revolution of the tft lcd technology for sale

Antigua and Barbuda, Aruba, Australia, Austria, Bahamas, Bahrain, Barbados, Belgium, Belize, Bermuda, Bolivia, Brunei Darussalam, Bulgaria, Cambodia, Canada, Cayman Islands, Cyprus, Czech Republic, Denmark, Dominica, Estonia, Finland, France, French Guiana, Germany, Gibraltar, Greece, Grenada, Guadeloupe, Guernsey, Hungary, Iceland, Ireland, Israel, Italy, Japan, Jersey, Jordan, Kuwait, Latvia, Liechtenstein, Lithuania, Luxembourg, Macau, Malaysia, Maldives, Malta, Martinique, Mexico, Monaco, Montserrat, Netherlands, New Zealand, Norway, Oman, Pakistan, Paraguay, Poland, Portugal, Qatar, Republic of Croatia, Reunion, Romania, Saint Kitts-Nevis, Saint Lucia, Saudi Arabia, Singapore, Slovakia, Slovenia, South Korea, Spain, Sri Lanka, Sweden, Switzerland, Taiwan, Turks and Caicos Islands, United Arab Emirates, United Kingdom, United States

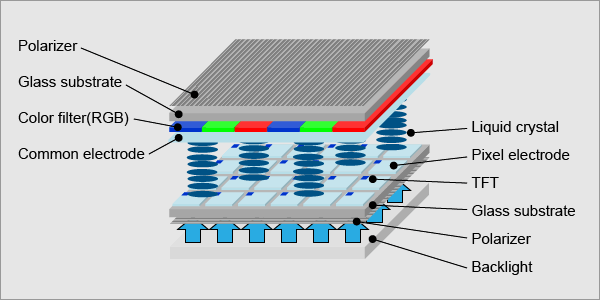

From the MOSFET, the TFT was born. The TFT varies from standard MOSFETs, or bulk MOSFETs, because, as the name implies, it uses thin films. The TFT began a new era of electronics. In 1968, just six years after the first TFT development, Bernard J. Lechner of RCA shared his idea of the TFT Liquid Crystal Display (LCD), something that would boom in popularity in our modern times. The TFT LCD was then first created in 1973 at the Westinghouse Research Laboratories. These LCDs were composed of pixels controlled by transistors. In FETs, substrates were just the semiconductor material, but in manufacturing TFT LCDs, glass substrates were used so that the pixels could be displayed.

But that was not the end of TFT developments. Soon after, in 1974, T. Peter Brody, one of the developers of the TFT LCD, and Fang-Chen Luo created the first active-matrix LCD (AM LCD). An active matrix controls each pixel individually, meaning that each pixel’s respective TFT had its signal actively preserved. This opened doors to better performance and speed as displays became more complex.

Though TFTs can use a variety of materials for their semiconductor layers, silicon has become the most popular, creating the silicon-based TFT, abbreviated as Si TFT. As a semiconductor device, the TFT, as well as all FETs, use solid-state electronics, meaning that electricity flows through the structure of the semiconductor layer rather than vacuum tubes.

Due to the variety in silicon’s possible structures, the Si TFT’s characteristics can vary as well. The most common form is amorphous silicon (A-Si), which is deposited during the first step of the semiconductor fabrication process onto the substrate in low temperatures. It is most usable when hydrogenated into the form A-Si:H. This then significantly alters the properties of A-Si; without the hydrogen, the material struggles with doping (the introduction of impurities to increase mobility of charges); in the form A-Si:H, however, the semiconductor layer becomes much more photoconductive and dopable. The A-Si:H TFT was first developed in 1979 which is stable at room temperature and became the best option for AM LCDs which consequently began rising in popularity after this breakthrough.

A second potential form of silicon is the microcrystalline silicon. Though it retains a similar form to A-Si, this type of silicon also has grains of what is known as crystalline structures. Amorphous structures have a more random, less geometric shape to their network-like structures, but crystalline, on the other hand, is more structured and organized. If grown correctly, microcrystalline silicon has better electron mobility than A-Si:H and greater stability too, as it has less hydrogen within its structure. It is deposited in a similar fashion to A-Si’s deposition.

And lastly, there is polycrystalline silicon, also known as polysilicon and poly-Si. Microcrystalline silicon is the middle between A-Si and poly-Si since poly-Si’s structure is composed of many crystallites. This specific form is made by annealing the silicon material which means adding heat to alter the properties of the structure. With poly-Si, the atoms in the crystal lattice shift and move when heated, and when cooled, the structure recrystallizes.

The biggest difference between these forms, notably A-Si and poly-Si, is that charge carriers are much more mobile and the material is much more stable when it comes to using poly-Si over A-Si. When creating complicated and high-speed TFT-based displays, poly-Si’s characteristics allow for this. Yet, A-Si is still very important due to its low-leakage nature, meaning that leakage current is not lost as heavily when a dielectric insulator is not totally non-conductive.

In 1986, the first low temperature poly-Si (LTPS) was demonstrated by Hitachi. LTPS plays a large role in the manufacturing of devices because the glass substrate is not as resistant to high temperatures, so in order to anneal the poly-Si, lower temperatures are used.

Several years later, another development was made in 2012 in the form of indium gallium zinc oxide (IGZO) which allowed for a more powerful display in terms of refresh rates and more efficiency in terms of power consumption. This semiconducting material, as stated in the name, uses indium, gallium, zinc, and oxygen. Though it is a form of zinc oxide (ZnO), the addition of indium and gallium allows this material to be deposited in a uniform amorphous phase but also maintaining the oxide’s high carrier mobility.

As TFTs began to increase their presence in display technology, transparent semiconductors and electrodes became more appealing to the manufacturers. Indium tin oxide (ITO) is an example of a popular transparent oxide used for its appearance, good conductivity, and ease of deposition.

Research of the TFT with different materials has led to the application of threshold voltage, or how much voltage is needed to turn on the device. This value is greatly dependent on thickness and choice of the oxide. When it comes to the oxide, this relates back to the idea of leakage current. With thinner layers and certain types of oxide, the leakage current may be greater, but this in turn could lower threshold voltage, as leakage into the device will also increase. In order to tap into the TFT’s potential for low power consumption, the lower the threshold voltage, the better the device’s appeal.

Another branch of development that stemmed from the TFT is that of organic TFTs (OTFT). First created in 1986, OTFTs usually use solution-casting of polymers, or macromolecules. This device made people hesitant, as it tended to have a slow carrier mobility, meaning slow response times. However, researchers have carried out experimentation with the OTFT because it has potential to be applied to displays different from those that traditional TFTs are used for, such as flexible, plastic displays. This research still continues today. With its simpler processing than traditional silicon technology, the OTFT holds much potential for modern day and future technologies.

The introduction of flat panel displays that are fabricated with thin-film-transistor liquid-crystal displays (TFT LCDs) has changed human"s lifestyle very significantly. Traditionally, the revolution of the TFT LCD technology has been presented by the timeline of product introduction. Namely, it first started with audio/video (AV) and notebook applications in the early 1990s, and then began to replace cathode-ray tubes (CRTs) for monitor and TV applications. Certainly, TFT LCDs will continue…Expand

TFT Liquid crystal display products are diversified, convenient and versatile, simple to keep up, upgrade, update, long service life, and have many alternative characteristics.

The display range covers the appliance range of all displays from one to forty inches and, therefore, the giant projection plane could be a large display terminal.

Display quality from the most straightforward monochrome character graphics to high resolution, high colour fidelity, high brightness, high contrast, the high response speed of various specifications of the video display models.

In particular, the emergence of TFT LCD electronic books and periodicals will bring humans into the era of paperless offices and paperless printing, triggering a revolution in the civilized way of human learning, dissemination, and recording.

It can be generally used in the temperature range from -20℃ to +50℃, and the temperature-hardened TFT LCD can operate at low temperatures up to -80 ℃. It can be used as a mobile terminal display or desktop terminal display and can be used as a large screen projection TV, which is a full-size video display terminal with excellent performance.

The manufacturing technology has a high degree of automation and sound characteristics of large-scale industrial production. TFT LCD industry technology is mature, with a more than 90% mass production rate.

It is an ideal combination of large-scale semiconductor integrated circuit technology and light source technology and has good potential for more development.

From the beginning of flat glass plates, its display effect is flat right angles, letting a person have a refreshing feeling. LCDs are simple to achieve high resolution on small screens.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

We develop, design, manufacture, and sell displays where it is necessary for the interface that deliver a lot of information at an instant and deliver it to the global market. We create interactive spaces that go beyond the expected, elevate everyday lives, and move people"s hearts. From bases in major cities in Asia, Europe, and North America, we build strong customer relationships by developing products that respond to market needs.

TFT LCD display is characterized by good brightness, high contrast, strong sense of layering, and bright colors, but it also has the disadvantages ofrelatively highpowerconsumptionand high cost. TFT LCD technology has accelerated the development ofmobile phone color screens. Many of the new-generation color screen mobile phones support 65536-color displays, and some even support 160,000-color displays. At this time, the advantages of TFT high contrast and rich colors are very important.

TFT technology was developed in the 1990s. It adopts new materials and new processes for large-scale semiconductor full integrated circuit manufacturing technology. It is aliquidcrystal(LC), inorganic and organic thin film electroluminescence (EL and OEL) flat panel display. basis. TFTs are formed on glass or plastic substrates and other non-single wafers (of course, they can also be on wafers) by sputtering and chemical deposition processes to form various films necessary for manufacturing circuits, and large-scale semiconductor integrated circuits (LSIC) are produced by processing the films . The use of non-single-crystal substrates can greatly reduce costs, which is the extension of traditional large-scale integrated circuits to large areas, multi-functions, and low costs.Manufacturing TFTs thatcontrolthe switching performance of pixels (LC or OLED) on large-area glass or plastic substrates is more difficult than manufacturing large-scale ICs on silicon wafers. The requirements for the production environment (purification degree is 100), the requirements for the purity of raw materials (the purity of electronic special gas is 99.999985%), the requirements for production equipment and production technology exceed the large-scale integration of semiconductors, and are the top of modern large-scale production technology. Its main features are:

(1) Large area: The first generation of large-area glass substrate (300mm×400mm) TFT-LCD production line was put into operation in the early 1990s. By the first half of 2000, the area ofthe glass substrate had been expanded to 680mm×880mm), and 950mm×1200mm The glass substrate will also be put into operation. In principle, there is no area limit.

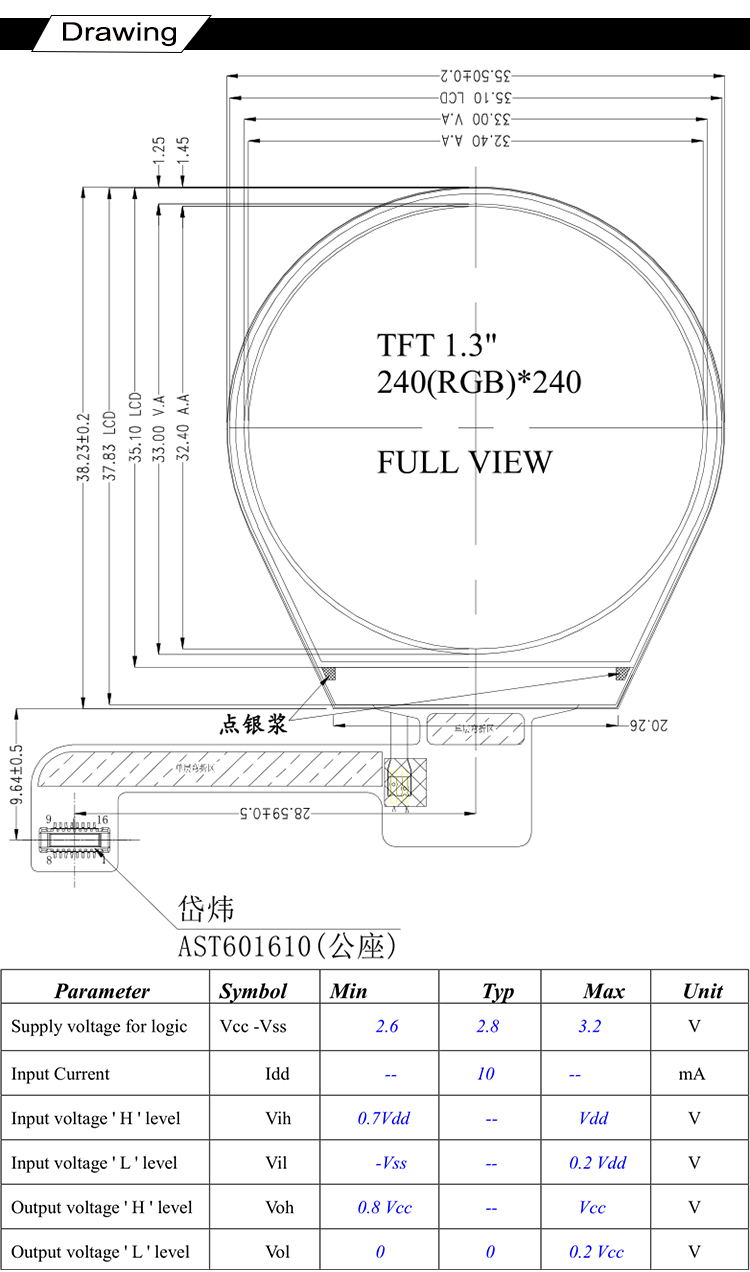

(2) High integration: The resolution of the 1.3-inch TFT chip used for liquid crystal projection is XGA containing millions of pixels. The 16.1-inch TFT array amorphous silicon with a resolution of SXGA (1280×1024) has a film thickness of only 50 nm, and TABONGLASS and SYSTEMONGLASS technologies. The IC integration, the requirements for equipment and supply technology, and the technical difficulty are more than traditional LSI.

(3) Powerful function: TFT was thefirst matrix addressingcircuitto improve the light valve characteristics of liquid crystal. For high-resolution displays, through the voltage adjustment in the range of 0-6V (its typical value is 0.2 to 4V), the precise control of the object element is realized, thereby making it possible for the LCD to achieve high-quality high-resolution display. TFT-LCD is the first flat panel display in human history that exceeds CRT in display quality. And people began to integrate the driver IC on the glass substrate, the function of the entire TFT will be more powerful, which is unmatched bytraditional large-scalesemiconductorintegrated circuits.

(4) Low cost: Glass substrates and plastic substrates have fundamentally solved the cost problem of large-scale semiconductor integrated circuits, and opened up a broad application space for the application of large-scale semiconductor integrated circuits.

(5)Flexibleprocess: In addition to sputtering, CVD (Chemical Vapor Deposition), MCVD (Molecular Chemical Vapor Deposition) and other traditional processes for film formation, laser annealing technology has also begun to be applied. It can produce both amorphous and polycrystalline films. A single crystal film can be manufactured. Not only can silicon films be made, but other II-VI and III-V semiconductor thin films can also be made.

(6) Wide application fields, LCD flat panel displays based on TFT technology are the pillar industries of the information society, and the technology can also be applied to the rapidly growing thin film transistor organic electroluminescence (TFT-OLED) flat panel displays. Growing up.

With the maturity of TFT technology in the early 1990s, color liquid crystal flat panel displays have developed rapidly. In less than 10 years, TFT-LCD has rapidly grown into a mainstream display, which is inseparable from its advantages. The main features are:

(1) Good use characteristics: low-voltage application, low driving voltage, solidified use safety and reliability improvement; flat, light and thin, saving a lot of raw materials and use space; low power consumption, its power consumption is about CRT display One tenth, reflective TFT-LCD is only about 1% of CRT, which saves a lot of energy; TFT-LCD products also have specifications, sizes, series, variety, convenient and flexible use, maintenance, update , Easy upgrade, long service life and many other features. The display range covers the application range of all displays ranging from 1 inch to 40 inches and the large plane of projection. It is afull-size displayterminal; the display quality ranges from the simplest monochrome character graphics to high resolution, high color fidelity, High-brightness, high-contrast and high-response video monitors of various specifications and models; display methods include direct-view type, projection type, perspective type, and reflective type.

(2) Good environmental protection characteristics: no radiation, no flicker, no damage to the user"s health. In particular, the emergence of TFT-LCD electronic books and periodicals will bring human beings into the era of paperless office and paperlessprinting, triggering a revolution in the way humans learn, spread, and document civilization.

(3) Wide application range, can be used normally within the temperature range from -20℃to +50℃, and the low-temperature working temperature of the TFT-LCD after temperature strengthening treatment can reach minus 80℃. It can be used as a mobile terminal display, desktop terminal display, and can also be used as a large-screen projection TV. It is a full-size video display terminal with excellent performance.

(4) The degree of automation of manufacturing technology is high, and the characteristics of large-scale industrial production are good. The technology of the TFT-LCD industry is mature, and the yield rate of large-scale production reaches more than 90%.

(5) TFT-LCD is easy to integrate and update, it is the perfect combination of large-scale semiconductor integrated circuit technology andlightsource technology, and there is great potential for continued development. There are currently amorphous, polycrystalline, and monocrystalline silicon TFT-LCDs, and in the future there will be TFTs of other materials, both glass substrates and plastic substrates.

TFT is an abbreviation for Thin Film Transistor, a flat panel display used to improve the operation and utility of LCD screens. In order to portray an appearance to the audience, a liquid crystal display (LCD) utilizes a crystalline-filled fluid to modify rear lighting polarized origin through the use of an electromagnetic force among two relatively thin metal wires such as indium oxide (ITO). However, color TFT displays are associated with this method, which can be employed in both divided and pixelated display systems.

With motion pictures displayed on an LCD, the intrinsic sluggish rate of increase between liquid phases over a significant number of pixel components can be an issue due to capacitance impacts, which can create a blurring of the visuals. Placing a high-velocity LCD control device inside the formation of a thin-film transistor immediately next to the cell component just on a glass screen, the issue of LCD picture speed may be substantially improved, and image blur can be eliminated for all useful purposes entirely.

Organic light-emitting diodes (AMOLEDs) are a type of flat light-emitting advanced technologies that are created by interspersing a succession of organic thin sheets over two conducting conductors. An electrical charge causes a brilliant light to be produced when the current flows. AMOLED displays are light-emitting screens that do not require a backlight, making them thinner and more energy-efficient than liquid crystal displays (LCDs) (which will need a white backlight).

AMOLED displays are not only thin and fuel-intensive, but they also deliver the highest image quality available, so they can be made translucent, elastic, bendable, or even rollable and stretchy in the future, allowing for a variety of applications. AMOLEDs are a revolutionary technology in terms of display devices! It is possible to create an AMOLED by sandwiching a sequence of thin films across phase conductors. Electric charge causes a brilliant light to be emitted when the current flows through the coil.

The color display is fantastic. Color intensity, sharpness, and luminance settings that are second to none and can be customized to meet the needs of any application.

Half-Life has been expanded. TFT displays have a far longer half-life than its LED equivalents, and they are available in a number of sizes, which might have an effect on the device"s half-life based on the phone"s usage as well as other variables. Touch panels for TFT screens can be either resistant or capacitance in nature.

As it is more affordable than capacitive, resistive is typically the preferred option. However, capacitive technology is compatible with a wide range of contemporary smartphones and digital gadgets.

Due to the apparent glass panels, there is limited functionality. For instance, there are ineffective for outdoor use because the glass can display glares from its natural lighting)

They rely on backlight to give illumination rather than generating their own light. Hence they require constructed light-creating diodes (LEDs) in their backlit display framework to ensure enough brightness.

Backlighting is unnecessary for AMOLEDs. LCDs produce images by selectively blocking parts of the illumination, whereas AMOLEDs produce light. AMOLEDs utilize less energy than LCDs since they don"t need backlighting. This is critical for battery-powered devices such as phones.

While AMOLED light-emitting sheets are lightweight, the substrate can also be elastic rather than stiff. AMOLED films are not limited to glass-like LEDs and LCDs.

AMOLEDs offer 170-degree ranges of vision. LCDs operate by obscuring the light. Hence they have intrinsic viewing obstacles. In addition, AMOLEDs have a substantially wider viewing spectrum.

AMOLEDs outperform LEDs. Since AMOLED organic coatings are less than LED inorganic crystal levels, AMOLED conducting and particle emitters layers can just be multi-layered. Also, LEDs and LCDs need glass backing, which absorbs light. AMOLEDs don"t need it.

AMOLEDs seem to be simpler to implement and larger. AMOLEDs are constructed of polymers and may be produced into big sheets. It takes a lot of extra liquid crystals to build and set down.

Due to the fact that AMOLED displays inherently emit illumination, they do not need a backlight when used on a monitor screen. Conversely, LCDs require backlights since the liquid crystals themselves are incapable of producing light under their own. Direct light emission from AMOLED displays also allows for the developing of lightweight display devices than others using TFT LCDs.

LCD displays have a higher brightness than AMOLED panels. This is owing to the LCD"s usage of led backlight, which may provide a brilliant illumination of the entire display. Despite the fact that AMOLEDs produce high levels of brilliance from their illumination, they will never be able to match the intensity of LCD lighting.

LCD screens use less power than AMOLED displays, which provides a slight advantage. The amount of energy consumed by AMOLED displays is dependent on the intensity of the screen. Lowered luminance results in lower energy usage, however, it might not be the best solution because the contrast would suffer as a result of the decreased brightness. In some situations, such as when to use an AMOLED device in direct sunlight, it is not an optimal situation.

However, the backlit keys of TFT displays account for the majority of their power usage. TFT screens" efficiency is considerably improved when the backlight is set to a lesser brightness level than the default setting. For example, replacing the light of an LCD TV with just an Led flash will have no effect on the image quality, but will result in lower power usage than replacing the light of an AMOLED TV.

With the exception of phones, numerous other technologies make use of displays to allow customers to engage in direct communication with them. To determine whether or not TFT LCD will be able to withstand the development of AMOLED innovation, we should first review the benefits of LCD technology. The backlighting quality ensures that whites are strong and brightness is superb but will deplete a battery much more quickly than just an AMOLED display. Furthermore, the cost of LCD screens is a considerable consideration. In addition to being less expensive and more easily accessible, they are produced in standard industry sizes, allowing them to be purchased for innovative products with relative ease.

NHS patients who suffer with kidney failure will now start to experience a more relaxed experience when connecting themselves to a dialysis machine. Thanks to Quanta Dialysis Technologies for coming up with its portable medical technology breakthrough, the Quanta SC+.

Quanta Dialysis Technologies, based in Alcester, UK have won an award for UK"s top engineering innovation of 2022 for its revolutionary portable dialysis machine. The Quanta SC+ enables patients to treat themselves at home and relieves pressure off the NHS.

Display Technology supplied the TFT LCD, with an optically bonded touchscreen and cover lens, that was manufactured at their site in Germering, Germany.

To improve the design lifecycle, this display was chosen for its industrial characteristics offering long-term availability, while maintaining high optical performance for a premium user experience.

The durable cover lens has been manufactured with numerous silkscreen layers to apply a brand identity, retaining market influence, and to label functional touch buttons for ease of use.

The shape of the cover lens is manufactured in such a way that it covers the front surface of the final device, making it easy to clean; this is critical for a medical device.

All the components chosen were optimum grade IC components, designed with EMC in mind, and the controller firmware was tuned for optimal touch performance in the specific environments the device will be used in.

Paul Hooper, Sales & Marketing Director at Display Technology says: “Our LCD display/touchscreen assembly is the right solution because of its excellent performance and long term availability. Our teams in both the UK & Germany have a wealth of experience in the medical sector and dealing with the challenges it brings. We are happy to be part of such an advanced technology case for the medical profession.”

If you would like to discuss your latest project needs, please email us at info@displaytechnology.co.uk, or send us an enquiry to find out more about our advanced display technology.

Established in 1996 as Display Solutions, later acquired by Display Technology in September 2018, the UK subsidiary of FORTEC Elektronik AG. Display Technology delivers the latest technical innovations in displays, touch screens and embedded computing backed by a market-leading service at every stage of the process, from initial consultation through to sample design, volume manufacturing and immediate-response after-sales support. The company’s dominant position within the UK, across all embedded computing market sectors, including industrial instrumentation and control, transportation, retail/point-of-sale, outdoor signage, medical, marine, audio and lighting control and energy management, has been achieved through a combination of application experience and innovation. For more information about Display Technology, please visit the website at: www.displaytechnology.co.uk

Fifty years ago, a pair of physicists in a Swiss laboratory began untangling a mystery that had been intriguing a handful of other scientists for several years.

Here was their conundrum: Could miniscule electrical jolts unwind the spiral molecular structure of a new substance known as “liquid crystal,” causing the crystals to block light, then re-twist them and allow light to pass through again?

The physicists – Dr. Martin Schadt and Dr. Wolfgang Helfrich – placed the liquid crystal between two plastic surfaces carrying a grid of transparent electrodes. In so doing, they discovered they could create individual picture elements, or “pixels,” which could be used to form shapes.

They filed a Swiss patent for the idea on Dec. 4, 1970. Though it attracted scant attention at the time, the milestone now stands as the birthdate of the liquid crystal display (LCD) – the technological platform which has transformed consumer electronics and presented a brilliant new way to view the world.

Early LCD developers took a few years to figure out that specialty glass, not plastic, was the best stable substrate for the delicate LCD circuitry and the color backplane component. Once they did, they turned increasingly to Corning to supply them with extraordinarily stable, flat, fusion-formed glass, able to preserve the critical properties of the liquid crystal and withstand high processing temperatures.

And LCDs rapidly transformed from “passive matrix” models, mostly used in pocket calculators and digital watches, to “active matrix” LCDs in which each sub-pixel was controlled with an isolated thin-film transistor. AMLCDs enabled wide viewing angles; brilliant, fast-moving images; and high-resolution images that had never been possible before.

Corning Incorporated was a critical player in this development, and eventually became the world’s leading supplier of LCD glass substrates. And Corning® EAGLE XG® Glass, the world’s first LCD substrate with no arsenic or other heavy metals, went on to exceed sales of 25 billion square feet, making it one of the most successful products in Corning’s history.

of users. the company uses tfts based on an oxide semiconductor from creavis technologies & innovation, the strategic research unit at evonik. it is a semiconductor that can be processed from a solution at low temperatures, which means that in the future a flexible plastic film will be able to serve as the substrate for tfts instead of the glass typically used for this purpose, thus making it possible to produce flexible displays.

The world of smartphones has been busy for the past few months. There have been numerous revolutionary launches with groundbreaking innovations that have the capacity to change the course of the smartphone industry. But the most important attribute of a smartphone is the display, which has been the focus for all prominent players in the mobile phone industry this year.

Samsung came up with its unique 18:5:9 AMOLED display for the Galaxy S8. LG picked up its old trusted IPS LCD unit for the G6’s display. These display units have been familiar to the usual Indian smartphone buyer. Honor, on the other hand, has just unveiled the new Honor 8 Pro for the Indian market that ships with an LTPS LCD display. This has led to wonder how exactly is this technology different from the existing ones and what benefits does it give Honor to craft its flagship smartphone with. Well, let’s find out.

The LCD technology brought in the era of thin displays to screens, making the smartphone possible in the current world. LCD displays are power efficient and work on the principle of blocking light. The liquid crystal in the display unit uses some kind of a backlight, generally a LED backlight or a reflector, to make the picture visible to the viewer. There are two kinds of LCD units – passive matrix LCD that requires more power and the superior active matrix LCD unit, known to people as Thin Film Transistor (TFT) that draws less power.

The early LCD technology couldn’t maintain the colour for wide angle viewing, which led to the development of the In-Plane Switching (IPS) LCD panel. IPS panel arranges and switches the orientation of the liquid crystal molecules of standard LCD display between the glass substrates. This helps it to enhance viewing angles and improve colour reproduction as well. IPS LCD technology is responsible for accelerating the growth of the smartphone market and is the go-to display technology for prominent manufacturers.

The standard LCD display uses amorphous Silicon as the liquid for the display unit as it can be assembled into complex high-current driver circuits. This though restricts the display resolution and adds to overall device temperatures. Therefore, development of the technology led to replacing the amorphous Silicon with Polycrystalline Silicon, which boosted the screen resolution and maintains low temperatures. The larger and more uniform grains of polysilicon allow faster electron movement, resulting in higher resolution and higher refresh rates. It also was found to be cheaper to manufacture due to lower cost of certain key substrates. Therefore, the Low-Temperature PolySilicon (LTPS) LCD screen helps provide larger pixel densities, lower power consumption that standard LCD and controlled temperature ranges.

The AMOLED display technology is in a completely different league. It doesn’t bother with any liquid mechanism or complex grid structures. The panel uses an array of tiny LEDs placed on TFT modules. These LEDs have an organic construction that directly emits light and minimises its loss by eradicating certain filters. Since LEDs are physically different units, they can be asked to switch on and off as per the requirement of the display to form a picture. This is known as the Active Matrix system. Hence, an Active Matrix Organic Light Emitting Diode (AMOLED) display can produce deeper blacks by switching off individual LED pixels, resulting in high contrast pictures.

The honest answer is that it depends on the requirement of the user. If you want accurate colours from your display while wanting it to retain its vibrancy for a longer period of time, then any of the two LCD screens are the ideal choice. LTPS LCD display can provide higher picture resolution but deteriorates faster than standard IPS LCD display over time.

An AMOLED display will provide high contrast pictures any time but it too has the tendency to deteriorate faster than LCD panels. Therefore, if you are after greater picture quality, choose LTPS LCD or else settle for AMOLED for a vivid contrast picture experience.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey