or residential ewaste disposal.

Liquid Crystal Displays (LCDs) have replaced Cathode Ray Tubes (CRTs) as the main display devices in recent years. To satisfy the increasing demands, billions of LCDs are manufactured annually. As more LCDs are produced and used, the amount of LCD waste is increasing at an alarming rate. Current treatment technologies can disassemble LCD into multiple components and recycle them according to their materials. However, there is no suitable model for treating LCD panels. Research has repeatedly shown the harmfulness of liquid crystal, indium and other heavy metals which LCD panels contain. As a result an increasing number of countries have classified LCD panels as hazardous waste. Because of this, future processing of LCD panel waste will require on-site burial, burning, or physical disposal, not only increasing processing costs, but also causing environmental damage. This is a huge problem. That is why this recycling technology for waste LCD panels is a kind of revolutionary breakthrough.

The pilot plant handles 3T of waste LCD panels daily, with a liquid crystal recycling rate of 100%, indium recovery rate of more than90% and glass recycling rate of 100%

Liquid crystal is the main component of LCD. It is a chemical with a high unit cost, high stability and low biodegradability. While the harmfulness of liquid crystal is uncertain, its structure contains a large volume of benzene rings, fluorine, chlorine, and bromine, which, if buried, may seep into subterranean water systems and impact ecosystems. Physical processing entails breaking down LCD panels and adding them to cement or concrete, which does not remove liquid crystals and heavy metals from the panels, so they may still enter and harm the environment following rain or washing. Based on environmental and economic considerations, the liquid crystal in the LCD panel should be reused.

To prevent the pollution caused by waste LCD panel disposal, and to control processing costs, ITRI thoroughly analysed the characteristics and reusability of each material contained in LCD panels, and designed a logical separation procedure according to the associations between each material, first separating liquid crystal, indium, and glass, and then developing purification technology for each material which enables the reuse of these materials. Liquid crystal can be reused in new LCDs or liquid crystal smart windows. Indium can be refined as the raw material of sputtering targets. Glass can become a humidity-controlling green building material or heavy-metal adsorption material.

ITRI’s pilot plant can treat 3 tons of waste LCD panel per day of operation, producing 3 kilograms of liquid crystal, 750 grams of indium, and about 2,550 kilograms of glass, which can be reused as humidity-controlling green building material or heavy-metal adsorption material. ITRI’s team uses the pilot plant for technical verification of on-line scrap LCD panels and end-of-life LCD panels. ITRI can build the LCD panel processing center for LCD manufacturers and e-waste recycling companies.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey