tft lcd thin film transistor liquid crystal display factory

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

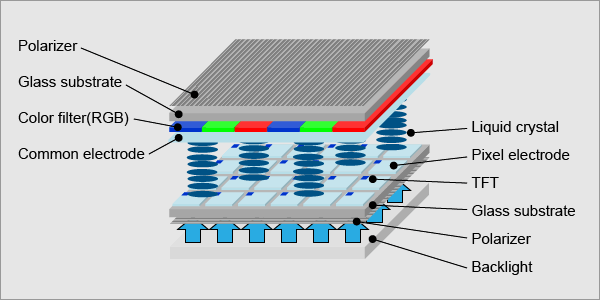

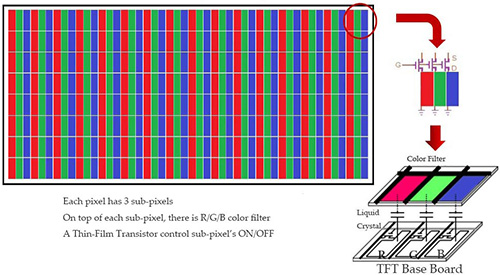

The liquid crystal displays used in calculators and other devices with similarly simple displays have direct-driven image elements, and therefore a voltage can be easily applied across just one segment of these types of displays without interfering with the other segments. This would be impractical for a large display, because it would have a large number of (color) picture elements (pixels), and thus it would require millions of connections, both top and bottom for each one of the three colors (red, green and blue) of every pixel. To avoid this issue, the pixels are addressed in rows and columns, reducing the connection count from millions down to thousands. The column and row wires attach to transistor switches, one for each pixel. The one-way current passing characteristic of the transistor prevents the charge that is being applied to each pixel from being drained between refreshes to a display"s image. Each pixel is a small capacitor with a layer of insulating liquid crystal sandwiched between transparent conductive ITO layers.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan"s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

When the field is on, the liquid crystal molecules start to tilt towards the center of the sub-pixels because of the electric field; as a result, a continuous pinwheel alignment (CPA) is formed; the azimuthal angle rotates 360 degrees continuously resulting in an excellent viewing angle. The ASV mode is also called CPA mode.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

With analogue signals like VGA, the display controller also needs to perform a high speed analog to digital conversion. With digital input signals like DVI or HDMI some simple reordering of the bits is needed before feeding it to the rescaler if the input resolution doesn"t match the display panel resolution.

The statements are applicable to Merck KGaA as well as its competitors JNC Corporation (formerly Chisso Corporation) and DIC (formerly Dainippon Ink & Chemicals). All three manufacturers have agreed not to introduce any acutely toxic or mutagenic liquid crystals to the market. They cover more than 90 percent of the global liquid crystal market. The remaining market share of liquid crystals, produced primarily in China, consists of older, patent-free substances from the three leading world producers and have already been tested for toxicity by them. As a result, they can also be considered non-toxic.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Kim, Sae-Bom; Kim, Woong-Ki; Chounlamany, Vanseng; Seo, Jaehwan; Yoo, Jisu; Jo, Hun-Je; Jung, Jinho (15 August 2012). "Identification of multi-level toxicity of liquid crystal display wastewater toward Daphnia magna and Moina macrocopa". Journal of Hazardous Materials. Seoul, Korea; Laos, Lao. 227–228: 327–333. doi:10.1016/j.jhazmat.2012.05.059. PMID 22677053.

The amount of pollutants produced during manufacturing processes of TFT-LCD (thin-film transistor liquid crystal display) substantially increases due to an increasing production of the opto-electronic industry in Taiwan. The total amount of wastewater from TFT-LCD manufacturing plants is expected to exceed 200,000 CMD in the near future. Typically, organic solvents used in TFT-LCD manufacturing processes account for more than 33% of the total TFT-LCD wastewater. The main components of these organic solvents are composed of the stripper (dimethyl sulphoxide (DMSO) and monoethanolamine (MEA)), developer (tetra-methyl ammonium hydroxide (TMAH)) and chelating agents. These compounds are recognized as non-or slow-biodegradable organic compounds and little information is available regarding their biological treatability. In this study, the performance of an A/O SBR (anoxic/oxic sequencing batch reactor) treating synthetic TFT-LCD wastewater was evaluated. The long-term experimental results indicated that the A/O SBR was able to achieve stable and satisfactory removal performance for DMSO, MEA and TMAH at influent concentrations of 430, 800, and 190 mg/L, respectively. The removal efficiencies for all three compounds examined were more than 99%. In addition, batch tests were conducted to study the degradation kinetics of DMSO, MEA, and TMAH under aerobic, anoxic, and anaerobic conditions, respectively. The organic substrate of batch tests conducted included 400 mg/L of DMSO, 250 mg/L of MEA, and 120 mg/L of TMAH. For DMSO, specific DMSO degradation rates under aerobic and anoxic conditions were both lower than 4 mg DMSO/g VSS-hr. Under anaerobic conditions, the specific DMSO degradation rate was estimated to be 14 mg DMSO/g VSS-hr, which was much higher than those obtained under aerobic and anoxic conditions. The optimum specific MEA and TMAH degradation rates were obtained under aerobic conditions with values of 26.5 mg MEA/g VSS-hr and 17.3 mg TMAH/g VSS-hr, respectively. Compared to aerobic conditions, anaerobic biodegradation of MEA and TMAH was much less significant with values of 5.6 mg MEA/g VSS-hr and 0 mg TMAH/g VSS-hr, respectively. In summary, biological treatment of TFT-LCD wastewater containing DMSO, MEA, and TMAH is feasible, but appropriate conditions for optimum biodegradation of DMSO, MEA, and TMAH are crucial and require carefully operational consideration.

A thin-film transistor liquid crystal display (TFT LCD) is a type of liquid crystal display (LCD) that makes use of thin-film transistor technology in order to improve qualities such as contrast and addressability. TFT technology means that an individual transistor is used to drive each individual pixel, allowing for faster response times.

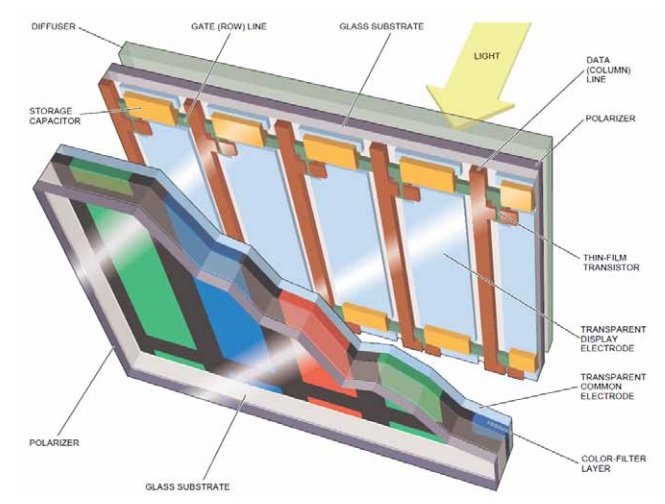

Thin-film transistor liquid crystal display technology uses "field-effect" transistors, which are built by layering thin films on a glass substrate, hence the name. This technique is commonly used for creating microprocessors. The TFT in the LCD controls individual pixels in the display by setting the level of the electric field across the three liquid crystal capacitors (one for each sub-pixel of red, green and blue) in the pixel in order to control the polarization of the crystal material. The amount of polarization in the crystal determines the amount of light that reaches the color filter from the backlight. Because of this ability to directly and quickly control each pixel, TFT is also called active-matrix LCD technology.

Optical and SEM (scanning electron microscopy) images of fabricated (a, b) CL and (c, d) CLSE pixel structures. The five white line patterns in (d) are the ITO interdigitated pixel and common electrodes. (e) Images from the normal direction and from 50 degrees to the left and right of a 2.3-inch-diagonal display incorporating the IPS TFT-LCD panel. (f) The three-black matrix (BM) patterns (top: BM covering both gate and data lines, middle: BM covering only the data lines, and bottom: without BM) and (g) optical images of pixels without BM (left: LC on and off voltages supplied to every other data line, right: LC off voltage supplied to all data lines).

Figure 3e shows images from the normal direction and from 50 degrees to the left and right of a 2.3-inch-diagonal display incorporating the IPS TFT-LCD panel fabricated in our laboratory, (f) the three black matrix (BM) patterns (top: BM covering both gate and data lines, middle: BM covering only the data lines, and bottom: without BM), and (g) optical images of panel areas without the BM (left: LC on and off voltages supplied to every other data line, right: LC off voltage supplied to all data lines). As can be seen in the image from the normal direction, the brightness and contrast of the display area with the top BM and middle BM patterns are almost the same, but the contrast of the display area without the BM is relatively lower because of the lower darkness level of the LC off pixels indicating “HITACHI”. As shown in Fig. 3g, this is due to light leaking through the aperture between the data line and adjacent common lines. Therefore, in the CL structure, the BM on the drain line is necessary to obtain a high contrast ratio by shielding light leakage. This is the same as in the conventional structure. On the contrary, there is no light leakage along the gate line through the gaps between the gate line and edges of the pixel/common electrodes, as is clearly shown in Fig. 3g. This is a unique advantage of the CL structure because the conventional structure must shield these gaps with the BM to prevent light leakage. The suppression of light leakage along the gate line in the CL structure is due to the driving scheme (see Fig. 2b,a for a comparison with the conventional structure). During the holding period (tOFF) in the conventional structure, regardless of the pixel voltage, Vp (including Vp = 0), nonzero Vgp and Vgc are always applied to keep the TFT off, and these voltages are applied to the LC layer, inducing light leakage as reported in

Figure 4a shows the gate voltage (Vg) dependence of the panel brightness, while the inset shows that of the TFT current (transfer characteristics). The gray curves are for the conventional IPS TFT-LCD with the TFT before enhancement, the common line, and the matrix BM (MBM) shown at the top of Fig. 3f. The blue curves are for the proposed CL structure with the enhanced TFT and the stripe BM (SBM) shown in the middle of Fig. 3f. In this case, enhanced TFT characteristics were obtained by using an MNOS TFT without back-channel oxidation that was enhanced by the BTS process. In both structures, the threshold voltages for panel brightness, defined by extrapolating the straight part of the brightness curves, reflect those of the TFT transfer curves defined as Vg at a drain current of 10−12 A, and they are well matched to be 4 V and 9 V, respectively. The maximum brightness for the CL structure is 137% higher than that for the conventional structure, which is due to the increase in the aperture ratio from 38 to 52% that results from the elimination of the common line and the BM covering the gate line.

(a) Dependence of panel brightness and TFT current on gate voltage for the conventional pixel structure of 38% aperture ratio (AR) with matrix black matrix (MBM) over both drain and gate lines and proposed CL pixel structure of 52% AR with strip black matrix (SBM) over only the drain lines. Transfer characteristics before and after bias temperature stress (BTS) treatment are shown in the inset. (b) Charging and (c) holding characteristics of enhanced TFT of the CL structure with gate as a common line. Vg and Vd in the TFT ON state are 30 V and +/−7 V, respectively.

To estimate the charging and holding characteristics of the MNOS-enhanced TFT in the panel, the gate TFT ON and OFF time dependences of the panel brightness were measured (Fig. 4b,c). The charging characteristics in Fig. 4b are plotted as a function of tON at tOFF = 16.6 ms, Vg = 30 V, and Vd = ± 7 V. The holding characteristics in Fig. 4c are plotted as a function of tOFF at tON = 34 μs. 95.1% charging at tON = 34 μs and 95.3% holding at tOFF = 16.6 ms indicate that the enhanced TFT has sufficient charging and holding performance to drive a standard VGA (640 × 480 pixels) panel (the number of scanning lines is estimated as tOFF/tON = 16.6/0.034 = 488).

To confirm the driving conditions for the CL structure without the BM along the gate line (with the SBM), the tOFF dependence of the contrast ratio (CR) in the CL panel was further investigated as shown in Fig. 5a, where CR is plotted as a function of tOFF for the CL panels with the matrix BM (MBM) and the strip BM (SBM). The inset shows the brightness in the bright (Vd = 7 V) and dark (Vd = 0 V) states of the CL panel with the SBM as a function of tOFF and an optical image of the panel with tOFF = 6.4 ms. The SBM and MBM panels keep CR higher than 240 with tOFF > 16.6 ms, the frame period of a display panel without flicker being noticeable to the human eye. both panels decrease CR when tOFF is less than 16.6 ms; the CR of the SBM panel decreases faster than the CR of the MBM panel. As shown in the inset, the decrease in CR was due to the increase in dark-state brightness with decreasing tOFF as light leakage increases along the gate line. This light leakage is induced by the voltage Vgp = Vgc = VgON = 30 V applied only for 34 μs during the TFT ON (charging) state, which is 1/488th the duration, tOFF = 16.6 ms, of the TFT OFF (holding) state with Vgp = Vgc = VgOFF = 0 V, but the ratio increases with decreasing tOFF and becomes effective enough to switch on LC layer and induce light leakage. However, it should be stressed again that the CL panel with the normal holding (TFT OFF) time of 16.6 ms does not suffer from the light leakage along the gate line, so the aperture ratio can be increased by removing the BM along the gate line.

Figure 6 indicates the effect of bias temperature stress (BTS) on the TFT characteristics. As the stressing time, tS, of the positive gate stress voltage, Vst = + 77 V, increases from 0 to 3600 s, the transfer (Id-Vg) curve shifts in the positive direction (Fig. 6a). Vth is defined as Vg at which Id = 10−12 A and ΔVth is defined as the Vth shift from the initial value via BTS. As shown in Fig. 6b, ΔVth increases logarithmically with increasing tS: ΔVth = 2.17 + 4.93 × log (tS). The mechanism behind the gate-stress-induced Vth shift is electron tunnel injection from the a-Si:H semiconductor into the SiOx gate insulator. For confirmation, ΔVth of MNOS TFTs with different SiOx thicknesses is plotted as a function of the electric field applied to the SiOx layer in Fig. 6c. Here, the thickness of the SiOx was varied (5, 10, 20, 50 nm), while the SiN thickness was fixed at 200 nm. The electric field applied to SiOx, Eox, was calculated using the following equation,

Effect of bias temperature stress (BTS) on TFT characteristics. (a) The transfer (Id–Vg) curve shifts in the positive direction with positive gate bias stress of Vst = + 77 V over the duration of 0–3600 s. (b) ΔVth, defined as the Vth shift from the initial value via BTS, increases logarithmically with increasing tS, following ΔVth = 2.17 + 4.93 × log (tS). (c) ΔVth of MNOS TFTs with different SiOx thicknesses from 5 to 50 nm as a function of the electric field applied to the SiOx layer.

Figure 7a shows the effect of back-channel oxidation (BCO) and passivation (PAS) on the Id-Vg characteristics of the MNOS TFT. The Id-Vg curve with Vth = 5.1 V is further enhanced to Vth = 10.9 V after BCO, although there is a slight degradation of the slope of the current increase in the sub-threshold region. The slope recovers after PAS without any change to the enhanced characteristics

(a) Effect of back-channel oxidation (BCO) and passivation (PAS) on Id–Vg characteristics of MNOS TFT. (b) Vth and Vth standard deviation, σVth, after BTS and after BCO without BTS treatments and (c) SiOX thickness as a function of position along gate-line, x.

The advantage of BCO over BTS is the uniformity of the enhanced characteristics; Fig. 7b shows the distribution of the enhanced Vth as a function of position along gate-line, x, for the MNOS TFTs connected with a 90-mm-long gate line in the TFT substrate after BTS and BCO treatments. The average value of Vth and the standard deviation, σVth, for pristine TFTs before BTS or BCO, are 5.1 V and 0.35 V, respectively. After BCO, Vth is uniformly enhanced, with an average Vth = 11 V and σVth = 0.4 V without increasing σVth. On the other hand, after BTS, Vth is nonuniformly enhanced with an average Vth = 9.3 V and σVth of 1.4 V. In particular, Vth increases linearly as a function of position along gate-line, x. As the gate SiOx thickness linearly decreases, from (54 nm) to (47 nm) with increasing x as shown in Fig. 7c, the increase in ΔVth after BTS with x is due to increase in the electric field applied to SiOx as shown in Fig. 6c and Eq. 1.

It has been shown that the Vth of the MNOS TFT is independent of the gate SiOx thickness when the thickness is more than 5 nm8a, Vth of the MNOS TFT with the BCO treatment becomes almost independent of the BCO SiOx thickness. As shown in the inset, the thickness of BCO SiOx composed of oxidized a-Si:H linearly increases with BCO processing time, and the Vth increase almost saturates at a BCO SiOx thickness greater than 5 nm. Therefore, the enhanced MNOS TFT after BCO has a uniformly high Vth that is robust to thickness fluctuations of the gate and BCO SiOx layers. BCO also has an advantage over BTS in terms of the stability of Vth as shown in Fig. 8b, which plots the annealing time dependence of Vth for BCO and BTS. In this experiment, the stoichiometry (x) of the gate SiOx was 1.78 for BTS and 1.78 and 1.9 for BCO. The annealing temperature in the N2 atmosphere was 200 °C. In the case of BTS, Vth decreased to the pristine value after approximately 5 h of annealing, while Vth decreased more slowly in the case of BCO. In particular, the annealing time required for Vth to fall to 7 V was 7.5 times longer than that of BTS. Increasing the stoichiometry (x) of the gate SiOx dramatically improved the BCO-enhanced Vth to as much as 11 V, which was stably maintained after 24 h of annealing at 200 °C.

(a) Dependence of Vth on thickness of back-channel oxidized (BCO) SiOX. The inset shows the SiOx thickness dependence on the BCO process time for RF powers of 200 W and 500 W. (b) Stability of Vth as a function of annealing time for three different TFTs with gate SiOx stoichiometry, x = 1.78 and bias temperature stress (BTS), x = 1.78 and BCO, and x = 1.9 and BCO. The temperature of annealing in the N2 atmosphere was 200 °C. (c) Band diagram of back-channel oxidized MNOS TFT. The red arrows show the electric dipoles at the SiOX/a-Si:H and a-Si:H/BCO SiOX interfaces.

A schematic band model for the MNOS TFT with the BCO treatment and the sectional structure of the interface between the a-Si:H and gate and BCO SiOx are shown in Fig. 8c. The uniformly high Vth that is independent of SiOx thickness is due to the dipoles generated at the channel and back-channel interfaces between a-Si:H and SiOx8 of reference

TFT-LCD was invented in 1960 and successfully commercialized as a notebook computer panel in 1991 after continuous improvement, thus entering the TFT-LCD generation.

Simply put, the basic structure of the TFT-LCD panel is a layer of liquid crystal sandwiched between two glass substrates. The front TFT display panel is coated with a color filter, and the back TFT display panel is coated with a thin film transistor (TFT). When a voltage is applied to the transistor, the liquid crystal turns and light passes through the liquid crystal to create a pixel on the front panel. The backlight module is responsible for providing the light source after the TFT-Array panel. Color filters give each pigment a specific color. The combination of each different color pixel gives you an image of the front of the panel.

The TFT panel is composed of millions of TFT devices and ITO (In TI Oxide, a transparent conductive metal) regions arranged like a matrix, and the so-called Array refers to the region of millions of TFT devices arranged neatly, which is the panel display area. The figure below shows the structure of a TFT pixel.

No matter how the design of TFT display board changes or how the manufacturing process is simplified, its structure must have a TFT device and control liquid crystal region (if the light source is penetration-type LCD, the control liquid crystal region is ITO; but for reflective LCD, the metal with high reflection rate is used, such as Al).

The TFT device is a switch, whose function is to control the number of electrons flowing into the ITO region. When the number of electrons flowing into the ITO region reaches the desired value, the TFT device is turned off. At this time, the entire electrons are kept in the ITO region.

The figure above shows the time changes specified at each pixel point. G1 is continuously selected to be turned on by the driver IC from T1 to TN so that the source-driven IC charges TFT pixels on G1 in the order of D1, D2, and Dn. When TN +1, gATE-driven IC is selected G2 again, and source-driven IC is selected sequentially from D1.

The more vertical the Angle at which the LIQUID crystal stands, the more light will not be guided by the LIQUID crystal. Different liquid crystal standing angles will direct different amounts of light. From the above examples, the larger the angle at which the liquid crystal stands, the weaker the light that can be penetrated. (The direction of the upper and lower polarizer will determine the intensity of penetration, so as long as you understand the Angle of the liquid crystal standing will guide the intensity of light).

Many people don’t understand the differences between generations of TFT-LCD plants, but the principle is quite simple. The main difference between generations of plants is in the size of glass substrates, which are products cut from large glass substrates. Newer plants have larger glass substrates that can be cut to increase productivity and reduce costs, or to produce larger panels (such as TFT display LCD TV panels).

The TFT-LCD industry first emerged in Japan in the 1990s, when a process was designed and built in the country. The first-generation glass substrate is about 30 X 40 cm in size, about the size of a full-size magazine, and can be made into a 15-inch panel. By the time Acer Technology (which was later merged with Unioptronics to become AU Optronics) entered the industry in 1996, the technology had advanced to A 3.5 generation plant (G3.5) with glass substrate size of about 60 X 72 cm.Au Optronics has evolved to a sixth-generation factory (G6) process where the G6 glass substrate measures 150 X 185 cm, the size of a double bed. One G6 glass substrate can cut 30 15-inch panels, compared with the G3.5 which can cut 4 panels and G1 which can only cut one 15-inch panel, the production capacity of the sixth generation factory is enlarged, and the relative cost is reduced. In addition, the large size of the G6 glass substrate can be cut into large-sized panels, which can produce eight 32-inch LCD TV panels, increasing the diversity of panel applications. Therefore, the global TFT LCD manufacturers are all invested in the new generation of plant manufacturing technology.

The TRANSISTor-LCD is an acronym for thin-film TFT Display. Simply put, TFT-LCD panels can be seen as two glass substrates sandwiched between a layer of liquid crystal. The upper glass substrate is connected to a Color Filter, while the lower glass has transistors embedded in it. When the electric field changes through the transistor, the liquid crystal molecules deflect, so as to change the polarization of the light, and the polarizing film is used to determine the light and shade state of the Pixel. In addition, the upper glass is fitted to the color filter, so that each Pixel contains three colors of red, blue and green, which make up the image on the panel.

– The Array process in the front segment is similar to the semiconductor process, except that thin-film transistors are made on glass rather than silicon wafers.

– The middle Cell is based on the glass substrate of the front segment Array, which is combined with the glass substrate of the color filter, and liquid crystal (LC) is injected between the two glass substrates.

The luminescence principle is tied to the vapor electroplating organic film between the transparent anode and the metal cathode. The electron and electric hole are injected, and the energy is converted into visible light by the composite between the organic film. And can match different organic materials, emit different colors of light, to achieve the requirements of the full-color display.

The organic light display can be divided into Passive Matrix (PMOLED) and Active Matrix (AMOLED) according to the driving mode. The so-called active driven OLED(AMOLED) can be visualized in the Thin Film Transistor (TFT) as a capacitor that stores signals to provide the ability to visualize the light in a grayscale.

Although the production cost and technical barriers of passive OLED are low, it is limited by the driving mode and the resolution cannot be improved. Therefore, the application product size is limited to about 5″, and the product will be limited to the market of low resolution and small size. For high precision and large picture, the active drive is mainly used. The so-called active drive is capacitive to store the signal, so when the scanning line is swept, the pixel can still maintain its original brightness. In the case of passive drive, only the pixels selected by the scan line are lit. Therefore, in an active-drive mode, OLED does not need to be driven to very high brightness, thus achieving better life performance and high resolution.OLED combined with TFT technology can realize active driving OLED, which can meet the current display market for the smoothness of screen playback, as well as higher and higher resolution requirements, fully display the above superior characteristics of OLED.

The technology to grow The TFT on the glass substrate can be amorphous Silicon (A-SI) manufacturing process and Low-Temperature Poly-Silicon (LTPS). The biggest difference between LTPS TFT and A-SI TFT is the difference between its electrical properties and the complicated manufacturing process. LTPS TFT has a higher carrier mobility rate, which means that TFT can provide more current, but its process is complicated.A-si TFT, on the other hand, although a-Si’s carrier movement rate is not as good as LTPS’s, it has a better competitive advantage in cost due to its simple and mature process.Au Optronics is the only company in the world that has successfully combined OLED with LTPS and A-SI TFT at the same time, making it a leader in active OLED technology.

Polysilicon is a silicon-based material about 0.1 to several um in size, composed of many silicon particles. In the semiconductor manufacturing industry, polysilicon should normally be treated by Low-Pressure Chemical Vapor Deposition. If the annealing process is higher than 900C, this method is known as SPC. Solid Phase Deposition. However, this method does not work in the flat display industry because the maximum temperature of the glass is only 650C. Therefore, LTPS technology is specifically applied to the manufacture of flat displays.

Let me suppose that it belongs to the SPC method. However, compared with traditional SPC, this method can produce polysilicon at low temperatures (about 500~600 C). This is because the thin layer of metal is coated before the formation of crystallization, and the metal composition plays an active role in reducing crystallization.

A method for direct deposition of Poly-film without vapor extraction. The sedimentation temperature may be below 300C. Growth mechanisms contain catalytic cracking reactions of SiH4-H2 mixtures.

This method is currently the most widely used. The Excimer laser is used for heating and melting A-SI. It contains low amounts of hydrogen and recrystallizes to Poly-film.

The LTPS membrane is much more complex than a-SI, yet the LTPS TFT is 100 times more mobile than A-SI TFT. And CMOS program can be carried out directly on a glass substrate. Here are some of the features that p-SI has over A-SI:

2. Vehicle for OLED: High mobility means that the OLED Device can provide a large driving current, so it is more suitable for an active OLED display substrate.

MVA technology not only improves the panel view but also solves most of the problems of gray-scale inversion due to the special arrangement mode of liquid crystals.

LCD screens are backlit to project images through color filters before they are reflected in our eye Windows. This mode of carrying backlit LCD screens, known as “penetrating” LCD screens, consumes most of the power through backlit devices. The brighter the backlight, the brighter it will appear in front of the screen, but the more power it will consume.

The “reflective” architecture USES an external light source to display the image via a reflector, which saves electricity but is harder to see in the absence of an external light source.

using the ODF process, we no longer need a vacuum tempering process, LIQUID crystal injection machine, sealing machine, and panel cleaning equipment after sealing.

Generally speaking, in the ODF process, the use efficiency of a LIQUID crystal is more than 95%, but compared with 60% of the traditional process, it can fully save more than 35% of the cost of liquid crystal materials. It can also save water, electricity, gas, and lotion when cleaning sealant and related panels.

Manufacturer of standard & custom touch screen displays & thin film transistor touchscreen monitors. Features include 17 in. to 23 in. LCD, rugged steel & aluminum construction, optional resistive or capacitive touch-screens, light textured powder coated black color, contrast filters, transmissive daylight modification, hard coated vandal shields, 16.7 million display colors, anti-glare hard coating, analog RGB input, weight ranging 13 lbs to 24 lbs & 1280 x 1024 SXGA or 1600 x 1200 UXGA resolution. Applications include use for rack, wall, panel or kiosk installations in commercial, military & broadcast industries. One year limited warranty. RoHS compliant. Meet NEMA & Military Spec.

Lin JT, Wu CH, Chen TL, Shih SH (2011) A stochastic programming model for strategic capacity planning in thin film transistor-liquid crystal display (TFT-LCD) industry. Comput Oper Res 38(7):992–1007

Park BC, Choi BK, Kim BH, Lee JH (2008) Simulation based planning and scheduling system for TFT-LCD fab. The 40th Conference on Winter Simulation. 2271–2276

Kuo Y, Yang T (2006) A case study on the operator allocation decision for TFT-LCD inspection and packaging process. J Manuf Technol Manag 17(3):363–375

Chen TL, Lin JT, Wu CH (2014) Coordinated capacity planning in two-stage thin-film-transistor liquid-crystal-display (TFT-LCD) production networks. Omega 42(1):141–156

Yang T, Shen YA (2011) The dynamic transfer batch-size decision for thin film transistor-liquid crystal display array manufacturing by artificial neural-network. Comput Ind Eng 60(4):769–776

Yang T, Hsieh CH, Cheng BY (2011) Lean-pull strategy in a reentrant manufacturing environment: a pilot study for TFT-LCD array manufacturing. Int J Prod Res 49(6):1511–1529

1971 – Lechner, F. J. Marlowe, E. O. Nester, and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs

2020 – TFT LCD display technology dominants the display market now. Within the last 20 years, it has wiped out the market of CRT (cathode-ray tube) and Plasma. The only challenges are OLED (organic light-emitting diode)and Micro LED (Maybe, still in lab).

TFT LCD Display (Thin-Film-Transistor Liquid Crystal Display) technology has a sandwich-like structure with liquid crystal material filled between two glass plates. Two polarizer filters, color filters (RGB, red/green/blue) and two alignment layers determine exactly the amount of light is allowed to pass and which colors are created.

Each pixel in an active matrix is paired with a transistor that includes a capacitor which gives each sub-pixel the ability to retain its charge, instead of requiring an electrical charge sent each time it needed to be changed. The TFT layer controls light flow a color filter displays the color and a top layer houses your visible screen.

Utilizing an electrical charge that causes the liquid crystal material to change their molecular structure allowing various wavelengths of backlight to “pass-through”. The active matrix of the TFT display is in constant flux and changes or refreshes rapidly depending upon the incoming signal from the control device.

The pixels of TFT displays are determined by the underlying density (resolution) of the color matrix and TFT layout. The more pixels the higher detail is available.Available screen size, power consumption, resolution, interface (how to connect) define the TFT displays.

The pixels of TFT displays are determined by the underlying density (resolution) of the color matrix and TFT layout. The more pixels the higher detail is available. Available screen size, power consumption, resolution, interface (how to connect) define the TFT displays.

The TFT screen itself can’t emit light like OLED display, it has to be used with a back-light of white bright light to generate the picture. Newer panels utilize LED backlight (light emitting diodes) to generate their light and therefore utilize less power and require less depth by design.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey