lcd display lifespan made in china

Much has been made of the longevity of LCD displays, at least compared to plasma monitors. The conventional wisdom is that LCD televisions last longer than their plasma TV counterparts, which is true. The problem is, a lot of people extrapolate from this that either (a) LCD displays last forever or (b) LCD monitors suffer no picture "wear" over time. Neither of these suppositions is correct.

Flat-panel LCD screen displays have a lifespan approaching 60,000 hours. The lifespan of an LCD display is generally longer than that of similar-sized plasma displays. Some manufacturers even claim that their LCDs can last upwards of 80,000 hours when used continuously under controlled conditions (e.g., in a room with "standard" lighting conditions and 77° temperatures throughout). Just how realistic such claims are is debatable. After all, whose living room has no windows and remains at a perfectly comfortable 77 degrees year-round?

In any case, the pictures on LCD displays will show some "wear" because they are generated by powerful lamps, which, like any lighting appliance, will dim over time and with use. The picture you see will dim ever so slightly as the lamp itself dims.

Therefore, the most important thing to consider when it comes to the lifespan of your LCD TV is the actual lifespan of the light source in your LCD. LCD TVs last as long as their lightsources do. So, the lightsource in your LCD monitor is the critical component of your LCD display unit.

The quality of your lightsource is particularly important for maintaining a proper white balance on your TV. As these florescent bulbs age, colors can become unbalanced, which could result in too much red, for example, in your picture. So, it pays to buy name-brand displays. You will definitely pay more for better LCD display brands like Sharp, Toshiba, JVC, or Sony than you will for cheap Chinese or Korean variety knock-offs, but you"ll get a backlighting bulb of higher quality and, in the end, a TV whose colors will stay truer longer.

To ensure the integrity of your lightsource for the duration of your LCD display"s lifespan, you will definitely want to adjust the CONTRAST setting of your LCD TV. Too high of a CONTRAST level will prematurely age your lightsource because it will have to work harder to maintain such light intensities. Your best bet is to keep your CONTRAST set appropriately for the conditions under which your view your LCD display. Higher light levels require slightly higher CONTRAST levels, while lower ambient light levels demand less CONTRAST.

You will also want to pay attention to the warranty for this particular feature, since it can be shorter than for the display as a whole. This means you might have to buy a whole new LCD monitor because the coverage on its backlight has expired. Moreover, some bulbs can be replaced, while others are built in to the unit itself. You should definitely do some research on the backlighting system, how it"s configured, and how it"s warranted.

Note: Sharp is currently the only manufacturer that makes LCD displays whose lamps can be changed out. This is definitely something to consider, given that LCD monitors dim as their lightsources do, so being able to replace its lamp will restore your picture to "like new" levels.

Perhaps you’ve wondered how long a digital display lasts. It’s a great question. One quick search on Google will tell you that an LCD panel has a lifespan of about 60,000 hours, which is equivalent to almost seven years.

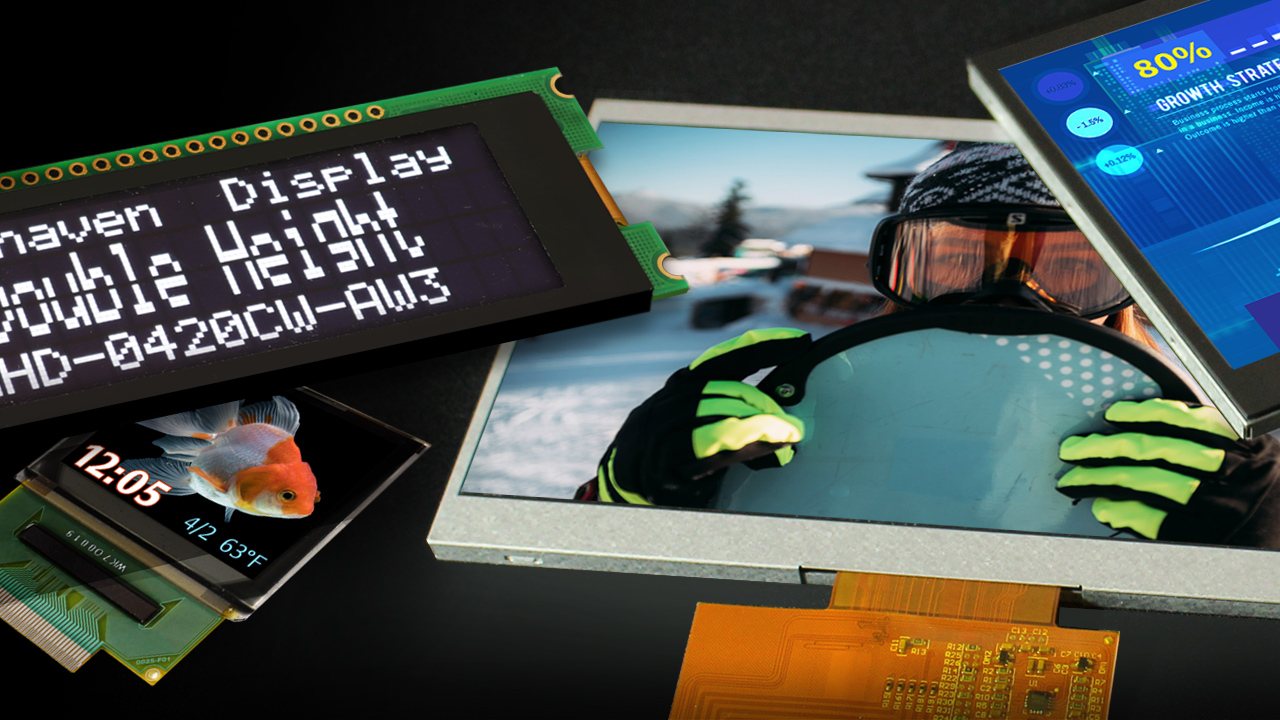

Of course, LCDs aren’t the only kind of displays. You also have LED, OLED, QLED, ELD, PDP, and MicroLED, plus many other variations. Obviously, that 7-year estimation will not apply across the board. For the sake of ease, let’s just focus on some of the common types of displays that most of us are familiar with.

Here’s some LCD alphabet soup: There are LED LCD displays, CFFL LCD displays, LED displays, and more. With all these acronyms, it can get a bit confusing. What"s important to note is whether or not the display uses an LCD panel, and how the LCD panel is illuminated. You can read more about thedifferences between types of LCD and LED signage, but these are the most common types:

LCD displaysgenerate images and colors via a Liquid Crystal Display (LCD) panel, which is not self-emitting and requires an external light source to illuminate the image, typically an LED backlight. Their full name "LED-backlit LCD display" is commonly shortened to "LED displays", which is why they"re often confused with the true LED displays we"ve identified above.

Unfortunately, LED backlights used in LCD displays burn out over time. If used at high or maximum brightness, which is necessary for outdoor applications,an LED backlight will last between 40,000 to 60,000 hours. Or, about 4.5 to 7 years.

OLED stands for Organic Light Emitting Diode. OLED displays differ from common LCD displays in that their pixels are self-illuminating. In other words, there is no LED backlight required to illuminate the the display image; everything occurs within the OLED pixels themselves. According to onearticle from the US Department of Energy,OLED screens have a life expectancy of about 40,000 hours at 25% brightness, and 10,000 hours at full brightness. That equates to about 1 to 4.5 years, which is a much shorter (albeit, brilliant) lifetime than an LCD display.

Perhaps you noticed that the acronym QLED closely resembles the acronym OLED. This is not accidental. QLED is basically Samsung’s original design built to compete with OLED technology. However, the two are not the same. QLED stands for Quantum Light Emitting Diode. While QLED is similar to a regular LED design, it in fact differs by using nanoparticles called “Quantum dots” to achieve its unique brightness and color. Samsung approximates that the lifespan ofQLED panels are likely to last 7-10 years. After that, a user is likely to notice traces of degradation.

MicroLED is an emerging display technology, consisting of small LEDs in tiny arrays within each pixel. This technology goes beyond the offerings of the formerly frontrunning OLEDs, with much darker blacks and more radiant contrast levels. And, unlike OLEDs, MicroLEDs are not organic. They are not as subject to burn-in, and thus, have a longer lifespan than OLEDs. However, they are significantly more expensive - so much, in fact, that they aren’t considered a viable option for the majority of consumers.According to Samsung, the lifespan of its MicroLED panels should last about 100,000 hours, or, roughly 11 years.

PDP stands for Plasma Display Panel, and it refers to displays that use small cells full of plasma. The atoms within the plasma emit light upon being charged by electricity. While PDP is generally considered to offer better colors than LCDs, they consume a lot more power and usually cannot be battery-operated.The average lifespan of the newest generation of PDPs is approximated to be 100,000 hours, or 11 years of continual use.

In some ways,reflective LCD panelsoperate similarly to other LCDs, only they have one key difference - they do not require a backlight. Instead, they rely on ambient light (or sunlight) in order to produce images. This opens the door to some groundbreaking possibilities. The first (and most appreciable) is low power consumption. Reflective displays use up to 95% less energy. Not bad - especially in a world that is continually looking for new ways to go green. Take into consideration the financial implications of this. Lower power means less money spent on operating costs.

Being that reflective displays do not require a backlight (a component that is particularly subject to degradation), and since they do not generate as much heat, it is safe to say that the lifespan of these displays should far exceed that of backlit LCD panels (which was 7 years at the high end). However, being that thisinnovative technologyis relatively new, its actual lifespan is therefore more difficult to estimate -- simply because it has yet to be reached.

There are also a few challenges that can affect reflective displays. For one, they rely on ambient light. On a nice sunny day, these displays perform beautifully and can be easily seen in even the brightest of conditions. This performance wanes as the available ambient light decreases. And, since they do not generate light of their own, they are not designed to be viewed under nighttime or extremely low light conditions (without additional lighting features). In short, their images are visible to the degree that ambient light is present. However, in light of this, side light (and front light) options are being explored.

One company at the front lines of this research isAzumo. Azumo has created a light guide that laminates to the front of a display. It requires 90% less energy than the backlight of a traditional LCD display. This greatly improves the problem of low light visibility otherwise encountered, and keeps reflective displays in the same low energy consumption ballpark. One issue, however, is that Azumo currently only offers its light guides for smaller-sized units. If you happen to want this feature applied to a display that is over 10” diagonally, then you’re still on the search for a solution.

One other factor to consider regarding reflective technology is its cost. That reflective layer is more costly to manufacture than many of the backlights it replaces, creating a seemingly greater upfront cost for those who are interested in investing in energy-efficient signage. However, these initial price points are quickly justified as buyers will recognize the significantly lower operating costs and increased longevity (not even including replacement costs of other “expired” displays) that comes with their purchase of reflective display signage. If a backlit LCD panel only lasts 7 years, for example, you’ll have paid for that LCD twice in the period of ten years. A very valid question arises… is that “cheaper” backlight really cheaper? Probably not. It only feels that way at first.

Sun Vision Displayis working hard to create reflective display solutions for the digital signage world. We are currently offering them in 32" and 43" diagonal sizes, with a 55” size in development. These displays are built formany environments. We are thrilled to be bringing such innovative solutions to the market.

If you’re designing a display application or deciding what type of TV to get, you’ll probably have to choose between an OLED or LCD as your display type.

Not sure which one will be best for you? Don’t worry! We’re here to help you figure out the right display for your project or application. In this post we’ll break down the pros and cons of these display types so you can decide which one is right for you.

LCDs utilize liquid crystals that produce an image when light is passed through the display. OLED displays generate images by applying electricity to organic materials inside the display.OLED and LCD Main Difference:

These different technological approaches to display technology have big impact in some features including contrast, brightness, viewing angles, lifespan, black levels, image burn-in, and price.

Everything from the environment your display will be used in, your budget, to the lighting conditions and the required durability will play a part in this decision.

Contrast refers to the difference between the lightest and darkest parts of an image. High contrast will produce sharper images and more easily readable text. It’s a crucial quality for high fidelity graphics and images or to make sure that a message on a display is very visible.

graphics and images visible. This is the reason you’re still able to see light coming through on images that are meant to be dark on an LCD monitor, display, or television.

OLEDs by comparison, deliver a drastically higher contrast by dynamically managing their individual pixels. When an image on an OLED display uses the color black, the pixel shuts off completely and renders a much higher contrast than that of LCDs.OLED vs LCD - Who is better at contrast?

Having a high brightness level is important if your display is going to be used in direct sunlight or somewhere with high ambient brightness. The display"s brightness level isn"t as important if it’s going to be used indoors or in a low light setting.OLED vs LCD - Who is better at Brightness?

This means the display is much thinner than LCD displays and their pixels are much closer to the surface of the display, giving them an inherently wider viewing angle.

You’ll often notice images becoming distorted or losing their colors when tilting an LCD or when you view it from different angles. However, many LCDs now include technology to compensate for this – specifically In-Plane Switching (IPS).

LCDs with IPS are significantly brighter than standard LCDs and offer viewing angles that are on-par with OLEDs.OLED vs LCD - Who is better at Viewing Angles?

LCDs have been on the market much longer than OLEDs, so there is more data to support their longevity. On average LCDs have proven to perform for around 60,000 hours (2,500) days of operation.

With most LCDs you can expect about 7 years of consistent performance. Some dimming of the backlight has been observed but it is not significant to the quality of the display.

OLEDs are a newer technology in the display market, which makes them harder to fully review. Not only does OLED technology continue to improve at a rapid pace, but there also hasn’t been enough time to thoroughly observe their performance.

You must also consider OLED’s vulnerability to image burn-in. The organic material in these displays can leave a permanent afterimage on the display if a static image is displayed for too long.

So depending on how your OLED is used, this can greatly affect its lifespan. An OLED being used to show static images for long periods of time will not have the same longevity as one displaying dynamic, constantly moving images.OLED vs LCD - Which one last longer?

There is not yet a clear winner when it comes to lifespans between LCD and OLED displays. Each have their advantages depending on their use-cases. It’s a tie!

For a display application requiring the best colors, contrast, and viewing angles – especially for small and lightweight wearable devices – we would suggest an OLED display.

In recent years, China and other countries have invested heavily in the research and manufacturing capacity of display technology. Meanwhile, different display technology scenarios, ranging from traditional LCD (liquid crystal display) to rapidly expanding OLED (organic light-emitting diode) and emerging QLED (quantum-dot light-emitting diode), are competing for market dominance. Amidst the trivium strife, OLED, backed by technology leader Apple"s decision to use OLED for its iPhone X, seems to have a better position, yet QLED, despite still having technological obstacles to overcome, has displayed potential advantage in color quality, lower production costs and longer life.

Which technology will win the heated competition? How have Chinese manufacturers and research institutes been prepared for display technology development? What policies should be enacted to encourage China"s innovation and promote its international competitiveness? At an online forum organized by National Science Review, its associate editor-in-chief, Dongyuan Zhao, asked four leading experts and scientists in China.

Zhao: We all know display technologies are very important. Currently, there are OLED, QLED and traditional LCD technologies competing with each other. What are their differences and specific advantages? Shall we start from OLED?

Huang: OLED has developed very quickly in recent years. It is better to compare it with traditional LCD if we want to have a clear understanding of its characteristics. In terms of structure, LCD largely consists of three parts: backlight, TFT backplane and cell, or liquid section for display. Different from LCD, OLED lights directly with electricity. Thus, it does not need backlight, but it still needs the TFT backplane to control where to light. Because it is free from backlight, OLED has a thinner body, higher response time, higher color contrast and lower power consumption. Potentially, it may even have a cost advantage over LCD. The biggest breakthrough is its flexible display, which seems very hard to achieve for LCD.

Liao: Actually, there were/are many different types of display technologies, such as CRT (cathode ray tube), PDP (plasma display panel), LCD, LCOS (liquid crystals on silicon), laser display, LED (light-emitting diodes), SED (surface-conduction electron-emitter display), FED (filed emission display), OLED, QLED and Micro LED. From display technology lifespan point of view, Micro LED and QLED may be considered as in the introduction phase, OLED is in the growth phase, LCD for both computer and TV is in the maturity phase, but LCD for cellphone is in the decline phase, PDP and CRT are in the elimination phase. Now, LCD products are still dominating the display market while OLED is penetrating the market. As just mentioned by Dr Huang, OLED indeed has some advantages over LCD.

Huang: Despite the apparent technological advantages of OLED over LCD, it is not straightforward for OLED to replace LCD. For example, although both OLED and LCD use the TFT backplane, the OLED’s TFT is much more difficult to be made than that of the voltage-driven LCD because OLED is current-driven. Generally speaking, problems for mass production of display technology can be divided into three categories, namely scientific problems, engineering problems and production problems. The ways and cycles to solve these three kinds of problems are different.

At present, LCD has been relatively mature, while OLED is still in the early stage of industrial explosion. For OLED, there are still many urgent problems to be solved, especially production problems that need to be solved step by step in the process of mass production line. In addition, the capital threshold for both LCD and OLED are very high. Compared with the early development of LCD many years ago, the advancing pace of OLED has been quicker.While in the short term, OLED can hardly compete with LCD in large size screen, how about that people may change their use habit to give up large screen?

Liao: I want to supplement some data. According to the consulting firm HIS Markit, in 2018, the global market value for OLED products will be US$38.5 billion. But in 2020, it will reach US$67 billion, with an average compound annual growth rate of 46%. Another prediction estimates that OLED accounts for 33% of the display market sales, with the remaining 67% by LCD in 2018. But OLED’s market share could reach to 54% in 2020.

Huang: While different sources may have different prediction, the advantage of OLED over LCD in small and medium-sized display screen is clear. In small-sized screen, such as smart watch and smart phone, the penetration rate of OLED is roughly 20% to 30%, which represents certain competitiveness. For large size screen, such as TV, the advancement of OLED [against LCD] may need more time.

Xu: LCD was first proposed in 1968. During its development process, the technology has gradually overcome its own shortcomings and defeated other technologies. What are its remaining flaws? It is widely recognized that LCD is very hard to be made flexible. In addition, LCD does not emit light, so a back light is needed. The trend for display technologies is of course towards lighter and thinner (screen).

But currently, LCD is very mature and economic. It far surpasses OLED, and its picture quality and display contrast do not lag behind. Currently, LCD technology"s main target is head-mounted display (HMD), which means we must work on display resolution. In addition, OLED currently is only appropriate for medium and small-sized screens, but large screen has to rely on LCD. This is why the industry remains investing in the 10.5th generation production line (of LCD).

Xu: While deeply impacted by OLED’s super thin and flexible display, we also need to analyse the insufficiency of OLED. With lighting material being organic, its display life might be shorter. LCD can easily be used for 100 000 hours. The other defense effort by LCD is to develop flexible screen to counterattack the flexible display of OLED. But it is true that big worries exist in LCD industry.

LCD industry can also try other (counterattacking) strategies. We are advantageous in large-sized screen, but how about six or seven years later? While in the short term, OLED can hardly compete with LCD in large size screen, how about that people may change their use habit to give up large screen? People may not watch TV and only takes portable screens.

Some experts working at a market survey institute CCID (China Center for Information Industry Development) predicted that in five to six years, OLED will be very influential in small and medium-sized screen. Similarly, a top executive of BOE Technology said that after five to six years, OLED will counterweigh or even surpass LCD in smaller sizes, but to catch up with LCD, it may need 10 to 15 years.

Xu: Besides LCD, Micro LED (Micro Light-Emitting Diode Display) has evolved for many years, though people"s real attention to the display option was not aroused until May 2014 when Apple acquired US-based Micro LED developer LuxVue Technology. It is expected that Micro LED will be used on wearable digital devices to improve battery"s life and screen brightness.

Micro LED, also called mLED or μLED, is a new display technology. Using a so-called mass transfer technology, Micro LED displays consist of arrays of microscopic LEDs forming the individual pixel elements. It can offer better contrast, response times, very high resolution and energy efficiency. Compared with OLED, it has higher lightening efficiency and longer life span, but its flexible display is inferior to OLED. Compared with LCD, Micro LED has better contrast, response times and energy efficiency. It is widely considered appropriate for wearables, AR/VR, auto display and mini-projector.

However, Micro LED still has some technological bottlenecks in epitaxy, mass transfer, driving circuit, full colorization, and monitoring and repairing. It also has a very high manufacturing cost. In short term, it cannot compete traditional LCD. But as a new generation of display technology after LCD and OLED, Micro LED has received wide attentions and it should enjoy fast commercialization in the coming three to five years.

Peng: It comes to quantum dot. First, QLED TV on market today is a misleading concept. Quantum dots are a class of semiconductor nanocrystals, whose emission wavelength can be continuously tuned because of the so-called quantum confinement effect. Because they are inorganic crystals, quantum dots in display devices are very stable. Also, due to their single crystalline nature, emission color of quantum dots can be extremely pure, which dictates the color quality of display devices.

Interestingly, quantum dots as light-emitting materials are related to both OLED and LCD. The so-called QLED TVs on market are actually quantum-dot enhanced LCD TVs, which use quantum dots to replace the green and red phosphors in LCD’s backlight unit. By doing so, LCD displays greatly improve their color purity, picture quality and potentially energy consumption. The working mechanisms of quantum dots in these enhanced LCD displays is their photoluminescence.

For its relationship with OLED, quantum-dot light-emitting diode (QLED) can in certain sense be considered as electroluminescence devices by replacing the organic light-emitting materials in OLED. Though QLED and OLED have nearly identical structure, they also have noticeable differences. Similar to LCD with quantum-dot backlighting unit, color gamut of QLED is much wider than that of OLED and it is more stable than OLED.

Given the relatively low resolution of printing technology, QLED shall be difficult to reach a resolution greater than 300 PPI (pixels per inch) within a few years. Thus, QLED might not be applied for small-sized displays at present and its potential will be medium to large-sized displays.

Peng: Good questions. Ligand chemistry of quantum dots has developed quickly in the past two to three years. Colloidal stability of inorganic nanocrystals should be said of being solved. We reported in 2016 that one gram of quantum dots can be stably dispersed in one milliliter of organic solution, which is certainly sufficient for printing technology. For the second question, several companies have been able to mass produce quantum dots. At present, all these production volume is built for fabrication of the backlighting units for LCD. It is believed that all high-end TVs from Samsung in 2017 are all LCD TVs with quantum-dot backlighting units. In addition, Nanosys in the United States is also producing quantum dots for LCD TVs. NajingTech at Hangzhou, China demonstrate production capacity to support the Chinese TV makers. To my knowledge, NajingTech is establishing a production line for 10 million sets of color TVs with quantum-dot backlighting units annually.China"s current demands cannot be fully satisfied from the foreign companies. It is also necessary to fulfill the demands of domestic market. That is why China must develop its OLED production capability.

Huang: Based on my understanding of Samsung, the leading Korean player in OLED market, we cannot say it had foresight in the very beginning. Samsung began to invest in AMOLED (active-matrix organic light-emitting diode, a major type of OLED used in the display industry) in about 2003, and did not realize mass production until 2007. Its OLED production reached profitability in 2010. Since then, Samsung gradually secured a market monopoly status.

Also, Samsung has spent considerable time and efforts on the development of the product chain. Twenty or thirty years ago, Japan owned the most complete product chain for display products. But since Samsung entered the field in that time, it has spent huge energies to cultivate upstream and downstream Korean firms. Now the Republic of Korea (ROK) manufacturers began to occupy a large share in the market.

Huang: The importance of China"s LCD manufacturing is now globally high. Compared with the early stage of LCD development, China"s status in OLED has been dramatically improved. When developing LCD, China has adopted the pattern of introduction-absorption-renovation. Now for OLED, we have a much higher percentage of independent innovation.

Peng: As mentioned above, there are two ways to apply quantum dots for display, namely photoluminescence in backlightingFor QLED, the three stages of technological development [from science issue to engineering and finally to mass production] have been mingled together at the same time. If one wants to win the competition, it is necessary to invest on all three dimensions.

units for LCD and electroluminescence in QLED. For the photoluminescence applications, the key is quantum-dot materials. China has noticeable advantages in quantum-dot materials.

After I returned to China, NajingTech (co-founded by Peng) purchased all key patents invented by me in the United States under the permission of US government. These patents cover the basic synthesis and processing technologies of quantum dots. NajingTech has already established capability for large-scale production of quantum dots. Comparatively, Korea—represented by Samsung—is the current leading company in all aspects of display industry, which offers great advantages in commercialization of quantum-dot displays. In late 2016, Samsung acquired QD Vision (a leading quantum-dot technology developer based in the United States). In addition, Samsung has invested heavily in purchasing quantum-dot-related patents and in developing the technology.

China is internationally leading in electroluminescence at present. In fact, it was the 2014 Nature publication by a group of scientists from Zhejiang University that proved QLED can reach the stringent requirements for display applications. However, who will become the final winner of the international competition on electroluminescence remains unclear. China"s investment in quantum-dot technology lags far behind US and ROK. Basically, the quantum-dot research has been centered in US for most of its history, and South Korean players have invested heavily along this direction as well.

Peng: If electroluminescence can be successfully achieved with printing, it will be much cheaper, with only about 1/10th cost of OLED. Manufacturers like NajingTech and BOE in China have demonstrated printing displays with quantum dots. At present, QLED does not compete with OLED directly, given its market in small-sized screen. A while ago, Dr. Huang mentioned three stages of technological development, from science issue to engineering and finally to mass production. For QLED, the three stages have been mingled together at the same time. If one wants to win the competition, it is necessary to invest on all three dimensions.

Huang: When OLED was compared with LCD in the past, lots of advantages of OLED were highlighted, such as high color gamut, high contrast and high response speed and so on. But above advantages would be difficult to be the overwhelming superiority to make the consumers to choose replacement.

It seems to be possible that the flexible display will eventually lead a killer advantage. I think QLED will also face similar situation. What is its real advantage if it is compared with OLED or LCD? For QLED, it seems to have been difficult to find the advantage in small screen. Dr. Peng has suggested its advantage lies in medium-sized screen, but what is its uniqueness?

Peng: New standard (BT2020) certainly helps QLED, given BT2020 meaning a broad color gamut. Among the technologies discussed today, quantum-dot displays in either form are the only ones that can satisfy BT2020 without any optical compensation. In addition, studies found that the picture quality of display is highly associated with color gamut. It is correct that the maturity of printing technology plays an important role in the development of QLED. The current printing technology is ready for medium-sized screen and should be able to be extended to large-sized screen without much trouble.

Liao: Due to their lack of kernel technologies, Chinese OLED panel manufacturers heavily rely on investments to improve their market competitiveness. But this may cause the overheated investment in the OLED industry. In recent years, China has already imported quite a few new OLED production lines with the total cost of about 450 billion yuan (US$71.5 billion).Lots of advantages of OLED over LCD were highlighted, such as high color gamut, high contrast and high response speed and so on …. It seems to be possible that the flexible display will eventually lead a killer advantage.

Zhao: Today there are really good observations, discussions and suggestions. The industry-academics-research collaboration is crucial to the future of China"s display technologies. We all should work hard on this.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

Sony produces and sells commercial MicroLED displays called CLEDIS (Crystal-LED Integrated Displays, also called Canvas-LED) in small quantities.video walls.

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Business Place Information – Global Operation | SAMSUNG DISPLAY". www.samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

Byeonghwa, Yeon. "Business Place Information – Global Operation – SAMSUNG DISPLAY". Samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

www.etnews.com (30 June 2017). "Samsung Display to Construct World"s Biggest OLED Plant". Archived from the original on 2019-06-09. Retrieved 2019-06-09.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey