lcd display lifespan factory

How long will your LED display last? In nearly every industry, from retail businesses to concert halls to corporate centers, decision makers need to evaluate the return on investment (ROI) of their LED signage. In most cases, potential buyers go straight to the obvious place: the LED manufacturer’s spec sheet. The industry standard for LED lifespan is 100,000 hours, or about 10 years, and most people assume that’s how long their display will last. But it’s not quite that simple.

The 100,000-hour figure assumes that every diode will be running at full brightness, consistently — which, on an LED screen, is virtually never the case. The lifespan figure can also be misleading because it indicates when a diode degrades to half-brightness, not completely dark. Many other variables affect an LED display’s lifespan; you can’t rely solely on the number on the diode spec sheet.

“The reality is, your screen can often last significantly longer than 100,000 hours,” says Kevin Izatt, a senior product manager in Samsung’s Display division. “We’ve had displays that have been up for 15-plus years with more than adequate brightness. Because the diode is actually only one factor in the lifespan of your LED display.”

The biggest contributor to diode degradation is heat. As you increase a diode’s brightness, it produces more heat. Your display’s physical environment also contributes to the temperature of the diodes, especially for outdoor displays.

The quality of your display’s power supply — and how hard it drives the diodes — can have a significant impact on your screen’s lifespan. The other components being powered, such as fans and electrical components, have their own lifespans as well, which are also impacted by the power supply.

“Fans are mechanical; they break down,” explains Izatt. “And similar to your computer, the electrical components don’t last forever. Together, these factors all contribute to the lifespan of an LED display. Looking at just the diode lifespan doesn’t give you the complete story — almost always, another part will go out first.”

It’s easy to see why: The circuit boards powering the display release heat, and that heat needs to go somewhere. Without a strong design, thermal stress will degrade the life of the display, except for the highest-quality parts — optimal conditions notwithstanding.

That’s not to say you should hold back on displaying rich, vibrant colors — after all, that’s what LED does best. But it does factor into your product’s life expectancy.

To help businesses transition from LCD to longer-lasting LED signage, Samsung has launched a trade-in program. Samsung will come on site to remove your existing display and provide a discount on a new LED bundle kit.

Traded-in LCD displays that are still operating will be refurbished and resold, and your business will receive a cash rebate. Nonworking displays will be recycled and their parts reused.

You can’t rely on the number on the diode spec sheet; the lifespan of your LED display depends on many more factors. “Overall quality has a tremendous impact on the life of the display that diode specs just don’t take into account,” says Izatt. Your best bet is to look at the purchase holistically and invest in a top-tier product.

As you plan your LED signage rollout — or an upgrade — learn how to configure and tailor your screens’ real-time messaging with an integrated CMS in thisfree guide. And if you haven’t decided what kind of display is best suited to your current project, compare all ofSamsung’s LED displays.

Perhaps you’ve wondered how long a digital display lasts. It’s a great question. One quick search on Google will tell you that an LCD panel has a lifespan of about 60,000 hours, which is equivalent to almost seven years.

Of course, LCDs aren’t the only kind of displays. You also have LED, OLED, QLED, ELD, PDP, and MicroLED, plus many other variations. Obviously, that 7-year estimation will not apply across the board. For the sake of ease, let’s just focus on some of the common types of displays that most of us are familiar with.

Here’s some LCD alphabet soup: There are LED LCD displays, CFFL LCD displays, LED displays, and more. With all these acronyms, it can get a bit confusing. What"s important to note is whether or not the display uses an LCD panel, and how the LCD panel is illuminated. You can read more about thedifferences between types of LCD and LED signage, but these are the most common types:

LCD displaysgenerate images and colors via a Liquid Crystal Display (LCD) panel, which is not self-emitting and requires an external light source to illuminate the image, typically an LED backlight. Their full name "LED-backlit LCD display" is commonly shortened to "LED displays", which is why they"re often confused with the true LED displays we"ve identified above.

Unfortunately, LED backlights used in LCD displays burn out over time. If used at high or maximum brightness, which is necessary for outdoor applications,an LED backlight will last between 40,000 to 60,000 hours. Or, about 4.5 to 7 years.

OLED stands for Organic Light Emitting Diode. OLED displays differ from common LCD displays in that their pixels are self-illuminating. In other words, there is no LED backlight required to illuminate the the display image; everything occurs within the OLED pixels themselves. According to onearticle from the US Department of Energy,OLED screens have a life expectancy of about 40,000 hours at 25% brightness, and 10,000 hours at full brightness. That equates to about 1 to 4.5 years, which is a much shorter (albeit, brilliant) lifetime than an LCD display.

Perhaps you noticed that the acronym QLED closely resembles the acronym OLED. This is not accidental. QLED is basically Samsung’s original design built to compete with OLED technology. However, the two are not the same. QLED stands for Quantum Light Emitting Diode. While QLED is similar to a regular LED design, it in fact differs by using nanoparticles called “Quantum dots” to achieve its unique brightness and color. Samsung approximates that the lifespan ofQLED panels are likely to last 7-10 years. After that, a user is likely to notice traces of degradation.

MicroLED is an emerging display technology, consisting of small LEDs in tiny arrays within each pixel. This technology goes beyond the offerings of the formerly frontrunning OLEDs, with much darker blacks and more radiant contrast levels. And, unlike OLEDs, MicroLEDs are not organic. They are not as subject to burn-in, and thus, have a longer lifespan than OLEDs. However, they are significantly more expensive - so much, in fact, that they aren’t considered a viable option for the majority of consumers.According to Samsung, the lifespan of its MicroLED panels should last about 100,000 hours, or, roughly 11 years.

PDP stands for Plasma Display Panel, and it refers to displays that use small cells full of plasma. The atoms within the plasma emit light upon being charged by electricity. While PDP is generally considered to offer better colors than LCDs, they consume a lot more power and usually cannot be battery-operated.The average lifespan of the newest generation of PDPs is approximated to be 100,000 hours, or 11 years of continual use.

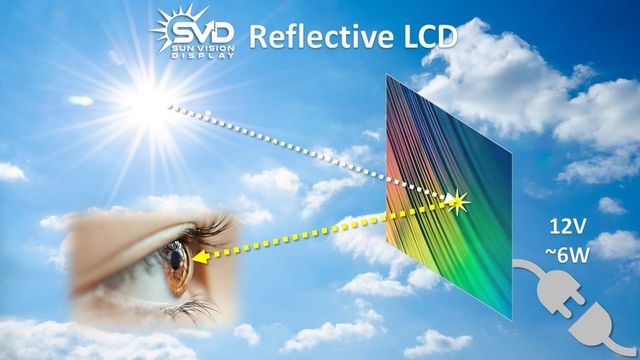

In some ways,reflective LCD panelsoperate similarly to other LCDs, only they have one key difference - they do not require a backlight. Instead, they rely on ambient light (or sunlight) in order to produce images. This opens the door to some groundbreaking possibilities. The first (and most appreciable) is low power consumption. Reflective displays use up to 95% less energy. Not bad - especially in a world that is continually looking for new ways to go green. Take into consideration the financial implications of this. Lower power means less money spent on operating costs.

Being that reflective displays do not require a backlight (a component that is particularly subject to degradation), and since they do not generate as much heat, it is safe to say that the lifespan of these displays should far exceed that of backlit LCD panels (which was 7 years at the high end). However, being that thisinnovative technologyis relatively new, its actual lifespan is therefore more difficult to estimate -- simply because it has yet to be reached.

There are also a few challenges that can affect reflective displays. For one, they rely on ambient light. On a nice sunny day, these displays perform beautifully and can be easily seen in even the brightest of conditions. This performance wanes as the available ambient light decreases. And, since they do not generate light of their own, they are not designed to be viewed under nighttime or extremely low light conditions (without additional lighting features). In short, their images are visible to the degree that ambient light is present. However, in light of this, side light (and front light) options are being explored.

One company at the front lines of this research isAzumo. Azumo has created a light guide that laminates to the front of a display. It requires 90% less energy than the backlight of a traditional LCD display. This greatly improves the problem of low light visibility otherwise encountered, and keeps reflective displays in the same low energy consumption ballpark. One issue, however, is that Azumo currently only offers its light guides for smaller-sized units. If you happen to want this feature applied to a display that is over 10” diagonally, then you’re still on the search for a solution.

One other factor to consider regarding reflective technology is its cost. That reflective layer is more costly to manufacture than many of the backlights it replaces, creating a seemingly greater upfront cost for those who are interested in investing in energy-efficient signage. However, these initial price points are quickly justified as buyers will recognize the significantly lower operating costs and increased longevity (not even including replacement costs of other “expired” displays) that comes with their purchase of reflective display signage. If a backlit LCD panel only lasts 7 years, for example, you’ll have paid for that LCD twice in the period of ten years. A very valid question arises… is that “cheaper” backlight really cheaper? Probably not. It only feels that way at first.

Sun Vision Displayis working hard to create reflective display solutions for the digital signage world. We are currently offering them in 32" and 43" diagonal sizes, with a 55” size in development. These displays are built formany environments. We are thrilled to be bringing such innovative solutions to the market.

All screens, whether commercial grade or consumer grade will have a limited lifespan. While the old CRT TVs could often to run for decades (well my trusty portable did, anyway) before expiring, the same cannot be said for modern LCDs and plasmas.

The lifespan of a modern flatscreen is measured by a half-life, when the screen’s dims to half its original brightness. With LCDs, while the actually display itself could perhaps run for decades, the TV’s half-life is governed by the backlight. And depending on what system provides the backlight (LEDs seem to have the longest life), a typical LCD display will last between 30,000-80,000 hours before the screen reaches its half-life, with commercial grade screens at the higher end.

Plasmas have less longevity with the plasma/gases powering the image decaying over time, providing a half-life perhaps half of that of LCDs, which is one of the reasons that plasmas are utilized less than LCDs for digital signage.

LCD enclosures are commonly used for outdoor digital signage and information screens in drafty concourses and manufacturing facilities as they weatherproofing and a ruggedness essential in these conditions; however, LCD enclosures also contain environmental systems such as air-filters, cooling fans, heaters (in cold areas), anti-glare screens—all ensuring the internal conditions of the LCD enclosure are the optimum for a screen to operate in, helping to the maximum the life-span of the screen, and ultimately saving money.

You may still remember the first TV that came into your home, probably fitted with a cathode ray tube. At the time, the idea of flat screens was almost a science fiction thing, and probably none of the people in the house thought that the appliance had an expiry date. Today, however, we know from experience that this is not the case, and that any gadget is designed to last, at most, as long as the technology on which it is based. So that you don’t have to replace your monitor prematurely, we would like to offer these tips to increase your LED display’s lifespan.

However, before getting into the subject, it is important to point out that we are dealing with a technology that is too recent to talk about complete life cycles. Even so, it is estimated that the average lifespan of an LED display is between 60,000 and 100,000 hours, depending on the use of the screen. Thus, in the best-case scenario, this would be equivalent to using an LED screen for six hours a day for 45 years.

Another aspect that must be made clear is that, when referring to lifespan, we always think of the main component of the screen: the panel, despite the fact that there are other elements that can negatively affect the operation of an LED display. Without going any further, it is much more likely that a circuit will be damaged before the panel is (ignoring, of course, the logical loss of brightness due to the passage of time and the appearance of dead pixels).

Likewise, the replacement of an LED display does not have to occur because it no longer works: its performance may no longer be optimal, which can compromise the achievement of the goals set in any given marketing campaign.

We know that the ideal location for an outdoor LED display, at least from an advertisement point of view, will not always coincide with the place that has the best climatic and atmospheric conditions for the conservation of your display. In any case, and although our outdoor LED displays are equipped with rain protection, a rather dry climate with a moderate number of hours of sunshine is more conducive to the conservation of any LED display than one that is rainier and sunnier. As for indoor LED displays, avoid placing them in rooms with humidity or where they tend to accumulate dust. In this way, you can better protect it from environmental conditions.

If you are installing indoor LED displays in your store window, make sure that the sunlight does not hit the display directly, as this would force you to adjust the contrast and brightness to very high levels. While Visual LED displays always ensure perfect visibility regardless of environmental brightness, forcing these settings would increase power consumption and therefore could shorten the life of the monitor. Keep this in mind when dealing with window display dressing in your business.

To extend your LED display’s lifespan, it is essential to always use products with a suitable formulation for the external components of the display. In saying this, we are not just referring to chemical products, but also to other products commonly used at home to polish televisions, such as vinegar. When you buy your screen, Visual Led will tell you which products are best suited to remove dirt from your LED display.

It may seem obvious, but this is one of the most common mistakes made by both individuals and companies. In case you need to change the location of your LED displays for shops and shop windows, always hold them at the ends. Obviously, you also have to be careful not to accidentally bang them.

Sony Semiconductor Solutions has strongly invested in R&D to overcome the inherent challenges of OLED micro-display technology. Exceptional results prove them right – like a long lifespan, stable brightness and the new burn-in avoiding Orbit technology.

Miniature OLED displays are cutting-edge small video displays providing fast response,high-contrast image technology and precise color reproduction. The very thin displays bring greater visual impact to Near-to-Eye (NTE) applications like industrial and consumer AR/VR/MR, broadcasting, electronic view finders, industrial maintenance, and, medical devices. Farrukh Hussain from Sony Semiconductor Solutions talks about the specific advantages of Sony’s OLED micro-display technology, and about selecting the optimal display model for facing the unique challenges in the five top industries.

The specific advantages depend on the environment in which the OLED micro-display is employed. I will focus on the Near-to-Eye (NTE) display systems, where the tiny pixelated display surface is magnified by dedicated auxiliary optics. Here, OLED micro-displays have three main benefits over other technologies like LCD, or LCOS displays.

First, no external backlight is requiredfor OLED displays. OLED is a self-emitting, electroluminescence display which is based on the substrate organic material. The lack of external backlight makes the display much thinner and lighter, resulting in an ideal form factor for NTE devices, and both low power consumption and low heat generation. Also, it is worth mentioning that each and every pixel is individually illuminated only when the current is applied to it that enhances image quality. In the case of LCD displays, the backlight is always on for the full display area, thereby reducing maximum contrast. At the same time, OLED micro-displays can significantly reduce power consumption as only active pixels require current.

Secondly, another advantage is the outstanding contrast. Each pixel is illuminated individually, and those pixels which need to be black are off, without requiring current. Therefore, black is truly black, without the light leakage that can be observed in LCD displays; here, black often appears to be gray. The application of OLED technology results in a contrast ratio that is greater than 100,000:1.

A third and truly innovative benefit is the fast response time; this feature is especially important for medical devices and the response time required by AR / VR headsets in gaming scenarios. The light emission occurs immediately after current is applied on each pixel. Therefore, the response time in OLED micro displays is in terms of microseconds (µs), compared to milliseconds (ms) for LCD displays. The liquid-crystal (LC) molecule has longer relaxation times and re-alignment takes more time after excitation. Also, the OLED response time remains unaffected by low temperatures, where the LCD response time is slower in cooler environments. Therefore, OLED micro-displays have a much wider operating temperature range than LCD displays.

However, like all emerging technologies, OLED micro-displays come with their inherent challenges. It is one of our most important goals at Sony Semiconductor Solutions to overcome these hurdles and explore new frontiers.

First of all, it is our incentive and corporate goal to constantly improve – we at Sony Semiconductor Solutions invest many R&D resources and research hours to focus on the aforementioned challenges. Let me explain how we attempt to solve these challenges: Today, the shorter lifespan of OLED devices is a kind of a pre-conception and always depends on operating conditions. Some of our panels would take many of thousands of hours to reach half-luminance levels, which means years or nearly decades of high-brightness operation, based on the given daily usage hours. Additionally, and as a testament to our products, Sony’s OLED micro-displays lifetime degradation performance is unmatched by our rivals.

Secondly, limited luminance levels are an inherent challenge for OLED display technology. Limited luminance levels, to a degree, are acceptable in applications like VR headsets or Electronic viewfinders. However, augmented reality (AR) applications require much higher luminance output levels from their display source. Most of our competitors can offer luminance up to maximum 1,000 or 2,000 cd/m2. Some of our latest display panels guarantee a luminance output of up to 3,000 cd/m2,without an impact on lifetime degradation. This high luminance output is a unique offering. Our goal is to double this luminance figure and eventually eliminate this drawback entirely for our customers.

Currently, we have succeeded with the effect of burn-in: The concern with burn-in is now redundant; we have developed a unique Orbit Function which blurs the sharp edges of static images, and makes it more difficult to detect the burn-in phenomenon in Sony OLED micro-displays.

The mass production of semiconductor components is a highly technical and complicated process. However, Sony Semiconductor Solutions is well known for selecting high purity SI wafers, the precise application of EL deposited layers, and final cell assembly. After many years of business, we have successfully shipped millions of OLED panel micro-displays panels from our factories. We are very proud to offer a very stable and robust supply chain on which our customers can rely.

Any near-to-eye system is a potential use for OLED micro-displays. Electronic View Finders for industrial and consumer cameras, electronic binoculars and monoculars for thermal imaging and bird watching, are two industries where OLED technology is at the forefront of development. Additionally, medical devices, remote procedures, fundus cameras, and ophthalmic devices are the focus of our customers. Gaming and entertainment headsets are the most common use cases for Virtual Reality (VR). Other examples are remote assistance wearables and mixed reality headsets in the area of Augmented Reality (AR). The application of OLED technology is not restrictive, especially in the industrial environment. Here, there are many individual examples in this environment that are dedicated to very specific applications.

In addition to these industry specific criteria, all of our OLED micro-displays function with large apertures, high luminance, a wide colour spectrum, less reflectance, and a high dynamic range. They operate with extreme speed and without motion lag, or blur.

The complete OLED portfolio is available through FRAMOS. The industry and product experts at FRAMOS are available to support customers with the integration of OLED displays into their applications and projects. The table below provides information to customers for selecting the optimal micro-display for their industrial application (Table 1):

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

Sony produces and sells commercial MicroLED displays called CLEDIS (Crystal-LED Integrated Displays, also called Canvas-LED) in small quantities.video walls.

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Business Place Information – Global Operation | SAMSUNG DISPLAY". www.samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

Byeonghwa, Yeon. "Business Place Information – Global Operation – SAMSUNG DISPLAY". Samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

www.etnews.com (30 June 2017). "Samsung Display to Construct World"s Biggest OLED Plant". Archived from the original on 2019-06-09. Retrieved 2019-06-09.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

OLED displays have higher contrast ratios (1 million : 1 static compared with 1,000 : 1 for LCD screens), deeper blacks and lower power consumption compared with LCD displays. They also have greater color accuracy. However, they are more expensive, and blue OLEDs have a shorter lifetime.

OLED displays offer a much better viewing angle. In contrast, viewing angle is limited with LCD displays. And even inside the supported viewing angle, the quality of the picture on an LCD screen is not consistent; it varies in brightness, contrast, saturation and hue by variations in posture of the viewer.

There are no geographical constraints with OLED screens. LCD screens, on the other hand, lose contrast in high temperature environments, and lose brightness and speed in low temperature environments.

Blue OLEDs degrade more rapidly than the materials that produce other colors. Because of this, the manufacturers of these displays often compensate by calibrating the colors in a way that oversaturates the them and adds a bluish tint to the screen.

With current technology, OLED displays use more energy than backlit LCDs when displaying light colors. While OLED displays have deeper blacks compared with backlit LCD displays, they have dimmer whites.

LCDs use liquid crystals that twist and untwist in response to an electric charge and are lit by a backlight. When a current runs through them, they untwist to let through a specific amount of light. They are then paired with color filters to create the display.

If you are new to the world of digital projectors, you won"t have to shop around long before discovering that the terms LCD and DLP refer to two different kinds of projectors. They are in fact two different kinds of microdisplay imaging technology. You might not even know what LCD and DLP are before asking the obvious question "which one is better?"

It is important to note there is a third significant light engine technology called LCoS (liquid crystal on silicon). It is developed and marketed by several vendors, most notably Canon, JVC, and Sony. Many excellent projectors have been made with LCoS technology, including several outstanding home theater projectors that can, in the opinion of many observers, surpass the value proposition of both LCD and DLP offerings. The discussion of LCoS technology is beyond the scope of this article, and will be addressed separately in an upcoming article.

You may have already seen the term 3LCD on websites and in projector literature and press releases. Several makers of LCD projectors have adopted 3LCD as a marketing brand name. It is intended to distinguish the specific implementation of LCD technology found in digital projectors from the more common direct view LCD displays found in a wide variety of consumer products. In LCD projectors there are always three LCD panels, and they are always light transmissive devices rather than reflective or direct view displays. Within the projector industry, there is no technical difference between 3LCD and LCD, and the terms can be used interchangeably.

Well, the answer to this question depends on your definition of the word "lead." As of this writing, DLP technology has a significant lead in terms of the number of models currently in production. As of this date, July 28, 2009, our database lists 704 different DLP-based models in production, as compared to 430 LCD models. Thus, DLP holds a commanding lead in the number and variety of models being produced.

However, this is not the whole story. Many of the best selling projectors these days are LCD models. As an example, at the moment, six of the Top 10 Most Popular 1080p home theater projectors on this site are LCD"s, two are DLP and two are LCoS. In fact, despite the clear advantage DLP has in the number of models in production, Pacific Media Associates reports that LCD projectors held a 51% market share by unit volume in 2008. Clearly both technologies have a huge market presence, and neither one is about to emerge as the dominant player.

LCD (liquid crystal display) projectors contain three separate LCD glass panels, one each for the red, green, and blue components of the video signal. Each LCD panel contains thousands (or millions) of liquid crystals that can be aligned in either open, closed, or partially closed positions to allow light to pass through. Each liquid crystal behaves in essence like a shutter or blind, and each represents a single pixel ("picture element"). As red, green, and blue light passes through the respective LCD panels, the liquid crystals open and close based on how much of each color is needed for that pixel at that moment in time. This activity modulates the light and produces the image that is projected onto the screen.

DLP ("Digital Light Processing") is a proprietary technology developed by Texas Instruments. It works quite differently than LCD. Instead of having glass panels through which light is passed, the DLP chip is a reflective surface made up of thousands (or millions) of tiny mirrors. Each mirror represents a single pixel.

Sealed imaging chip. Most DLP projectors have sealed DLP chips that eliminate the possibility of a dust particle alighting on the imaging plane, which could create a dust spot on the projected image. LCD projectors do not have sealed panels, and the possibility of getting a dust spot exists. This is especially true when air filters are not cleaned periodically as per operator manual instructions.

Recognizing dust as a potential problem, Mitsubishi has taken extra steps to combat dust contamination in their latest filter-free DLP projectors, the XD3200 and WD3300. They have sealed the color wheel to prevent dust from reaching it. They have also made design improvements to the light pipe and airflow channels which reduce the amount of dust that can reach the lamp. These changes are intended to help maintain the lamp"s lumen output potential over its lifespan.

Those who advocate using air filters on projectors maintain that dust is never good inside a projector, and that the user is better off with a filtered design that prevents dust from entering the projector to begin with. All LCD projectors use air filters, as do some of the higher end 3-chip DLP models from vendors such as Runco and Digital Projection.

Those who support filter-free designs point out that many users of filtered projectors do not follow recommendations for cleaning or replacing air filters. If an air filter gets clogged over time, it can inhibit airflow, increase internal operating temperatures, and adversely affect the life of the LCD panels.

No convergence problems. All projectors using three imaging devices, whether they are LCD, DLP, or LCoS, must have all three devices aligned perfectly so that the red, green, and blue information for each pixel is in convergence. Over time, these three device systems can slip out of alignment. On occasion they can come out of the box, brand new, with slight convergence errors. Convergence errors can soften the projector"s image and create color artifacts where there shouldn"t be any.

Contrast advantages. Most business class DLP projectors (those intended for portable presentation or conference room use) have much higher Full On/Off contrast ratings than comparably priced LCD models. ANSI contrast figures are rarely published in the projector industry, but our measurements indicate DLP projectors usually have an edge over the LCD competition in ANSI contrast as well. However, with the introduction of inorganic LCD panels that are now used in most LCD 1080p home theater products, DLP"s traditional advantage in contrast within the home theater market niche has been neutralized to a large extent.

No image persistence. If one displays a static image for an extended period of time, an LCD projector with organic LCD panels may have a tendency to retain a subtle ghost of that image even after the subject matter is switched to another image. This does not occur on a DLP projector. Nor does it occur on LCD projectors that use inorganic panels.

Some of the advertising hyperbole has blown the seriousness of this issue out of proportion. Anti-LCD ads have claimed that LCD projectors are subject to "burn-in." Strictly speaking, this is not really true. Burn-in, in traditional usage, refers to permanent damage that can be suffered by CRT or plasma phosphor-based displays. Once a static image has been etched into a phosphor display through long term exposure, it cannot be removed. This is a different phenomenon than we see on LCDs. On organic LCD displays, when image persistence occurs, it is temporary and can normally be erased by displaying a white screen for a period of time.

Nevertheless, the point is that image persistence does not occur on either DLP projectors or inorganic LCD projectors. So on these products there is never any need to take steps to erase a persisting image.

No degradation of image quality over time. There is usually no degradation of image quality on DLP projectors when used over long periods of time, other than that which might result from excessive internal dust build-up. But in any event, the DLP chips themselves will not degrade. Conversely, LCD panels and polarizers can degrade with time, causing color shifts, unevenness of illumination, and reduction of contrast. The degree to which LCD degradation is a problem on current products is somewhat of a mystery since those who know the most about it (the LCD manufacturers) don"t discuss it publicly. This issue will be discussed further below.

Somewhat less pixelation/screendoor effect on low resolution products. One of the historical advantages of DLP over LCD has been a reduced level of pixelation in the image. Pixels tend to have sharper definition on an LCD projector, and this can produce a more visible pixel structure in the image. This is often called the screendoor effect, since the picture on low resolution projectors can look like it is being viewed through a screendoor.

However, the differences between LCD and DLP in this regard are not as great as they used to be for two reasons. First, LCD makers have achieved smaller interpixel gaps, making the screendoor effect much less visible. Second, the average native resolution of projectors being sold today has increased dramatically over what it was several years ago. With increases in resolution come smaller pixels and a less noticeable pixelation across the board. Nevertheless, on low resolution products like SVGA and even standard XGA, DLP projectors still have an advantage in manifesting somewhat less visible pixel structure than LCD projectors. (Note: There is a disadvantage to having less distinct pixel structure, which is reduced image sharpness. We will discuss this further below.)

DLP leads in miniaturization. The single-chip light engine affords the opportunity for extreme miniaturization that LCD cannot quite match. At the moment there are 15 DLP projectors on the market that weigh less than 3 lbs and put out more than 1000 lumens. By comparison, the lightest 3LCD projector on the market weighs 3.5 lbs and most are 4 lbs or more.

Since LCD projectors and 3-chip DLP projectors always deliver a constant red, green, and blue image simultaneously, they do not create rainbow artifacts.

Today, some DLP projectors being built for the home theater market use a color wheel containing two sets of red, green, and blue filters. This wheel still spins at 7200 RPM, but because red, green, and blue are refreshed twice in every rotation rather than once, the industry refers to this as a 4x rotation speed. And by increasing the physical rotation speed beyond 7200 RPM, some projectors now have 5x or 6x speed wheels. For the large majority of users, the 5x and 6x speed wheels in most current home theater models have reduced rainbow artifacts in video display to the point where they are of little or no concern.

However, most DLP projectors built for commercial/presentation use still use 2x speed wheels because they are less expensive. This is perfectly fine if the presentation matter is static charts, graphics, photography, or anything that does not stimulate rapid eye movement. We do not recommend DLP projectors with 2x speed wheels to buyers for whom video display or part time home theater are important intended uses.

Color saturation/color brightness. Some DLP projectors have excellent color saturation, and some are exceptionally poor. This is related more to the vendor"s implementation than anything inherent in the technology itself. Advocates of 3LCD technology have been quite vocal about the lack of color brightness on single-chip DLP products, particularly those that have white segments in the color wheel. This phenomenon is worth commenting on.

When you use a light meter to measure the brightness of red, green, and blue on an LCD projector, the sum of the values usually adds up to the brightness reading you get for white. This makes sense because on an LCD projector, white is created by turning the red, green, and blue channels all fully on. But on a DLP projector, this is often not the case. Due to the presence of a white segment in the wheel, the white reading can be as much as double the sum of the brightness readings for red, green, and blue. In other words, if an LCD projector measures 2000 lumens of white light, you will also get 2000 lumens of color light out of it. If a DLP projector measures 2000 lumens of white, you might get only 1000 lumens of actual color light from it, the rest being white light.

Because of this, proponents of 3LCD technology have been lobbying for color brightness specs to be included along with ANSI lumen specs on the industry"s specification sheets, and support for this has been building in the industry. In the spec wars, quite clearly this would be one metric on which LCD has a commanding advantage over DLP. Not surprisingly, Epson and Sony have already begun to publish color brightness specs on their LCD projectors to drive home the point. The color spec is always the same as the ANSI lumen rating, and the specs will read, as an example, "2600 lumens color light output, 2600 lumens white light output."

From a practical perspective, we have mixed feelings about all of this. Clearly, the 3LCD camp is correct that the traditional ANSI lumen spec does not tell the whole story. But neither does the color brightness spec. To be sure, the color on some DLP projectors looks dull and anemic next to some LCD models of the same lumen rating. Ironically, this can be particularly true when the "BrilliantColor" feature is enabled. Though BrilliantColor boosts the brightness of the image, it can substantially reduce color saturation in the process. It is peculiar that in order to get the richest and most saturated color from many DLP projectors, one needs to turn BrilliantColor off. (This is not universally true of all DLP projectors with BrilliantColor, since the BrilliantColor system can behave quite differently based on how it is implemented by the vendor.)

Oddly enough, on some DLP models with white segments in the wheel, even those on which color brightness falls far short of white, we see a rich, vibrant color that can easily match an LCD projector in the same price and lumen class. One reason is that the color filter configuration of the wheel has a lot to do with the end results. Another reason is that, though the DLP"s color brightness may fall short of white, the effect of the DLP"s inherent contrast advantage helps to compensate for it. That compensating effect cannot be quantified in a spec. Even when color brightness falls very far short, the picture sometimes does not end up looking much dimmer at all when put side by side with an LCD projector of the same white light output.

When a DLP projector"s color vibrancy looks poor next to a comparably priced and spec"d LCD projector, it is due to a variety of design and product cost decisions made by the vendor, and not anything inherent to DLP technology per se. DLP can look truly spectacular or downright dismal depending on what is done with it. With so many variables in play, the specs can"t tell the whole story, even if a color brightness spec were added to the mix. The publication of color brightness specs would be interesting, and would certainly draw attention to a noteworthy technical difference between LCD and DLP. But it is not conclusive information that would help an astute buyer sort out which model to buy.

Dithering artifacts. At any moment in time, each mirror position on a DLP chip is either fully on to render maximum brightness, or fully off to render black. There is no way a DLP mirror can be "partially on" to represent gray, like an LCD liquid crystal can. Therefore, the way the DLP chip renders gray is to flip the mirrors on and off very rapidly, such that they are on just enough of the time for the eye to average the "on"s and off"s" to a desired level of perceived brightness. This approach to rendering grays is called dithering. It works well enough for rendering gray values, but it can produce some visible instability in solid fields, mostly dark areas, referred to as dithering artifacts. It looks like digital noise, but it is a separate type of artifact caused by DLP technology itself, and not by the signal.

Dithering artifacts do not occur on LCD products because there is no dithering used to achieve varying levels of gray. The liquid crystals can be either fully open, or closed, or partially opened at intermediate positions to achieve the desired level of light transmission--again, similar in concept to shutters on a window.

Restricted compatibility with zoom lenses and lens shift. Due to the nature of DLP light engine mechanics, it is difficult for vendors to incorporate long zoom lenses or extended range lens shift features into a DLP projector. These limitations are not relevant in mobile presentation projectors since the primary design objective is small physical size, so none of them have big zooms or lens shift anyway. But in the home theater market in particular, LCD vendors have captured significant market share in part due to their ability to incorporate long 2.0x zoom lenses and extensive lens shift capability into LCD projectors. This makes it much easier for the consumer to install the projector anywhere they want, which is quite frequently on a rear shelf in the room. Due to lens restrictions on DLP projectors it is rare to be able to install a DLP model on a rear shelf.

Many of the advantages and limitations of 3LCD have already been touched on above within the context of the DLP discussion. However, there are several advantages of LCD not yet discussed, and some of the issues already noted warrant a recap and/or further expansion. The following are the key benefits of LCD technology:

Better price/performance in HT products. The primary key to the success of LCD products in the home theater market is their tremendous price advantage. In the 1080p niche in particular, LCD products deliver outstanding image quality performance for the money. Moreover, they are generally loaded with extra features that don"t appear on DLP models in the same price range, if they are offered on any DLP model at all.

The price advantage of LCD over DLP is most obvious in consumer/home theater products. There is no similar disparity in pricing on commercial products built for mobile presentation and conference room use. One reason is that DLP makers can use the cheaper 2x speed wheels on most business products, whereas it is mandatory to have high speed color wheels and the faster electronics associated with them on products designed for home theater.

Higher contrast in HT products. Many LCD projectors built for home theater have achieved better overall contrast performance and deeper black levels than DLP models. This is specifically the case on LCD models using inorganic LCD panels and auto iris technology. Inorganic panels are more expensive to produce, so they are not used in cheaper, commercial grade business projectors. They achieve higher contrast due in part to the fact that the resting position of the liquid crystal is closed (i.e., black), and voltage is required to open it. This is the opposite of traditional organic LCDs wherein the resting position is open (maximum light transmission), and voltage is required to close it. The inherent contrast advantage of inorganic panels has made LCD substantially more competitive in the home theater marketplace. ANSI contrast in particular has seen significant improvement. In our measurements, LCD projectors with organic panels typically run in the range of 250:1 ANSI contrast, whereas the models with inorganic panels have been reaching performance levels of 400:1 to 450:1.

3LCD vendors have been aggressive in developing effective auto iris systems which contribute an incremental perceived contrast advantage on screen. There is no technical restriction that we know of that would prohibit DLP vendors from doing the same thing. But it would add further cost to DLP projectors that are already at an apparent cost disadvantage relative to LCD in the home theater market. There is also a perception among vendors that DLP contrast, while not leading edge, is sufficient, so enhancement via auto iris is not vital. Thus, most DLP vendors have been slow to incorporate auto iris systems on DLP projectors being marketed for home theater.

Fewer artifacts/greater image stability. As noted previously, dithering artifacts and rainbow artifacts are unique to single-chip DLP projectors. Since these artifacts do not exist on LCD products, it is not unusual to perceive a more stable video image on an LCD projector when viewed side by side with a DLP counterpart in a similar price and performance class. The LCD"s video image can look cleaner and more free of noise.

Sharper image with data display. Since LCD pixel structure is more sharply defined that DLP pixel structure, it tends to render a sharper image. This is most noticeable in lower resolution business products (SVGA and XGA), and specifically with data display. It is in these resolutions that LCD"s screendoor effect is somewhat more visible in a video image, but the advantage is that the sharper pixel definition can produce a sharper display of data. By comparison, a DLP projector in SVGA and XGA resolution can look a bit soft when displaying data images.

On higher resolution products the difference in apparent sharpness is minimal, and it is a non-issue with video display on 1080p products. Both technologies can produce very sharp images in 1080p, and any perceived differences in sharpness typically have to do with factors unrelated to the display technology, such as lens quality and video processing.

Greater installation flexibility in HT products. LCD projectors built for home theater often feature 2.0x zoom lenses and extensive vertical and horizontal lens shift. This makes them easy to install just about anywhere. By comparison, DLP projectors usually have short zooms with little or no lens shift. Fixed throw angles limit the projection geometry, and often dictate where a DLP projector must be placed in order to accommodate a given screen size and location.

For the DIY home theater enthusiast on a budget, the lens flexibility of LCD models has great appeal. For the fact is, most DLP projectors need to be ceiling mounted, and most LCD projectors don"t. Thus they save the extra cost of a ceiling mount and long run video cables. They also eliminate the prospect of having to run cables through walls and ceiling, or living with an unsightly track of cables across the ceiling.

Better light efficiency, less power usage. LCD technology is inherently more light efficient. For the most part LCD projectors use lower wattage lamps to produce the same image brightness that you"d get from DLP. This is most noticeable when comparing LCD projectors to DLP projectors that have no white segment in the color wheel. As an example, compare two currently popular 1080p home theater projectors--the Panasonic AE3000 LCD projector uses a 165-watt lamp to produce 1600 ANSI lumens. Meanwhile, the Sharp Z15000 DLP projector needs a 250-watt lamp to get the same 1600 lumens. That can make a noticeable difference in power consumption. It can also make a difference in the amount of heat being generated by the projector"s exhaust in the viewing room.

Unknown lifespan of LCD panels. Given enough prolonged exposure to high intensity UV light and extreme heat, the organic compounds used in most LCD panels are expected to degrade over long periods of time. This degradation can lead to a discoloration of the image and a reduction in contrast. The only way to fix it is to replace the damaged LCD panel, which is typically a cost-prohibitive proposition. You are normally better off buying a new projector.

The big question of course is how long the panels will last. There is no good data on this subject that has been compiled by an independent lab and published for general consumption. LCD vendors do not typically acknowledge LCD degradation can occur, so they don"t make any representations about expected life. In general, most LCD vendors maintain that to the degree LCD panels might be subject to eventual degradation, it will be beyond the practical life of the product.

One trusted and very experienced industry source who develops products using both LCD and DLP technology believes that LCD panels have a lifespan in the range of 4,000 to 10,000 hours, with the lifespan depending on how bright the projector is--the brightest LCD light cannons will produce the most stress on the panels resulting in quicker degradation. Low brightness models such as those made for home theater will produce the least stress, and are expected to last longer.

Texas Instruments has performed several tests on LCD lifespan over the past seven years. Based on these tests, they believe that LCD panels will degrade faster than the LCD vendors are willing to admit, and certainly more quickly than the 4000 hours just quoted. The 3LCD camp"s response is that TI"s tests have been performed by running LCD projectors continuously 24 hours a day, 7 days a week, for several months straight. According to 3LCD and Epson, since the projectors used in TI"s lab tests were never designed for a continuous operation high-stress duty cycle, the results are not indicative of what the typical user would experience.

The introduction of inorganic LCD panels is an important new development that is germane to this issue. Inorganic LCD panels, in theory, should not be subject to the same degradation patterns as organic LCDs, simply because the organic compounds that fail under intense heat and UV light are not present in inorganic LCDs. However, the LCD camp will not confirm or deny any anticipated differences in panel life because as a matter of policy they do not discuss the issue at all. Texas Instruments has not commented on the expected lifespan of inorganic LCDs either.

Lower contrast ratings in business products. Most commercial and education LCD projectors are made with the relatively inexpensive organic LCDs and no auto-iris. Contrast ratings on these models typically run in the 400:1 to 700:1 range. Meanwhile, DLP projectors in the same resolution, lumen, and price class can often be rated at 2000:1 or higher.

In reality, this constitutes more of a marketing disadvantage than a technical one. In most business/commercial and classroom settings, projection display is done with room lights on. With moderate ambient light--enough for children in a classroom to take notes for example--a projector"s contrast rating is largely irrelevant. Actual contrast on screen with moderate ambient light is typically in the range of 50:1 regardless of the theoretical contrast potential of the projector. But for buyers who are not aware of the huge impact of ambient light on contrast ratios, the apparent advantage of DLP over LCD in contrast ratings can appear to be more significant than it really is.

Susceptible to dust spots. Since LCD light engines are not sealed, it is possible for dust particles to alight on the LCD panels, thereby creating a dull, indistinct spot on the projected image. This usually causes little distraction when displaying static images such as data or photographs. But in full motion video, seeing a stationary element in a moving picture can be extremely distracting.

When dust lands on an LCD in the red or blue channel it is rarely visible enough to create a distraction. But when it occurs in the green channel it can become quite visible. Some vendors have provided methods by which the user can remove the dust without having to send the unit in for cleaning. Sanyo"s home theater models come with a hand pump that will blow a jet of air across the panels, but since we"ve never seen a dust spot on a Sanyo projector, we"ve never been able to test the device. Other than this sort of solution, packing the projector up and sending it to a maintenance depot for cleaning is the method of last resort for getting the projector back into serviceable shape.

LCD makers claim that today"s air filter systems are superior than those of the past, and that dust contamination is highly unusual if the filters are cleaned and replaced as per normal maintenance instructions. Most LCD vendors cover dust removal under warranty, which is a good reason to buy LCD projectors with extended warranties.

When we review projectors, we have no way to assess the actual risk to the user of dust contamination on any particular model. We can say that it is rare for us to notice dust spots on LCD projectors that we get in for review, or on units that we keep in operation for ongoing reference purposes. However, it is easy for users to forget to clean filters since under normal usage vendors recommend this be done every two months or so. When filters are left unattended, the user increases the risk that dust will eventually find its way into the projector.

The fight for market share between 3LCD and DLP continues at a fevered pitch. It is a fascinating thing to watch as vendors of both technologies continue to innovate to stay a step ahead of the competition. Picture quality in digital projectors has improved dramatically over the past decade with significant increases in contrast, resolution, and color performance. Prices have dropped like a rock, and high quality projection systems that once were within financial reach of wealthy consumers or businesses who really needed them, are now within the budgets of mass consumers. Thus the consumer is the ultimate beneficiary of the intense competitive struggle between the DLP and 3LCD technologies.

As we"ve tried to make clear in this article, both DLP and 3LCD have key advantages over the other. They also both have limitations that the buyer should be aware of. But in the end, we see better image quality performance today from both LCD and DLP than we"ve ever seen in the past. And it just keeps getting better.

Based on my experience with LCD projectors, my rule of thumb for organic LCD panel degradation is to assume that the projector will be unusable by the time you finish the second bulb. So if the bulb is rated at 3000 hours, I would assume a useful life of the projector at no more than 6000 hours. If you use such an organic LCD projector as a TV replacement you will likely have to replace it every few years.

Owner of 14 projectors I have used both LCD and DLP projectors in a 24 hour a day operation with static images on the screen for the most part. I have found DLP projectors out perform LCD in many areas. I have middle of the road $5k DLP projectors and one high end >$12k all of which have lasted years longer than my LCD projectors all of which were >$10k. I actually replaced LCD panels regularly in one manufacturers and the burn out was quick. The other projector was cost prohibitive to replace. I will go with DLP unless the unit is not used much.

If an LCD panel can produce for example 2000 Lumens at white (all 3 panels on full), then how can it produce 2000 Color Lumens? Like if it"s a Red color being displayed, it wouldn" t use all 3 panels on full thus the Lumen output would have to be greatly reduced. It would be primarily the red panel on and the other would be off or greatly reduced.

Is there any anecdotal evidence that inorganic LCD panels do last longer? I"d be particularly interested in hearing from someone like Richard who appears to really put projectors through their paces.

I have to wonder if the fact that TI has not published the results of a study on inorganic LCD means that the panel life is long enough to be a non-issue. This isn"t evidence in itself, but it is one plausible explanation.

I"ve had a DLP projector in the past and was relatively happy with it. I"ve been considering LCD, mainly because of the placement flexibility of zoom & lens shift, but things like dust blobs and panel life have made it difficult to pull the trigger on those purchases.

It would have been interesting to hear details on why DLP cannot have the zoom and lens shift flexibility of LCD. I"ve heard the lens shift is because of the issue of bouncing of the light off the DLP chip through the color wheel and then through the lens so that in order to shift the lens you"d have to move the entire light path. I"ve not heard any reasoning for the lack of zoom found on DLP.

Wish the LCoS comparison had been included with this article, but will wait patiently for it and hopefully it will compare and contrast against DLP/LCD and not simply be a stand alone tech summary.

What a great article! Very fair and balanced- unlike some news channels! I have had a Panasonic AE700 LCD projector for 5 years now and have had no dust blobs or PQ degradation whatosever. I am still using the original bulb, and the picture is still stunning. I love the 2X zoom lens and wide-range lens shift which lets me mount the projector out of sight on a rear shelf. I just would not take the risk of seeing the DLP artifacts, so my next projector will definately be 3LCD.

This is the first I"ve heard that dust deposits lead to the lamp becoming dim. I find this a little hard to believe. If it were true then LCD projectors with dust filters would have substantially longer bulb lives than filterless DLP projectors. I don"t think this is true.

When the Panasonic PT-AE700U 3LCD projector was the hot new player on the price/performance curve I installed two of them. One was in a friend’s dedicated home theater and the second was in my family’s home theater/living room.

The AE700U in my home developed severe blue discoloration in the lower left side of the image due to the organic LCD panels. One can find many users so afflicted on the forums. Of course this did not come up when the AE700 was the hot new piece because no one had the hours on it necessary to cook the panels.

When the second bulb in our AE700 was used up I could not bring myself to spend $375 to watch 1/3 blue HDTV. As a stopgap I purchased a factory refurbished 1024x768 DLP projector for less than the cost of a new bulb for the AE700. The picture is not bad, I can see it is not as good as the new AE700 was or the 1080P Toshiba flat panel we have in the den, but the family thinks it looks good. My hope is by the time the XGA DLP projector needs a new bulb the market has an affordable 108

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey