are lcd touch screen controls better than glass touch controls in stock

LCD (liquid crystal display) is the technology used for displays in notebook and other automated industry computers. It is also used in screens for mobile devices, such as laptops, tablets, and smartphones.

Like light-emitting diode (LED) and gas-plasma technologies, LCDs allow displays to be much thinner than cathode ray tube (CRT) technology. LCDs consume much less power than LED and gas-display displays because they work on the principle of blocking light rather than emitting it.

Each LCD touch screen monitor contains a matrix of pixels that display the image on the screen. Early LCDs screen had passive-matrix screens, which controlled individual pixels by sending a charge to their row and column. Since a limited number of electrical charges could be sent each second, passive-matrix screens were known for appearing blurry when images moved quickly on the screen.

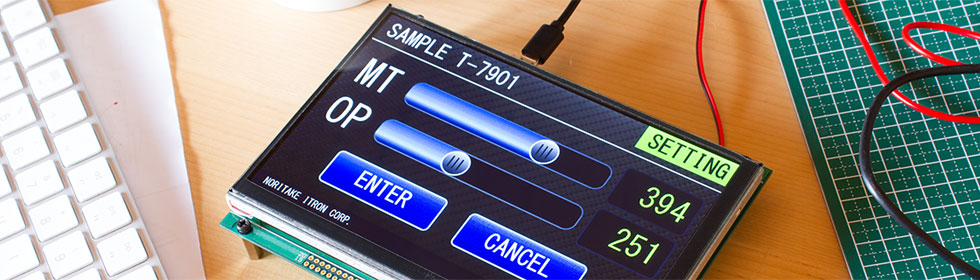

Modern LCDs display typically use active-matrix technology, which contains thin film transistors, or TFTs touch screen. These transistors include capacitors that enable individual pixels to "actively" retain their charge. Therefore, the active-matrix LCDs touch panel are more efficient and appear more responsive than passive-matrix displays.

The backlight in liquid crystal display provides an even light source behind the LCD screen. This light is polarized, meaning only half of the light shines through to the liquid crystal layer.

The liquid crystals are made up of a part solid, part liquid substance that can be "twisted" by applying an electrical voltage to them. They block the polarized light when they are off, but reflect red, green, or blue light when activated.

The touchscreen panel a display device that senses physical touch by a person’s hands or fingers, or by a device such as a stylus, and then performs actions based on the location of the touch as well as the number of touches.

Touch screen glass can be quite useful as an alternative to a mouse or keyboard for navigating a graphical user interface. Touch screens are used on a variety of devices such as computer and laptop displays, smartphones, tablets, cash registers, and information kiosks.

A touch-screen digitizer is one piece in a multilayered "sandwich." In modern devices, the screen that produces the images is found at the bottom layer; the digitizer is a transparent sheet that occupies a middle layer on top of the screen, and a thin sheet of hard, protective glass forms the top layer.

Touching the screen triggers touch sensors immediately under your fingertip; a specialized electronic circuit receives signals from these sensors and converts them into a specific location on the screen as X and Y coordinates. The circuit sends the location to software that interprets the touch and location according to the app you"re using.

For example, when you dial a phone number, your fingers touch the numbers on a virtual keypad on the phone"s screen. The software compares the locations touched against the keypad and generates a phone number one digit at a time.

Touch Screen Glass– The bottom layer is the ITO glass, typically thickness is between 1 and 3 millimetre. If you drop your device, the cracked glass ends up resembling an elaborate spiderweb.

Digitizer – The digitizer is located above the glass screen. It is the electrical force that senses and responds to touch. When you tap your fingertip or swipe it across the screen, the mere touch acts as data input to the device’s center. If your device fails to respond to touch, it’s time for a new digitizer.

The touch screen digitizer is an electrical mechanism that is fused with the glass screen; so if you need to replace the digitizer, you’ll have to replace the glass, too, and vice versa.

Touch Screen Panel- Touchscreen is the thin transparent layer of plastic, which reads the signal from the touch and transports it to the processing unit. It is the part that you can touch without disassembling the device.

LCD – LCD display is an acronym for liquid crystal display. The LCD is the visual component underneath the glass that displays the image on the screen. You can not get to the LCD without taking the device apart first.

![]()

• Perform highly diversified duties to install and maintain electrical apparatus on production machines and any other facility equipment (Screen Print, Punch Press, Steel Rule Die, Automated Machines, Turret, Laser Cutting Machines, etc.).

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

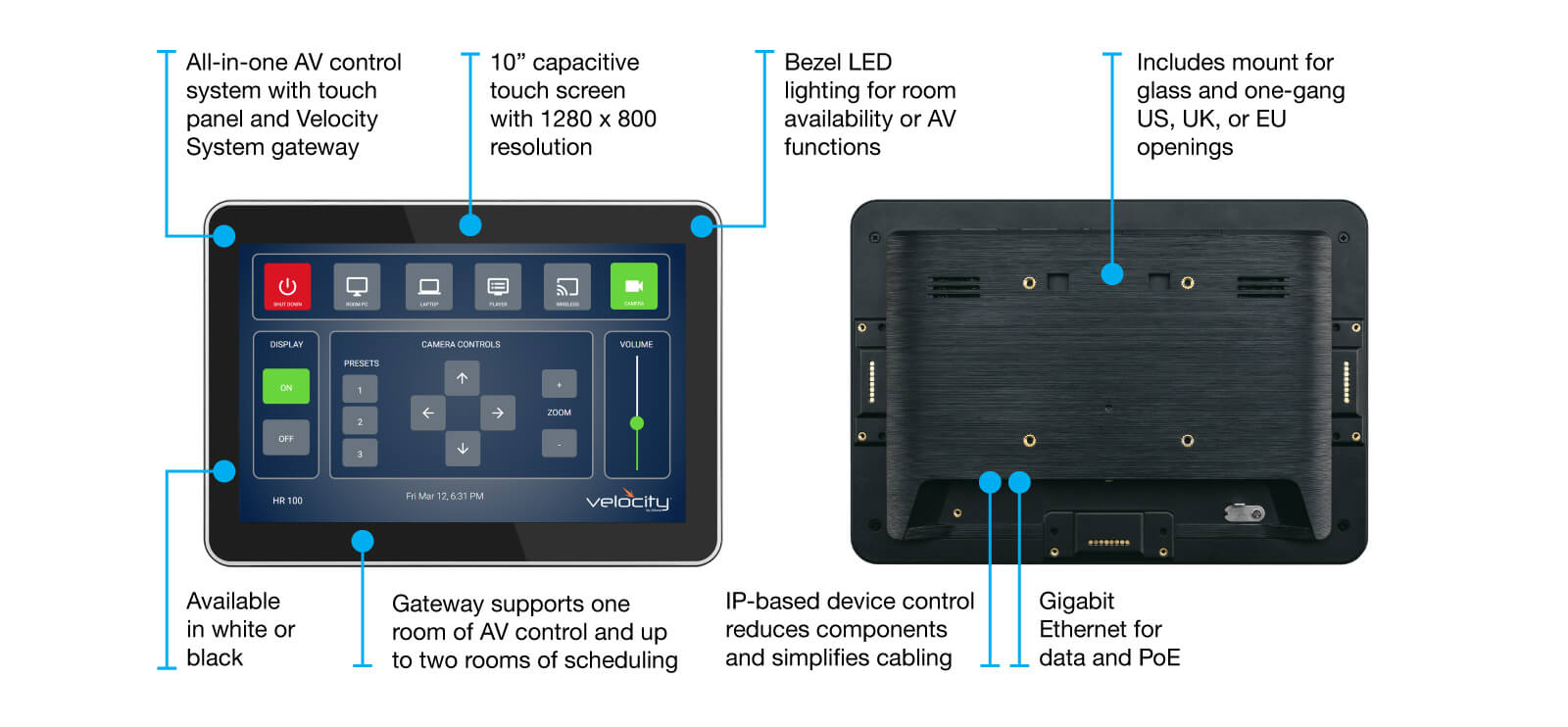

Touch screens give the user control of a device through simple or multi-touch gestures. They enable the user to interact directly with what is displayed rather than using a mouse, trackpad, or other separate components.

Selecting the most suitable type of touch screen for your project can improve device functionality and durability, which can mean a significant increase in customer adoption.

This article highlights the unique advantages and drawbacks of common touch screen technology, to help product design engineers make an informed decision.

Resistive touch is a legacy form of touch screen technology that was broadly popular for many years, but has been replaced by capacitive touch for many applications. Currently, resistive touch has a smaller range of common uses, but can still capably address certain needs.

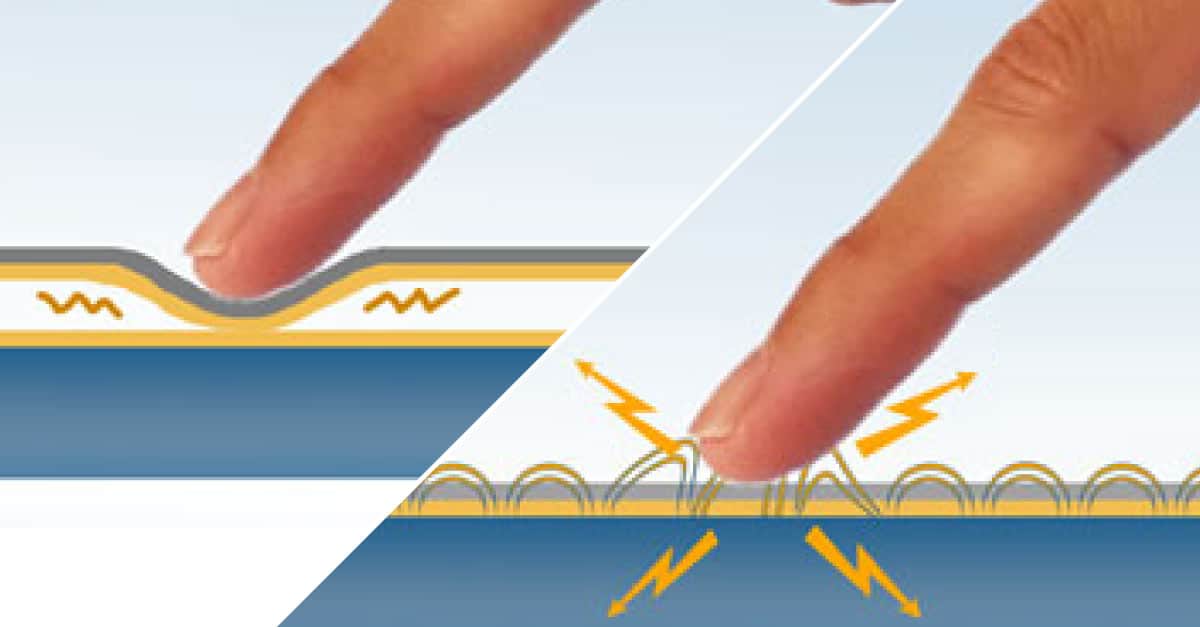

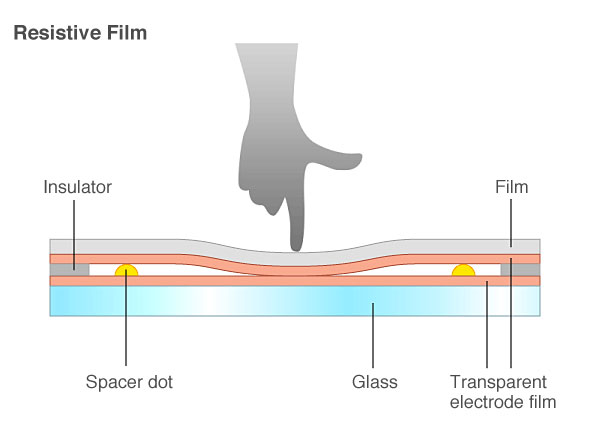

The core elements of a resistive touch screen are two substrate layers, separated by a gap filled with either air or an inert gas. A flexible film-based substrate is always used for the top layer, while the bottom layers substrate can be either film or glass. A conductive material is applied to the inner-facing sides of the substrate layers, across from the air gap.

When a user applies pressure to the top surface, the film indents and causes the conductive material on the top layer to make an electrical contact with the conductive surface of the bottom layer. This activity creates a difference in voltage that the system registers as a touch. The location of this contact is pinpointed on the X and Y axes, and the touch controller then interprets the action. Because physical force is needed for a resistive touch screen to function, it is similar to a mechanical switch.

Resistive touch screens must be calibrated before they are used to ensure accurate and reliable operation. A user must apply pressure to the four corners of the screen, and sometimes on its center, to calibrate the screen with the rest of the system via a lookup database.

Because resistive touch screens interpret physical pressure as a touch, they are effective in a variety of environments using single touch. Any object capable of applying force to the screen can be used with the same result. For example, in applications where end users wear gloves, resistive touch screens offer reliable single-touch functionality.

Since resistive touch screens area actuated via mechanical force, they continue to function as intended even when liquids or debris are present on the surface. This makes them especially useful in situations where substances could disrupt the function of other types of touch screens. For example, on single-touch applications within agricultural equipment, boats and underwater machinery.

Besides the functional advantages of resistive touch screens, price is a common reason why OEMs select this option. In projects where cost is a top concern, companies can use this option to realize savings that may not be possible with alternatives.

The configuration of a resistive touch screen removes the possibility of gestures, such as pinching and zooming, or any actions requiring multi-touch functionality. These screens cannot determine the location of a touch if more than one input is present.

In terms of visibility, the film substrate commonly used as the top surface in resistive touch screens is less transmissive than glass. This leads to reduced brightness and a certain level of haze compared to touch screens with a top layer of glass. The film layer can also expand or contract based on temperature, which alters the distance between the two layers and affects touch accuracy. Additionally, the film substrates are susceptible to scratches and can start to wear away with repeated use, necessitating occasional recalibration or replacement over time.

Capacitive touch screens were invented before resistive touch screens. However, early iterations of this technology were prone to sensing false touches and creating noise that interfered with other nearby electronics. Due to these limitations, resistive touch screens and other options, like infrared touch screens, dominated the industry.

With more development and refinement of controller ICs, projected capacitive (PCAP) touch screens became the preferred touch technology for a majority of applications. For example, this technology is now commonly used on tablets, laptops and smartphones. Though PCAP stands for “projected capacitive (PCAP) touch”, it’s more commonly referred to as “capacitive touch”.

The foundation of PCAP touch screens is an array of conductors that create an electromagnetic field. As a user touches a PCAP screen, the conductive finger or object pulls or adds charge to that field, changing its strength. A touch controller measures the location of this change and then instructs the system to take a certain action, depending on the type of input received.

For a device with PCAP touch technology to acknowledge an input, users simply need to touch the screen. No physical pressure is required, unlike resistive touch screens.

Another key difference from resistive touch technology is that PCAP screens can accommodate a variety of inputs, with different gestures and more contact points instructing the system to take a variety of actions. PCAP touch can support multi-touch functionality, swipes, pinches, and zoom gestures which aren’t possible with resistive touch screens.

A PCAP touch screen is very similar to a solid state switch, as its mechanism of action requires a change in the electrical field over a control point.

The value that comes with recognizing multiple inputs is a clear and positive differentiator for PCAP touch screens. Users can initiate a variety of commands, providing more functionality in devices where this technology is used. Consider how consumers now expect smartphones, tablets, and interactive laptop screens to support actions requiring two fingers, like pinching and zooming. In more specialized settings, such as multi-player gaming applications, PCAP touch screens can support more than 10 inputs at a single time.

PCAP touch screens do not require initial calibration, offering a simpler experience than resistive touch screens. Additionally, PCAP touch screens are highly accurate even as they support a variety of gestures and subsequent actions by the system.

Since their top layer is usually made of glass, PCAP touch screens offer a high degree of optical transmission and avoid the appearance of haze to users. Additionally, the glass top layerprovides improved durability compared to the film top layer of resistive touch screens – even for the largest sizes of up to 80 inches (and growing).

Operation in environments where a PCAP screen may be exposed to liquids or moisture — including conductive liquids like salt water — is possible through specialized controller algorithms and tuning. PCAP technology has evolved to support medical glove and thick industrial glove operation, as well as passive stylus operation.

PCAP touch screens can be customized with different cover lens materials (soda lime, super glasses, PMMA) based on application specific needs. Cover lenses can be ruggedized with chemical strengthening and substrates that improve impact resistance. This can be especially valuable for public-facing applications, like ATMs, gas pump displays, and industrial applications. Specialized films or coatings – such as AG (anti-glare), AR (anti-reflective), AF (anti-fingerprint) – can be added to the cover lens substrate to improve optical performance.

Unlike resistive touch screens, PCAP touch screens depend on variations in an electrical field to operate. While a passive stylus can activate this screen, a non-conductive tool like a pencil can’t.

If cost is a top concern for a project, PCAP may not align with budget limits. It is a more expensive technology than resistive screens, although it continues to grow more accessible in terms of price as the technology advances and improves.

The below table compares the advantages and disadvantages of projected capacitive touch vs resistive touch screens.CharacteristicsPCAP TouchResistive TouchRequires calibrationNoYes

As a leading manufacturer of touch and display products, New Vision Display can help you determine the specific needs of your project and tune your PCAP touchscreen controllers to meet them. Our PRECI-Touch® products are based primarily on PCAP touch technology and can be customized for a variety of applications using a wide range of materials, stacks, and controllers.

Whether your product will be used in a life-saving medical device, the center console of an automobile, or the navigation controls on a yacht – we can deliver an effective solution for your application. To get started on your project, contact our specialists today.

Ready to get started or learn more about how we can help your business? Call us at +1-855-848-1332 or fill out the form below and a company representative will be in touch within 1 business day.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

An infrared touchscreen uses the same magic-eye technology that Tom Cruise had to dodge in the movie Mission Impossible. When your fingers move up close, they break invisible beams that pass over the surface of the screen between LEDs on one side and photocells on the other.

A surface-acoustic wave screen is a bit like an infrared screen, but your finger interrupts high-frequency sound beams rippling over the surface instead of invisible light beams.

With a near-field imaging screen, small voltages are applied at the corners, producing an electric field on the surface. Your finger alters the field as it approaches.

Drawing on a screen with a light pen back in 1973. Although you can"t see it from this photo, the light pen is actually connected to the computer by a long electric cable. Photo by courtesy of NASA Ames Research Center (NASA-ARC).

Photo: Touchscreens are widely used in outdoor applications, such as ticket machines at railroad stations and bank ATMs ("cashpoint" machines). Unlike keyboards, they have no moving parts so they"re robust: safe, vandal-proof, and weatherproof.

Photo: Look, no keyboard! The Sony ebook Reader features an infrared touchscreen (described in more detail below). That eliminates the need for a separate keyboard and allows the gadget to be smaller, more portable, and more reliable. You press the screen to turn pages and create bookmarks, and you can use a pop-up on-screen keyboard to make notes in the books you"re reading.

but they"re very useful where pointing and dragging makes more sense than typing and clicking. This photo shows a US Navy system called DSIMS (Deployable Ship Integration Multitouch System), used for training people in managing the movements of planes and other equipment onboard aircraft carriers. You simply click a plane and drag it where you want it to move to on the flight deck.

that touch technologies would feature prominently in future versions of the Windows operating system—potentially making computer mice and keyboards obsolete. Four years later, it unveiled its Surface range of

Though most of us happily swipe away at our smartphones and tablets every day of our lives, when it comes to work, we"re still largely locked into our old-style desktop computers and operating systems, and the old ways of using them—namely keyboards and mice. In other words, it"s important to recognize that touch technology makes more sense for some applications than others. It"s great to point and click on a smartphone app when you"re doing something as simple as ordering a pizza or checking your bank balance, but if you want to edit an essay, write complex computer code, debug a broken website, or anything that requires quite a lot of fiddly input, touchscreen interfaces can slow you down and frustrate you: they"re just too clumsy and imprecise. Most of us who write a lot will find an ordinary computer keyboard far quicker and more accurate than the pop-up keyboards on tablets and smartphones—and it"s telling that so many people find the need to improve their phones using plug-in keyboards. Rather than trying to be all things to all people, touchscreen devices need to be optimized for those applications where they make most sense. Keyboards, mice, pen tablets, joysticks, speech recognition, and other forms of input will continue to work happily alongside them for many years to come.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

You interact with a touch screen monitor constantly throughout your daily life. You will see them in cell phones, ATM’s, kiosks, ticket vending machines, manufacturing plants and more. All of these use touch panels to enable the user to interact with a computer or device without the use of a keyboard or mouse. But did you know there are several uniquely different types of Touch Screens? The five most common types of touch screen are: 5-Wire Resistive, Surface Capacitive touch, Projected Capacitive (P-Cap), SAW (Surface Acoustic Wave), and IR (Infrared).

We are often asked “How does a touch screen monitor work?” A touch screen basically replaces the functionality of a keyboard and mouse. Below is a basic description of 5 types of touch screen monitor technology. The advantages and disadvantages of type of touch screen will help you decide which type touchscreen is most appropriate for your needs:

5-Wire Resistive Touch is the most widely touch technology in use today. A resistive touch screen monitor is composed of a glass panel and a film screen, each covered with a thin metallic layer, separated by a narrow gap. When a user touches the screen, the two metallic layers make contact, resulting in electrical flow. The point of contact is detected by this change in voltage.

Surface Capacitive touch screen is the second most popular type of touch screens on the market. In a surface capacitive touch screen monitor, a transparent electrode layer is placed on top of a glass panel. This is then covered by a protective cover. When an exposed finger touches the monitor screen, it reacts to the static electrical capacity of the human body. Some of the electrical charge transfers from the screen to the user. This decrease in capacitance is detected by sensors located at the four corners of the screen, allowing the controller to determine the touch point. Surface capacitive touch screens can only be activated by the touch of human skin or a stylus holding an electrical charge.

Projected Capacitive (P-Cap) is similar to Surface Capacitive, but it offers two primary advantages. First, in addition to a bare finger, it can also be activated with surgical gloves or thin cotton gloves. Secondly, P-Cap enables multi-touch activation (simultaneous input from two or more fingers). A projected capacitive touch screen is composed of a sheet of glass with embedded transparent electrode films and an IC chip. This creates a three dimensional electrostatic field. When a finger comes into contact with the screen, the ratios of the electrical currents change and the computer is able to detect the touch points. All our P-Cap touch screens feature a Zero-Bezel enclosure.

SAW (Surface Acoustic Wave) touch screen monitors utilize a series of piezoelectric transducers and receivers. These are positioned along the sides of the monitor’s glass plate to create an invisible grid of ultrasonic waves on the surface. When the panel is touched, a portion of the wave is absorbed. This allows the receiving transducer to locate the touch point and send this data to the computer. SAW monitors can be activated by a finger, gloved hand, or soft-tip stylus. SAW monitors offer easy use and high visibility.

IR (Infrared) type touch screen monitors do not overlay the display with an additional screen or screen sandwich. Instead, infrared monitors use IR emitters and receivers to create an invisible grid of light beams across the screen. This ensures the best possible image quality. When an object interrupts the invisible infrared light beam, the sensors are able to locate the touch point. The X and Y coordinates are then sent to the controller.

We hope you found these touch screen basics useful. TRU-Vu provides industrial touch screen monitors in a wide range of sizes and configurations. This includes UL60601-1 Medical touch screens, Sunlight Readable touch screens,Open Frame touch screens, Waterproof touch screens and many custom touch screen designs. You can learn more HERE or call us at 847-259-2344. To address safety and hygiene concerns, see our article on “Touch Screen Cleaning and Disinfecting“.

Touch screens are found everywhere from our smartphones to self-serve kiosks at the airport. Given their many uses, it should come as no surprise that there are several touch monitor types. Each has its advantages and disadvantages and is suited to specific tasks.

That’s right. Long before your precious smartphone entered the market in the late 00s, touch panels had already been an established technology for nearly 4 decades.

It’s quite possible that you’re not clear on exactly what a touch panel is, what the touch panel types are, or how they’re applied in your daily life, beyond that of your smartphone. For that and more, we’re here to help.

Quite simply, touch panels, which are also known as touchscreens or touch monitors, are tools that allow people to operate computers through direct touch. More specifically, via the use of internal sensors, a user’s touch is detected, then translated, into an instructional command that parlays into visible function.

Delving deeper into the technical side of things, touch panels are not as cut-and-dry as they may seem. In fact, the way they sense and react to touch can widely differ based on their inherent designs. As such, there are 4 touch panel types in regular use – Resistive, Optical Imaging, Projected Capacitive, and Infrared. Below, we’ll dig into their specifics, which include their advantages, disadvantages, and real-life product applications.

Resistive touch panels are cost-effective variants that detect commands by way of pressure placed on the screen. This pressure sensitivity is generally limited to single-point touch, with a 20-inch maximum screen, which is fine for many usage cases. These range from styluses to fingertips. As a result, if used correctly, resistive touch panels will remain functional even if a water drop has landed on the screen.

As a result of this versatility, however, many will find that resistive touch panels are less durable than their competitors. Moreover, with its reliance on single-point touch, this touch panel type is not actually capable of multi-touch functionality. Regardless, resistive touch panels are often found in grocery stores, where stylus-based signatures are typically required after credit card purchases.

Some like it hot and some don’t. Infrared touch panels definitely fall into the latter category. By setting up a grid of infrared beams across the panel, which may be up to 150-inches, touch is detected by way of this panel’s disruption.

Although infrared touch panels are durable and support multi-touch functionality, it does possess one potential drawback. Depending on where you sit, literally.

Despite infrared implying heat, infrared touch panels actually perform rather poorly in it, particularly in direct sunlight. In those circumstances, the infrared light beams can be disrupted by the sun’s rays, as opposed to your fingers. As such, be sure to place your infrared touch panel device in an appropriately dark location.

Light, and the disruption thereof, is not just a great way to produce a shadow, but also to design a touch panel type. To take advantage of this principle, optical imaging touch panels are designed to sense touch through infrared cameras and the disruption of light strips. This can be achieved through any input you want, across its 100-inch maximum size, from gloves to bare hands, and beyond.

All in all, optical imaging touch panels are just about the most versatile option the touch-based world can offer. From durability to multi-touch, and universal input prospects, the possibilities may truly be endless. Although its only disadvantage may be its non-compact design, common applications of optical imaging touch panels include certain varieties of interactive whiteboards.

If you identify with the phrase, “go with what you know”, then projected capacitive touch panels are the touch panel type for you. For now, you can guess where you know it from.

By way of their electrical-based touch detection, Projected Capacitive touch panels are known for their high precision and high-speed response times. What’s more is that they possess multi-touch functionality and can be used within small, compact, yet expensive, devices. Due to their underlying technology, it has proven challenging to scale up to larger sizes. Figured it out yet?

Assuming you haven’t, or would like to enjoy the gratified feeling associated with being right, allow us to reveal where you interact with projected capacitive touch panels on a daily basis – Smart Phones! What’s more is that they’re not alone, with tablet computers and GPS devices also utilizing projected capacitive touch screens.

It would be a mistake to assume that the applications of all these touch panel types are limited to that of consumer-level devices, or even those that have been previously mentioned. Really, these touch panel types can be found throughout everyday life and in a variety of industries.

What’s more is that in many of these industries, these touch panel types are used less to market products to consumers, and more to sell solutions to businesses. Whether it be in regards to finance, manufacturing, retail, medicine, or education, there is always a need for touch-based solutions. In conjunction with the so-called ‘Internet-of-things’, these touch-based solutions play a key role in practices related to industry 4.0.

In practice, these solutions largely offer a form of personnel management. In hospitals, stores, or banks, for instance, these touch panel types can be used to answer basic questions, provide product information, or offer directions, based on the user’s needs. When it comes to manufacturing, on the other hand, these solutions enable employee management in the possible form of workplace allocation or attendance tracking.

At the end of the day, touch panels are here to stay. In the four decades since their inception, the level of adoption this technology has experienced is remarkable. They transform how we teach in classrooms and collaborate with colleagues.

Although you may not have been clear on the specific details of each touch panel type, we hope that you are now. This knowledge will absolutely serve you well, particularly if you’re interested in ViewSonic’s selection of touch-based solutions.

OVERVIEW Laid flat or angled for customized comfort, this display delivers touchscreen versatility to the max. Offering fantastic flexibility for retail, education, or business settings, the ViewSonic® TD2430 is a 24” (23.6” viewable) Full HD display with 10-point multi-touch functionality. Delivering adjustable positioning, wide-angle viewing, and a durable design, the TD2430 has everything to accommodate your unique needs. Adding even more convenience, cross-compatibility with a wide range of operating systems includes Windows 10/11, and certain Android and Linux versions.* With a sleek edge-to-edge screen and frameless bezel, this intuitive touchscreen performs like your favorite tablet or smartphone to deliver a highly accurate, ultra-responsive touch experience ideal for interactivity in public environments, kiosk and wayfinding applications, classroom settings, and more. *Supports Windows 7/8/10/11, Linux 2.6.38 or later, and Android 4.0 or later.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Here"s a question: What is a technology that you can"t see, but is essential to smartphones, tablets and other mobile devices -- and is estimated to generate $16 billion in revenues this year (according to DisplaySearch)? The answer is multitouch touch screens -- which have sparked the explosive growth of the mobile device market.

It was not so long ago that we would tap away on a PalmPilot with a tiny stylus, or exercise our thumbs on a BlackBerry micro-keyboard. Then, in January 2007, along came the , and everything changed. Suddenly, people were wiping their fingers across screens, pinching images and performing other maneuvers that had not previously been part of the interface.

Now we not only take touch input for granted, we expect to be able to use multitouch (using more than one finger on the screen at a time) and gestures as well. What made this touch screen revolution possible, and where is it likely to take us?

According to touch industry expert Geoff Walker of Walker Mobile, there are 18 distinctly different touch technologies available. Some rely on visible or infrared light; some use sound waves and some use force sensors. They all have individual combinations of advantages and disadvantages, including size, accuracy, reliability, durability, number of touches sensed and -- of course -- cost.

As it turns out, two of these technologies dominate the market for transparent touch technology applied to display screens in mobile devices. And the two approaches have very distinct differences. One requires moving parts, while the other is solid state. One relies on electrical resistance to sense touches, while the other relies on electrical capacitance. One is analog and the other is digital. (Analog approaches measure a change in the value of a signal, such as the voltage, while digital technologies rely on the binary choice between the presence and absence of a signal.) Their respective advantages and disadvantages present clearly different experiences to end users.

The traditional touch screen technology is analog resistive. Electrical resistance refers to how easily electricity can pass through a material. These panels work by detecting how much the resistance to current changes when a point is touched.

This process is accomplished by having two separate layers. Typically, the bottom layer is made of glass and the top layer is a plastic film. When you push down on the film, it makes contact with the glass and completes a circuit.

The glass and plastic film are each covered with a grid of electrical conductors. These can be fine metal wires, but more often they are made of a thin film of transparent conductor material. In most cases, this material is indium tin oxide (ITO). The electrodes on the two layers run at right angles to each other: parallel conductors run in one direction on the glass sheet and at right angles to those on the plastic film.

When you press down on the touch screen, contact is made between the grid on the glass and the grid on the film. The voltage of the circuit is measured, and the X and Y coordinates of the touch position is calculated based on the amount of resistance at the point of contact.

Many vendors are quick to trumpet the use of Corning"s Gorilla Glass in their products. The glass is used as a protective outer layer for many devices, from smartphones to large flat panel televisions. But what makes Gorilla Glass different?

The answer lies in the composition of the glass itself. Most display glass is an alumina silicate formulation, which is made up of aluminum, silicon, and oxygen. The glass also contains sodium ions spread throughout the material. And this is where the difference starts.

The glass is put in a bath of molten potassium at about 400 degrees. The sodium ions are replaced by potassium ions in a process that"s a bit like soaking a pickle in salty brine. It"s a diminishing process: More of the sodium ions are replaced by potassium at the surface of the glass, and then fewer and fewer are exchanged as you go further into the glass.

Why change from sodium to potassium? Sodium (Na) has an atomic number of 11, while potassium (K) has an atomic number of 19. If you remember your high school chemistry, this indicates that the potassium atoms are significantly larger than the sodium atoms. (The atomic radius of a neutral sodium atom measures out as 180 picometers and potassium at 220 picometers, so potassium measures out as more than 20% larger.)

That"s what happens with glass when the potassium ions take the place of the sodium ions. The potassium ions take up more space and create compression in the glass. This makes it more difficult for a crack to start, and even if one does start, it is much less likely to grow through the glass.

The concept of strengthening glass through ion exchange is not new; it has been known since at least the 1960s. And other companies offer glass that has been strengthened by this type of process. Corning"s Gorilla brand of strengthened glass has gained considerable market share, however, and has a very visible presence in the marketplace.

There are a variety of touch technologies available today, with each working in different ways, such as using infrared light, pressure or even sound waves. However, there are two touchscreen technologies that surpass all others - resistive touch and capacitive touch.

There are advantages to both capacitive and resistive touchscreens, and either can be suited for a variety of applications dependent on specific requirements for your market sector.

Resistive touchscreens use pressure as input. Made up of several layers of flexible plastic and glass, the front layer is scratch resistant plastic and the second layer is (usually) glass. These are both coated with conductive material. When someone applies pressure to the panel, the resistance is measured between the two layers highlighting where the point of contact is on the screen.

Some of the benefits of resistive touch panels include the minimal production cost, flexibility when it comes to touch (gloves and styluses can be used) and its durability – strong resistance to water and dust.

In contrast to resistive touchscreens, capacitive touchscreens use the electrical properties of the human body as input. When touched with a finger, a small electrical charge is drawn to the point of contact, which allows the display to detect where it has received an input. The result is a display that can detect lighter touches and with greater accuracy than with a resistive touchscren.

If you want increased screen contrast and clarity, capacitive touch screens are the preferred option over resistive screens, which have more reflections due to their number of layers. Capacitive screens are also far more sensitive and can work with multi-point inputs, known as ‘multi-touch’. However, because of these advantages, they are sometimes less cost-effective than resistive touch panels.

Although capacitive touchscreen technology was invented long before resistive touchscreens, capacitive technology has seen more rapid evolution in recent years. Thanks to consumer electronics, particularly mobile technology, capacitive touchscreens are swiftly improving in both performance and cost.

At GTK, we find ourselves recommending capacitive touchscreens more regularly than resitive ones. Our customers almost always find capacitive touchscreens more pleasant to work with and appreciate the vibrancy of image that cap touch TFTs can produce. With constant advancements in capacitive sensors, including new fine-tuned sensors that work with heavy duty gloves, if we had to pick just one, it would be the capacitive touchscreen.

A surface capacitive touchscreen uses a transparent layer of conductive film overlaid onto a glass sublayer. A protective layer is then applied to the conductive film. Voltage is applied to the electrodes on the four corners of the glass sublayer to generate a uniform electric field. When a conductor touches the screen, current flows from the electrodes to the conductor. The location of the conductor is then calculated based on the activity of the currents. Surface capacitive touchscreens are often used for large screen panels.

Projected capacitive touchscreens are extremely precise and quick to respond and are typically found on smaller devices such as iPhones, iPod touches, or iPads. Unlike the surface capacitive touchscreens, which use four electrodes and a transparent conductive film, the projected capacitive touchscreens use a vast amount of transparent electrodes arranged in a specific pattern and on two separate layers. When a conductor moves near the screen, the electrical field between the electrodes changes, and sensors can instantly identify the location on the screen. Projected capacitive touchscreens can accurately register multi-touch events.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey