revolution of the tft lcd technology manufacturer

The introduction of flat panel displays that are fabricated with thin-film-transistor liquid-crystal displays (TFT LCDs) has changed human"s lifestyle very significantly. Traditionally, the revolution of the TFT LCD technology has been presented by the timeline of product introduction. Namely, it first started with audio/video (AV) and notebook applications in the early 1990s, and then began to replace cathode-ray tubes (CRTs) for monitor and TV applications. Certainly, TFT LCDs will continue to expand in all areas of our daily life in the future. Here a new concept of the revolution of the TFT LCD technology is presented for the major TFT LCD makers. In this new concept, there are four waves of technology revolution with the following themes, respectively: 1) product introduction; 2) performance enrichment; 3) power and material utilization; and 4) functions for human interface. The role of the LCD-TV in the revolution is also discussed.

The introduction of flat panel displays that are fabricated with thin-film-transistor liquid-crystal displays (TFT LCDs) has changed human"s lifestyle very significantly. Traditionally, the revolution of the TFT LCD technology has been presented by the timeline of product introduction. Namely, it first started with audio/video (AV) and notebook applications in the early 1990s, and then began to replace cathode-ray tubes (CRTs) for monitor and TV applications. Certainly, TFT LCDs will continue to expand in all areas of our daily life in the future. Here a new concept of the revolution of the TFT LCD technology is presented for the major TFT LCD makers. In this new concept, there are four waves of technology revolution with the following themes, respectively: 1) product introduction; 2) performance enrichment; 3) power and material utilization; and 4) functions for human interface. The role of the LCD-TV in the revolution is also discussed.

The introduction of flat panel displays that are fabricated with thin-film-transistor liquid-crystal displays (TFT LCDs) has changed human"s lifestyle very significantly. Traditionally, the revolution of the TFT LCD technology has been presented by the timeline of product introduction. Namely, it first started with audio/video (AV) and notebook applications in the early 1990s, and then began to replace cathode-ray tubes (CRTs) for monitor and TV applications. Certainly, TFT LCDs will continue…Expand

With its excellent performance, mass production, a high degree of automation, low cost of raw materials, and broad development space,TFT-LCDwill rapidly become the mainstream product in the new century and a bright spot in the global economic growth in the 21st century.

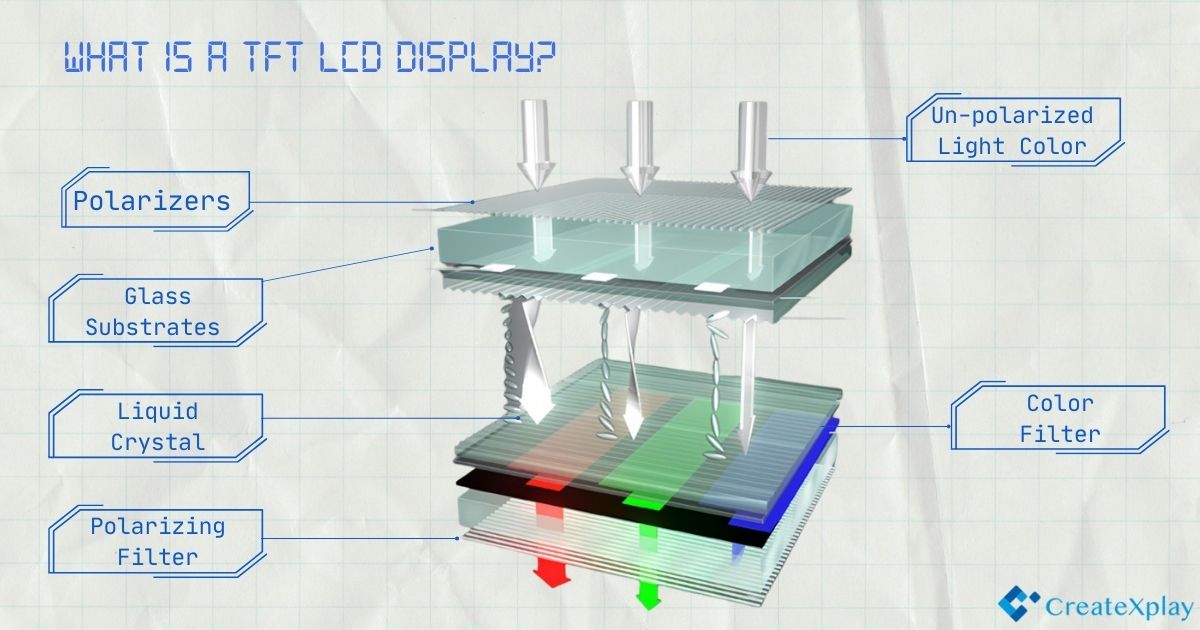

And TN technology is different,TFTdisplay using "back-penetrating" irradiation - imaginary light source path is not like TN liquid crystal as from top to bottom, but from the bottom up. This approach is to set up a special light tube in the back of the liquid crystal, the light source when irradiated through the lower polarizer upward transmission. As the electrodes of the upper and lower sandwich layer are changed to FET electrodes and common electrodes when the FET electrode is turned on, the performance of the liquid crystal molecules will also change, which can be shaded and transmitted to achieve the purpose of display, and the response time is greatly improved to about 80ms. Because it has a higher contrast ratio and richer colors than TN-LCD, the screen update frequency is also faster, so TFT is commonly known as "true color".

Compared to DSTN, TFT LCD"s main feature is to configure a semiconductor switching device for each pixel. Since each pixel can be directly controlled through the dot pulse. Thus, each node is relatively independent and can be continuously controlled. This design method not only improves the response speed of the display but also can accurately control the display grayscale, which is theTFTcolor is more realistic than the DSTN reasons.

With the maturity of TFT technology in the early nineties, color LCD flat panel display rapid development, less than 10 years, TFT LCD rapidly grew into the mainstream display, which has the advantages of it is inseparable. The main features are.

(1) use characteristics: low-voltage applications, low driving voltage, solidified use of safety and reliability; flat, and thin, saving a lot of raw materials, and use of space. Low power consumption, its power consumption is about one-tenth of the CRT display, reflective TFT LCD even only about one percent of the CRT, saving a lot of energy. TFT LCD products and specifications, size series, variety, easy and flexible use, maintenance, update, easy to upgrade, long service life, and many other features. The display range covers all display applications from 1" to 40" as well as large projection surfaces, making it a full-size display terminal. The display quality ranges from the simplest monochrome character graphics to high resolution, high color fidelity, high brightness, high contrast, and high responsiveness of video displays of all sizes and models. Display methods include direct view, projection, see-through, and reflective.

(2) Good environmental characteristics: no radiation, no flicker, no harm to the user"s health. In particular, TFT LCD electronic books and magazines will bring mankind into the paperless office, paperless printing era, leading to human learning, dissemination and record planted civilization way of revolution.

(3) wide range of applications, from -20 ℃ to +50 ℃ of the temperature range can be used normally, through the temperature hardening process of TFT LCD low temperature operating temperature can reach minus 80 ℃. Can be used as a mobile terminal display, desktop terminal display, and can be used for large-screen projection TV, which is an excellent performance of the full-size video display terminal.

(4) manufacturing technology, a high degree of automation, large-scale industrial production characteristics of good. TFT LCD industry, mature technology, large-scale production of the yield rate of more than 90%.

(5) TFT LCD easy integration and upgrading, is a perfect combination of large-scale semiconductor integrated circuit technology and light source technology, continue to develop great potential. At present there are amorphous, polycrystalline, and monocrystalline silicon TFT LCD, the future will have other materials of TFT, both glass substrate and a plastic substrate.

TFT Liquid crystal display products are diversified, convenient and versatile, simple to keep up, upgrade, update, long service life, and have many alternative characteristics.

The display range covers the appliance range of all displays from one to forty inches and, therefore, the giant projection plane could be a large display terminal.

Display quality from the most straightforward monochrome character graphics to high resolution, high colour fidelity, high brightness, high contrast, the high response speed of various specifications of the video display models.

In particular, the emergence of TFT LCD electronic books and periodicals will bring humans into the era of paperless offices and paperless printing, triggering a revolution in the civilized way of human learning, dissemination, and recording.

It can be generally used in the temperature range from -20℃ to +50℃, and the temperature-hardened TFT LCD can operate at low temperatures up to -80 ℃. It can be used as a mobile terminal display or desktop terminal display and can be used as a large screen projection TV, which is a full-size video display terminal with excellent performance.

The manufacturing technology has a high degree of automation and sound characteristics of large-scale industrial production. TFT LCD industry technology is mature, with a more than 90% mass production rate.

It is an ideal combination of large-scale semiconductor integrated circuit technology and light source technology and has good potential for more development.

From the beginning of flat glass plates, its display effect is flat right angles, letting a person have a refreshing feeling. LCDs are simple to achieve high resolution on small screens.

Every year, motorcycle manufacturers make various improvements to their lineup, everything from little internal details, to new paint, to full-on redesigns. Over the years we’ve watched these machines get better, faster, and safer. In the 2020 model year, though, the majority of motorcycle manufacturers seem to be hopping on the TFT wagon. What does that mean for us, the riders?

We are all familiar with the Thin Film Transistor, or TFT screen, on our smartphones, hand-held video game displays, computer monitors, and car “infotainment” systems. The technology has advanced rapidly in the last few years, and motorcycle manufacturers have suddenly determined that they are ready for the harsh environment a motorcycle display needs to endure. During an attentive walk around of the International Motorcycle Show in New York City this past weekend, we noticed that new bikeswithoutTFT screens are becoming the rare exception.

Some manufacturers began outfitting their newest bikes with TFT screens a couple of years ago, but the 2020 model year has seen a sudden industry-wide shift. Major manufacturers like BMW, Kawasaki, Honda, and Yamaha, and even smaller companies like Energica, outfit their bikes with a TFT.

All of us who have been riding for many years are used to analog dials and gauges. Some of us are concerned about the longevity of the TFT, and in my opinion, those concerns are valid. Certainly, we’ve all seen our smartphone screens give up the ghost after only a few years of use. Some of us have an affinity for older motorcycles and have repaired or restored those old analog speedometers and gauges. We know that they often work flawlessly for decades. When they need repair, it’s a question of fixing or replacing internal mechanical parts. Not so with the futuristic TFT screens.

Those of us who are not hopeless luddites tend to sing the praises of a screen that can and does change to show machine and engine speed, a navigation display, the state of the motorcycle’s electronic suspension, tire pressure, the traction control setting, and a whole host of other information. The versatility of a TFT over traditional analog gauges is unquestionable: we might soon be able to program them ourselves with our preferred screen settings, just like our smartphones.

From a manufacturing point of view, TFTs simplify the process. The same TFT can be used on every motorcycle in a manufacturer’s lineup, with only a change of software to make the screen bike-specific. Does that mean a TFT will eventually be extremely inexpensive and easy to replace, should it ever go bad? Right now they’re too new to know for sure, but manufacturers are installing them everywhere, so we will all find out soon enough!

The transistor is widely regarded as one of the most important inventions of the 20th century, and is the key enabling technology in virtually every electronic device today. From smartphones to satellites, without transistors most of today"s modern technology would not exist.

A TFT acts like an electronic valve: when a voltage is applied to the gate, the semiconductor material is switched “on”, allowing current to flow from the source to the drain:

At a basic level, a display is made up of two parts: a frontplane, the layer that makes the image you see, and a backplane, an array of TFTs that control which pixels in the frontplane turn on and off. Most of the time, when you hear about displays, you hear about the frontplane technology–e.g. LCD, OLED, e-Paper, etc.–because that"s the part you see.

If you want to make a display flexible, however, you need both the frontplane and the backplane to be flexible, and you need both to be durable enough to be used in the real world. OLED and e-Paper frontplane technologies already have the required levels of flexibility and durability, however, the backplane has previously been a constraint.

The functions of our boards include, but are not limited to, adjustment of brightness, sound output, touch interface, extra data transmission, and gyroscope.

![]()

Liquid crystals (LCs) are state of matter that has properties between those of conventional liquids and those of solid crystals, in which the constituent molecules tend to align themselves relative to each other. Liquid crystal displays (LCD) use the unique character of Nematic LC which are optically active and align themselves with an applied field.

The character of Nematic phase LC: The center of gravity of the molecules in the Nematic phase lacks positional order, allowing it to flow free and their center of mass positions are randomly distributed as in a liquid, but the directors of the molecules are spontaneously aligned with their long axes roughly parallel.

There are two ways to drive the working of LC in the electric field, either with a passive matrix or an active matrix grid. Therefore, LCD can be classified as Passive Matrix LCD (PMLCD) and Active Matrix LCD (AMLCD).

Passive matrix display is the first commercialized LCD technology, which is designed with a simple grid of row and column electrodes respective on the top and bottom plates to address the pixels.

The working principle of the passive display is to use the input signal to drive the electrodes of each row in turn, so when a row is selected, the electrodes on the column will be triggered to turn on those pixels located at the intersection of the row and the column.

These switches are usually implemented through transistors, which are fabricated by using the current-carrying thin film (usually a film of silicon—Si) and therefore called thin film transistors, TFTs.

Similar to the passive matrix LCD, the upper and lower layers of the active matrix LCD are also arranged vertically and horizontally with transparent electrodes made ofindium tin oxide (ITO).

It allows the column voltages to be applied only to the row that is being addressed, while the storage capacitormaintains the pixel information for the whole frame also when the addressing signal is removed.

Thus, high contrastis possible and a fast LC mixture can be used, since the pixel no longer has to respond to the average voltage over a whole frame period, as in PMLCDs. For the same reason, the phenomenon of crosstalk is also minimized.

Early passive matrix screens relied on twisted nematic (TN)designs. The polarizing directions of the upper and lower polarizing plates are at 90°, so the liquid crystal in the middle is twisted at 90°.

The resulting LCD panels have low contrast and slow response times. This method works well for low-information displays but not for computer displays.

The Super Twisted Nematic (STN) method is improved by changing the chemical composition of LC so that the LC molecules are twisted more than once, therefore, the light twist reaches 180° to 270°, which can greatly improve the contract.

In the early 1980s, STN technology was very popular. But it comes along with a color shift in light, especially where the screen is off-axis. This is why early computer screens were always bluish and yellowish.

To solve the color shift problem, double layer STN (DSTN) and further improved technology Film-compensated STN (FSTN)were developed with comparable display quality and low cost.

And the dual scan concept for FSTN was proposed in the early 1990s, to solve the ghost phenomenon and significantly improve contrast, and graphic quality, and shorten the response time. It is still widely used in low-priced computers.

Drawbacks were the limited viewing angle and color gamut, poor black level, low peak luminance and slow response time of the LC-material, high cost, and low yield in production.

Since 2005, the picture quality of LCDs for TV surpassed that of CRTs, the milestone is Full High Definition (FHD) LC-modules with 1080 lines introduced into the market, which has good daylight contrast and high resolution.

The viewing angle could be enlarged spectacularly by applying new LC structures like In-Plane Switching (IPS)and Vertically Aligned Nematic (VAN) LCs.

Since the panel costof a TFT LCD module is relatively high, decreasing the cost of manufacturing an LC panel is one of the main issues. The most effective way is to enlarge the mother glass or substrate of the back and front plates.

Until 2021, Gen11 is in production, which can process the size of glass substrate 3000*3320(mm). (In the industry, “Gen” stands for generation, which is used to indicate the size of the glass substrate for an LC panel. )

Even though AMLCD (TFT LCD) takes advantage of the display technology and display quality, the cost of some modules can compete with the similar size of passive LCDs.

Passive Matrix LCDActive Matrix LCDWorking PrinciplePixels are addressed directly and they must retain their state between screen refreshes without the benefit of a steady electrical charge.A switch is placed at each pixel which decouples the pixel-selection function. Thin Film Transistor is the main technology of the AMLCD subgroup.

ApplicationNumerical displays, mono color word processors, mainly low cost, low power monochrome display, and graphic display.Mobile phones, computer screens, monitors, television, and mainstream color displaysFigure5: Comparison between PMLCD and AMLCD

With the benefit of the active matrix display technology and the technology development of related materials, components, and production in recent years, the TFT-LCD has attracted markets to adopt this technology.

For instance, the 1.3-inch TFT can have a resolution of XGA (1024 x 768) containing millions of pixels, while the TFT film for 16.1-inch with a resolution of SXGA (1280×1024) is only 50 nm.

From an industrial perspective, the application of glass substrates and plastic substrates fundamentally solves the cost problem oflarge-scale semiconductor integrated circuits.

And with the optimization of production and technology in the last 30 years, the yield rate has improved, average above 90%, much better than OLED of about 80%.

In comparison with CRT, TFT LCD consumes about one-tenth of the power of a CRT display, and the reflective TFT LCD is even only about one-hundredth of that.

The power consumption of the TFT display is mainly from the backlight, accounting for about 90%. Reducing the power consumption of BL is the focus of the future development of TFT liquid crystal display, as well as improving its lifespan.

Because backlight is also the key factor that determines the service life of LCD. When the backlight turns dark while it reaches its maximum service life, the LCD screen will wear out. Even before then, the display quality will go down.

TFT displays are full color LCDs providing bright, vivid colors with the ability to show quick animations, complex graphics, and custom fonts with different touchscreen options. Available in industry standard sizes and resolutions. These displays come as standard, premium MVA, sunlight readable, or IPS display types with a variety of interface options including HDMI, SPI and LVDS. Our line of TFT modules include a custom PCB that support HDMI interface, audio support or HMI solutions with on-board FTDI Embedded Video Engine (EVE2).

Recently, there is a lot of buzz about whether Apple will choose Mini-LEDover OLED, for the next round of iPads, MacBooks and other products. Regardless of the fascination analyzing current product releases, or one specific consumer-product company, the more significant movement over the last 5~10 years, has been the steep upwards ramp in Micro-LED Startups, IP, investments and acquisitions by: Apple, Facebook, and Google. And from the chip makers themselves such as Intel, Global-Foundries, in Startups such as Luxview, InfiniLED, Plessey, Aledia, Compound Photonics and more.

For an industry that is literally in the business of visualization, the display industry often seems rather opaque, mysterious, and even geo-politically contentious (refer: Foxconn"s LCD Fab in Wisconsin). These articles will cover aspects not well-elaborated in popular analysis, and also provide an update to the material presented 5yrs ago at the Bay-Area SID (Society for Information Displays), on why this technology, is so different, so disruptive, and how it will reach far beyond even the wildest market projections. But for a background on the basics of how & why, vision, the brain and displays work, recommend an easy to digest, and popular, book by Mark Changizi: The Vision Revolution. There are also excellent industry analysts, who cover displays professionally, and in much finer-grain detail, such as Yole Development (thanks to Eric Virey for source graphics) and DSCC (thanks to Ross Young & team for references, and feedback).

Firstly, to be clear: the flat-panel display industry is a semiconductor industry. This is the critical "border", where electrons of digital information, are turned into photons of visual information. And the pixels you see, while reading this article, are driven by transistors - Thin-Film Transistors (TFT) - somewhere between 3 and 12 transistors per pixel, depending on the type of display (OLED needs more than LCD), and the maker. The Transistor, Resistor, Capacitor circuits are built by nano-scale material deposition processes, on a glass substrate (the backplane), via semiconductor manufacturing equipment, from suppliers including US"s Applied Materials, Japan"s Canon Tokki, Korea"s SNU Precision, Wonik IPS and more. Yet it has not attracted the same strategic interest from within the US, as other semiconductor industry segments e.g. processor chips. While there is a drive to increase the number of (existing) semiconductor chip fabs on US soil, the fact is that the US has no significant domestic display manufacturing capability at all, effectivelyzero. And the same is true for most of the technology ingredients comprising the display, such as the film layers, LED’s & OLED and their ingredient materials, and the controller & driver chips - which is dominated entirely by non-US companies you probably never heard of, such as Taiwan Novatek (the 13th largest semi maker, worldwide), Taiwan Himax, Taiwan Parade, and Japan"s Renesas. That is, until one of them has a problem.

So if the geopolitical semiconductor war gets any rougher, you might be wondering, where is this chip (that Biden is holding) going to display it"s output ? On an etch-sketch ? (perhaps the only display device still made in the US ?)

Since more than 40% of our brain is devoted to vision, more than all of the other senses combined, this would seem an important gap. After all, light, color and contrast are the fundamentals of art, literature, civilization, as well as your next Zoom virtual meeting. Of course we need to see the results of the computation of AI, CPU, Memory, GPU, Network, 5G ... processors, appear on some display eventually, right ? So this article also aims to provide some more insights on key factors in the previous transition, what"s going on now, why it"s important, and how it may matter in real-life terms.

Secondly, (and this an easy bet) you’re more likely reading this article on an LCD flat-panel Display, rather than OLED or ePaper. But all 3 have been transformational technologies of the 21st century. Could modern society continue to communicate effectively, presenting a person in front of you from anywhere/anytime, productivity continuing virtually, during a Global Pandemic ? What would it have been like if we were still sharing the 20th century family’s TV ? (recap for millennials: the Cathode Ray Tube TV was a 50 ~ 100 lb, X-Ray-emitting, monster appliance, using electron beam scanning technology from the 1920"s, and with coarse interlaced video rendering designed to save 6MHz (3 Mbit/s by modern standards) of precious radio-frequency bandwidth). Even the 12yr old iPhone 3GS could muster more than that, on a bad day.

As for myself, am writing this article across two of my favorite consumer flat-panel devices: a newer 15” Retina MacBook Pro and an older 17” MacBook Pro. Partly because both are still the best, un-compromised, example of the portability & performance enabled by the Hybrid Graphics technology, a Display & GPU technology, drove across the laptop industry while working at NVIDIA. But mostly because Apple consistently aims for excellence in their displays. Am enjoying a large, bright, 300 “nit” (candela/meter2) LCD screen, an excellent 900~1000:1 contrast ratio, a full DCI-P3 color gamut, and sharp 220 ppi "retina" resolution that renders crisp text and beautiful images. The recurring theme: light, color, contrast.

However, at the 2019, 2020 and 2021 CES, Micro-LED and Mini-LED began appearing across more and more applications (e.g. TV, AR, Monitors, Digital Signage), and demo"s like the Samsung Wall and Sony MicroLED continue to attract the largest, most excited crowds, have ever seen at CES (before it went virtual). Back in 2017, I wrote this article about Micro-LED & Mini-LED"s, talking about potential applications, and specifically about the key challenges to this visual revolution, that PixelDisplay set out to solve: in the color conversion material needed to more economically create Red & Green from the high efficiency Blue. In November 2020, PixelDisplay publicly disclosed details of NanoBright™solution, at the Phosphor & QD Summit, and is now offered for sale on PixelDisplay.com

In the Mini-LED ecosystem, the role of NanoBright is often used the same as per regular white LED"s, which in 2018 PixelDisplay estimated to be worth $750m/yr, but this market is now projected to be worth $5b, for Mini-LED"s overall, by 2025. The color converter can be simply coated on the Mini-LED and surrounding backplane (providing a high efficiency, bright-contrast, High-Dynamic-Range with DCI-P3 wide-color gamut), but there are more interesting benefits e.g. eliminating existing LCD films to make thinner, borderless and more efficient.

But to put this in larger perspective, here"s the role NanoBright™fills in the Micro-LED ecosystem, as described in DSCC"s ( @Guillaume Chansin) excellent LinkedIn article.

But why should this Micro-LED technology be of any broader importance ? Why is it any different than OLED, or LCD ? How is it a disrupting technology ? What difference does it have from any of the other opaque display industry machinations that means it will have significant impact in our lives? It"s a great test to ask: "would my mother care ?".

To start with how it"s different, and how it is disruptive, we need to recap on how we got here on the glass backplane of LCD and OLED. And to fully appreciate the magnitude of the disruption represented by the Micro-LED revolution, we have to also understand the scale of the investment behind the commercializing flat-panel glass, and to the display TFT semiconductor industry.

Am not going to cover the long sordid history of display technologies, nor the detailed lineage of LCD, or OLED. But it is worth noting that both technologies were born in the US, the LCD from RCA, and the OLED from Kodak - and ironically, both pioneering companies are now just brands - non practicing entities. But there are other pioneers, such as UDC, who have persisted, and remain necessary ingredients in the ecosystem (we"ll touch on "why ?" later). But instead, will identify two key elements from the 1990"s, that were the major accelerators flat-panel displays to escape velocity in 2000"s, launched the FPD revolution into orbit, and led to the proliferation of what we enjoy today:

1) TFT follows Square-Rule Growth:To understand the explosion in the economics of producing glass flat panel displays covered in TFT pixels, we can start with the size increases of the glass processing fabrication itself. The term, "Gen" refers to the size generation, the capability of the TFT panel fab, by the dimensions of the glass sheet that it can process, which typically entails creating deposition layers stacked layer-by-layer, to build the TFT pixels - whether OLED or LCD, it starts with TFT pixels on a sheet of glass. In the late 90’s, massive government investments spurred the creation of ever larger display fabrication facilities, with ever larger deposition equipment based on the successful A-Si (amorphous Silicon) process, which grew quickly from Gen 3.5 (0.62 x 0.75m) to Gen 5 (1.1 x 1.3m) to Gen 6 (1.5 x 1.85m) glass substrates, in just a handful of years. Every sheet of glass processed in an LCD production line is cut into smaller panels, making TV’s, Monitors, laptops, tablets and phones.

But unlike Moore’s Law (which doubles transistors every 18months), the glass panel area increase (width x height) results in a faster, power-of-2 square-rule, increase in the number of pixels, and thus the number of TFT transistors. In fact, the number of semiconductor transistors on glass TFT was increasing at 2.5x Moore’s Law, during the last decade. While it took 10 years to go from 5mil transistors in Intel’s Pentium Pro 1995, to 169 mil transistors in the Prescott CPU 2005 – the LCD display industry made the same increase in the number of TFT transistors for 8K resolution, in roughly 5 years (from the PixelDisplay presentation at the 2018 DSCC Future Display Technology Conference).

By early 2000"s, Plasma was beyond hope, the transition from CRT"s was in full-swing, the IBM Thinkpad was a staple of corporate life, and laptops had crossed the 8hr battery-life mark thanks to display efficiency improvements (as we"ll discuss later the display is the key enabler of longer battery-life). The LCD plants were pumping out everything from laptop screens, to LCD monitors, to 60" large-screen LCD TV"s, at lower-and-lower price-points - from fabs based in Japan, then Taiwan, and Korea. By the late 2000"s, the Fab-depreciation (eff. cost of borrowed capital) was the most significant component of the LCD panel prices, and panel makers squeezed the margins out of everyone in the supply chain including films, LED, controller and driver chips. Major winners were the materials suppliers: Corning Inc (the Glass), Merck (the LCD material itself), Nichia (the backlight LED"s), and Canon Tokki & Applied Materials (TFT-glass deposition equipment).

Meanwhile in the US, Intel made a huge bet in 2001, that LCD would not scale, and that LCOS would provide solutions, and enable larger-screen, like the earlier (CRT-based TV) projection displays. But in just 3~4 years, it became clear the LCD square-rule economies were different, ever-larger ever-cheaper LCD panels seemed to be viral, ramping to fill the large-screen TV market. The LCOS & DLP were relegated to the projector market, and Intel exited LCOS in late 2004. It"s worth noting Intel has gradually become more active in the display industry, and Intel Capital has made multiple investments in the Micro-LED partnerships for GaN-on-Si (and we"ll come back to that later).

Outside the US, the display industry has been the target of massive strategic investments for Asia for over 3 decades. Starting with Japan government forcing the collaboration of Sony, Hitachi and Toshiba to create JDI (which made the first iPhone and iPad screens), and the INCJ (a government investment consortium) of Japan, then Korea and Taiwan Governments, and then China. Today this industry is dominated by China, as per the reports from analysts e.g. this one from Display Supply Chain Consultants. The government of China and private investors, aggressively funded the rise of China from sub 10% a decade ago, to owning more than 63% of the world’s display production. By 2017, the Taiwan government had publicly stated they were no longer going to invest in more LCD fabs, and in 2018 the chairman of LG got up in front of the entire company taking a sledge hammer to smash an LCD TV, in a symbolic communication of the company"s shift in focus to the highly profitable OLED (not facing competition from China) - the fate of LCD flat-panels was sealed.

One example of China"s investment in display leadership is Beijing Opto Electronics (BOE). And I have visited BOE’s Gen 6, 8.5, and 10.5 (2.9m x 3.4m) fabs in HeFei and Beijing. This picture below is a panorama I took standing outside one of the older (smaller, older) Gen 8.5 Fab"s from a visit to the BOE facility in HeFei. At the time, they had built a Gen 10 behind it, and building another beside that.

But when you’re outside looking at a factory that is literally over 1.3 kilometer per side, the staggering magnitude of China"s investment in display leadership, is simply breathtaking. The first Gen 10.5 fab located in Sakai Japan, was also Japan"s last one. But at last count there are seven (7) Gen 10.5 fabs in Mainland China, and still more are being built. There is no questioning China’s intent to seize control over the majority of eye-balls, from the source.

2) Inorganic Solid-State gives 4x increase in efficiency: The second important innovation was the In/GaN-based Blue LED. Invented in Japan (ironically, US-based CREE had a blue LED earlier, but failed to productize until much later), from which Nichia made White LED’s, by adding yellow-emitting YAG:Ce inorganic phosphor, they had left over from their CRT phosphor business. It was a cheap trick to synthesize something that looked White, from a psycho-visual hack of using two complementary colors: Blue + Yellow. But in short, the poor color was an acceptable tradeoff for higher-efficiency, smaller size, more robust inorganic solid-state solution. LED backlights quickly transformed the industry from (thicker, bulky, and very fragile) fluorescent tube (CCFL) backlights, into thin/efficient LED backlights, in the early-mid 2000"s. And the lead inventors, including Shuji Nakamora of Nichia, won the 2014 Nobel prize for the work on GaN LED.

This was an important step forward in the story. Originally, the CCFL backlit display was 70~80% of the total power consumption of an idle Laptop. In fact, back in 2001 while at Intel, together with Ying Cui we invented and implemented Intel’s Backlight Modulation Technology (called DPST(tm)) which was like an inverse-High-Dynamic Range, it proportionally increased pixel contrast, in order to allow decreasing the CCFL backlight brightness and provide huge system power-savings. That was the star feature of Intel’s EBL (Extended Battery Life) initiative, saving more system power than other, more publicized, Intel CPU features (e.g. Geyserville aka "SpeedStep"). For me, that was a first introduction to the value and importance of the flat-panel display technology, as the essential ingredient in portable platforms. But LED"s further helped enable the "implosion" of visual-compute portability into sub-8lb / sub-1inch Laptops. And the displays that appeared in Phones and Tablets, were using LED"s that are only 0.4~0.6 mm tall, fitting in the edge of the panel.

Today, LED efficiency is over 200 lm/W (4x the efficiency of older CCFL), but efficiency improvements in processor and memory technology means the display is still typically 50~70% of total system power for phone or laptop, and this is worse for OLED (than LCD) because of how poorly OLED technology handles mostly-white backgrounds (e.g. of browsers, text & productivity applications).

The LED industry has also been a source of massive investment and deeply geopolitical rifts as Japan (e.g. Nichia) vs Korea (e.g. Seoul Semi Conductor) vs Taiwan (e.g. Foxconn/AOT, LiteOn, Epistar) vs China (e.g. CSOT, SanAn). Initially dominated by IP held by Nichia, CREE and Osram, those players now have diminished roles, but it has remained a complex ecosystem.

Tiny efficient LED"s enable 2D-array backlighting on LCD to achieve HDR (High-Dynamic-Range). Higher-end LCD TV"s were the first consumer displays to use LED"s with better R-G Phosphors to create a wider DCI-P3 color gamut. Firstly, arranging the Edge-Backlight LED"s to control 1-Dimensional regions, from along the edge. And then advancing into 2D-array of LED"s, to create active-region backlight. This enabled LCD"s to increase the contrast ratio beyond 1000:1, and peak brightness beyond traditional edge illumination, creating the High-Dynamic Range (HDR) experience first popularized by BrightSide (later acquired by Dolby, to form DolbyVision, and which is now licensed-technology on the iPhone). Today HDR content leverages individual screen-region lighting, to create brighter highlights, and the deeper-blacks to create a more realistic and dynamic experience. In summary, HDR LCD TV with 2D backlight became commercially practical as a result of small (less than 3.0 x 3.0 mm) LED"s with over 220 Lm/W efficiency - 13x more efficient than incandescent bulbs Brightside originally used, which had required huge exotic water cooling solution.

Challenges of the "Crystal Cycle":the size of these glass-processing fab investments is so large, and the equipment CapEx expenditures are so huge, that this leads to massive disconnect between supply and demand, causing large cyclical swings in pricing, which became known as the "Crystal Cycle"

To ride the economies of scale requires increasing the glass handling size, which requires ever larger investments, just as the second of Moore’s Laws predicts. For example, BOE’s invested US$7 billion to make a Gen 10.5 fab. And in an interesting geopolitical twist, after the Taiwan (once a former colony of Japan) government declared they were not investing anymore in the LCD business, Terry Guo (Taiwan Foxconn CEO), acquired a majority of Sharp, and their huge LCD display production lines in Kameyama (which made the innovative IGZO-based LCD panels, which enabled the thinner/more-efficient iPhone 6, and iPad Air), and Japan’s only Gen 10.5 plant in Sakai, which is making 8K TV’s (was spun-off into Sakai Display Corporation). Foxconn was already a large player in the display industry owning Taiwan’s #2 maker, Innolux Optoelectronics. Far beyond merely being “the sport of king’s”, the display industry has been “the sport of nations”.

OLED is doubly challenged: and it has not become progressively cheaper with economies-of-scale as many expected. In LCD only a tiny current is needed to flip a pixel, all of the light is produced from a thin string of backlight LED"s. Whereas in OLED, every pixel is itself a light emitting organic-LED, with many orders of magnitude higher current required at every pixel. The high contrast emissive pixel design of OLED displays provides excellent contrast, but typically requires the use of the more expensive and complex LTPS (low-temperature polycrystalline silicon) process to produce the active TFT driving backplane. LTPS involves a more complex 11-step process, with much higher-temperatures that only a few materials (glass, clear polyamide) can sustain. LTPS requires a high-power excimer laser to anneal the surface, forming the layer of polycrystalline silicon - this is slow, and does not scale well into larger sizes. The OLED fabs have thus been limited to Gen 6 (1.5 x 1.85m) or smaller, in glass size. Even though this is big enough to make a few TV"s, the smaller starting glass size means the cost-curve is sub-optimal, unless partitioned into many smaller panels e.g. the higher-cost has lower impact for smaller smartphone screen. While an oxide deposition process called LTPO (a simpler Oxide process, borrowing from the IGZO process that delivered LCD efficiency improvements in iPhone 6 & iPad Air), offers some hope in the future, there’s another additional challenge.

The complexities of driving a large number of emitters from a thin layer on glass backplane has also meant limits on full-screen brightness, and limited ability to address higher resolutions. A full screen of white does not occur often on a OLED TV, as it does on an Tablet or Laptop, but if you do witness a larger amount of white (as in productivity apps on a Laptop) you"d notice the whole OLED screen goes dimmer, this is done in order to limit the total current across the thin conductor traces that feed the pixels on the glass.

Unlike LCD TFT (which only requires a single transistor and storage capacitor), a typical OLED driving circuit can have 3~6 transistor (and similar number of capacitors) per color i.e. 9~18 transistors per pixel. This driving complexity also limits the net active emitting area of the pixel, versus the inactive driving circuit, also called the "Fill-Ratio". And that"s part of the reason why the Oculus and Samsung Gear VR headsets look like watching everything through a thick fly-screen mesh - the amount of non-emitting "dark-area" per pixel is huge (much larger than LCD). Laying out complex circuits naturally extends the non-emitting pixel-area, horizontally outwards in width & length, that is of course a limitation of thin deposition layers on glass. This limits both the ability to go into finer pitch (>1000ppi and 40Kx16K resolution is the ultimate goal for x-Reality displays), and also to create larger emitters for higher brightness.

Furthermore, the front-plane of an OLED panel requires ultra-precise patterning with emissive organic phosphor materials, with tightly controlled size & depth-tolerances. This has switched from vapor deposition, to inkjet patterning to save some cost, but because of the non-uniformity it is limited in ability to go into very fine pitch, retina-quality displays. But either way, the OLED materials themselves remain very expensive, with Universal Display Corp (UDC) maintaining a tight grip on the materials supply chain, thanks to a portfolio of significant & early IP. The alternatives to UDC patents, such as HF (Hyper fluorescence e.g. KyuLux) or TADFL (thermally activated delayed fluorescence e.g. Cynora) are really 5~10yrs out, and merging QD on OLED aka "QD-OLED (e.g. Nanosys & Samsung) has consistently missed every promised demo/roll-out, and feels more like either a science project, or a ploy for negotiating UDC pricing.

But since OLED breaks-down with age, and even faster with moisture, heat, and higher-energy blue/uv photons (reminder, the “O” in OLED, stands for Organic), the use of glass (or expensive polyamide materials) with low gas & moisture permeability remains a requirement, since lifetime & brightness remain the bigger issues for OLED. In the phone industry, key manufacturers came to embrace OLED since it looks fantastic but wears out - after-all consumers are more motivated to buy a new phone, if it looks noticeably brighter and sharper, than the worn-out 2-year-old one in hand. While higher production costs, aging and burn-in problems of OLED have been acceptable (even desirable) in the phone business, they have hampered the progression of OLED into IT and Automotive applications. And while OLED came with the promise of more freedoms than LCD, in creating foldable and flexible displays, the fact remains: it lasts longer when hermetically encapsulated in glass the best barrier protecting from oxygen and moisture.

While OLED has not enjoyed the same cost-reduction curve, as in the LCD proliferation, the higher-end and visually-satisfying (initial) experience continue to feed hope & investment. Glass TFT has both enabled, and limited OLED"s ability to achieve higher brightness, and higher resolution. There"s frequently news of better OLED solution coming down the research pipeline, and we"ve already touched on the bigger ones (e.g. Hyperfluorescence, Thermally Activated Delayed Fluorescence, Quantum Dot on OLED), but the reality has fallen far short, nor is there anything helping to break-free from the most expensive TFT processes. OLED is very likely to continue to service the small display markets, products that have a shorter life expectancy, and only need a lower-brightness display (e.g. TV"s, which only need 100nits of brightness).

The industry is ripe for disruption from a brighter, more robust inorganic solution, that comes with a better (near-term) ability to reduce cost as it scales.

Unmet needs, in important niche markets: is the essential formula, for the beginning of disruption, as outlined by Clayton Christensen. Who described the formula for disruption as essentially: a niche market (of future importance) with unmet needs, that can afford to adopt a more expensive solution, where that solution has an ability to scale and leverage the niche-win to expand into broader markets, displacing incumbent technologies. Some example display niche markets:Automotive and Smartwatches displays have been over 1,000 nits for some time, but need much more to compete with typical daylight glare.

Autonomous vehicles (e.g. robo-taxis) are on the horizon, but pause for a moment to consider how they will visually communicate to passengers & pedestrians, when no human is present ? No driver to confirm name or usher in passenger, or gesticulate with body language to other less-patient human drivers. The solutions are being developed right now (and PixelDisplay is involved), they of course need to operate in bright daylight, and be colorful & robust as the painted bumper panel or shatter-resistant safety-glass, they"ll be integrated-into.

When the HDR standards were formed, they included a high peak-brightness of 10,000 nits (far beyond wildest dreams of OLED and Quantum Dots), and real-world contrast ratio"s (>10x that available on LCD with edge backlight). And studio-grade content-authoring displays can do well over 4,000 nits, but need constant recalibration to account for non-uniformity from wear, and sometimes replaced after only a year. We can expect this to migrate into more consumer displays over the next 5yrs, and the Gaming/TV/Video/Movie content standards (BluRay-UHD, VESA DisplayHDR and the Hollywood UHD-Alliance) already integrated that support.

These are markets that will pay for a more expensive solution, that can deliver unmet needs of bright, high (HDR) contrast, deep-black and defined shadows, and crisp-rich colors (like OLED), in a thin form-factor, but with higher brightness and longer lifetime (like LED-backlit LCD).

The value of the Flat Panel Display: the industry is worth over $120 billion (3x the value of the GPU market), and is project to grow to well over $200 billion by 2025. Yearly production (rough numbers): over 1.8 billion smartphone panels, 300 million laptop and tablet panels. This thin, complex, glass-stack, in the flat-panel module, still represents the single most expensive component in the phone & tablet (and many laptops also).

In the iPhone BOM, the display has, at times, been more than 2~3x the cost of the SoC (CPU & GPU) and RF BaseBand chips, combined. And in the iPhone 12, the new OLED display is responsible for 35% of the BOM cost increase vs iPhone 11. It should then, be unsurprising that Apple (unlike Intel, NVIDIA, AMD, DELL or any other OEM that I know), has multiple (large) divisions devoted just to display technology - one in each of their business verticals. Staffed with display architects, and engineers refining technologies, sourcing core materials (even the phosphors), creating new designs. Even custom-designing the display controller and driver chips, for the panel makers to insert inside displays made - exclusively for Apple - that are not available to any other panel customers. Perhaps because it is the most critical border of the Visual Information Age, and obviously because it is necessary to control the border to control your future, right ?

In summary,during this pandemic we"re able to adapt and continue our communications visually; collaborating, pitching, working efficiently, and remotely from anywhere; thanks to the internet, wireless connectivity, and the glass flat-panel visual interface. Long Zoom sessions can be taxing, but imagine if this had happened in the 1950"s, 1970"s or 1990"s ? Would our children have been able to engage in school remotely ? Would we have remained as connected, and as productive ?

The technology innovations may have US origins, but the major enablers of the last visual revolution were: a) execution driven by massive investments in manufacturing & commercialization from: Japan, Taiwan, Korea and China in flat-panel display leadership, b) faster than Moore’s Law growth in the economies-of-scale of glass-substrate TFT pixels, and c) the shift to cheaper/smaller/robustsolid-state In/GaN semiconductor LED technology.

Now there’s a another shift happening. With the Micro-LED & Mini-LED generation, there"s a new, and very different, formula. Unlike the past display technologies: Micro-LED are innately decoupled from the glass backplane, and that changes everything.

In the next article,more details of how this visual revolution is progressing, firstly re-igniting LCD 2.0 with Mini-LED"s, and breaking through the glass-barrier with Micro-LED"s, and what displays of the future will look like.

www.electronicdesign.com is using a security service for protection against online attacks. An action has triggered the service and blocked your request.

Please try again in a few minutes. If the issue persist, please contact the site owner for further assistance. Reference ID IP Address Date and Time 72f34325e42ecb179a2ad5981afc8831 63.210.148.230 01/15/2023 01:05 PM UTC

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey