3d printer lcd panel with buttons supplier

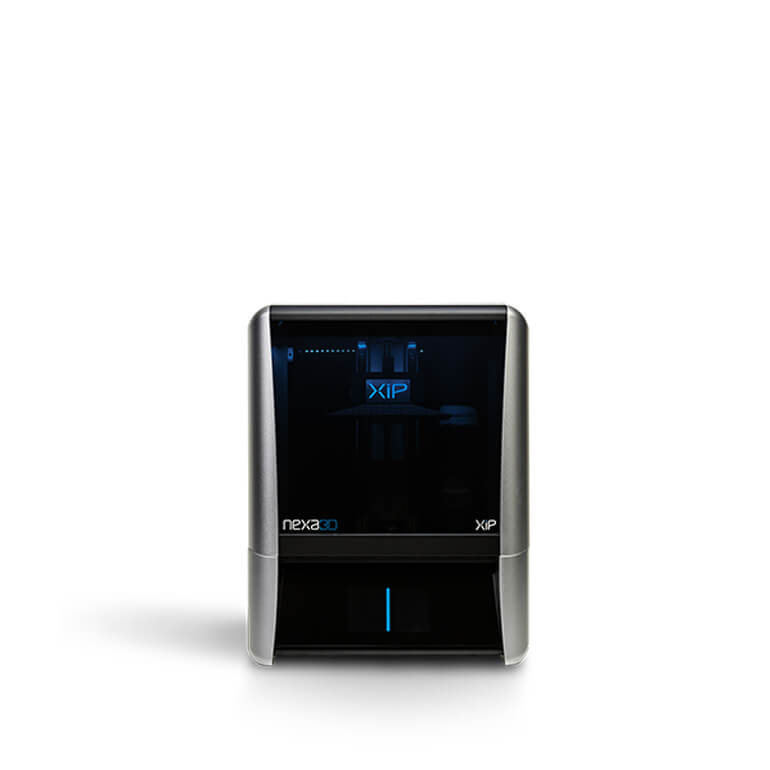

Nexa3D is a leading provider of ultrafast 3D printing solutions. Our photopolymer and thermoplastic range of industrial 3D printers offer unrivaled speed and throughput, superb surface finish, all on an open material platform. Our patented Lubricant Sublayer Photo-curing (LSPc) 3D printing process unlocks productivity gains by as much as 20x greater than those of conventional SLA or DLP processes. We offer a range of polymer solutions, spanning from a desktop resin 3D printer, industrial 3D printers, and a thermoplastic laser sintering solution for serial production.

We collect user journey data to show you relevant sponsored content about our products. For example, we use information from your previous purchases and interactions with the site. We may share this information and a customer identifier, such as device data, with third parties such as Facebook and Google. We use the following services on this site:

Easy to use 3D Printing Pen with LCD screen, temperature adjustment, and sliding feed adjustment. This 3D Pen is great for users of all levels and is the exact same Pen you find on Amazon and Matterhackers for $60+. We get our Pens directly from the factory in China, and they come with a 1 year warranty (so far we"ve only had 1 fail out of over 100 sold).

I’m Tom and today i’m going to show you how to add an LCD screen control panel and an SD card reader to your 3D printer for # under 13€ – that’s about 16 US dollars including tax. Why would you want that? Well, even though i use OctoPrint as my main way of interfacing with the printer (which i show you how to set up right here), i still needed a way to work the basic controls of my printer without having to fiddle around on my phone or having to bring down my Laptop. And the LCD control panel gives you just enough control for when you want to tweak or stop a print, change filament or even just jog one of your printer’s axis. And as a bonus, you also get an SD card slot, so if aren’t using OctoPrint, you can use that to print files without needing to have a computer sitting right next to your printer all the time. So let’s get started!

Here’s what you’ll need! First of all, the LCD panel itself. I used the Full Graphic Smart Controller because it’s # the biggest, baddest one out there and really isn’t any more expensive than other solutions. You can also use other panels, for example in the style of the Ulticontroller, but those usually have smaller and less detailed screens. If you want to buy a Smart controller and want to support my videos at the same time, get one here [World/DE]. It’s pretty much the best price out there anyways.

You will also need a way to connect the LCD panel to your printer’s electronics. There are adapters available for the most popular boards, for example for the RAMPS or the RAMBo, and they often come with the LCD panel or your control board, but you can hook them up to pretty much any board out there, including the humble Printrboard. A quick Google search will usually bring up a couple of guides about how you need to connect everything or sometimes even options to order pre-made adapter boards. For the sake of simplicity, i’ll be showing this on my RepRapElectro RAMBo. You can find a review of that right here.

And just like for setting up anything else like auto bed tilt compensation, you will need a readily configured version of your printer’s firmware, preferably Marlin. If you don’t have a version ready to go, check out my guide on the basics of Marlin to get you started.

Before we start hooking things up, i placed a strip of Kapton tape between the LCD screen and the secondary board since it looked like some of the pins would potentially short others out. Then we can hook everything up: Place the adapter board on your mainboard, then plug in both ribbon cables to the panel and the adapter. Now, many adapters don’t clearly label which of these is header one and which is header two, but you won’t damage anything if you get them wrong. Just make sure you don’t plug in one of the connectors backwards.

Next up, we can start digging into the firmware. So open up your Marlin.ino and hop over to the configuration.h file. In here, you’ll want to scroll almost all the way down to the LCD and SD support section. Now, the exact options relevant to you will, again, depend on the specific model of your controller panel, but for the Full Graphic Smart Controller, all you need to do to get it working is to uncomment the line / #define REPRAP_DISCOUNT_FULL_GRAPHIC_SMART_CONTROLLER. And right here is a reminder that you need to add the U8glib library to your assortment of Arduino libraries, and thanks to the fine folks at Arduino, that is now a super simple process. Download the right zip for your operating system from the link in the description, then, in the Arduino software, hit Sketch, import library, add library, then choose the zip file you just downloaded. / Done.

Now, to fix the scrolling direction, you need to head over to the pins.h file, which is kind of hard to reach from within the Arduino IDE, so open that file up in Notepad or Notepad++ after you’ve closed the Arduino IDE. Then scroll down to the section for your particular board and swap the numbers after BTN_EN1 and BTN_EN2 in the Smart Controller or NEWPANEL section. If that didn’t fix the scroll direction after saving the file and reuploading with Arduino, you probably edited the wrong section. By the way, the beeper on the board annoyed the crap out of me, so i completely disabled mine by changing the BEEPER pin to minus 1.

So, here’s two more things that are specific to using the Smart controller i bought: One, the software contrast setting doesn’t do anything, there’s a potentiometer for that on the board, and two, the LCD’s backlight on this panel is only enabled for a while if you press the “light” button, which just wouldn’t do it for me. To permanently turn it on, simply move the jumper on the back of the board to the opposite side.

And we’re done! You’ll probably still want to print some sort of mount and case, and you can find cases and knobs for all versions of the Smart Controller on the various 3D model sharing sites.

I was rebuilding one of my 3D printers — again — and decided I needed a display upgrade. A color screen is nice, but there are some limitations. I also found there are ways around these limitations, so I wanted to share my thoughts on a dual-mode color touch screen LCD controller for your 3D printer. The screen in question is a TFT35 from BigTree Tech. It is similar to an MKS screen, but it can operate in two different modes, as you will see.

A few years ago, I picked up an Anet A8 which was very inexpensive, especially on sale. Not the best printer, though, because it has that cheap acrylic frame. No problem. A box full of aluminum extrusion later, the printer was reborn. Over time, I’ve completely reworked the extrusion system and the Y-axis, leaving only the motors, bearings, and the controller/display as the original.

That last part was what bothered me. The Anet board is actually pretty capable for a small cheap board. But it is just what the printer needs and nothing more. If you wanted to hack the printer there was very little memory left and only one spare pin for I/O. So it was time to replace the board and why not the controller, too?

The A8 has an LCD2004. That means it has a 20×4 LCD. Instead of an encoder knob, there are five buttons: basically up, down, left, right, and enter. Most printers now have an LCD12864 which, as you can probably guess, is a 128×64 LCD and they use an encoder knob for direction that you can push for the enter key.

I happened to have one of these lying around so when I installed a new motherboard — a Fysetc Spider if you are curious — I also wired in the new LCD. I had to recompile Marlin, of course, but that’s easy. It all worked, it just looked a little bland.

There’s another way to control a printer, and it’s one you may have thought of before. Since the printer accepts commands via a serial port, you could take a computer like a Raspberry Pi with a nice LCD and just have it issue commands to the serial port. Bonus points if the board has more than one serial port so you can still hook up a PC or a Raspberry Pi running Octoprint or similar. Turns out, you don’t have to build this. The MKS touchscreen uses an ARM chip (it isn’t a Pi, though) and has a touch screen that you can use to control the printer. These come in different sizes and are usually called something like TFT35 for 3.5 inch display.

The advantage isn’t just appearance. Having a bunch of touch screen buttons makes many things easier. For example, if the printer is at (0,0) and you want to jog the head to (100,200), that ends up being a lot of button pushes in Marlin. With the touch display, you can bring up a navigation screen that makes it easy. Or, you can bring up an entire terminal and enter G-code. When you press Send, it shows the results of the command, if any. You can set a temperature with the knob, on-screen buttons, or press the number and type in what you want with a virtual keypad.

These displays are colorful and nice, but there are a few things they can’t do. Marlin has some wizards and user interaction that insist on a proper, local LCD. But the Marlin code thinks the MKS display is a remote host computer, connected over serial. Displays that can act like both types of LCDs are a sweet hack, and here’s the part that was never clear to me before: these displays can switch modes during printer operation. In other words, it is not a case of selecting a mode and rebooting everything. You can be looking at the colorful touchscreen, then switch over to the stock display while printing and then switch back any time you want. The best of both worlds.

On the face of it, the display looks like an MKS TFT. You have colorful menus and a touch screen. The connection for that is a simple two-wire serial port, along with — of course — power, ground, and an optional reset connection. They provide a cable you can use or modify to connect to your setup. There is also an EXT3 port for boards that have that connector.

However, if you wire the normal EXT1 and EXT2 ribbon cables to your printer, the display can emulate a normal 128×64 LCD. If you are already set up to use one of these displays, you should not need to recompile Marlin to use this display. However, if you are set up for a different type of display, you’ll need to tell Marlin to use the normal “REPRAP DISCOUNT GRAPHICS CONTROLLER.”

That’s huge. It means you can have a nice user interface that lets you control the printer, print from an SD card or USB stick, and even make customizations to the menu with the source code provided on GitHub or with a simple configuration file edit. (And, yes, you can add custom menu items simply.) But when you need to do something very specific to Marlin, or a new feature shows up that the LCD doesn’t know about yet, you can simply switch to the Marlin display mode. Then you can switch back.

The process to switch is simple. Just hold down the encoder knob or push the screen for a few seconds. A screen will show up allowing you to pick the Marlin mode or the BTT mode. Just touch the one you want. In Marlin mode, the touchscreen does nothing except switch modes, so you might want to use that method. If you hold the encoder down in Marlin mode, the printer will also see the repeated enter keys until the LCD pops up the selection screen.

If you use a bezel, be careful. If you tighten a case down enough to make the touch screen think you are pressing the screen, you’ll get stuck in the selection mode, which makes sense. Just don’t overtighten the LCD!

Installing the LCD was straightforward save a few problems. For some reason, the pin 1 designation for EXP1 and EXP2 are not consistent among vendors. A Geeetech display worked fine with the Spider board, but the TFT35 didn’t want to come up in Marlin mode at all. I applied power at the serial port and the board appeared hung. The answer was to snip off the alignment tabs on the ribbon cables and flip them 180 degrees.

The serial port was also a mystery. With so little documentation on anything, I just soldered the power and ground wires and then hand twisted RX and TX so I could swap them until it worked. As I expected, the cable needed a cross on those lines to work. You also have to match the display’s baud rate to the port you are using.

After that, it all worked fine. The EXP1 and EXP2 connectors do connect to the board’s reset, so you don’t need to wire the serial port’s reset pin if you have those connected. However, I did notice that switching the mainboard to DFU mode will sometimes fail with the display plugged in. Reflashing the display requires an SD card that flashes a binary file and then reboots and loads fonts and icons. If it is connected to the Spider, it sometimes hangs when trying to reboot during an update. It also works sometimes, though, so I suspect it is just loading on the reset line. In any event, popping the connectors will make it work if you don’t want to try repeatedly.

The display has a number of other ports, but you probably shouldn’t use them. For example, there’s a port for a filament runout sensor. But if you connect it there, it will only work if you are printing using an SD card or USB stick in the display. A better option is to connect it to your printer and tell Marlin to notify the host if a filament break occurs. This will work with the display or something like Octoprint.

In theory, you should be able to connect Octoprint itself through one of the extra serial ports. However, I never got this to fully work. The subordinate port seems to work pretty well, but it never sends Octoprint acknowledgments so Octoprint waits forever or until you force it to continue — use the Fake Acknowledgment button in the terminal. Since the Spider has multiple serial ports, it isn’t a big deal, but in theory, the TFT should work a little better if it can intercept and filter the data stream between the printer and the host software. In practice, I don’t really notice any problems. Some Octoprint plugins like DisplayLayer can send status information to the TFT, anyway.

The truth is, I don’t switch over to Marlin mode very often, but it is nice to have it if I want it, and you can even change the colors to suit you. I really wanted the passthrough mode to work but couldn’t figure out what was going on without digging into the source code, and that might be a project for another day.

Another note: Using the jog keys sets the printer to relative mode. If you are used to popping codes into a terminal, you might want to get used to issuing a G90 before you send a move because the TFT will change it to relative anytime you do a jog.

These displays are inexpensive and easy to interface and since they can still work as a classic display, there’s no reason not to do this easy upgrade. There are plenty of mounting options you can print, of course. The finished result looks great and doing things like moving in both X and Y are much easier with the new display.

SUNLU launched a natural green LCD-3D photocuring material that uses soybean oil as raw material in order to reduce the impact of chemicals on the environment and the human health.

3D Printing has had its ups and downs over the years. When it was introduced, the world went crazy with anticipation because the ability to print three-dimensional objects was unheard of, and there was a technology that was providing just that. However, it was very expensive back then due to the cost of setting up the entire machine and the software to run the entire process.

However, that’s no longer a stumbling block. There are a number of new technologies that have been created, bringing down the cost of 3D printing significantly. One of those is the LCD 3D printer.

We are going to explore what anLCD 3D printer machineis, the parts that make it work, the process itself, the benefits it has brought to the industry, and the challenges people who operate them experience. If you have always had a curiosity about how 3D printing is all about, then you are in the right place.

3D Printing has been around since the early 80s where it began as a concept that sought to answer the question of whether the more complicated objects can be reproduced within a three-dimensional structure without compromising the structural integrity. The following is aquick timeline of how 3D printing technology has grown over the years to the present.

1980:An application for the first patent for RP technology was filed by Dr. Kodama in Japan in the month of May 1980. This set of a series of innovations that spurred a race to get 3D printing technology right.

What followed next was a number of companies like Google investing a lot of money in developing 3D printing further. This not only made them smaller but brought their access closer to the people. Although the technology still has a long way to go, the many contributions that have been added over the years have made it possible for 3D printing to gain so much in a short period of time. It"s only a matter of time before they become the norm in the daily lives of people. Now for less than $300, you can get yourself an LCD 3D printer.

An LCD printer is a type of printer that uses an array of UV LCDs as the source of light. The light emanates from the flat LCD panels and is shined directly in a parallel manner against the surface of the building area. The light is very focused without any expansion, a feature that reduces pixel distortion that is common in many other 3D printing techniques in the market right now.

Due to this, LCD 3D printers are in high demand around the world as their print quality is higher. The higher the LCD density, the more pixels the final output has and the sharper and more realistic it gets.

As earlier mentioned, the technology behind 3D Printing has become cheaper by the day, and now you can have your own 3D printer in your house. But to safely operate the machine, you have to understand how it works in the first place. The following are the steps that an LCD 3D Printer uses to create an object from scratch.

Step 1:You begin by pouring theliquid polymer, also called resin, into the crucible. This is then spread by the printer’s roller into arazor-thin layeracross the entire platform to make sure that there’s uniformity in terms of thickness. Consistency is key in this situation.

Step 2:The UV-sensitiveliquid polymeris then hit with a computer-controlled UV laser to change the resin into a solid-state from the aqueous solution. In layman’s terms, this is the point where the laser draws the outlines of whatever you are trying to print onto the resin layer, hardening the needed parts only with every touch. The parts that are not needed will not be touched by the laser, and they maintain their liquid state.

Step 4:Once the printing is done, the object is raised out of the resin tank, with the excess fluid flowing back into the tank for further use. The final product is then finished off outside for the final touches. This includes removing the support structures, smoothing surfaces, or spray painting them.

Caution should be excised whenhandling resin. You should always ensure you are wearing protective gloves and masks because coming into contact with resin is harmful to your health. When washing off the excess resin, make sure you use the correct liquids and don’ drain that water into the sink. Once you have cleaned the excess resin off, don’t touch the final product with bare hands until it undergoes a UV light treatment. You can either let it stand in the sun for a few minutes or if you have a working UV light machine, use it for a few minutes. Once you have covered all that, you are now free to handle the final product.

3D printing technology has transformed human lives in ways that cannot be described, and the more advanced and cheaper they become, the more their applications and benefits they bring. The following are some of the notable benefits of using an LCD 3D printer.

There is nothing that cannot be made using a 3D printer, and this has made things very convenient. You can make all kinds of additions and omissions in real-time however you want. This has allowed people to create a lot of shapes and objects that would otherwise have been impossible by any other means. You can even see the same printing chamber to create a number of objects at the same time at no added cost at all. The cheaper these machines become the more customization capabilities.

It would cost a lot of money to create objects of great complexity by other normal means like manufacturing. However, 3D printing has made that work faster, cheaper and accessible. You can create objects of such a high level of complexity that could even blow your mind. You are only limited by your imagination. The complexity offered by 3D printers has transformed the lives of designers and artists as they are now able to turn their art into realistic 3D objects without compromising on the detailing and sophistication aspects.

3D printing is slated to bring down the cost of manufacturing once it goes into mass production. There are no tools involved in 3D printing, all you require is a computer, a modeling program, and the printer itself, and you are set. This will reduce lead times, the costs of getting tools, and the labor costs of having to operate those tools. The ability to make complex objects without any use of other tools is going to transform the manufacturing industry in a very significant way in the near future. You only need someaccessories and add-onsto make the process easier.

With fewer tools, less energy, and less raw materials, 3D printing is the mosteco-friendly manufacturing processso far. The utilization rate of raw materials is over 90%, with most of the residue recyclable, which means nothing really goes to waste. The finished products are also very hardy and durable, which gives them a decent longevity period of use before they are discarded; this reduces the number of plastics in the environment.

The best part of 3D printing is that finally, manufacturing can be controlled based on need and demand rather than manufacturing in anticipation of demand which leads to surplus and waster of energy. This will eliminate huge inventories, the need to hire storage as well as cut down on the costs of transportation.

3D printing is becoming faster by the day, and when you consider that it involves creating something from scratch using rudimentary raw materials, the sheer brilliance behind the technology starts making sense. One of the manufacturing processes that has benefited greatly from these increased speeds is theprototyping segment, where different parts of the same items can be made at the same time in concurrent processes and later joined up, cutting down the time needed to create products. Once this goes full scale, we will experience manufacturing speeds never seen before.

A goodLCD 3D printerwill save you a lot of money and headache. There are currently a good number of models and brands in the market, each claiming to be better than the next. Making the selection can therefore be a little confusing if you don"t know what it is you are looking for exactly. The following are some of the factors you have to keep in mind when choosing a quality LCD 3D printer.

Size of the print bed:The bigger the bed, the bigger the prints you can make and vice versa. A bigger bed also means you can print several products at the same time concurrently without interfering with the quality of each. This could come in handy considering how time-consuming and complicated setting up the inter for a single operation can be.

Calibration:Some machines require the user to calibrate them before use, and this can be a little time-consuming. It involves adjusting the nozzle until it assumes the right position. You would be served better going for a primer that comes with automated calibration, but that will cost you extra.

Cost of resin:Resin is the material used to make the products, and it is not cheap. There are many types in the market, and each has its own unique properties. Most are sold per pound, and they can vary from $35-$70. As 3D printing picks up, the resin is expected to become cheaper, but at the moment, these are the prices that are in the market.

The Software:There are two types of software you have to deal with. The first one is the modeling software that you use to design the products you want to print. It has to have all the tools, and it must be compatible with the printer. The second software is the one that runs the printer. It should be ‘open source,’ meaning it has to be customizable, allowing the user to set it in line with their needs.

LCD display:A primer that allows you to operate without the need for a computer nearby is more convenient. Having an LCD display withcontroller boardsmakes your work easier as you have fewer buttons to deal with. It also reduces the complications associated with setting up a computer nearby.

Durability and ease of maintenance:As much as their prices have come down considerably, there’s no reason why you should have to be subjected to breakdowns and the need for maintenance after every use. Go for a 3D printer that is durable and can run for long without any maintenance. Having totroubleshoot problemsevery few days will disrupt the quality and speed of your work.

Current trends and the space of development point to a future where 3D printers will be so widespread that people will own them in their houses the same way they own electronics. This will change consumption patterns for people as they will have the power to create most of what they need, and that is a good thing. If you are interested in knowing more about LCD 3D printers, feel free tocheck out the websiteat your own time, and if you have any questions, our team of experts will be there to address every single one of them.

This 18-bit capable 320x240 pixel IPS display adheres majestically to the back of your Pico, and has lush colours and great viewing angles. Just like our original Display Pack, we"ve surrounded it with four tactile buttons so you can use your human fingers (or other non-human appendages) to interface with your Pico. There"s also an RGB LED that you can use as an indicator, for notifications or just for adding extra rainbows.

Pico Display 2.0 lets you turn a Pico into a user interface device for a bigger project, capable of giving instructions, displaying readouts and even incorporating elaborate nested menus. If you"d rather use your Pico as a standalone device you could fill up all that prime screen real estate with digitally generated, Mandelbrot-esque art, beautiful graphs or readouts from lots of sensors. You could even make a device for getting folks to share their secrets via Telnet!

The labels on the underside of Pico Display Pack 2.0 will show you which way round to plug it into your Pico - just match up the USB port with the markings on the board.

The easiest way to get started is by downloading and copying our custom MicroPython uf2 to your Pico, it includes all the libraries you"ll need to use our add-ons. The beginner friendly tutorial linked below will show you how to get to grips with pirate-brand MicroPython.

Display Pack 2.0 also works very nicely with CircuitPython and Adafruit"s DisplayIO library - look for the Display Pack 2.0 ST7789 example in the library bundle to get started!

This screen is a wee bit taller than the surrounding buttons, so it"s worth taking care when pressing the buttons that you"re not also pressing down on the screen, particularly at the edge with the ribbon cable. Careful pressing with fingertips rather than full on thumb mashing is the way forward.

Even though it"s bigger than our other Pico Packs, Display 2.0 will still work with Pico Omnibus or Pico Decker, if you want to use more than one Pico Pack at once. Please note that if you plug Display 2.0 into a Pico Decker, it will overhang the addon slot next to it.

Raspberry Pi Pico is a flexible, low cost microcontroller development board from the folks at Raspberry Pi, based on their very own chip - the RP2040. It"s easily programmable over USB with C/C++ or MicroPython, and ideal for using in all sorts of physical computing projects, devices and inventions - we"re so excited to see what you make with it!

We"ve called our Pico-sized add-ons packs, as they"re designed to attach to the back of your Pico as if it were wearing a very stylish back pack (or a miniature jet pack, if you prefer). We"ve also got Pico bases (larger add-on boards with a space to mount your Pico on top) and some other boards that let you do interesting hackerly things like using multiple packs at once - click here to view them all!

Ohio-based chemicals and materials company Lubrizol has announced the release of ESTANE 3D TPU M88A thermoplastic polyurethane (TPU) under a selective availability program. This grade was specifically…

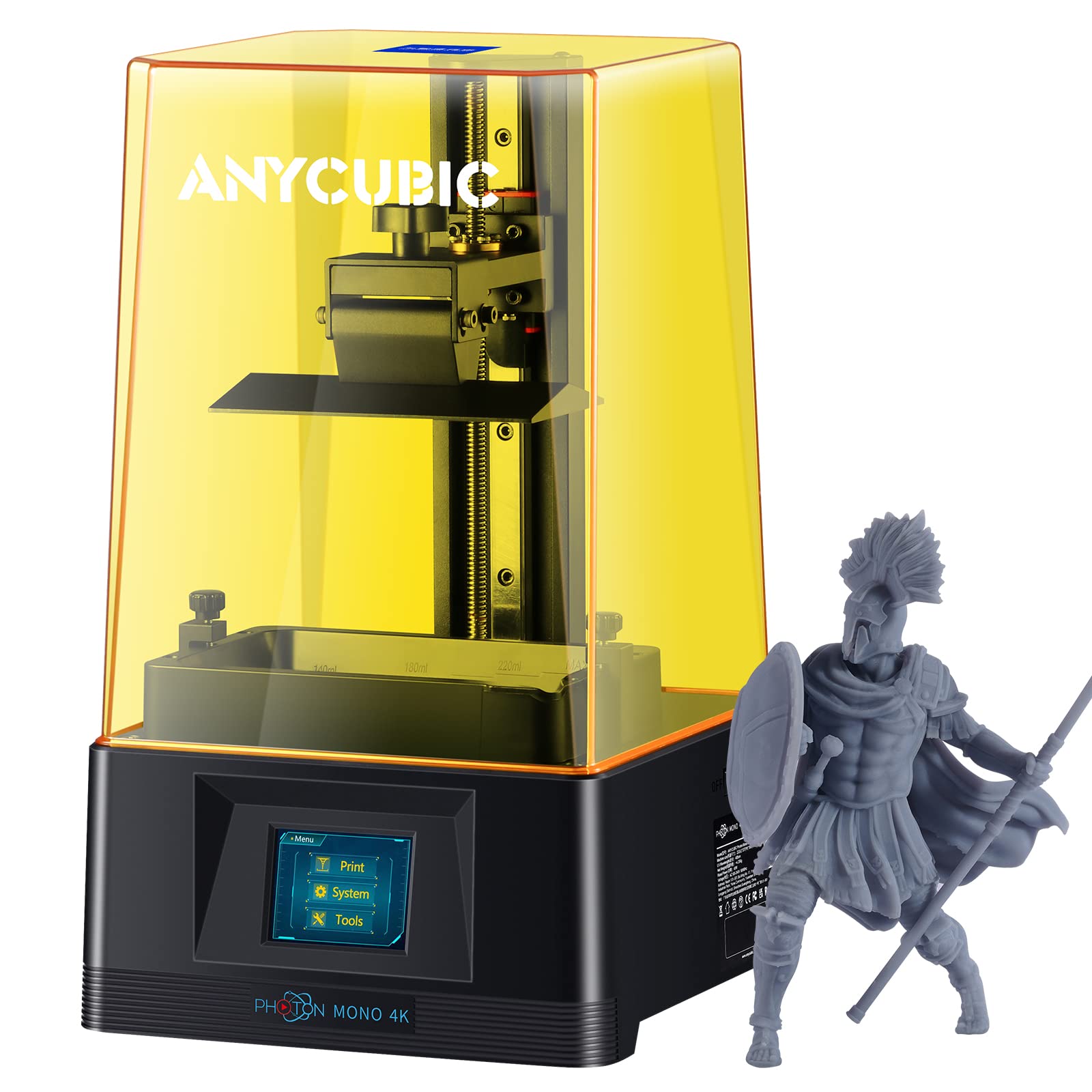

If you’re reading this I assume you are interested in 3D printing miniatures and/or Wargames Terrain. Great, because just below we are going to take a look at the current best 3D printers for Miniatures & Models. There are a lot of options to choose from and everyone has a certain need to balance with their own budget. Check our guide and follow the steps to get the perfect printer for you. (Updated article from best 3d printer miniatures 2021 and now best 3d printer miniatures 2022)

Already have a resin 3D printer? miniatures and scale models are some of the most amazing things to create. It’s such a perfect combination of products for your hobby. But you can do much more with your 3D printer, Action Figures are another popular choice. If you love Warhammer specifically then this goes great when 3D printing parts for the Mcfarlane Warhammer Action Figures. Want another use for your 3D printer? Anime Figures, Scenery, Props, the list goes on. One of my favourite things to make with my 3d printer, lego figures. If you dream it, you can do it. One of the most popular uses in our hobby is with personalised games, such as d&d miniatures, 3D print is to D&D what butter is to bread.

If you aren’t too bothered about any reasoning and just want to see the list, check out this quick summary below of the best 3D printers for Miniatures & Models.

If this is your first printer, get the Elegoo Mars 3 pro. It’s a 4K printer with monochrome LCD, Elegoo has a great history of being the starting spot for printer enthusiasts. If you want something a bit bigger, the Saturn 2 8k has a bigger screen and a better resolution.

If you can stretch to a Saturn 2, definitely get that as the print quality output is nigh on par with something like the Sonic Mini 8k, just not quite – but can your eyes even tell?! The convenience of a far larger print bed is frequently worth more than the potential resolution difference!

If you want the best quality miniatures possible. You want the Phrozen Sonic Mini 8k it’s results when dialled in are on par (I’d argue better in some cases) with plastic miniatures from Games Workshop. For miniatures though, our recommendation over this is the Anycubic Photon Ultra, which proves that DLP is the future of 3D printing technologies.

Despite a much lower printing resolution, the sharpness of DLP (providing results on par with the Mini 8k) coupled with Anycubic’s softer Craftsman Resin and Cheaper Price make this a much more balanced choice. It’s super quiet, low energy and the projector lasts 10x longer than an LCD. It’s super fast with very little in the way of fumes. and unlike the Mini 8k, There’s far less to go wrong and because you don;t get anywhere near as much outward light bleed as you do with LCD printers. dialing the exposure settings in for sharp prints is a breeze.

Everything else is in the middle of the road so read below what the benefits are (normally at the cost of print quality) to see if it’s the right printer for your needs.

Before we begin properly, let’s get this out of the way. Now is the perfect time to get a 3D printer, miniatures, d&d, Warhammer, proxies, unique sculpts and more are readily available at comparable quality to retail products from your favourite brands. This is perfect for people who want truly unique d&d miniatures, 3D print them in just a few short hours.

Yes In 2022 it’s finally possible to recreate the model quality you’ll see from some of your favourite manufacturers, using consumer-grade home 3D printers. do you play Warhammer? 3D printed miniatures will probably be a very appealing prospect. and yeah you can easily just print a whole army of proxy models to use in Warhammer Games. Also, you can still print a ton of stuff to enhance your existing force, giving some incredible and unique style to your models.

However, It’s not only illegal to steal other company’s Intellectual Property, but just finding the 3d printer miniatures models to create such a force is nigh-on impossible, When you want the style of your 3D printed parts to match eachother. Companies like Games Workshop are clamping down on the models which bear obvious similarities with their products. – though there is a growing number of companies out there providing, not only proxies, but also their own games. And this makes the idea of 3D printing for miniature gamers – highly attractive. You can make some incredibly decent 3D printed d&d miniatures or miniatures for various other games. Or even just to paint because they look awesome. 3d printing wargaming miniatures is so much fun!

If you want to know how to paint 3D printed miniatures? well, thankfully it’s exactly the same as any other miniature and unlike most retail resin sculpts. Once fully cleaned and cured, you shouldn’t need to do any further cleanup and a primer will stick great. 3dpreinter and miniature models go hand in hand.

3d printing miniature figurines are really fun and rewarding, it’s essentially a hobby in itself. When you don’t need to worry about stealing from someone else’s IP. You can get some incredible creations.

In fact, generic models are aplenty online, if you’re looking at 3d printing tabletop miniatures or you’re after 3d printed RPG miniatures. Then there are sites which will let you design a custom model and download the file to print it with. This also extends to 3d printing ww2 miniatures and 3d print Napoleonic miniatures too. From full models to components, this opens up a whole new world of possibilities to many modellers.

There are certainly a lot of things to learn when it comes to getting the best out of 3D prints, supporting the components, printing orientation, layer heights and exposure settings. Then once printed you do need to deal with trimming down the areas which supported the printed model. But when you dial your printer in for its environment. You’ll soon and rapidly be printing miniatures at a higher quality than even the likes of Games Workshop produce.

Whilst the process of “whole models printed at 28mm” isn’t quite at its pinnacle yet. Larger models and slightly lesser detailed 3d printer gaming miniatures are still very achievable, even with the existing printers, people are improving on their model printing results every day.

FauxHammer.com is dedicated to finding the best tools for your hobby. Start with our list of Essential Hobby Tools which will lead you to find the Top-10 tools for each category.

8k is further off the mark, with screens at only 7680px wide, itss called 8k, because it’s double the standard 4k. Wait until we see the 12k standard which is closer to 15,000 than 16,000.

So when you are looking at a 2k, 4k, 6k or even 8k printer. you also need to check the screen size. Because any 8k screen which is physically twice as large as an equivalent 4k screen has the exact same resolution for a model printed at the same size on each. Meaning print quality will generally be the same. The bigger printer in this example is only really better if you want to print larger things…

Creality has made a name for themselves by being amongst the first to launch consumer-grade 3D FDM printers, but when it comes to resin, they are still playing catch-up.

The Harlot-One is a solid addition to the range of available 3D printers with impressive resolution and light uniformity. This is a great entry-level Resin 3D printer.

You can still easily use this without issue, but when it comes to dialling in the settings to get the absolute best out of it, you’re a bit more on your own. But to be fair, dialling in settings for a particular resin is easier than most people think. No more than trying to get a stable temperature in your printing room and printing a small resolution tester at various settings so see which looks most crisp.

When it comes to entry-level resin printers, nothing currently beats the popularity of the Mars 2. When I first wrote this article in 2019. It was head to head for the Photon S vs the original Mars, and whilst my preference was for the Anycubic offering for its out-of-box ease of use. The price point for the Mars saw it gain the lead in the engaged community.

Once again, thanks to that community, people have not only dialled in the best curing settings to the millisecond. they have done this with such a variety of resins that is now super easy to get started with just a bit of community support (check [printer name] Facebook groups).

Several popular miniature bitz companies selling physical copies of their own designs have been doing so on the original mars. That’s just popular the printer has become.

And now we have a 4k Printer. Phrozen are an exceptionally well-respected brand but tends to be on a fewer-purchased list, simply because their products aren’t on the world’s most popular marketplace, Amazon.

But check out Phrozen’s own website for a whole host of incredible offerings including printers and their very, very good resin. Of all the manufacturer’s own brand resins, I generally rate Phrozen as the highest.

Even though this is slightly lower on the list than other 4k printers, doesn’t mean it’s necessarily a worse printer. Phrozen is currently the more respected brand and the only reason we have this item lower on the list than the others is because whilst it’s 4k, it’s is over a larger screen area. giving it an ever so slightly smaller YX resolution. And for miniatures, that resolution is paramount to detail.

Yeah sure, when it comes to miniatures we want to print the smaller things, but this is one of the largest resin printers available. Build area wise it rivals the Saturn by an inch, well technically 2 inches. With a 192mm x 120mm x 245mm (7.55″ x 4.72″ x 9.84″) build volume. it can make taller models. Trus me, 2″ can make the difference

Unfortunately once launched, the Photon suffered a myriad of problems. From Cracked build plates to failing LCD’s it did not go as smooth as it could. People have had issues with the antialiasing function too. Whilst Elegoo also had its share of launch issues and general “not up to personal expectation” complaints. By the time the Mono X came to market. The Saturn was already established and generally considered as working.

The mono screen really (as above) helps with these printers. as the normal UV backlight is removed, in it’s place are a grid of UV LED casting light to the curing plate. This allows a more uniform light to be cast across the surface. Allowing the edges to be more defined and speeding up layer cure time.

With a comparatively massive 192x120x200mm (7.55in4.72in7.87in) build area. this really brings 3D resin printing home. The entry-level models are great for a few parts, but whilst you initially buy a resin printer for miniatures and parts. You’ll soon want to throw out larger stuff. This will still give you something the size of a standard action figure.

The reason this is higher up the list than the photon is because of its popularity. Once again, like the Mars, because of the success of the launch and the lower price point. More people have these. more people have tested these with different resins. So if you are looking to skip past a lot of trial and error when it comes to dialling in your settings. there are a ton of people out there to help you.

This is the printer I want. this is the printer you want. This is a veritable wardrobe of goodness when it comes to 3D resin printing. When 3d printing, maximum size may be your consideration. This offers it.

Sure sure, we’re talking about the best printer for miniatures here, and this beast is designed to print some absolutely huge models. And what could be better than printing massive versions of your miniatures? Or printing a whole army in just a few hours on the build plate’s massive surface area!?

Allowing prints up to the maximum build volume of 33 x 18.5 x 40 cm. the things you can make with this are insane. The unit is powered by an 8k 15″ panel – that’s the size of a small TV! The build plate is so large it has relief holes drilled through it just so the resin can get back to the FEP in time to cure the next layer!

Sure, it’s on the more expensive side of printers shown here, but with ‘s sturdy case and incredible build quality. everything is neatly contained in this professional-level unit.

This is an entry-level printer from Anycubic, but as noted above it has some talent. it still has a 4k screen squashed into a small area and is therefore capable of comparable print quality to the other two printers in this category.

if you can see a difference in print quality between them, I’ll be shocked. If you really want to squeeze your budget and get an entry level printer. this is a solid contender

yep, another 4k printer, but this one is especially good for printing miniatures, as I said at the top of the article, 4k vs 4k, doesn’t really matter. It’s Pixels Per Inch (ppi) which is responsible for the X+Y- axis level of detail. And here, because the 4k screen’s printing area is only 6.1″. That’s a lot of resolution in a super small area. 722PPI in fact

The quality of prints you can get from this thing is just absolutely stunning. don’t take my word for it. Don’t even take Phrozen’s word for it. Check out what the community are making in the Phrozen 3D Facebook group

Also noted in his Reddit post is a link to this initial grid of Slicer Settings for this printer using different resins at standard 0.05mm layer heights.

The Elegoo Mars 3 Pro is possibly the best beginner 3D printer on the market right now. And the only reason it’s not number 1 on the list is that the below printers offer better quality miniatures and a few more ease-of-use features.

But the Mars 3 pro is a simple and solid printer which I’ve been having a ton of fun with lately despite owning (what are arguably) better printers. As for build volume, Here’s a quick look at a small force of 3D printed Halo Miniatures (32mm) I printed out in just 2 print sessions! One session for the vehicle and another for the Marines

To get the only negatives out of the way, there are a couple of annoying niggles I have with the Mars 3 pro but in all honesty, I can ignore them and I’m only aware of them because again, I have other printers which don’t have these quirks.

One, The printer’s cooling fan runs whenever the printer is on, rather than when it is printing. So even when I’m not printing, this thing is whirring away, but if anything, this is a handy reminder to turn it off. And Two, most printers nowadays use a Z sensor to automate the levelling process. the Mars 3 pro still requires a manual adjustment by moving the print bed up and down in 0.01mm increments to get the bed level. It’s not a problem just a lack of convenience that other modern printers have provided. on the other side of that coin though, not having this sensor, it’s one less point of failure.

Once you get the layer exposure time dialled in for your environment, just the first level of Antiailising is applied, along with Image blur, you can get super sharp miniatures with only minimal layer lines. And these are pretty much gone after the paint is applied.

On the advancement side though, this printer comes with a powered and refillable carbon filter to remove all those nasty smells and toxins from your printing environment. This works and it works really well. I have this printer in the same office that I’m typing from, and I can’t smell it at all.

The main benefit of the Mars 3 pro for printing miniatures is the huge community behind it. Elegoo has intelligently carved itself out a solid lead in the resin 3D printer space with several notable creators selling hobby parts back from the days of the original Mars.

Any issues with this printer or support you need dialling it in can be found in various online social forums such as Facebook Groups or Reddit Communities. Though, unlike their competitors, Elegoo Manage only one Elegoo Support Group, rather than having a dedicated community per printer, which would be better for us all.

Anycubic’s resin range is already wide and weird so this mid-point printer sits in an odd place. Check their website and you’ll find the M3 category and the Photon category. But within the Photon category, you’ll find all the M3 printers because they are called “Photon M3” So why bother splitting it at all?

Whilst the printer is quoted at 6k (not a real thing just halfway between 4k and 8k), it also has a larger build plate than the printers above. about 30% larger in fact.

If you are looking at the printers above, you could always stretch to this for the convenience of a larger build plate. Buf if you can stretch this far, consider stretching a little farther for the printers below which will give you a solid (8 µm) print quality improvement too.

There seems to be a pattern with 3D printers emerging. Phrozen is often first to come out with a printer range. in this case, it was a 10″ 8k printer. And they don’t rush them out, the build quality of these units is incredible. But then a few months later, the other brands come out with a similar printer of the same quality spec. but they normally add slightly more to the build volume and significantly reduce the price.

For a long time, this was a great little sweet spot for people looking for incredible quality and larger print areas. unfortunately, it’s hard to resist the printers below with their lower price and slightly taller build volume.

OOf the 10″ 8k printers, this model frequently comes in the cheapest. This is fantastic considering that all of these printers are capable of the same print-quality output. The 28.5 µm quoted XY pixel size is a testament to the quality of printers nowadays, the fact that manufacturers are claiming that half-micron in the specs is an arguably pointless metric when you’d be hard-pressed to see the difference between a full micron. or several in fact.

In Practical reality, I can’t see the difference in print quality between one of these and a 22 µm printer. The benefit here is that you have a 10″ LCD, almost a third again over a more standard-size entry-level printer. I’ve quickly found myself opting to print on this far more frequently than a higher-resolution printer, just for the convenience of a larger plate at the cost of a negligible quality difference.

What is Elegoo doing? Well, my guess would be – making sure they are cornering the market. I’ll be honest with you, this printer should have been on this list a lot sooner, but despite me keeping an eye on the announcements from 3D printing companies. I didn’t even know that the Saturn 8k was a thing.

Well, the main one that sticks out is the form factor, unlike the angular style of the Saturn 2, this is essentially similar in profile to the original Saturn, but with the Saturn 2’s 10″ 8k screen.

The difference with the internals is that the Saturn 8k uses a 28 Lamp UV light source, whereas the Saturn 2 has a 48 LED array and a fresnel lens. In theory this should provide us with more intense light and the fresnel lens should help to focus it and make it more uniform.

But if you want a printer “now” and are on a budget. yes, this will give you 95% of what a Saturn 2 gives you at a much lower price… The resulting print quality from each printer would be indistinguishable.

Once again a printer with nigh-on identical specs to those above. But where this is worth the extra money is in the name “Premium” because this really is a Premium printer. Not only is it the best that Anycubic offers, but it is also one of the best-built consumer-grade printers that I’ve ever used.

The Z-Rod alone is about 3-times bigger than the one on the Mighty 8k. The printer itself is huge, much larger than I expected for a 10″ printer and all of that appears to go into the build quality! And there’s more you get here too.

This printer also comes with the benefit of two internal USB-powered Carbon filters. Whilst I have gone nose-blind to resin smells, I had noticed my wife complaining far-less when this printer is running. Additionally, this comes with a screen protector pre-installed and is bubble-free. They also give you a spare too!

Finally, the FEP film has been swapped out for NFEP. which is much tougher than traditional FEP. This has many benefits. It’s made so that resin detaches easier and it should also last longer (assuming you don’t pierce it with stray cured spikes of resin). Beyond that, it is firmer which means your lift height can be lower with NFEP. Sorely needed for a build of this size. But any seasoned resin printer user will know, your total print time is affected more by lifting and retracting than cure time, having this will speed prints up greatly.

All of that extra is worth more than the bump in the price of this printer, but you won’t get noticeably better print quality from this versus any other 10″ 8K printer.

The (not so mini) Mini 8k is the present pinnacle of LCD quality. Whilst the screen has a weird aspect ratio (it’s far wider than it is tall) it is still the highest resolution screen available at this size.

The details this thing can produce are absolutely superb. and it’s here where the line between companies like Games Workshop and what you can print at home – truly start to blur. Yes, you can print better than forgeworld quality models with this thing.

Don’t believe me? well check these out, these are Space Marine Accessories printed on one of our Mini 8K printers. no Anitailising applied, these are as direct to the 3D file as you can get. And go-on. find a layer line? Try…

These parts are nigh on part with production quality models. I know a lot of people worry that printing will kill Games Workshop. That’s highly doubtful, but it has certainly changed the landscape for the quality of the miniatures – now very much in favour of 3D printed parts.

Whilst resin prints aren’t as convenient to work with as GW’s HIPS plastics. What this Mini 8k printer can produce, definitely provides better quality (read as “sharper and more accurate”) parts than what Forge World put out.

So, this is the second consumer-grade DLP printer, as direct sequel to the Photon Ultra. Whilst it feels a bit cheap with its mostly plastic components, including the resin vat. – it’s managed to get our number 1 pick!

Put simply, it’s just so much easier to use than an LCD printer. LCD printers can overexpose and bloat details on a print softening sharp edges. you need to dial them in to 0.1 or even 0.01 seconds per layer to get the perfect exposure time. But on DLP, because the light is so direct, you hardly get any outward light bleed. so once you have the minimum exposure time locked in, you can often go several seconds above that with no discernable impact to print detail.

From our own personal experience, we’ve been able to print higher-quality miniatures on this, far more easily than with the Phrozen 8k – (please note, results will vary from person to person. but my OOB experience was superb). That’s even more impressive when you learn that the resolution is only somewhere around 498ppi (51µm pixel size) (WHAAAAAATTTTT! That’s only 2k, we had those years ago!)

Yeah, that’s 4x less than the Mini 8k, and is actually the lowest XY resolution on this list, well, it shows initially. The huge difference between these and LCD printers is that DLP printers are super sharp when projecting light. Instead of projecting a whole chamber of light and having an LCD block it out (leaving some light bleed around the edges, these DLP models actually project light in the shape of the layer, and only that much light toward the resin. Very Precise.

But by adding 16x antialiasing and 2x Image blur in your slicer, you’ll pretty much make all of that disappear. But because DLP’s project direct light, you still get super-sharp details in the final result whereas an LCD panel will always have some outward light projection no matter what you do.

The added benefit to getting this printer for miniatures is that the included DLP Craftsman Resin is sharp but still quite soft and has some comfortable flex to it, whereas the resin included with the Mini 8k is quite firm and brittle. With that resin you only need to pick up a miniature the wrong way and parts can snap off. With this stuff, it should easily survive the odd drop or fall.

There are a lot of great reasons to use 3D printing in your miniature Hobby. You can incredibly detailed 3d printed custom miniatures. Albeit not quite to the same quality level as the extruded plastic models you will get from retail. But still god enough to exist as parts of your armies. They’re great for making a great multitude of terrain pieces. But the best thing is making custom components and conversion parts for existing models. Think Weapons, Emblems and armour pieces.

Another fun thing to do with 3D printers is to make yourself some hobby tools or supporting components. You can make brush or paint holders, storage for your models, water pots and mini holders. A fan favourite Miniature Painter Garfy, who is very active in the community and has written a ton of incredible guides over on Tale of Painters (one of my personal favourite blogs) has even started up his own 3d printed miniatures business, making some of the Best Miniature Painting Handles you can buy.

If you are wondering “can I sell 3d printed miniatures?” Well, many early adopters have made their investments back 100-fold by selling parts online. I was even considering opening a shop called “3d printed miniatures UK”, specifically as a 3d printing service UK miniatures. But unfortunately, I just don’t have the time.

It doesn’t take much to put 3d printed miniatures for sale on eBay or etsy or quickly create your own 3d printing miniatures service. 3d printed miniatures as a business is still a fully untapped goldmine. Tons of people are looking online for where to buy 3d printed miniatures. So if you are wondering “is 3d printing miniatures worth it?”. Yes, yes it is!

All in all though the process of 3d printing your own miniatures is really rewarding in its own right. Here we are on the first step toward the replicators from Star Trek. Whilst you can already 3D print various foods with these machines, none of them will be edible.

Can you 3d print Warhammer? Meaning generic off-brand miniatures to use in that particular game? Well yeah, (legalities of this is different beast we will go into below) But it’s not just Warhammer, 3D printing has opened up the Quality of Warhammer to so many other areas of this hobby. below we have listed just some of the different things you can look for and many may inspire your creative brain-juices. So have a look and see what takes your fancy.

A friend of mine recently asked me to 3D print some shoulder pads and heads for his Space Marines after seeing all of the custom parts I was using on my Mk VI Horus Heresy Models. He offered to pay me for them.

£0.60p That’s your 3d printing miniatures cost, A similar set of parts would be somewhere around £120 at £15 per set of 100 heads or shoulders. Nothing is wasted either? If you only want 5, print 5.

And this is mostly because the parts in this scenario were only available at a cost. Once you have your printer and resin, you can essentially 3d print miniatures free.

If you want to know how to 3d print rpg miniatures and the like, it really depends on the printer you get. If you what to know which 3D printer for miniatures you should get, this depends on what you want to print.

It’s worth noting that there are 2 main types of 3D printer tabletop miniatures. One of them uses a plastic filament which is fed through a nozzle (or multiple nozzles) These are Fused Deposition Modeling (FDM) printers. The other uses a bath of liquid resin which is hardened when light is focussed within it, commonly known as resin printers. Even within these 2 main categories, there are some further subcategories.

Have a reel of plastic wire called PolyLactic Acid (PLA) or Acrylonitrile Butadiene Styrene (ABS). often referred to as 3d printing miniatures “filament”. The latter of which is generally stronger, but requires more head to become usable. They are types of thermoplastic which means they can be heated to a temperature which makes them act like a liquid.

An FDM printer will feed this reel of plastic wire into a nozzle which heats it to its reformable temperature. The plastic is extruded through the printer’s nozzle and the print head is moved around. The printer extrudes the plastic layers. Once a layer of a model is complete, the head moved up and prints the next layer.

The quality of these prints is based on many factors, so you may want to check for your printer’s best filament for 3d printing miniatures – the type of plastic used. Also the size of the nozzle, the minimum layer height you can achieve and your patience. But generally (when compared to resin 3d printers below) the print quality is much lower but you can make much larger models. Once printed you’ll need to look up techniques on how to smooth 3d printed miniatures such as how to sand 3D printed miniatures or how to smooth 3D printed miniatures. It’s not a fun process in either case and often leads to softening of many details.

The printers are quite a different beast altogether when compared with FDM above. Instead of a reel of plastic wire, you create a bath of liquid resin. the resin hardens when UltraViolet (UV) Light is directed at it. here’s where we have the subcategories.

StereoLithography Apparatus(SLA) technology uses UV lasers focused on particular points causing the resin to harden. Unlike FDM printers where the print head moves. with Resin printers, the light sits below the resin bath. The print base itself is raised upwards as the laser is focused. You’ll see that with resin printers, they actually print the models upside down.

Digital Light Processing (DLP) is identical in the way it works except instead of lasers this uses a UV projector. This also prints in layers, however with SLA printers where the laser traces the surface of each layer (like some high-tech etch-a-sketch)). DLP will actually print a whole layer at the same time. This makes them faster than SLA printers. DLP printers have the advantage of using a projector to focus light. As you may know, light does not easily travel in a straight line. So where LCD printers with a large array of light shone through them causes outward fade which naturally softens edges on prints. DLP printers are capable of incredibly sharp results as the light projection is more direct. (these types of printers currently provide the sharpest results – but in some cases, maybe that’s too sharp). DLP printers also last much longer than LCD printers where the LCD itself is classed as a consumable component.

The difference really is that DLP printers will project the shape of each layer up at the resin, whereas LCD printers will project light and the screen blocks it out, leaving only the shape you want for each layer.

Liquid Crystal Display (LCD) is the most common type of resin printer, though even within this category there are subcategories such as monochrome panels providing darker blacks and preventing light bleed through blacked-out areas. The newer printers also tend to come with a reflected UV array of lights rather than a UV lit backlight – All that is before we even start to consider printer resolution (below). AS stated above. We’ll go into the details below, but the general challenge with LCD over DLP is that between the (0.02mm – 0.05mm) LCD and the build plate, the light is not focussed, so whilst it cures upwards, it also slightly cures outwards, softening the edges of a print. but at super high resolutions, does this even matter? well, no not so much.

Generally, though, the most noticeable impact on quality is with the individual layers of the model. If these are too thick (deep/tall), you can see ridges on the individual layers which are printed. These are especially prominent on FDM printers and will show even after a model is primed. There are ways to smooth these out like manually sanding, which takes forever or using acetone-like vapours which smooths out the whole model, including any intentionally sharp edges. You could also coat FDM prints in liquid resin and then cure that with UV light.

3D printing is as much a skill as it is a new technology. If you want to get the best out of any of these printers, it’s unlikely you will get those results out of the box. There are a lot of settings to understand for 3D printing which makes or breaks a quality model.

In a similar vein to 2D printers, there are various options to consider. When you get a 2D printer (it’s rather standardised now) you get the option to print in various qualities. Black & White or Colour? are you printing documents or photographs? What quality do you want in that photograph? All of these options can use more or less ink, and print quicker or slower. Even the paper you use and your knowledge of working with that paper type can have a dramatic impact on the result.

It’s the same with 3D printing but more, much more. 3D printing doesn’t have many standards yet, it’s still in its infancy which should excite

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey