4th dimensional innovations tft display factory

Leveraging 50 years of presence in avionic cockpit lighting we provide the ultimate display solutions. Cevians has rapidly become the fastest-growing privately owned company offering fully customized TFT-LCDs. Our highly vertically integrated technological foundation, from material science, thin-film coatings, optical designs, electronics and electro-mechanical designs to system engineering, makes Cevians’ capabilities and product offerings truly unique and the natural partner for Tier 1 OEMs.

Understanding the diverse industry ecosystem, we offer the level of product that integrates perfectly in each customer’s base model, from supplying custom TFT-LCD to LCD modules, display head assemblies (DHA), and fully ruggedized display systems. This flexible strategy allows our customers to efficiently use their resources for core competencies.

Superior materials and modern technology are adopted for tft panel. The raw materials vary with items. The first step in a procedure is frequently the most essential. Therefore, manufacturers in this industry pay great attention to raw materials and never spare raw materials. Changes in the quality of the raw materials used in production often result in changes in the quality of the final product.

Take your design to the next level with our range of TFT Displays including latest IPS TFT, circular and bar shape as well as large size TFT. With or without touch, these are fully customisable to your system requirements.

TFT-LCD technology is now fairly mature. As a result, manufacturing processes are efficient and production yields are high, leading to very competitive unit prices. Upgrading from a monochrome display to a TFT is now an affordable way to give your product an uplift.

Users of industrial display devices are wanting the same experience they have come to expect from a consumer device with all-round viewing angles. Switching to a superior IPS TFT display has become very cost effective as production increases and unit prices decrease.

Choosing a circular display for your next product design could really set you apart from your competition. Models are available from 1" to 4.2"in TFT, PMOLED and AMOLED, we have something to suit every application.

It is now possible to transform from a monochrome display to a colour display in space constrained systemsby using a letterbox shaped display. These ultra-wide displays are ideal for applications with restricted build height such as rack mount systems or landscape format front panels.

Large TFT display systems are increasingly being used for transportation information, retail signage and vending machines and kiosks. We can supply a large range of TFT solutions up to 65" diameter and in bar-style, square or rectangular configurations.

We are now offering increasing cover lens customisation options and processes to make your TFT LCD user interface truly stand out! Anders’ experienced marketers and engineers work with our manufacturing partners around the world to keep informed of the latest innovations, including mirrored glass,tinted glass, spot-facing, three dimension glass, and many more!

Here at Anders we don"t just strive to design a best in class display solution for your product, but we also want to make sure the display is driven with the right embedded system. We can help achieve a hardware solution that ensures your display works perfectly within your application. Hardware solutions include:

Get started quickly on your new user interface with our HMI development kits. The display, the processor and the OS work together out of the box with optimised QT GUI images. We"ll then optimise the kit to meet exactly your system requirements with our design services.

At Anders we understand that no two customers are the same, which is why we specialise in custom display solutionsand offer unique productstailored to your end application.

See below our range of TFT Displayswith sizes ranging from0.96" to 64.5" and including circular and bar type shape. All our displays can be tailored to suit your application antimicrobial coating technology,

We aim to offer reliable and long-term solutions to our B2B customers. If you are a business and would like to discuss your display and/or embedded system requirements please contact us below

A TFT display is a form of Liquid Crystal Display with thin film transistors for controlling the image formation. The TFT technology works by controlling brightness in red, green and blue sub-pixels through transistors for each pixel on the screen.

There are many display technologies, but do you know which one would be better for your application? Particularly when considering optimum viewing angle and contrast. We discuss 2 of the best options.

Compare IPS vs TFT displays - the TFT display is the display of choice for industrial designs, but it can have its limitations. A newer technology called IPS (in plane switching) offers better viewing angles and colours, but is it really the best choice - we discuss benefits and negatives of both types of TFT display.

Sharp demonstrated a fourteen-inch TFT-LCD for TV in 1988 when the display size of the mass-produced TFT-LCD was three inches. The high display quality in Cathode Ray Tube size convinced other electronic companies to join the infant TFT-LCD industry aimed at emerging full-color portable PCs. Two decades later, TFT-LCDs replaced CRTs, making the vision of RCA"s LCD group in the 1960s a reality.

Describe briefly the intended site(s) of the milestone plaque(s). The intended site(s) must have a direct connection with the achievement (e.g. where developed, invented, tested, demonstrated, installed, or operated, etc.). A museum where a device or example of the technology is displayed, or the university where the inventor studied, are not, in themselves, sufficient connection for a milestone plaque.

Sharp Technology Innovation Museum is located in the premise of Sharp Technology Center where LCD research was started and culminated in mass-producing the world-first mini-calculator mounted with LCD and C-MOS logic : the calculator is displayed at the British Science Museum.

It showed that an ideal display, namely, a flat, low-power, light-weight, CRT-sized full-color video display ,which could be used also in high ambient light, is technologically feasible, and that is exactly what had been long waited for to be used in an emerging information age since LCD was press-released in 1968 by RCA.

3. A large mother glass scheme could work for a-Si-TFT-LCD, which was proved by the high display uniformity across the entire display area. The mother glass 300mm x 320mm was the very forerunner of the mother glass generation competition which started around 1990, 2 years after Sharp 14-in. full color TFT-LCD was demonstrated.

At the time when a mere small 3-in. a-Si-TFT-LCD production was just started with poor yield, unstable and far-from-being-matured production equipment, small output capacity drivers, engineers had to prepare line-defect free TFT-LCD panels with high display quality, meaning large contrast ratio, high color saturation with high uniformity, and they made a precise electrical and physical system analysis and designing and devised redundant pixel and bus line schemes, and employed normally-white LCD operation mode, which was first employed in 3-in. TFT-LCD panel, and developed the TFT-LCD panel and its driving scheme to achieve higher contrast ratio, better gray scale and full-color rendition, wider tolerance in temperature and cell-gap variations, leading higher display uniformity across the entire large display area, than normally-black mode could achieve in those days.

Sharp"s first application of TFT-LCD was television which is supposed to be exposed to "critical" consumers 3-5 hours everyday for more than 10 years.

So, from the very beginning of development project started in April 1984, TV business group, who understand the market, located in Yaita-shi, Tochigi-ken, and TFT-LCD research group located in Tenri-shi, Nara-ken, worked closely; even though, two places are about 600km apart.

TV group, headed by Magohiro ARAMOTO, whose leading member was Masakazu YAMAMOTO, joined by Shuhji KOHZAI later on, showed the clear target specifications and pointed out critical display quality factors to be improved, and also transferred TV evaluation methods to TFT-LCD research group; TFT-LCD research group, headed by Masataka MATUURA, whose leading members were Funada FUMIAKI, with Yutaka ISHII as sub-leader, for LC material and operation mode and acting deputy to Matsuura, Kohzo YANO for TFT process, Hiroshi TAKE for system designing of TFT, LCD panel and driving circuitry, and evaluation of TFT-LCD as an integrated system, achieved and acquired them.

In the production project started in November 1985, LCD business group, headed by Mitsuo ISHII, located in Yamato-Kohriyama-shi, Nara-ken, joined the project, bringing in panel production technology including large mother glass handling know-hows, and, the thin-film solar battery group, headed by Toshio TAKEMOTO, located in Shinjoh-shi, Nara-ken, was also incorporated into ISHII"s group,afterward, bringing in amorphous-Silicon(a-Si) thin-film solar-cell mass-production technology whose basics are similar to those of a-Si TFT.

In the Japanese Consumer Electronics Show, October 1986, the production project demonstrated 3-inch TFT-LCD TV which employed a normally-white LCD operation mode. The mechanical design of the 3-inch TFT-LCD module mounted on the demonstrated TV was done by Kenichi UKAI who joined the project June 1986 from Electronic Component Business Division, whose main products included miniaturized electronic TV tuners, located in Osaka-shi, Osaka-fu.

The world-first TFT-LCD factory with a large mother glass 300mmx320mm was build in the precinct of Research and Development Group, located in Tenri-shi, Nara-ken, toward the end of 1986, near the Central Reaearch Laboratories TFT-LCD research group belonged to.

April 1987, YANO and TAKE of TFT-LCD research group moved to LCD Business Division whose general manager was Isamu WASHIZUKA, to be the technology and engineering core members of the newly-created The 3rd Production Department which had all the essential functions to execute TFT-LCD business, such as TFT-LCD process engineering, electronics and mechanical engineerings, administration, and production, irregularly incorporated with Mitsuo ISHII as general manager.

The 1st Sharp LC-TV "3C-E1" with 3-inch TFT-LCD, display dot 384Hx240V in a triangle arrangement, was put on the martket June 1987, half a year later than originally scheduled; the TFT-LCD production yield was miserable, though.

In one of meetings held everyday in the evening to improve production yield of 3-inch TFT-LCD panel, Washizuka gave an additional mission to look into the future, and to search for TFT-LCD technology capability for TV, and instigated young engineers to study and propose larger display prototype development plans without giving any clear target size numbers and time frames.

Around middle of 1987, a voluntary project team was set up, headed by Mitsuo ISHII, whose leading members were Toshio AKAI for product planning, Kohzo YANO for TFT-LCD process and Hiroshi TAKE for electronics and system.

The project team almost reached a consensus to adopt 8.9-in. size for a challenging target: 6.6-in. seemed to give only a small impact; 14-in. seemed to be too risky to get good panels, meaning with high display uniformity across the entire display area, no-line defects and acceptable dot defects by infant technology and equipment.

TAKE made a phone call to Magohiro ARAMOTO, general manager of TV Division, and had guided the TFT-LCD development project to improve display quality for TV, to try to understand the TV market, and asked ARAMOTO what would be the minimum size of TFT-LCD to be widely used by people.

TAKE, evaluation and characterization research engineer by background, knew the difficulty to prepare 14-in. panel using the same process and equipment used to mass-produce 3-in. panels with poor yield, but decided to accept ARAMOTO’s number 14-in., saying to himself the possible largest size on the mother glass would show up, more clearly than smaller sizes, problems and issues TFT-LCD had to solve and tackle with to be a viable technology in TV and other markets dominated by CRTs.

The panel should be compatible with NTSC/M TV system, and display dot number was decided to be 642Hx480V with available analog driver-LSI output terminal numbers taken into consideration. The trios of red, green and blue primary color dots were arranged in a triangle pattern to maximize the resolution with the limited display dot number.

The target TFT-LCD panel specifications was accepted in the project team after YANO, with Hiroaki KATOH as his process designing section leader, made a thorough review of the TFT-LCD process and equipment in the 3-in.-mass-producing factory to make sure 14-in. was NOT impossible , and authorized by WASHIZUKA afterwards.

The 14-in. TFT-LCD panels were prepared by using the production line whose main product was 3-inch TFT-LCD panel, and 4-inch TFT-LCD production was just started.

There were a lot of fierce arguments and misunderstandings within the newly-formed production department whoes members had been recruited from various departments of various business divisions of Sharp Corporation, but those were managed and solved by tightly sharing the common mission: Make TV displays for OUR TVs!: Sharp Corporation mass-produced B/W CRT-TV in 1953, 1st in Japan, under the license agreement with RCA, and had been one of the leading worldwide TV makers, but had not produced CRTs inhouse; all CRTs on Sharp TVs been bought from outside.

At the very beginning of a-Si-TFT-LCD business startup, this work clearly showed a-Si-TFT-LCD have the potential to replace monster CRT in the coming information age by its superior characteristics: flatness, light-weight, small power consumption, high saturation full-color rendition, high readability in high ambient light, realized on the 14-in. display size, the most dominant size in the contemporary market by using the technology which was developed to mass-produce twenty 3-in. TFT-LCD TV panels laid out on the mother glass of 300mm x 320mm dimensions.

TV business group knew the market and joined the development project from the very beginning and gave a clear display quality target to TFT-LCD research group to achieve and make the TFT-LCD a viable display technology against CRT dominance.

[114] T. Nagayasu, T. Oketani, T. Hirobe, H. Kato, S. Mizushima, H. Take, K. Yano, M. Hijikigawa, and I. Washizuka, “A 14-in-diagonal full color a-Si TFT LCD,” in Proc. Int. Display Research Conf., San Diego, CA, Oct. 1988, pp. 56–58.

[9] G. H. Heilmeier, “Liquid crystal displays: An experiment in interdisciplinary research that worked,” IEEE Trans. Electron Devices, vol. ED-23, July 1976.

[2] B.J.Lechner, "History Crystallized_A First-Person Account of the Development of Matrix-Addressed LCDs for television at RCA in the 1960s",Information Display 1/08 p26-30

Innovation in Global Industries challenges this thinking. The book, a collection of individually authored studies, examines in detail structural changes in the innovation process in 10 service as well as manufacturing industries: personal computers; semiconductors; flat-panel displays; software; lighting; biotechnology; pharmaceuticals; financial services; logistics; and venture capital. There is no doubt that overall there has been an acceleration in global sourcing of innovation and an emergence of new locations of research capacity and advanced technical skills, but the patterns are highly variable. Many industries and some firms in nearly all industries retain leading-edge capacity in the United States. However, the book concludes that is no reason for complacency about the future outlook. Innovation deserves more emphasis in firm performance measures and more sustained support in public policy.

Sharp demonstrated a fourteen-inch TFT-LCD for TV in 1988 when the display size of the mass-produced TFT-LCD was three inches. The high display quality in Cathode Ray Tube size convinced other electronic companies to join the infant TFT-LCD industry aimed at emerging full-color portable PCs. Two decades later, TFT-LCDs replaced CRTs, making the vision of RCA"s LCD group in the 1960s a reality.

Describe briefly the intended site(s) of the milestone plaque(s). The intended site(s) must have a direct connection with the achievement (e.g. where developed, invented, tested, demonstrated, installed, or operated, etc.). A museum where a device or example of the technology is displayed, or the university where the inventor studied, are not, in themselves, sufficient connection for a milestone plaque.

Sharp Technology Innovation Museum is located in the premise of Sharp Technology Center where LCD research was started and culminated in mass-producing the world-first mini-calculator mounted with LCD and C-MOS logic : the calculator is displayed at the British Science Museum.

It showed that an ideal display, namely, a flat, low-power, light-weight, CRT-sized full-color video display ,which could be used also in high ambient light, is technologically feasible, and that is exactly what had been long waited for to be used in an emerging information age since LCD was press-released in 1968 by RCA.

3. A large mother glass scheme could work for a-Si-TFT-LCD, which was proved by the high display uniformity across the entire display area. The mother glass 300mm x 320mm was the very forerunner of the mother glass generation competition which started around 1990, 2 years after Sharp 14-in. full color TFT-LCD was demonstrated.

At the time when a mere small 3-in. a-Si-TFT-LCD production was just started with poor yield, unstable and far-from-being-matured production equipment, small output capacity drivers, engineers had to prepare line-defect free TFT-LCD panels with high display quality, meaning large contrast ratio, high color saturation with high uniformity, and they made a precise electrical and physical system analysis and designing and devised redundant pixel and bus line schemes, and employed normally-white LCD operation mode, which was first employed in 3-in. TFT-LCD panel, and developed the TFT-LCD panel and its driving scheme to achieve higher contrast ratio, better gray scale and full-color rendition, wider tolerance in temperature and cell-gap variations, leading higher display uniformity across the entire large display area, than normally-black mode could achieve in those days.

Sharp"s first application of TFT-LCD was television which is supposed to be exposed to "critical" consumers 3-5 hours everyday for more than 10 years.

So, from the very beginning of development project started in April 1984, TV business group, who understand the market, located in Yaita-shi, Tochigi-ken, and TFT-LCD research group located in Tenri-shi, Nara-ken, worked closely; even though, two places are about 600km apart.

TV group, headed by Magohiro ARAMOTO, whose leading member was Masakazu YAMAMOTO, joined by Shuhji KOHZAI later on, showed the clear target specifications and pointed out critical display quality factors to be improved, and also transferred TV evaluation methods to TFT-LCD research group; TFT-LCD research group, headed by Masataka MATUURA, whose leading members were Funada FUMIAKI, with Yutaka ISHII as sub-leader, for LC material and operation mode and acting deputy to Matsuura, Kohzo YANO for TFT process, Hiroshi TAKE for system designing of TFT, LCD panel and driving circuitry, and evaluation of TFT-LCD as an integrated system, achieved and acquired them.

In the production project started in November 1985, LCD business group, headed by Mitsuo ISHII, located in Yamato-Kohriyama-shi, Nara-ken, joined the project, bringing in panel production technology including large mother glass handling know-hows, and, the thin-film solar battery group, headed by Toshio TAKEMOTO, located in Shinjoh-shi, Nara-ken, was also incorporated into ISHII"s group,afterward, bringing in amorphous-Silicon(a-Si) thin-film solar-cell mass-production technology whose basics are similar to those of a-Si TFT.

In the Japanese Consumer Electronics Show, October 1986, the production project demonstrated 3-inch TFT-LCD TV which employed a normally-white LCD operation mode. The mechanical design of the 3-inch TFT-LCD module mounted on the demonstrated TV was done by Kenichi UKAI who joined the project June 1986 from Electronic Component Business Division, whose main products included miniaturized electronic TV tuners, located in Osaka-shi, Osaka-fu.

The world-first TFT-LCD factory with a large mother glass 300mmx320mm was build in the precinct of Research and Development Group, located in Tenri-shi, Nara-ken, toward the end of 1986, near the Central Reaearch Laboratories TFT-LCD research group belonged to.

April 1987, YANO and TAKE of TFT-LCD research group moved to LCD Business Division whose general manager was Isamu WASHIZUKA, to be the technology and engineering core members of the newly-created The 3rd Production Department which had all the essential functions to execute TFT-LCD business, such as TFT-LCD process engineering, electronics and mechanical engineerings, administration, and production, irregularly incorporated with Mitsuo ISHII as general manager.

The 1st Sharp LC-TV "3C-E1" with 3-inch TFT-LCD, display dot 384Hx240V in a triangle arrangement, was put on the martket June 1987, half a year later than originally scheduled; the TFT-LCD production yield was miserable, though.

In one of meetings held everyday in the evening to improve production yield of 3-inch TFT-LCD panel, Washizuka gave an additional mission to look into the future, and to search for TFT-LCD technology capability for TV, and instigated young engineers to study and propose larger display prototype development plans without giving any clear target size numbers and time frames.

Around middle of 1987, a voluntary project team was set up, headed by Mitsuo ISHII, whose leading members were Toshio AKAI for product planning, Kohzo YANO for TFT-LCD process and Hiroshi TAKE for electronics and system.

The project team almost reached a consensus to adopt 8.9-in. size for a challenging target: 6.6-in. seemed to give only a small impact; 14-in. seemed to be too risky to get good panels, meaning with high display uniformity across the entire display area, no-line defects and acceptable dot defects by infant technology and equipment.

TAKE made a phone call to Magohiro ARAMOTO, general manager of TV Division, and had guided the TFT-LCD development project to improve display quality for TV, to try to understand the TV market, and asked ARAMOTO what would be the minimum size of TFT-LCD to be widely used by people.

TAKE, evaluation and characterization research engineer by background, knew the difficulty to prepare 14-in. panel using the same process and equipment used to mass-produce 3-in. panels with poor yield, but decided to accept ARAMOTO’s number 14-in., saying to himself the possible largest size on the mother glass would show up, more clearly than smaller sizes, problems and issues TFT-LCD had to solve and tackle with to be a viable technology in TV and other markets dominated by CRTs.

The panel should be compatible with NTSC/M TV system, and display dot number was decided to be 642Hx480V with available analog driver-LSI output terminal numbers taken into consideration. The trios of red, green and blue primary color dots were arranged in a triangle pattern to maximize the resolution with the limited display dot number.

The target TFT-LCD panel specifications was accepted in the project team after YANO, with Hiroaki KATOH as his process designing section leader, made a thorough review of the TFT-LCD process and equipment in the 3-in.-mass-producing factory to make sure 14-in. was NOT impossible , and authorized by WASHIZUKA afterwards.

The 14-in. TFT-LCD panels were prepared by using the production line whose main product was 3-inch TFT-LCD panel, and 4-inch TFT-LCD production was just started.

There were a lot of fierce arguments and misunderstandings within the newly-formed production department whoes members had been recruited from various departments of various business divisions of Sharp Corporation, but those were managed and solved by tightly sharing the common mission: Make TV displays for OUR TVs!: Sharp Corporation mass-produced B/W CRT-TV in 1953, 1st in Japan, under the license agreement with RCA, and had been one of the leading worldwide TV makers, but had not produced CRTs inhouse; all CRTs on Sharp TVs been bought from outside.

At the very beginning of a-Si-TFT-LCD business startup, this work clearly showed a-Si-TFT-LCD have the potential to replace monster CRT in the coming information age by its superior characteristics: flatness, light-weight, small power consumption, high saturation full-color rendition, high readability in high ambient light, realized on the 14-in. display size, the most dominant size in the contemporary market by using the technology which was developed to mass-produce twenty 3-in. TFT-LCD TV panels laid out on the mother glass of 300mm x 320mm dimensions.

TV business group knew the market and joined the development project from the very beginning and gave a clear display quality target to TFT-LCD research group to achieve and make the TFT-LCD a viable display technology against CRT dominance.

[114] T. Nagayasu, T. Oketani, T. Hirobe, H. Kato, S. Mizushima, H. Take, K. Yano, M. Hijikigawa, and I. Washizuka, “A 14-in-diagonal full color a-Si TFT LCD,” in Proc. Int. Display Research Conf., San Diego, CA, Oct. 1988, pp. 56–58.

[9] G. H. Heilmeier, “Liquid crystal displays: An experiment in interdisciplinary research that worked,” IEEE Trans. Electron Devices, vol. ED-23, July 1976.

[2] B.J.Lechner, "History Crystallized_A First-Person Account of the Development of Matrix-Addressed LCDs for television at RCA in the 1960s",Information Display 1/08 p26-30

GD24TWD-GTT24P123 VER:3.00 Color Digital TFT LCD Module is comprised by driver board GD24TWD VER:3.00 and TFT LCD Display GTT24P123. The LCD module supports CVBS signal input, NTSC and PAL formats which two formats applies to auto identification.

GD24TWD-GTT24P123 VER:3.00 Color Digital TFT LCD Module is comprised by driver board GD24TWD VER:3.00 and TFT LCD Display GTT24P123. The LCD module supports CVBS signal input, NTSC and PAL formats which two formats applies to auto identification. Button adjustment with OSD menu control. It is mainly used for video phones and other display electronic devices

{"specs":[],"skus":[{"id":4696,"useViewType":false,"productId":282,"templateId":1,"code":"","name":"2.4 inch TFT LCD display module with drive board, GD24TWD-GTT24P123","stock":0,"price":0.00,"retailPrice":0.00,"weight":0.00,"status":"1","isDefault":"1","createDate":"2022-03-08 11:33:19","updateDate":"2022-03-08 11:33:19","productSkuSpecs":[],"moq":1,"skuId":0,"chargedWeight":0.00}],"specConfs":[]}

We realize the innovation of 10 4 tft touch, 4 3 inch tft lcd touch screen, tft display 7 inch through organization and technical innovation, hoping to occupy the market with high technology and products and drive the progress and development of the industry.The company adheres to the principles of "customer interests first" and "small profits but quick turnover", abides by the business style of "loyalty, pragmatism, communication, and stability", strives to improve product quality, and strives to lead the new trend of 4 3 Inch TFT LCD 500 Nits development. With excellent culture as a strong guarantee, we are committed to developing into a first-class company with global operation. If you have a specific requirement for this product, please contact us, we would be happy to discuss your requirements in details. Our independent innovation ability is increasing day by day, which provides strong technical support for the construction of enterprise technology reform and greatly promotes the scientific and technological progress of the industry. We always give priority to strengthening environmental protection, developing green manufacturing and practicing social responsibility. We pursue the spirit of innovation and scientific attitude, quick response and planning, and high efficiency through high efficiency. We have rich experience in international trade, global sales and service network, and perfect service quality. For a long time, we have continued to participate in social welfare while operating and developing our business.

Comparing to standard 4.3” TFT LCD screen, this 480x272 4.3inch TFT LCD module is a high brightness display panel, with 7 LEDs connected in serial, brightness achieves to 500 cd/m2

Distributor of component LCDs for equipment which provide high-contrast ratio, color saturation, luminance and performance enhancements such as advanced wide viewing (AWV) for true color fidelity, super-high brightness (SHB) and wide temperature range. Focus on industrial, instrumentation, hand-helds, medical and other low-to-medium volume markets. High-bright LED backlights for outdoor use. LVDS interfaces decrease EMI. Factory installed touch screen solutions. 3.5" to 12.1" QVGA, HVGA, VGA, WVGA, SVGA, XGA, WXGA. Also distributes other related products including LED drivers, lamps, indicators, LED assemblies, segment displays, LED mounts, LEDs, and light pipes. Distributor of electronic components, hardware and fasteners and provides design/value engineering support, fulfillment strategies, procurement services and transactional models to meet specific needs and priorities.

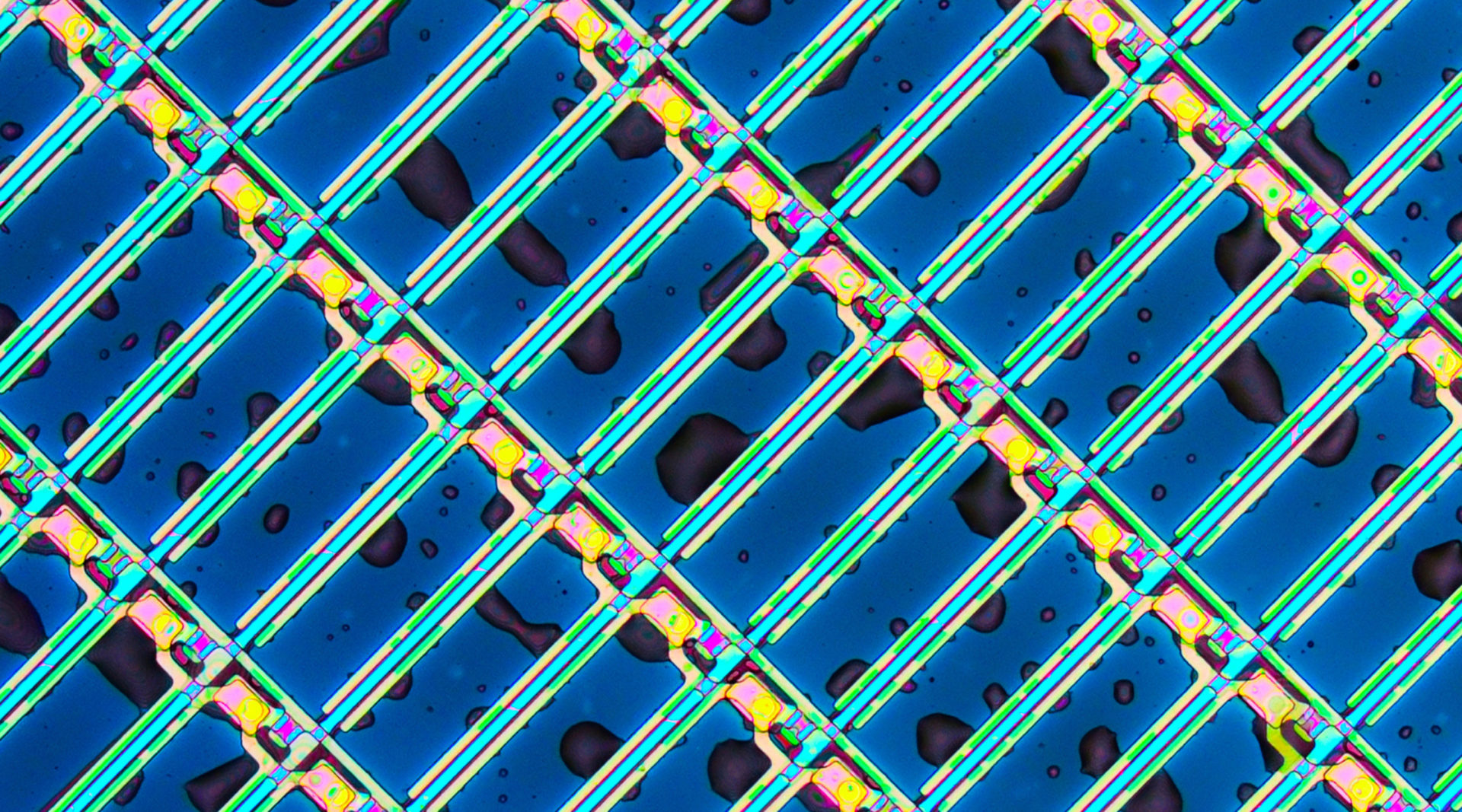

Thin-Film Transistor Liquid Crystal Displays use thin-film transistors to control the voltage applied to the liquid crystal layer at a sub-pixel level. The structure of TFT LCDs consists of a TFT “sandwich” and a BLU (Backlight Unit). A typical configuration is shown in the schematic diagram below.

Firstly, between the back and front polarizers, TFT LCD cells are made with two glass substrates – one for color filters, the other for a TFT array – and a liquid crystal layer sandwiched in between.

For normally black TFT LCDs, if we follow along a piece of light setting off from its backlight source, it will bea)guided uniformly by LGP;b)reflected and enhanced by BEF and DBEF;c)polarized by the back polarizer;d)polarization changed by twisted LC under the voltage applied by TFT arrays;e)“tinted” red/green/blue by corresponding color filter of the subpixel;f)let through the front polarizer by matched polarization; andg)finally, it will reach the surface and appears in viewer’s eyes.

For normally white panels, processd)will be the opposite – known as the polarization rotation effect, light is twisted in a voltage-off stage and can pass through the front polarizer by default, thus displaying white normally. However, when the voltage applied increases, this polarization rotation effect would be gradually diminished. And the light would not be able to pass through the front polarizer anymore without changing its polarization. In this way, certain pixels will appear in different colors.

Normally black LCDs have higher contrast and wider viewing angles without grayscale inversion phenomenon compared to their normally white relatives. And whether TFT LCDs are normally black or white depends on their LC switching mode:

2Chen, HW., Lee, JH., Lin, BY.et al.Liquid crystal display and organic light-emitting diode display: present status and future perspectives.Light Sci Appl7,17168 (2018).https://doi.org/10.1038/lsa.2017.168

As previously mentioned, TN mode functions with the polarization rotation effect. Under traditional TN/VA display mode, the liquid crystal molecules are vertically arranged, with a relatively narrow visual angle. When an external force is exerted on the screen, the liquid crystal molecular structure will sink in a herringbone pattern to slowly recover – a pattern called vertical alignment. Therefore, an evident “water ripple” usually appears when the display surface is touched and impacts the user experience. In comparison, the VA mode provides higher contrast. And MVA (multi-domain vertical alignment) is an upgraded version of VA with improved viewing angles.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey