tft lcd thin film transistor liquid crystal display pricelist

Orient Display sunlight readable TFT displays can be categorized into high brightness TFT displays, high contrast IPS displays, transflective TFT displays, Blanview TFT displays etc.

The brightness of our standard high brightness TFT displays can be from 700 to 1000 nits. With proper adding brightness enhancement film (BEF) and double brightness enhancement film (DBEF) and adjustment of the LED chips, Orient Display high brightness TFT products can achieve 1,500 to 2,000 nits or even higher luminance. Orient Display have special thermal management design to reduce the heat release and largely extend LED life time and reduce energy consumption.

Our high contrast and wide viewing angle IPS displays can achieve contrast ratio higher than 1000:1 which can make readability under strong sunlight with lower backlight luminance. High brightness IPS displays have been widely accepted by our customers with its superb display quality and it has become one of the best sellers in all our display category.Transflective display is an old monochrome display technology but it has been utilized in our color TFT line for sunlight readable application. Orient Display has 2.4” and 3.5” to choose from.

Blanview TFT displays are the new technology developed by Ortustech in Japan. It can provide around 40% of energy consumption for TFT panels which can use smaller rechargeable or disposable batteries and generate less heat. The price is also lower than traditional transflective TFT displays. Orient Display is partnering with the technology inventor to provide 4.3” and 5.0”.

Orient Display can also provide full customized or part customized solutions for our customers to enhance the viewing experience. Orient Display can provide all the different kinds of surface treatments, such as AR (Anti-reflection); AG (Anti-glare), AF (Anti-finger print or Anti-smudge); AS (Anti-smashing); AM (Anti-microbial) etc. Orient Display can also provide both dry bonding (OCA, Optical Clear Adhesive), or wet bonding (OCR, Optical Clear Resin and OCG, Optical Clear Glue) to get rid of light reflective in air bonding products to make the products much more readable under sunlight and be more robust.

Touch panels have been a much better human machine interface which become widely popular. Orient Display has been investing heavy for capacitive touch screen sensor manufacturing capacity. Now, Orient Display factory is No.1 in the world for automotive capacitive touch screen which took around 18% market share in the world automotive market.

Based on the above three types of touch panel technology, Orient Display can also add different kinds of features like different material glove touch, water environment touch, salt water environment touch, hover touch, 3D (force) touch, haptic touch etc. Orient Display can also provide from very low cost fixed area button touch, single (one) finger touch, double finger (one finger+ one gesture) touch, 5 finger touch, 10 points touch or even 16 points touch.

Considering the different shapes of the touch surface requirements, Orient Display can produce different shapes of 2D touch panel (rectangle, round, octagon etc.), or 2.5D touch screen (round edge and flat surface) or 3D (totally curved surface) touch panel.

Considering different strength requirements, Orient Display can provide low cost chemical tampered soda-lime glass, Asahi (AGC) Dragontrail glass and Corning high end Gorilla glass. With different thickness requirement, Orient Display can provide the thinnest 0.5mm OGS touch panel, to thickness more than 10mm tempered glass to prevent vandalizing, or different kinds of plastic touch panel to provide glass piece free (fear) or flexible substrates need.

Of course, Orient Display can also offer traditional RTP (Resistive Touch Panel) of 4-wire, 5-wire, 8-wire through our partners, which Orient Display can do integration to resistive touch screen displays.

Engineers are always looking for lower cost, faster, more convenient interfaces to transmit signals and to accept data and commands. The numbers of available interfaces available in the market can be dazzling. Orient Display follows market trends to produce various kind of interfaces for our customers to choose.

Genetic Interfaces: Those are the interfaces which display or touch controller manufacturers provide, including parallel, MCU, SPI(,Serial Peripheral Interface), I2C, RGB (Red Green Blue), MIPI (Mobile Industry Processor Interface), LVDS (Low-Voltage Differential Signaling), eDP ( Embedded DisplayPort) etc. Orient Display has technologies to make the above interface exchangeable.

High Level Interfaces: Orient Display has technologies to make more advanced interfaces which are more convenient to non-display engineers, such as RS232, RS485, USB, VGA, HDMI etc. more information can be found in our serious products. TFT modules, Arduino TFT display, Raspberry Pi TFT display, Control Board.

The TFT-LCD (Flat Panel) Antitrust Litigationclass-action lawsuit regarding the worldwide conspiracy to coordinate the prices of Thin-Film Transistor-Liquid Crystal Display (TFT-LCD) panels, which are used to make laptop computers, computer monitors and televisions, between 1999 and 2006. In March 2010, Judge Susan Illston certified two nationwide classes of persons and entities that directly and indirectly purchased TFT-LCDs – for panel purchasers and purchasers of TFT-LCD integrated products; the litigation was followed by multiple suits.

TFT-LCDs are used in flat-panel televisions, laptop and computer monitors, mobile phones, personal digital assistants, semiconductors and other devices;

In mid-2006, the U.S. Department of Justice (DOJ) Antitrust Division requested FBI assistance in investigating LCD price-fixing. In December 2006, authorities in Japan, Korea, the European Union and the United States revealed a probe into alleged anti-competitive activity among LCD panel manufacturers.

The companies involved, which later became the Defendants, were Taiwanese companies AU Optronics (AUO), Chi Mei, Chunghwa Picture Tubes (Chunghwa), and HannStar; Korean companies LG Display and Samsung; and Japanese companies Hitachi, Sharp and Toshiba.cartel which took place between January 1, 1999, through December 31, 2006, and which was designed to illegally reduce competition and thus inflate prices for LCD panels. The companies exchanged information on future production planning, capacity use, pricing and other commercial conditions.European Commission concluded that the companies were aware they were violating competition rules, and took steps to conceal the venue and results of the meetings; a document by the conspirators requested everybody involved "to take care of security/confidentiality matters and to limit written communication".

Companies directly affected by the LCD price-fixing conspiracy, as direct victims of the cartel, were some of the largest computer, television and cellular telephone manufacturers in the world. These direct action plaintiffs included AT&T Mobility, Best Buy,Costco Wholesale Corporation, Good Guys, Kmart Corp, Motorola Mobility, Newegg, Sears, and Target Corp.Clayton Act (15 U.S.C. § 26) to prevent Defendants from violating Section 1 of the Sherman Act (15 U.S.C. § 1), as well as (b) 23 separate state-wide classes based on each state"s antitrust/consumer protection class action law.

In November 2008, LG, Chunghwa, Hitachi, Epson, and Chi Mei pleaded guilty to criminal charges of fixing prices of TFT-LCD panels sold in the U.S. and agreed to pay criminal fines (see chart).

The South Korea Fair Trade Commission launched legal proceedings as well. It concluded that the companies involved met more than once a month and more than 200 times from September 2001 to December 2006, and imposed fines on the LCD manufacturers.

Sharp Corp. pleaded guilty to three separate conspiracies to fix the prices of TFT-LCD panels sold to Dell Inc., Apple Computer Inc. and Motorola Inc., and was sentenced to pay a $120 million criminal fine,

In South Korea, regulators imposed the largest fine the country had ever imposed in an international cartel case, and fined Samsung Electronics and LG Display ₩92.29 billion and ₩65.52 billion, respectively. AU Optronics was fined ₩28.53 billion, Chimmei Innolux ₩1.55 billion, Chungwa ₩290 million and HannStar ₩870 million.

Seven executives from Japanese and South Korean LCD companies were indicted in the U.S. Four were charged with participating as co-conspirators in the conspiracy and sentenced to prison terms – including LG"s Vice President of Monitor Sales, Chunghwa"s chairman, its chief executive officer, and its Vice President of LCD Sales – for "participating in meetings, conversations and communications in Taiwan, South Korea and the United States to discuss the prices of TFT-LCD panels; agreeing during these meetings, conversations and communications to charge prices of TFT-LCD panels at certain predetermined levels; issuing price quotations in accordance with the agreements reached; exchanging information on sales of TFT-LCD panels for the purpose of monitoring and enforcing adherence to the agreed-upon prices; and authorizing, ordering and consenting to the participation of subordinate employees in the conspiracy."

On December 8, 2010, the European Commission announced it had fined six of the LCD companies involved in a total of €648 million (Samsung Electronics received full immunity under the commission"s 2002 Leniency Notice) – LG Display, AU Optronics, Chimei, Chunghwa Picture and HannStar Display Corporation.

On July 3, 2012, a U.S. federal jury ruled that the remaining defendant, Toshiba Corporation, which denied any wrongdoing, participated in the conspiracy to fix prices of TFT-LCDs and returned a verdict in favor of the plaintiff class. Following the trial, Toshiba agreed to resolve the case by paying the class $30 million.

WASHINGTON – A Thin-Film Transistor-Liquid Crystal Display (TFT-LCD) producer and seller has agreed to plead guilty and pay $220 million in criminal fines for its role in a conspiracy to fix prices in the sale of liquid crystal display panels, the Department of Justice announced today.

According to a one-count felony charge filed today in U.S. District Court in San Francisco, Chi Mei Optoelectronics participated in a conspiracy to fix the prices of TFT-LCD panels sold worldwide from Sept. 14, 2001, to Dec. 1, 2006. According to the plea agreement, which is subject to court approval, Chi Mei has agreed to cooperate with the department’s ongoing antitrust investigation.

TFT-LCD panels are used in computer monitors and notebooks, televisions, mobile phones and other electronic devices. By the end of the conspiracy period, the worldwide market for TFT-LCD panels was valued at $70 billion. Companies directly affected by the LCD price-fixing conspiracy are some of the largest computer and television manufacturers in the world, including Apple, Dell and HP.

According to the charge, Chi Mei carried out the conspiracy by agreeing during meetings, conversations and communications to charge prices of TFT-LCD panels at certain pre-determined levels and issuing price quotations in accordance with the agreements reached. As a part of the conspiracy, Chi Mei exchanged information on sales of TFT-LCD panels for the purpose of monitoring and enforcing adherence to the agreed-upon prices.

Anyone with information concerning illegal conduct in the TFT-LCD industry is urged to call the Antitrust Division’s San Francisco Field Office at 415-436-6660.

After months of price cuts, manufacturers of large-size liquid-crystal displays (LCDs) are under pressure to reduce panel prices further, following a major build-up of inventory. A recent report from US business analyst iSuppli revealed that the second quarter of 2010 saw the manufacture of 52 million large (ten inches and above) LCD television panel shipments, but the sale of only 38.7 million LCD television sets. The resulting imbalance between supply and demand is having a strong impact on the sector.

“This gap is higher than anything seen in 2009. Over-supply persisted in the first two months of the third quarter as buyers cut orders in July and August,” says iSuppli analyst Sweta Dash. “LCD television brands are expected to lower prices more aggressively to reduce their inventory levels, thus putting mounting pressure on panel suppliers to reduce prices further.”

Dash points out that manufacturers of monitor and notebook panels have been reducing supply to mitigate excessive inventory levels, and that panel prices are now stabilizing as a result. In contrast, high depreciation costs at relatively new LCD television panel fabrication plants mean suppliers have been less willing to reduce production.

However, Dash predicts that the potentially strong sales of LCD television sets in China could reduce inventory levels and help to steady panel prices by the end of the fourth quarter of 2010.

At the same time, rapidly rising sales of smart phones and tablet PCs are predicted to see the global market for small- and medium-size thin-film transistor (TFT) LCDs expanding at its fastest pace for three years. According to analyst Vinita Jakhanwal, also from iSuppli, global shipments of TFT LCD panels are set to rise by 28.1% in 2010, from 1.8 billion to 2.3 billion units.

“Sales of smart phones and tablets are booming thanks to the iPhone, iPad and other competing products,” explains Jakhanwal. “Smart phone manufacturers are now adopting TFT LCDs that use in-plane switching technology, which supports a wider viewing angle and better picture quality than a conventional LCD.” But the fast-paced market expansion probably won"t last, predicts Jakhanwal. “Growth in TFT LCD shipments will slow in 2011 and beyond as the expansion of smart phone and tablet markets cools to more normal levels.”

The adoption of touch-screen technology in the mobile phone industry is fuelling the demand for active-matrix organic light-emitting diode (AMOLED) displays, reports US market research firm DisplaySearch. AMOLED displays have been the only technology in the mobile phone display market to increase revenues every quarter this year, as both unit shipments and average prices have risen. “With an average worldwide market penetration of mobile phones at 70%, manufacturers are eager to introduce new features such as touch-screens to ensure continued growth this year,” says Calvin Hsieh, research director at DisplaySearch. “The success that AMOLED displays are finding in high-end smart phones reflects these trends.”

AMOLED technology rose in popularity after its integration into mobile phones manufactured by Samsung and HTC. In the first quarter of 2010, the average screen size for an AMOLED display exceeded three inches, which is larger than that of competing TFT LCDs. Taiwan-based display manufacturers AUO and Chimei Innolux are scheduled to start mass-producing AMOLED displays in 2011. Hsieh believes AMOLED technology will now see increased year-on-year growth, although TFT LCDs will still ship more units.

US-based quantum-dot and materials developer Nanosys has opened a new facility in Gyeonggi-do, Korea, to support its recent expansion into the Asian market. Led by former LG Electronics vice president Jong-Uk Bu, Nanosys Korea will develop "architected materials" for Asian electronics manufacturers, including high-performance LED backlights for displays and silicon composite anode materials for use in lithium–ion batteries. Earlier this year, Nanosys unveiled QuantumRail, quantum-dot-based LED backlighting units that improve LED backlit display colour gamut and efficiency. Nanosys says that its quantum dot LED technology makes it possible to deliver saturated red, green and blue colours that exceed the NTSC 1953 guidelines for displays. This latest announcement follows collaborations with Korea-based electronics manufacturers LG Innotek and Samsung Electronics to develop display products based on quantum-dot crystals.

The statistic shows the supply and demand for large thin-film transistor liquid crystal displays (TFT LCD) worldwide from 2015 to 2021. Demand for large TFT LCDs is expected to rise to around 217 million square meters in 2021.Read moreLarge thin-film transistor liquid crystal display (TFT LCD) supply and demand worldwide from 2015 to 2021(in million square meters)CharacteristicDemandCapacity---

Statista. (July 19, 2018). Large thin-film transistor liquid crystal display (TFT LCD) supply and demand worldwide from 2015 to 2021 (in million square meters) [Graph]. In Statista. Retrieved January 15, 2023, from https://www.statista.com/statistics/883811/worldwide-tft-lcd-display-supply-demand/

Statista. "Large thin-film transistor liquid crystal display (TFT LCD) supply and demand worldwide from 2015 to 2021 (in million square meters)." Chart. July 19, 2018. Statista. Accessed January 15, 2023. https://www.statista.com/statistics/883811/worldwide-tft-lcd-display-supply-demand/

Statista. (2018). Large thin-film transistor liquid crystal display (TFT LCD) supply and demand worldwide from 2015 to 2021 (in million square meters). Statista. Statista Inc.. Accessed: January 15, 2023. https://www.statista.com/statistics/883811/worldwide-tft-lcd-display-supply-demand/

Statista. "Large Thin-film Transistor Liquid Crystal Display (Tft Lcd) Supply and Demand Worldwide from 2015 to 2021 (in Million Square Meters)." Statista, Statista Inc., 19 Jul 2018, https://www.statista.com/statistics/883811/worldwide-tft-lcd-display-supply-demand/

Statista, Large thin-film transistor liquid crystal display (TFT LCD) supply and demand worldwide from 2015 to 2021 (in million square meters) Statista, https://www.statista.com/statistics/883811/worldwide-tft-lcd-display-supply-demand/ (last visited January 15, 2023)

Large thin-film transistor liquid crystal display (TFT LCD) supply and demand worldwide from 2015 to 2021 (in million square meters) [Graph], Statista, July 19, 2018. [Online]. Available: https://www.statista.com/statistics/883811/worldwide-tft-lcd-display-supply-demand/

TFT stands for "thin-film transistor" and it is a type of technology used by LCD (liquid crystal display) screens. Older LCD screens used a type of display called "passive" and they were plagued with ghosting and slow refresh rates. "Active" technology using thin-film transistors makes for brighter and faster screens, so all current color LCD displays use TFT technology.

Plasma is another display technology that competes with LCD. Plasma technology works by exciting pixels with a plasma discharge between two glass plates. It is fairly exotic technology and it can produce exceptionally pleasing pictures. That"s why plasma screens are generally more expensive than LCD.

When choosing between plasma and LCD TVs, you"re actually selecting between two competing technologies, both of which achieve similar features (i.e., ,bright crystal-clear images, super color-filled pictures) and come in similar packages (i.e., 3.5 inch depth flat screen casing). To complicate the decision-making process further, price and size are two previous considerations that are rapidly becoming non-issues as LCD TVs are now being made in larger sizes and at competing prices with plasma.

Plasma technology consists hundreds of thousands of individual pixel cells, which allow electric pulses (stemming from electrodes) to excite rare natural gases-usually xenon and neon-causing them to glow and produce light. This light illuminates the proper balance of red, green, or blue phosphors contained in each cell to display the proper color sequence from the light. Each pixel cell is essentially an individual microscopic florescent light bulb, receiving instruction from software contained on the rear electrostatic silicon board. Look very closely at a plasma TV and you can actually see the individual pixel cell coloration of red, green, and blue bars. You can also see the black ribs which separate each.

Whether spread across a flat-panel screen or placed in the heart of a projector, all LCD displays come from the same technological background. A matrix of thin-film transistors (TFTs) supplies voltage to liquid-crystal-filled cells sandwiched between two sheets of glass. When hit with an electrical charge, the crystals untwist to an exact degree to filter white light generated by a lamp behind the screen (for flat-panel TVs) or one projecting through a small LCD chip (for projection TVs). LCD TVs reproduce colors through a process of subtraction: They block out particular color wavelengths from the spectrum of white light until they"re left with just the right color. And, it"s the intensity of light permitted to pass through this liquid-crystal matrix that enables LCD televisions to display images chock-full of colors-or gradations of them.

Liquid crystal was discovered by the Austrian botanist Fredreich Rheinizer in 1888. "Liquid crystal" is neither solid nor liquid (an example is soapy water).

In the mid-1960s, scientists showed that liquid crystals when stimulated by an external electrical charge could change the properties of light passing through the crystals.

The early prototypes (late 1960s) were too unstable for mass production. But all of that changed when a British researcher proposed a stable, liquid crystal material (biphenyl).

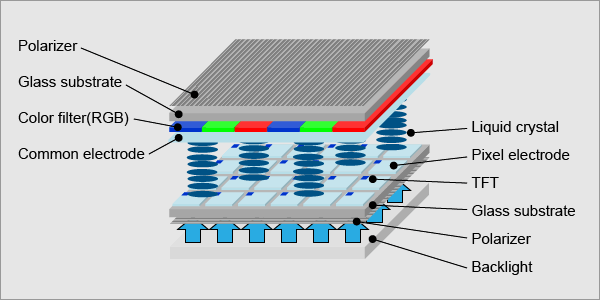

TFT Glass has as many TFTs as the number of pixels displayed, while a Color Filter Glass has color filter which generates color. Liquid crystals move according to the difference in voltage between the Color Filter Glass and the TFT Glass. The amount of light supplied by Back Light is determined by the amount of movement of the liquid crystals in such a way as to generate color.

The most common liquid-crystal displays (LCDs) in use today rely on picture elements, or pixels, formed by liquid-crystal (LC) cells that change the polarization direction of light passing through them in response to an electrical voltage.

As the polarization direction changes, more or less of the light is able to pass through a polarizing layer on the face of the display. Change the voltage, and the amount of light is changed.

The segment drive method is used for simple displays, such as those in calculators, while the dot-matrix drive method is used for high-resolution displays, such as those in portable computers and TFT monitors.

Two types of drive method are used for matrix displays. In the static, or direct, drive method, each pixel is individually wired to a driver. This is a simple driving method, but, as the number of pixels is increased, the wiring becomes very complex. An alternative method is the multiplex drive method, in which the pixels are arranged and wired in a matrix format.

To drive the pixels of a dot-matrix LCD, a voltage can be applied at the intersections of specific vertical signal electrodes and specific horizontal scanning electrodes. This method involves driving several pixels at the same time by time-division in a pulse drive. Therefore, it is also called a multiplex, or dynamic, drive method.

In passive-matrix LCDs (PMLCDs) there are no switching devices, and each pixel is addressed for more than one frame time. The effective voltage applied to the LC must average the signal voltage pulses over several frame times, which results in a slow response time of greater than 150 msec and a reduction of the maximum contrast ratio. The addressing of a PMLCD also produces a kind of crosstalk that produces blurred images because non-selected pixels are driven through a secondary signal-voltage path. In active-matrix LCDs (AMLCDs), on the other hand, a switching device and a storage capacitor are integrated at the each cross point of the electrodes.

The active addressing removes the multiplexing limitations by incorporating an active switching element. In contrast to passive-matrix LCDs, AMLCDs have no inherent limitation in the number of scan lines, and they present fewer cross-talk issues. There are many kinds of AMLCD. For their integrated switching devices most use transistors made of deposited thin films, which are therefore called thin-film transistors (TFTs).

An alternative TFT technology, polycrystalline silicon - or polysilicon or p-Si-is costly to produce and especially difficult to fabricate when manufacturing large-area displays.

Nearly all TFT LCDs are made from a-Si because of the technology"s economy and maturity, but the electron mobility of a p-Si TFT is one or two orders of magnitude greater than that of an a-Si TFT.

This makes the p-Si TFT a good candidate for an TFT array containing integrated drivers, which is likely to be an attractive choice for small, high definition displays such as view finders and projection displays.

The TFT-array substrate contains the TFTs, storage capacitors, pixel electrodes, and interconnect wiring. The color filter contains the black matrix and resin film containing three primary-color - red, green, and blue - dyes or pigments. The two glass substrates are assembled with a sealant, the gap between them is maintained by spacers, and LC material is injected into the gap between the substrates. Two sheets of polarizer film are attached to the outer faces of the sandwich formed by the glass substrates. A set of bonding pads are fabricated on each end of the gate and data-signal bus-lines to attach LCD Driver IC (LDI) chips

To reduce the footprint of the LCD module, the drive circuit unit can be placed on the backside of the LCD module by using bent Tape Carrier Packages (TCPs) and a tapered light-guide panel (LGP).

The performance of the TFT LCD is related to the design parameters of the unit pixel, i.e., the channel width W and the channel length L of the TFT, the overlap between TFT electrodes, the sizes of the storage capacitor and pixel electrode, and the space between these elements.

The design parameters associated with the black matrix, the bus-lines, and the routing of the bus lines also set very important performance limits on the LCD.

In a TFT LCD"s unit pixel, the liquid crystal layer on the ITO pixel electrode forms a capacitor whose counter electrode is the common electrode on the color-filter substrate.

Applying a positive pulse of about 20V peak-to-peak to a gate electrode through a gate bus-line turns the TFT on. Clc and Cs are charged and the voltage level on the pixel electrode rises to the signal voltage level (+8 V) applied to the data bus-line.

The voltage on the pixel electrode is subjected to a level shift of DV resulting from a parasitic capacitance between the gate and drain electrodes when the gate voltage turns from the ON to OFF state. After the level shift, this charged state can be maintained as the gate voltage goes to -5 V, at which time the TFT turns off. The main function of the Cs is to maintain the voltage on the pixel electrode until the next signal voltage is applied.

By scanning the gate bus-lines sequentially, and by applying signal voltages to all source bus-lines in a specified sequence, we can address all pixels. One result of all this is that the addressing of an AMLCD is done line by line.

Virtually all AMLCDs are designed to produce gray levels - intermediate brightness levels between the brightest white and the darkest black a unit pixel can generate. There can be either a discrete numbers of levels - such as 8, 16, 64, or 256 - or a continuous gradation of levels, depending on the LDI.

The digital LDI produces discrete voltage amplitudes, which permits on a discrete numbers of shades to be displayed. The number of gray levels is determined by the number of data bits produced by the digital driver.

The color filter of a TFT LCD TV consists of three primary colors - red (R), green (G), and blue (B) - which are included on the color-filter substrate.

Berger Montague served on the Plaintiffs’ executive committee in In re TFT-LCD Antitrust Litigation, a class action lawsuit against the world’s leading manufacturers of Thin Film Transistor Liquid Crystal Displays (“TFT-LCDs”) and products incorporating TFT-LCDs.

TFT-LCDs are used in flat-panel televisions as well as computer monitors, laptop computers, mobile phones, personal digital assistants, and other devices. The Plaintiffs, who directly purchased from a Defendant the TFT-LCDs or the products containing them, alleged the Defendants fixed the prices of the TFT-LCDs, causing the Plaintiffs to pay more than they should have.

On July 3, 2012, a federal jury found that the remaining defendant, Toshiba Corporation, participated in the conspiracy to fix prices of TFT-LCDs and returned a verdict for the plaintiff class.

TFT is a Thin Film Transistor, TFT refers to each LCD liquid crystal display pixels that are driven by integration in the behind of the Thin Film Transistor. Therefore, the TFT-type display has the advantages of high responsiveness, high brightness, and high contrast, and its display effect is close to that of CRT display, TFT-LCD is one of the most liquid crystal displays.TFT display is also a kind of active-matrix liquid crystal display equipment. TFT-LCD is one of the best LCD color displays, TFT-LCD has the advantages of fine and vivid image, lightweight, low power consumption, and good environmental protection performance, widely used in TV, laptop, mobile phone, monitor, medical beauty, and other equipment.

Unlike TN, TFT displays are “backlit” – the imaginary light path is not from top to bottom, as in TN, but from bottom to top. In this way, a special light tube is set on the back of the liquid crystal, and the light source shines upward through the lower polarizer. Since the upper and lower interlayer electrodes are changed into FET electrodes and common electrodes, the performance of liquid crystal molecules will also change when the FET electrode is switched on. The display purpose can be achieved through shading and light transmission, and the response time is greatly improved to about 80ms.TFT is commonly known as “true color” because it has higher contrast and richer colors than TN-LCD, and the screen updates faster.

The main feature of TFT-LCD, as opposed to TN, is one semiconductor switch per pixel. Because each pixel can be directly controlled by point pulses. Therefore, each node is relatively independent and can be controlled continuously. Such a design method not only improves the response speed of the display screen but also can accurately control the display grayscale, which is why TFT color is more realistic than DSTN.

The TFT panel is cut from a larger substrate. LCD products also have a large array of transistors to control the three primary colors, and current manufacturing technology is difficult to ensure that tens or even hundreds of millions of transistors on a large substrate are without a single problem. If there is a problem with one of the transistors, then the corresponding color of the corresponding point of the transistor will go wrong (only a certain fixed color can be displayed), and this point is commonly called “bad point”. The probability of bad spots is not fixed in position, so a substrate is likely to be wasted a lot. Generally, LCD requires that the bad point is less than 5, and some large manufacturers have narrowed the standard to 3, or even 0, which will reduce the yield rate. Some smaller manufacturers expand the bad points, which naturally reduces costs and quality, which is one reason why some manufacturers have been able to slash prices.

Although there are many manufacturers capable of producing LCDs, there are only a handful of manufacturers capable of producing TFT panels.ACER, as a well-known enterprise in the IT industry, is quite powerful. Although IT does not have the ability to produce TFT panels by itself,

The display sets the electron, the communication and the information processing technology in one body, is considered as the electron industry after the 20th-century microelectronics, the computer another important development opportunity.

With the rapid development of science and technology, a revolution is taking place in display technology. After more than 20 years of research, competition, and development, the flat-panel display has entered the role and become the mainstream of display products in the new century. There are four types of flat-panel displays with the most fierce competition:

The principle of field emission flat display is similar to that of CRT, which only has one to three electron guns and up to six. The field emission display adopts an electron gun array (electron emission micro tip array, such as diamond film tip cone), and the display with a resolution of VGA (640×480×3) needs 921,600 electron emission micro tips with uniform performance.

Glow plasma display are through small vacuum plasma discharge excitation discharge cavity light-emitting materials, luminous effect, and low power consumption is its shortcomings (only 1.2 lm/W, and lamp luminous efficiency more than 80 lm/W, 6 watts per square inch display area), but in 102 ~ 152 cm diagonal field of the large-screen display has a strong competitive advantage.

The semiconductor light-emitting diode (LED) display scheme, due to the successful development of GaN blue light-emitting diode, has won absolute control over the market of the video display with very large screens, but this kind of display is only suitable for large outdoor displays, and video display with a small and medium screen does not have its market.

Special TFT – LCD, LCD flat panel display, is the only one in the brightness, contrast, such as power, life, volume and weight of integrated performance to catch up with and surpass that of the CRT display device, it features good performance, large-scale production, a high degree of automation, low cost of raw materials, the vast development space, will quickly become the mainstream product of the new century, is one of the highlights of the 21st-century global economic growth.

TFT-LCD, which USES liquid crystal as the excellent characteristic of the light valve, divides the luminous display device into two parts, namely the light source and the control of the light source. As a light source, no matter from luminous efficiency, full color, or life, has achieved brilliant results, but also in continuous deepening. Since the invention of the LCD, the backlight has been continuously improved, from monochrome to color, from thick to thin, from side fluorescent lamps to flat fluorescent lamps. The latest achievements in light sources will provide a new backlight for LCD. With the progress of light source technology, there will be newer and better light sources and LCD applications. Is the control of the light source, the rest of the large scale integrated circuit technology and semiconductor technology transplanted, successfully developed the thin film transistor (TFT) production technology, implements the matrix addressing the control of the liquid crystal light valve, solved the LCD light valve and the controller, so that the advantages of liquid crystal display (LCD).

The TFT thin-film transistor (matrix) — which “actively” controls individual pixels on the screen — is the origin of the so-called active matrix TFT.So how exactly do images come about? The basic principle is simple: a display screen consists of a number of pixels that can emit light of any color, and controlling each pixel to display a corresponding color does the trick. In TFT LCD, backlight technology is generally adopted. In order to accurately control the color and brightness of each pixel, a switch similar to a shutter needs to be installed after each pixel. When the “shutter” is opened, light can come through, but when the “shutter” is closed, light cannot come through.

Of course, it’s not as simple technically as that. Liquid Crystal Display USES the properties of Liquid crystals (Liquid when heated and solid when cooled)

Liquid crystal displays (LCDs) are filamentous, and their molecular structure changes as the environment change, giving them different physical properties — allowing light to pass through or block it — in the case of louvers.

You know the three primary colors, so each pixel on the display needs to be made up of three similar basic components described above, which control the red, green, and blue colors respectively.

TFT color filter is divided into red, green, and blue according to the color, which is successively arranged on the glass substrate to form a group (dot pitch) corresponding to a pixel. Each monochrome filter is called a sub-pixel. That said, if a TFT display supports a maximum resolution of 1280×1024, it needs at least 1280×3×1024 sub-pixels and transistors. For a 15-inch TFT display (1024 x 768), a pixel is about 0.0188 inches.

As you know, pixels are critical to a display, and the smaller each pixel, the larger the maximum possible resolution of the display. But because of the physical limitations of transistors, the TFT is roughly 0.0117 inches (0.297mm) per pixel, so the maximum resolution for a 15-inch display is 1,280 by 1,024.[1]

TFT technology is the basis of liquid crystal (LC), inorganic and organic thin-film electroluminescence (EL and OEL) flat panel displays.TFT is a kind of film necessary for manufacturing circuits formed by sputtering and chemical deposition process on the non-single wafers such as glass or plastic substrate, and large-scale semiconductor integrated circuit (LSIC) is produced by processing of the film. Using non-single-crystal substrate can greatly reduce the cost, which is the extension of traditional LSI to large-area, multi-function, and low-cost direction.

The first generation of large-area glass substrate (300mm×400mm) TFT-LCD production line was put into production in the early 1990s. By the first half of 2000, the area of glass substrate has been expanded to 680mm×880mm), and the recent 950mm×1200mm glass substrate will also be put into operation. In principle, there is no area limit.

The 1.3-inch TFT chip used for liquid crystal projection has a resolution of one million pixels in XGA.The resolution of the SXGA (1280×1024) 16.1-inch TFT array amorphous silicon film thickness is only 50nm, and the TAB ON GLASS and SYSTEM ON GLASS technology, its IC integration, requirements for equipment and supply technology, technical difficulty than the traditional LSI.

TFT was first used as a matrix location circuit to improve the optical valve characteristics of liquid crystals. For high-resolution displays, the accurate control of object elements is realized through voltage adjustment in the range of 0-6v (its typical value is 0.2 to 4V), thus making it possible for LCD to achieve a high-quality high-resolution display.TFT-LCD is the first flat panel display in human history to surpass CRT in display quality. Now people are starting to integrate the drive IC into the glass substrate, and the whole TFT will be more powerful than traditional large-scale semiconductor integrated circuits.

In addition to traditional film formation processes such as sputtering and CVD (chemical vapor deposition) and MCVD (molecular chemical vapor deposition), laser annealing technology has also been applied, which can produce amorphous and polycrystalline films as well as monocrystalline films. Not only can make silicon membrane but also can make other Ⅱ – Ⅵ and Ⅲ – Ⅴ semiconductor thin film.

Low voltage applications, low drive voltage, solid use safety, and reliability improvement; Flat, light, and thin, saving a lot of raw materials and space; Low power consumption, its power consumption is about one-tenth of the CRT display, reflective TFT-LCD is only about one percent of the CRT, saving a lot of energy; TFT-LCD products also have specifications, models, size series, variety, convenient and flexible use, maintenance, update, upgrade easy, long service life and many other characteristics. The display range covers the application range of all monitors from 1 inch to 40 inches and the large projection plane, which is a full-size display terminal; Display quality from the simplest monochrome character graphics to high resolution, high color fidelity, high brightness, high contrast, the high response speed of various specifications of video display; Display mode has direct vision type, projection type, perspective type, and reflection type.

No radiation, no flicker, no harm to the user’s health. In particular, the appearance of TFT-LCD electronic books and periodicals will bring mankind into the era of a paperless office and paperless printing, and trigger the revolution of human learning, communication, and recording civilization.

The temperature range from -20℃ to +50℃ can be used normally, and the low temperature working temperature of TFT-LCD after temperature reinforcement can reach -80 ℃. It can be used as a mobile terminal display, desktop terminal display, and large screen projection TV. It is a full-size video display terminal with excellent performance.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

One of the industry’s leading oxide panel makers selected Astra Glass as its backplane glass substrate because it has the inherent fidelity to thrive in high-temperature oxide-TFT glass fabrication for immersive high-performance displays.

![]()

Dublin, April 23, 2021 (GLOBE NEWSWIRE) -- The "Thin Film Transistor Market - Growth, Trends, COVID-19 Impact, and Forecasts (2021 - 2026)" report has been added to ResearchAndMarkets.com"s offering.

The thin-film transistor market is expected to register a CAGR of 17.34% over the forecast period (2021 - 2026). Thin-film transistors (TFTs) are critical elements used for thin film electronics, and their most important application includes the pixel switching elements on flat panel displays (FPDs). A thin film transistor is also known as matrix display technology, which is more responsive to change.

The thin film transistors are expected to have a higher growth rate in the forecast period due to features such as low price, increasing demand of compact size, low power consumption displays, reduced weight and in consumer electronic goods and rising disposable incomes. Due to the continuous innovation in technology, there is an increase in the demand for thin film transistor displays.

Less availability of high-resolution TFTs for professional applications and high cost of manufacturing are some of the factors responsible for hindering the growth of the market. The market has various opportunities in the field of robotics, flexible electronics, and medical science. The excellent growth potential in emerging economies is also expected to drive the market.

TFT technology is investigated for use in microelectronic devices, X-ray detection, biochemical sensing, and chemical sensing. The technology offers advantages such as low power consumption, low cost, better response time, and faster refresh rate. Most of the companies are in the process to develop organic TFT technology, which makes it possible to have flexible display surfaces.

Consumer Electronics Expected to Have Significant Growth Thin film transistor (TFT) technology is widely used in flat-panel displays found in computers, televisions, smartphones, and laptops. The technology is revolutionizing the video system, enabling the manufacture of large-dimension flat-panels. For example, 164-inch diagonal dimension substrates are used for TFT LCD fabrication. Stability of processes for large-scale fabrication, an improved semiconductor layer and the development of processing equipment to manufacture large devices are advancing thin film transistor technology.

There is a decline in the open-cell LCD TV panel prices including 4K UHD TV panels, and price erosion of smartphone display panel is expected to increase revenue and maintain the market in a full state, during the forecast period. New applications in non-LCD applications are now being developed. This coupled with the ongoing research may increase the number of opportunities for products using TFT in their core. These application sub-segments are expected to boost the demand in the market during the forecast period.

Asia-Pacific Expected to Witness Significant Growth Asia-Pacific is one of the most significant markets for thin film transistor owing to the massively growing demand for consumer electronics, and also the semiconductor manufacturing industry is booming in the region. The region is also a global manufacturing hub for consumer electronics, especially smartphones and LCDs which are the major consumers of the technology. Additionally, the regional governments are also increasingly regulating policies which are further helping in the studied market growth. Also more and more regional SMEs manufacturers are penetrating into the manufacturing business of thin film transistors which is expected to bring down the overall cost and increase the innovations.

Demand for consumer goods such as televisions, monitor, smartphones, laptops and other consumer goods with displays is a rise in Asia-Pacific, which in turn, is fueling the demand for TFTs in this regional market. Growth in this region is the highest among all geographic regions considered. Increase in the net disposable income of consumers in this region, along with the declining price of the finished products using TFTs has increased the demand for thin-film transistors in the region. End products from application segment LCD have demand originating from the middle-class income group population. Presence of crucial display manufacturers in this region is also assisting in products to be offered at competitive prices.

The thin film transistor market is fragmented without many dominant players present in the market. Efforts are being taken by many companies to upgrade their research and development activities to analyze further applications that are expected to generate profitable growth opportunities for the market. March 2019 - Gas Turbine Controls introduced LCD Thin Film Transistor which will replace the outdated CRT of Speedtronic Mark IV. The company introduced the technology to create an LCD flat screen with anti-glare properties and high resolution.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey