msk tft display factory

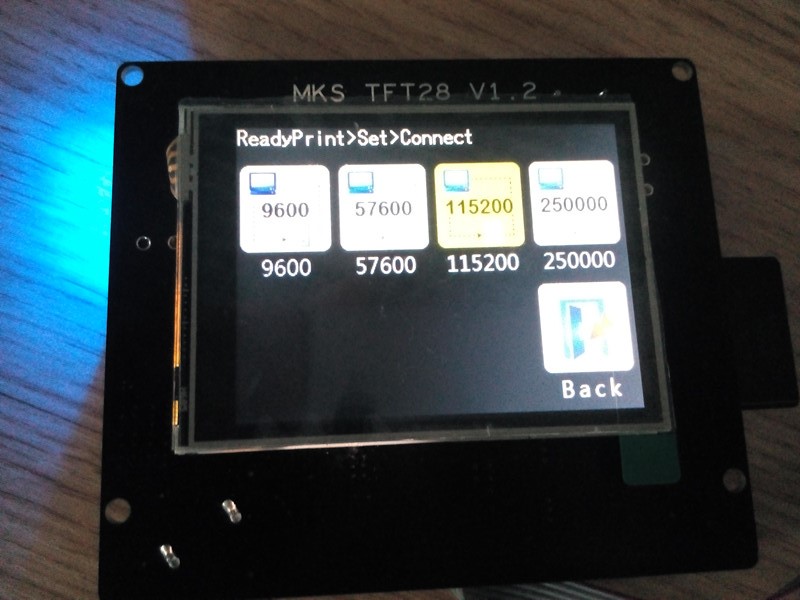

It is highly recommend to use external 12V/1A adapter to supply power to MKS TFT 2.8″ screen. Before plug the 12V power adapter to 2.8″ screen, please plug the “power select” jumper into DC12V position.

MKS TFT2.8″ use a special 8 pin parallel cable to connect the board to ramps1.4 main board. This cable is different from traditional 8 pin parallel cable which is often used to connect DVD and hard driver. We highly recommend you to use the Osoyoo factory 8 pin cable which comes with the 2.8 inch screen.

Sometimes your screen might not display anything. This is because you have used a traditional 8 pin cable, you need turn cable head 180 degrees and then push itby forceinto the “mainboard interface” socket, then the screen will work.

5) After setting baud rate, you can test MKS-TFT2.8″ screen now. If you find the motor does not move, please check the wire connection first, then check if thermistance(heat sensor) is connected, then check if external 12V power and 12VDC jumper is connected. If these 3 connection is not properly done, motor will not move.

If you want to change some function or add new function and so on, you can refer to MKS TFT source code and build it, update it to MKS TFT, Link as below:

Important technical improvements of LCD, such as LED backlighting and wide viewing Angle, are directly related to LCD. And account for an LCD display 80% of the cost of the LCD panel, enough to show that the LCD panel is the core part of the entire display, the quality of the LCD panel, can be said to directly determine the quality of an LCD display.

The production of civil LCD displays is just an assembly process. The LCD panel, the main control circuit, shell, and other parts of the main assembly, basically will not have too complex technical problems.

In addition, there is a driving IC and printed circuit board beside the LCD panel, which is mainly used to control the rotation of LCD molecules in the LCD panel and the transmission of display signals. The LCD plate is thin and translucent without electricity. It is roughly shaped like a sandwich, with an LCD sandwiched between a layer of TFT glass and a layer of colored filters.

First of all, the motion and arrangement of LCD molecules need electrons to drive them. Therefore, on the TFT glass, the carrier of LCD, there must be conductive parts to control the motion of LCD. In this case, we use ITO (Indium Tin Oxide) to do this.ITO is transparent and also acts as a thin-film conductive crystal so that it doesn’t block the backlight.

The different arrangement of LCD molecules and the rapid motion change can ensure that each pixel displays the corresponding color accurately and the image changes accurately and quickly, which requires the precision of LCD molecule control.ITO film needs special treatment, just like printing the circuit on the PCB board, drawing the conductive circuit on the whole LCD board.

First, the ITO film layer needs to be deposited on the TFT glass, so that there is a smooth and uniform ITO film on the whole TFT glass. Then, using ionized water, the ITO glass is cleaned and ready for the next step.

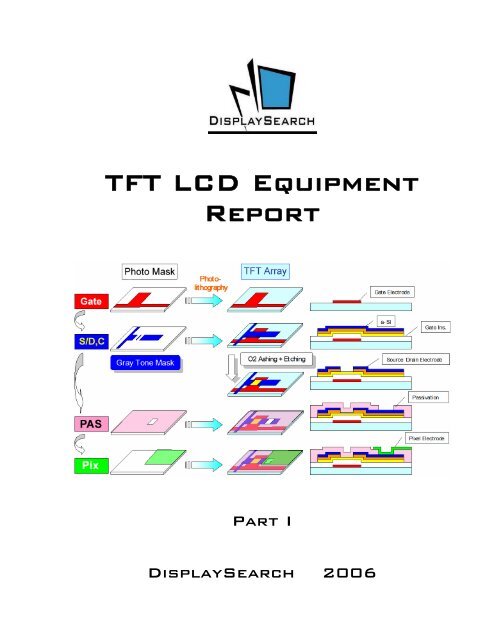

This completes the previous Array process. It is not difficult to see from the whole process that ITO film is deposited, photoresist coated, exposed, developed, and etched on TFT glass, and finally, ITO electrode pattern designed in the early stage is formed on TFT glass to control the movement of LCD molecules on the glass. The general steps of the whole production process are not complicated, but the technical details and precautions are very complicated, so we will not introduce them here. Interested friends can consult relevant materials by themselves.

The glass that the LCD board uses makes a craft also very exquisite. (The manufacturing process flow of the LCD display screen)At present, the world’s largest LCD panel glass, mainly by the United States Corning, Japan Asahi glass manufacturers, located in the upstream of the production of LCD panel, these manufacturers have mastered the glass production technology patents. A few months ago, the earthquake caused a corning glass furnace shutdown incident, which has caused a certain impact on the LCD panel industry, you can see its position in the industry.

As mentioned earlier, the LCD panel is structured like a sandwich, with an LCD sandwiched between the lower TFT glass and the upper color filter. The terminal Cell process in LCD panel manufacturing involves the TFT glass being glued to the top and bottom of a colored filter, but this is not a simple bonding process that requires a lot of technical detail.

After the TFT glass substrate is cleaned, a sealant coating is applied to allow the TFT glass substrate to be bonded to the color filter and to prevent LCD outflow.

Finally, the conductive adhesive is applied to the frame in the bonding direction of the glass of the color filter to ensure that external electrons can flow into the LCD layer. Then, according to the bonding mark on the TFT glass substrate and the color filter, two pieces of glass are bonded together, and the bonding material is solidified at high temperatures to make the upper and lower glasses fit statically.

When making LCD panel, must up and down each use one, and presents the alternating direction, when has the electric field and does not have the electric field, causes the light to produce the phase difference and to present the light and dark state, uses in the display subtitle or the pattern.

The rear Module manufacturing process is mainly the integration of the drive IC pressing of the LCD substrate and the printed circuit board. This part can transmit the display signal received from the main control circuit to the drive IC to drive the LCD molecules to rotate and display the image. In addition, the backlight part will be integrated with the LCD substrate at this stage, and the complete LCD panel is completed.

Next is the drive IC press. The main function of the drive IC is to output the required voltage to each pixel and control the degree of torsion of the LCD molecules. The drive IC is divided into two types. The source drive IC located in the X-axis is responsible for the input of data. It is characterized by high frequency and has an image function. The gate drive IC located in the Y-axis is responsible for the degree and speed of torsion of LCD molecules, which directly affects the response time of the LCD display. However, there are already many LCD panels that only have driving IC in the X-axis direction, perhaps because the Y-axis drive IC function has been integrated and simplified.

LCD (LC) is a kind of LCD, which has the properties of light transmission and refraction of solid Crystal, as well as the flow property of Liquid. It is because of this property that it will be applied to the display field.

However, LCD does not emit light autonomously, so the display equipment using LCD as the display medium needs to be equipped with another backlight system.

First, a backplate is needed as the carrier of the light source. The common light source for LCD display equipment is CCFL cold cathode backlight, but it has started to switch to an LED backlight, but either one needs a backplate as the carrier.

At the top of the diffusion plate, there will be 3~4 diffuser pieces, constantly uniform light to the whole surface, improve the uniformity of light, which is directly related to the LCD panel display effect. Professional LCD in order to better control the brightness uniformity of the screen, panel procurement, the later backlight control circuit, will make great efforts to ensure the quality of the panel.

MKS TFT 2.4 inch touch screen to control a 3D printer or CNC machine. This high quality touch screen is a controller on its own, because it has own processor onboard and does not rely on the processor of the 3D printer or CNC machine. Due to this the screen features a 2.4 inch full colour touch screen, can be integrated with WIFI upgrade, can read a SD card, can detect power failure with power detection module and filament runout with runout module.

The thin film transistor-liquid crystal display (TFT-LCD) has been used all over the world. Although the manufacture process of TFT-LCD was highly automated, employees are hired to do manual job in module assembly process. The operators may have high risk of musculoskeletal disorders because of the long work hours and the repetitive activities in an unfitted work station. The tools of this study were questionnaire, checklist and to evaluate the work place design. The result shows that the participants reported high musculoskeletal disorder symptoms in shoulder (59.8%), neck (49.5%), wrist (39.5%), and upper back (30.6%). And, to reduce the ergonomic risk factors, revising the height of the work benches, chairs and redesigning the truck to decrease the chance of unsuitable positions were recommended and to reduce other ergonomics hazards and seta good human machine interface and appropriate job design.

The thin film transistor-liquid crystal display (TFT-LCD) has been used all over the world. Although the manufacture process of TFT-LCD was highly automated, employees are hired to do manual job in module assembly process. The operators may have high risk of musculoskeletal disorders because of the long work hours and the repetitive activities in an unfitted work station. The tools of this study were questionnaire, checklist and to evaluate the work place design. The result shows that the participants reported high musculoskeletal disorder symptoms in shoulder (59.8%), neck (49.5%), wrist (39.5%), and upper back (30.6%). And, to reduce the ergonomic risk factors, revising the height of the work benches, chairs and redesigning the truck to decrease the chance of unsuitable positions were recommended and to reduce other ergonomics hazards and seta good human machine interface and appropriate job design.

This research is mainly to explore the treatment capacity for TFT-LCD industrial wastewater recycling by the processes combined with membrane bioreactor (MBR), reverse osmosis (RO) and ozone(O3). The organic wastewater from the TFT-LCD industry was selected as the target. MBR, RO and ozone plants were established for evaluation. An MBR plant consisted of a 2-stage anoxic/aerobic bioreactor and an immersed UF membrane unit was employed. The effluent of MBR was conducted into the RO system then into the ozone system. The RO system consisted of a spiral membrane in the vessel. One bubble column, 75 cm high and diameter 5 cm, were used as the ozonation reactor. On the bottom of ozonation reactor is a porous diffuser for releasing gas, with an aperture of 100 microm (0.1 cm). Over the whole experimental period, the MBR process achieved a satisfactory organic removal. The COD could be removed with an average of over 98.5%. For the TOC item, the average removal efficiency was 97.4%. The stable effluent quality and satisfactory removal performance were ensured by the efficient interception performance of an immersed UF membrane device incorporated with the biological reactor. Moreover, the MBR effluent did not contain any suspended solids and the SDI value was under 3. After the treatment of RO, excellent water quality was found. The water quality of permeate was under 5 mg/I, 2 mg/l and 50 micros/cm for COD, TOC and conductivity respectively. The treated water can be recycled and reused for the cooling tower make-up water or other purposes. After the treatment of ozone, the treated water quality was under 5 mg/l and 0.852 mg/l for COD and TOC respectively. The test results of MBR, MBR/RO and MBR/RO/ozone processes were compared as possible appropriate treatment technologies applied in TFT-LCD industrial wastewater reuse and recycling.

In this study, we employ the following operating conditions: varied pressure (25 kgf/cm(2)), sintering temperature (900-1200 degrees C), sintering time (6h), percentage of thin film transistor liquid crystal display (TFT-LCD) waste glass by weight (0-50%) and temperature rising at a rate of 5 degrees C/min, to fabricate clay tiles. The sintering characteristics of the clay blended with TFT-LCD waste glass tiles are examined to evaluate the feasibility of the reuse of TFT-LCD waste glass. TFT-LCD waste glass contains large amounts of glass. The TCLP leaching concentrations all met the ROC EPAs current regulatory thresholds. The addition of TFT-LCD waste glass to the mixture, increased the apparent weight loss. The incorporation of 50% TFT-LCD waste glass resulted in a significant increase in the porosity ratio of the specimens compared to the porosity ratio of the ceramic tile containing TFT-LCD waste glass. The main constituent in both the clay tile and the clay with TFT-LCD waste glass samples is quartz. Increasing the temperature resulted in an increase in the flexural strength and resistance to abrasion in the tiles. The porosity ratio decreases as shrinkage increases. The relation between the porosity ratio and the hardness of the tiles used in the study is also shown.

The amount of pollutants produced during manufacturing processes of TFT-LCD (thin-film transistor liquid crystal display) substantially increases due to an increasing production of the opto-electronic industry in Taiwan. The total amount of wastewater from TFT-LCD manufacturing plants is expected to exceed 200,000 CMD in the near future. Typically, organic solvents used in TFT-LCD manufacturing processes account for more than 33% of the total TFT-LCD wastewater. The main components of these organic solvents are composed of the stripper (dimethyl sulphoxide (DMSO) and monoethanolamine (MEA)), developer (tetra-methyl ammonium hydroxide (TMAH)) and chelating agents. These compounds are recognized as non-or slow-biodegradable organic compounds and little information is available regarding their biological treatability. In this study, the performance of an A/O SBR (anoxic/oxic sequencing batch reactor) treating synthetic TFT-LCD wastewater was evaluated. The long-term experimental results indicated that the A/O SBR was able to achieve stable and satisfactory removal performance for DMSO, MEA and TMAH at influent concentrations of 430, 800, and 190 mg/L, respectively. The removal efficiencies for all three compounds examined were more than 99%. In addition, batch tests were conducted to study the degradation kinetics of DMSO, MEA, and TMAH under aerobic, anoxic, and anaerobic conditions, respectively. The organic substrate of batch tests conducted included 400 mg/L of DMSO, 250 mg/L of MEA, and 120 mg/L of TMAH. For DMSO, specific DMSO degradation rates under aerobic and anoxic conditions were both lower than 4 mg DMSO/g VSS-hr. Under anaerobic conditions, the specific DMSO degradation rate was estimated to be 14 mg DMSO/g VSS-hr, which was much higher than those obtained under aerobic and anoxic conditions. The optimum specific MEA and TMAH degradation rates were obtained under aerobic conditions with values of 26.5 mg MEA/g VSS-hr and 17.3 mg TMAH/g VSS

In TFT-LCD industry, water plays a variety of roles as a cleaning agent and reaction solvent. As good quality water is increasingly a scarce resource and wastewater treatment costs rises, the once-through use of industrial water is becoming uneconomical and environmentally unacceptable. Instead, recycling of TFT-LCD industrial wastewater is become more attractive from both an economic and environmental perspective. This research is mainly to explore the capacity of TFT-LCD industrial wastewater recycling by the process combined with membrane bioreactor and reverse osmosis processes. Over the whole experimental period, the MBR process achieved a satisfactory organic removal. The COD could be removed with an average of over 97.3%. For TOC and BOD5 items, the average removal efficiencies were 97.8 and 99.4% respectively. The stable effluent quality and satisfactory removal performance were ensured by the efficient interception performance of the UF membrane device incorporated with biological reactor. Moreover, the MBR effluent did not contain any suspended solids and the SDI value was under 3. After treatment of RO, excellent water quality of permeate were under 5 mg/l, 2.5 mg/l and 150 micros/cm for COD, TOC and conductivity respectively. The treated water can be recycled for the cooling tower make-up water or other purposes.

In this study, indium-tin-oxide (ITO) nanoparticles were simply recovered from the thin film transistor-liquid crystal display (TFT-LCD) panel scraps by means of lift-off method. This can be done by dissolving color filter (CF) layer which is located between ITO layer and glass substrate. In this way the ITO layer was easily lifted off the glass substrate of the panel scrap without panel crushing. Over 90% of the ITO on the TFT-LCD panel was recovered by using this method. After separating, the ITO was obtained as particle form and their characteristics were investigated. The recovered product appeared as aggregates of particles less than 100 nm in size. The weight ratio of In/Sn is very close to 91/9. XRD analysis showed that the ITO nanoparticles have well crystallized structures with (222) preferred orientation even after recovery. The method described in this paper could be applied to the industrial recovery business for large size LCD scraps from TV easily without crushing the glass substrate.

In this study, indium-tin-oxide (ITO) nanoparticles were simply recovered from the thin film transistor-liquid crystal display (TFT-LCD) panel scraps by means of lift-off method. This can be done by dissolving color filter (CF) layer which is located between ITO layer and glass substrate. In this way the ITO layer was easily lifted off the glass substrate of the panel scrap without panel crushing. Over 90% of the ITO on the TFT-LCD panel was recovered by using this method. After separating, the ITO was obtained as particle form and their characteristics were investigated. The recovered product appeared as aggregates of particles less than 100 nm in size. The weight ratio of In/Sn is very close to 91/9. XRD analysis showed that the ITO nanoparticles have well crystallized structures with (222) preferred orientation even after recovery. The method described in this paper could be applied to the industrial recovery business for large size LCD scraps from TV easily without crushing the glass substrate. PMID:28788267

The residual stress of the glass substrate might be one of causes to produce the non-uniform light distribution defect, i.e. Mura, in thin film transistor-liquid crystal display (TFT-LCD) panels. Glass is a birefringent material with very low birefringence. Furthermore, the thinner and thinner thickness request from the market makes the traditional photoelasticity almost impossible to measure the residual stresses produced in thin glass plates. Recently, a low-level stress measurement method called transmissivity extremities theory of photoelasticity (TEToP) was successfully developed to measure the residual stress in glass plate. Besides, to measure the stress of the glass plate in the TFT-LCD panel whose rear surface may has different kinds of coatings, an advanced reflection photoelasticity was also developed. In this paper, three commercially available glass plates with 0.33mm nominal thickness and three glass circular disks with different coatings were inspected to verify the feasibility of the TEToP and the advanced reflection photoelasticity, respectively.

Many volatile organic compounds (VOCs) are emitted during the manufacturing of thin film transistor liquid crystal displays (TFT-LCDs), exposure to some of which has been reported to be associated with kidney dysfunction, but whether such an effect exists in TFT-LCD industry workers is unknown. This cross-sectional study aimed to investigate the association between exposure to VOCs and kidney dysfunction among TFT-LCD workers. The results showed that ethanol (1811.0+/-1740.4 ppb), acetone (669.0+/-561.0 ppb), isopropyl alcohol (187.0+/-205.3 ppb) and propylene glycol monomethyl ether acetate (PGMEA) (102.9+/-102.0 ppb) were the four dominant VOCs present in the workplace. The 63 array workers studied had a risk of kidney dysfunction 3.21-fold and 3.84-fold that of 61 cell workers and 18 module workers, respectively. Workers cumulatively exposed to a total level of isopropyl alcohol, PGMEA and propylene glycol monomethyl ether> or =324 ppb-year had a significantly higher risk of kidney dysfunction (adjusted OR=3.41, 95% CI=1.14-10.17) compared with those exposed to <25 ppb-year after adjustment for potential confounding factors. These findings indicated that array workers might be the group at greatest risk of kidney dysfunction within the TFT-LCD industry, and cumulative exposure to specific VOCs might be associated with kidney dysfunction. Crown Copyright 2010. Published by Elsevier B.V. All rights reserved.

Green supply chain has become an important topic these days due to pollution, global warming, extreme climatic events, etc. A green product is manufactured with the goal of reducing the damage to the environment and limiting the use of energy and other resources at any stage of its life, including raw materials, manufacture, use, and disposal. Carbon footprint is a good measure of the impact that a product has on the environment, especially in climate change, in the entire lifetime of the product. Carbon footprint is directly linked to CO2 emission; thus, the reduction of CO2 emission must be considered in the product life cycle. Although more and more researchers are working on the green supply chain management in the past few years, few have incorporated CO2 emission or carbon footprint into the green supply chain system. Therefore, this research aims to propose an integrated model for facilitating the new product development (NPD) for green and low-carbon products. In this research, a systematic model based on quality function deployment (QFD) is constructed for developing green and low-carbon products in a TFT-LCD manufacturer. Literature review and interviews with experts are done first to collect the factors for developing and manufacturing green and low-carbon products. Fuzzy Delphi method (FDM) is applied next to extract the important factors, and fuzzy interpretive structural modeling (FISM) is used subsequently to understand the relationships among factors. A house of quality (HOQ) for product planning is built last. The results shall provide important information for a TFT-LCD firm in designing a new product.

Defect detection has been considered an efficient way to increase the yield rate of panels in thin film transistor liquid crystal display (TFT-LCD) manufacturing. In this study we focus on the array process since it is the first and key process in TFT-LCD manufacturing. Various defects occur in the array process, and some of them could cause great damage to the LCD panels. Thus, how to design a method that can robustly detect defects from the images captured from the surface of LCD panels has become crucial. Previously, support vector data description (SVDD) has been successfully applied to LCD defect detection. However, its generalization performance is limited. In this paper, we propose a novel one-class machine learning method, called quasiconformal kernel SVDD (QK-SVDD) to address this issue. The QK-SVDD can significantly improve generalization performance of the traditional SVDD by introducing the quasiconformal transformation into a predefined kernel. Experimental results, carried out on real LCD images provided by an LCD manufacturer in Taiwan, indicate that the proposed QK-SVDD not only obtains a high defect detection rate of 96%, but also greatly improves generalization performance of SVDD. The improvement has shown to be over 30%. In addition, results also show that the QK-SVDD defect detector is able to accomplish the task of defect detection on an LCD image within 60 ms. PMID:22016625

Defect detection has been considered an efficient way to increase the yield rate of panels in thin film transistor liquid crystal display (TFT-LCD) manufacturing. In this study we focus on the array process since it is the first and key process in TFT-LCD manufacturing. Various defects occur in the array process, and some of them could cause great damage to the LCD panels. Thus, how to design a method that can robustly detect defects from the images captured from the surface of LCD panels has become crucial. Previously, support vector data description (SVDD) has been successfully applied to LCD defect detection. However, its generalization performance is limited. In this paper, we propose a novel one-class machine learning method, called quasiconformal kernel SVDD (QK-SVDD) to address this issue. The QK-SVDD can significantly improve generalization performance of the traditional SVDD by introducing the quasiconformal transformation into a predefined kernel. Experimental results, carried out on real LCD images provided by an LCD manufacturer in Taiwan, indicate that the proposed QK-SVDD not only obtains a high defect detection rate of 96%, but also greatly improves generalization performance of SVDD. The improvement has shown to be over 30%. In addition, results also show that the QK-SVDD defect detector is able to accomplish the task of defect detection on an LCD image within 60 ms.

Participants performed a word-non-word discrimination task within a car control display emulated on a thin film transistor liquid-crystal display (TFT-LCD). The task simulated an information read-out from a TFT-LCD-based instrument panel. Subsequently, participants performed a low-contrast object detection task that simulated the detection of objects during night-time driving. In experiment 1, words/non-words were presented black-on-white (positive polarity) or white-on-black (negative polarity). In experiments 2 and 3, display colour was additionally manipulated. A positive polarity advantage in the discrimination task was consistently observed. In contrast, positive displays interfered more than negative displays with subsequent detection. The detrimental after-effect of positive polarity displays was strong with white and blue, reduced with amber and absent with red displays. Subjective measures showed a preference for blue over red, but a slight advantage for amber over blue. Implications for TFT-LCD design are derived from the results. STATEMENT OF RELEVANCE: When using TFT-LCDs as car instrument panels, positive polarity red TFT-LCDs are very likely to lead to good instrument readability while at the same time minimising - relative to other colours - the negative effects of an illuminated display on low-contrast object detection during night-time driving.

The amount of pollutants produced during manufacturing processes of thin-film transistor liquid crystal display (TFT-LCD) substantially increases due to an increasing production of the opto-electronic industry in Taiwan. This study presents the treatment performance of one aerobic and one anoxic/oxic (A/O) sequencing batch reactors (SBRs) treating synthetic TFT-LCD wastewater containing dimethyl sulfoxide (DMSO), monoethanolamine (MEA), and tetra-methyl ammonium hydroxide (TMAH). The long-term monitoring results for the aerobic and A/O SBRs demonstrate that stable biodegradation of DMSO, MEA, and TMAH can be achieved without any considerably adverse impacts. The ammonium released during MEA and TMAH degradation can also be completely oxidized to nitrate through nitrification in both SBRs. Batch studies on biodegradation rates for DMSO, MEA, and TMAH under anaerobic, anoxic, and aerobic conditions indicate that effective MEA degradation can be easily achieved under all three conditions examined, while efficient DMSO and TMAH degradation can be attained only under anaerobic and aerobic conditions, respectively. The potential odor problem caused by the formation of malodorous dimethyl sulfide from DMSO degradation under anaerobic conditions, however, requires insightful consideration in treating DMSO-containing wastewater. Copyright (c) 2010 Elsevier Ltd. All rights reserved.

An empirical study was carried out to examine the effects of color combination and ambient illumination on visual perception time using TFT-LCD. The effect of color combination was broken down into two subfactors, luminance contrast ratio and chromaticity contrast. Analysis indicated that the luminance contrast ratio and ambient illumination had significant, though small effects on visual perception. Visual perception time was better at high luminance contrast ratio than at low luminance contrast ratio. Visual perception time under normal ambient illumination was better than at other ambient illumination levels, although the stimulus color had a confounding effect on visual perception time. In general, visual perception time was better for the primary colors than the middle-point colors. Based on the results, normal ambient illumination level and high luminance contrast ratio seemed to be the optimal choice for design of workplace with video display terminals TFT-LCD.

In this paper, we propose a novel cascade detection algorithm which focuses on point and line defects on TFT-LCD. At the first step of the algorithm, we use the gray level difference of su-bimage to segment the abnormal area. The second step is based on phase only transform (POT) which corresponds to the Discrete Fourier Transform (DFT), normalized by the magnitude. It can remove regularities like texture and noise. After that, we improve the method of setting regions of interest (ROI) with the method of edge segmentation and polar transformation. The algorithm has outstanding performance in both computation speed and accuracy. It can solve most of the defect detections including dark point, light point, dark line, etc.

The TFT-LCD (thin film transistor liquid crystal display) industry is rapidly growing in Taiwan and many other countries. A large number of workers, mainly women, are employed in the light-on test process to detect the defects of products. At the light-on test workstation, the operator is generally exposed to low humidity (in the clean room environment), flashing light, and low ambient illumination for long working hours. Many workers complained about eye discomfort, and therefore we conducted a study to evaluate the tear secretion function of light-on test workers of a TFT-LCD company. We recruited workers engaged in light-on tests in the company during their periodical health examination. In addition to a questionnaire survey of demographic characteristics and ophthalmic symptoms, we evaluated the tear secretion function of both eyes of each participant using the Schirmer"s lacrimal basal secretion test with anaesthesia. A participant with one or both eyes yielding abnormal test results was defined as a case of tear secretion dysfunction. During the study period, a total of 371 light-on test workers received the health examination at the clinic of the park, and 52 of them were excluded due to having ophthalmic diseases and other systemic diseases that may affect ophthalmic function. All the remaining 319 qualified workers agreed to participate in this study, and they were all females working by 4-shift rotations. The average age was 24.2 years old (standard deviation [SD] = 3.8), and the average employment duration was 13.6 months (SD = 5.7). Among the 11 ophthalmic symptoms evaluated, eye dryness was the most prevalent (prevalence = 43.3%). In addition, the prevalence of tear secretion dysfunction in at least one eye was 40.1% (128 cases), and contact lens users had an odds ratio of 1.73 (95% confidence interval = 1.02-2.94) in comparison with non-contact lens users. Comparing the Schirmer"s test results of those who also participated in the screening in the

Background The TFT-LCD (thin film transistor liquid crystal display) industry is rapidly growing in Taiwan and many other countries. A large number of workers, mainly women, are employed in the light-on test process to detect the defects of products. At the light-on test workstation, the operator is generally exposed to low humidity (in the clean room environment), flashing light, and low ambient illumination for long working hours. Many workers complained about eye discomfort, and therefore we conducted a study to evaluate the tear secretion function of light-on test workers of a TFT-LCD company. Methods We recruited workers engaged in light-on tests in the company during their periodical health examination. In addition to a questionnaire survey of demographic characteristics and ophthalmic symptoms, we evaluated the tear secretion function of both eyes of each participant using the Schirmer"s lacrimal basal secretion test with anaesthesia. A participant with one or both eyes yielding abnormal test results was defined as a case of tear secretion dysfunction. Results During the study period, a total of 371 light-on test workers received the health examination at the clinic of the park, and 52 of them were excluded due to having ophthalmic diseases and other systemic diseases that may affect ophthalmic function. All the remaining 319 qualified workers agreed to participate in this study, and they were all females working by 4-shift rotations. The average age was 24.2 years old (standard deviation [SD] = 3.8), and the average employment duration was 13.6 months (SD = 5.7). Among the 11 ophthalmic symptoms evaluated, eye dryness was the most prevalent (prevalence = 43.3%). In addition, the prevalence of tear secretion dysfunction in at least one eye was 40.1% (128 cases), and contact lens users had an odds ratio of 1.73 (95% confidence interval = 1.02–2.94) in comparison with non-contact lens users. Comparing the Schirmer"s test results of those who also

In this study the anisotropic characteristics of TFT-LCD (Thin-Film-Transistor-Liquid Crystal Display) screens were examined. Anisotropy occurs as the distribution of luminance and contrast changes over the screen surface due to different viewing angles. On the basis of detailed photometric measurements the detection performance in a visual reaction task was measured in different viewing conditions. Viewing angle (0 degrees, frontal view; 30 degrees, off-axis; 50 degrees, off-axis) as well as ambient lighting (a dark or illuminated room) were varied. Reaction times and accuracy of detection performance were recorded. Results showed TFT"s anisotropy to be a crucial factor deteriorating performance. With an increasing viewing angle performance decreased. It is concluded that TFT"s anisotropy is a limiting factor for overall suitability and usefulness of this new display technology.

Standard projection techniques using liquid crystal (LCD) or thin-film transistor (TFT) technology show drastic distortions in luminance and contrast characteristics across the screen and across grey levels. Common luminance measurement and calibration techniques are not applicable in the vicinity of MRI scanners. With the aid of a fibre optic, we measured screen luminances for the full space of screen position and image grey values and on that basis developed a compensation technique that involves both luminance homogenisation and position-dependent gamma correction. By the technique described, images displayed to a subject in functional MRI can be specified with high precision by a matrix of desired luminance values rather than by local grey value.

Only a few studies in the literature have focused on the effects of age on virtual environment (VE) sickness susceptibility and even less research was carried out focusing on the elderly. In general, the elderly usually browse VEs on a thin film transistor liquid crystal display (TFT-LCD) at home or somewhere, not a head-mounted display (HMD). While the TFT-LCD is used to present VEs, this set-up does not physically enclose the user. Therefore, this study investigated the factors that contribute to cybersickness among the elderly when immersed into a VE on TFT-LCD, including exposure durations, navigation rotating speeds and angle of inclination. Participants were elderly, with an average age of 69.5 years. The results of the first experiment showed that the rate of simulator sickness questionnaire (SSQ) scores increases significantly with navigational rotating speed and duration of exposure. However, the experimental data also showed that the rate of SSQ scores does not increase with the increase in angle of inclination. In applying these findings, the neuro-fuzzy technology was used to develop a neuro-fuzzy cybersickness-warning system integrating fuzzy logic reasoning and neural network learning. The contributing factors were navigational rotating speed and duration of exposure. The results of the second experiment showed that the proposed system can efficiently determine the level of cybersickness based on the associated subjective sickness estimates and combat cybersickness due to long exposure to a VE.

This study evaluated TMAH biodegradation under methanogenic conditions. Under methanogenic conditions, a sludge from a full-scale UASB treating TFT-LCD wastewater was able to degrade 2,000 mg/L of TMAH within 10 h and attained a specific degradation rate of 19.2 mgTMAH/gVSS-h. Furthermore, several chemicals including some surfactants, DMSO, and sulfate were examined for their potential inhibitory effects on TMAH biodegradation under methanogenic conditions. The results indicated that surfactant S1 (up to 2%) and DMSO (up to 1,000 mg/L) presented negligible inhibitory effects on TMAH degradation, while surfactant S2 (0.2-1%) might inhibit methanogenic reaction without any TMAH degradation for 3-5 h. At sulfate concentrations higher than 300 mg/L, a complete inhibition of methanogenic reaction and TMAH biodegradation was observed. Results from cloning and sequencing of archaeal 16S rRNA gene fragments showed that Methanosarcina barkeri and Methanosarcina mazei were the dominant methanogens in the UASB treating TMAH-containing TFT-LCD wastewater.

Photocurable and highly condensed fluorinated methacrylate oligosiloxane, with a low dielectric constant (kappa = 2.54), was prepared by a nonhydrolytic sol-gel condensation reaction. The oligosiloxane resin was then spin-coated, photocured, and thermally baked in order to fabricate a fluorinated methacrylate hybrid material (FM hybrimer) thin film. This study investigated the application of this FM hybrimer film as a low-kappa passivation layer in LCD-based thin film transistors (TFT). It was found that a dielectric constant as low as kappa = 2.54 could be obtained, without introducing pores in the dense FM hybrimer films. This study compares FM hybrimer film characteristics with those required for passivation layers in LCD-TFTs, including thermal stability, optical transmittance, hydrophobicity, gap fill, and planarization effects as well as electrical insulation.

The objectives of this study are: (1) to determine the effect of pH, initial concentration of Fe(2+) and H(2)O(2) dosage on the removal efficiency of MEA by fluidized-bed Fenton process and Fenton process, (2) to determine the optimal conditions for the degradation of ethanolamine from TFT-LCD wastewater by fluidized-bed Fenton process. In the design of experiment, the Box-Behnken design was used to optimize the operating conditions. A removal efficiency of 98.9% for 5mM MEA was achieved after 2h under optimal conditions of pH3, [Fe(2+)]=5mM and [H(2)O(2)]=60mM. Copyright © 2011 Elsevier Ltd. All rights reserved.

This study investigated the linkage between performance of two full-scale membrane bioreactor (MBR) systems treating thin-film transistor liquid crystal display (TFT-LCD) wastewater and the population dynamics of dimethylsulfoxide (DMSO)/dimethylsulfide (DMS) degrading bacteria. High DMSO degradation efficiencies were achieved in both MBRs, while the levels of nitrification inhibition due to DMS production from DMSO degradation were different in the two MBRs. The results of real-time PCR targeting on DMSO/DMS degrading populations, including Hyphomicrobium and Thiobacillus spp., indicated that a higher DMSO oxidation efficiency occurred at a higher Hyphomicrobium spp. abundance in the systems, suggesting that Hyphomicrobium spp. may be more important for complete DMSO oxidation to sulfate compared with Thiobacillus spp. Furthermore, Thiobacillus spp. was more abundant during poor nitrification, while Hyphomicrobium spp. was more abundant during good nitrification. It is suggested that microbial population of DMSO/DMS degrading bacteria is closely linking to both DMSO/DMS degradation efficiency and nitrification performance. Copyright © 2013 Elsevier Ltd. All rights reserved.

Defect inspection plays a critical role in thin film transistor liquid crystal display (TFT-LCD) manufacture, and has received much attention in the field of automatic optical inspection (AOI). Previously, most focus was put on the problems of macro-scale Mura-defect detection in cell process, but it has recently been found that the defects which substantially influence the yield rate of LCD panels are actually those in the TFT array process, which is the first process in TFT-LCD manufacturing. Defect inspection in TFT array process is therefore considered a difficult task. This paper presents a novel inspection scheme based on kernel principal component analysis (KPCA) algorithm, which is a nonlinear version of the well-known PCA algorithm. The inspection scheme can not only detect the defects from the images captured from the surface of LCD panels, but also recognize the types of the detected defects automatically. Results, based on real images provided by a LCD manufacturer in Taiwan, indicate that the KPCA-based defect inspection scheme is able to achieve a defect detection rate of over 99% and a high defect classification rate of over 96% when the imbalanced support vector machine (ISVM) with 2-norm soft margin is employed as the classifier. More importantly, the inspection time is less than 1 s per input image. PMID:20057957

Defect inspection plays a critical role in thin film transistor liquid crystal display (TFT-LCD) manufacture, and has received much attention in the field of automatic optical inspection (AOI). Previously, most focus was put on the problems of macro-scale Mura-defect detection in cell process, but it has recently been found that the defects which substantially influence the yield rate of LCD panels are actually those in the TFT array process, which is the first process in TFT-LCD manufacturing. Defect inspection in TFT array process is therefore considered a difficult task. This paper presents a novel inspection scheme based on kernel principal component analysis (KPCA) algorithm, which is a nonlinear version of the well-known PCA algorithm. The inspection scheme can not only detect the defects from the images captured from the surface of LCD panels, but also recognize the types of the detected defects automatically. Results, based on real images provided by a LCD manufacturer in Taiwan, indicate that the KPCA-based defect inspection scheme is able to achieve a defect detection rate of over 99% and a high defect classification rate of over 96% when the imbalanced support vector machine (ISVM) with 2-norm soft margin is employed as the classifier. More importantly, the inspection time is less than 1 s per input image.

This investigation studies the electro-regeneration of Ce(IV) from Ce(III) in 4 M HNO(3) in the presence/absence of NH(4)(+) and real spent thin-film transistor liquid-crystal display (TFT-LCD) Cr-etching solutions. On Pt, at 2 A and 70 °C for 100 min, the Ce(IV) yield and apparent rate constant of Ce(III) oxidation in 4 M HNO(3) without NH(4)(+) were 100% and 5.54 × 10(-4) s(-1), respectively (and the activation energy was 13.1 kJ mol(-1)). Cyclic voltammetric and electrolytic measurements consistently support the noticeable inhibition by NH(4)(+) of Ce(III) oxidation and lowering of the Ce(IV) yield, respectively. The apparent diffusion coefficients for 0.2 and 0.02 M Ce(III) oxidation in 4 M HNO(3) that contained 0-0.6 M NH(4)(+) were (0.38-0.25) × 10(-5) and (1.6-0.9) × 10(-5) cm(2) s(-1), respectively. Because of combined effects of NH(4)(+) and anion impurities, the 100 min Ce(IV) yield of a real spent TFT-LCD Cr-etching solution (with [NH(4)(+)]/[Ce(III)] = 0.74 M/0.39 M) was 82%, lower than that of 4 M HNO(3) without NH(4)(+), but higher than those of 4 M HNO(3) that contained anion impurities with/without 0.4 M NH(4)(+). Copyright © 2012 Elsevier Ltd. All rights reserved.

This study evaluated biological treatment of TMAH in a full-scale methanogenic up-flow anaerobic sludge blanket (UASB) followed by an aerobic bioreactor. In general, the UASB was able to perform a satisfactory TMAH degradation efficiency, but the effluent COD of the aerobic bioreactor seemed to increase with an increased TMAH in the influent wastewater. The batch test results confirmed that the UASB sludge under methanogenic conditions would be favored over the aerobic ones for TMAH treatment due to its superb ability of handling high strength of TMAH-containing wastewaters. Based on batch experiments, inhibitory chemicals present in TFT-LCD wastewater like surfactants and sulfate should be avoided to secure a stable methanogenic TMAH degradation. Finally, molecular monitoring of Methanomethylovorans hollandica and Methanosarcina mazei in the full-scale plant, the dominant methanogens in the UASB responsible for TMAH degradation, may be beneficial for a stable TMAH treatment performance. Copyright © 2012 Elsevier Ltd. All rights reserved.

To overcome the technological and economic obstacles of amorphous indium-gallium-zinc-oxide (a-IGZO)-based display backplane for industrial production, a clean etch-stopper (CL-ES) process is developed to fabricate a-IGZO-based thin film transistor (TFT) with improved uniformity and reproducibility on 8.5th generation glass substrates (2200 mm × 2500 mm). Compared with a-IGZO-based TFT with back-channel-etched (BCE) structure, a newly formed ES nano-layer ( 100 nm) and a simultaneous etching of a-IGZO nano-layer (30 nm) and source-drain electrode layer are firstly introduced to a-IGZO-based TFT device with CL-ES structure to improve the uniformity and stability of device for large-area display. The saturation electron mobility of 8.05 cm2/V s and the V th uniformity of 0.72 V are realized on the a-IGZO-based TFT device with CL-ES structure. In the negative bias temperature illumination stress and positive bias thermal stress reliability testing under a ± 30 V bias for 3600 s, the measured V th shift of CL-ES-structured device significantly decreased to - 0.51 and + 1.94 V, which are much lower than that of BCE-structured device (- 3.88 V, + 5.58 V). The electrical performance of the a-IGZO-based TFT device with CL-ES structure implies that the economic transfer from a silicon-based TFT process to the metal oxide semiconductor-based process for LCD fabrication is highly feasible.

In this study, we attempted to enhance the removal efficiency of a honeycomb zeolite rotor concentrator (HZRC), operated at optimal parameters, for processing TFT-LCD volatile organic compounds (VOCs) with competitive adsorption characteristics. The results indicated that when the HZRC processed a VOCs stream of mixed compounds, compounds with a high boiling point take precedence in the adsorption process. In addition, existing compounds with a low boiling point adsorbed onto the HZRC were also displaced by the high-boiling-point compounds. In order to achieve optimal operating parameters for high VOCs removal efficiency, results suggested controlling the inlet velocity to <1.5m/s, reducing the concentration ratio to 8 times, increasing the desorption temperature to 200-225 degrees C, and setting the rotation speed to 6.5rpm.

In the automatic disassembly line of waste LCD displays, LCD displays are disassembled into plastic shells, metal shields, circuit boards, and LCD panels. Two industrial robots are used to cut metal shields and remove circuit boards in this automatic disassembly line. The functions of these two industrial robots, and the solutions to the critical issues of model selection, the interfaces with PLCs and the workflows were described in detail in this paper.

UV lamp systems have been used for cleaning of display panels of TFT LCD or Plasma Display Panel (PDP). However, the needs for high efficient cleaning and low cost made high voltage plasma cleaning techniques to be developed and to be improved. Dielectric-barrier discharges (DBDs), also referred to as barrier discharges or silent discharges have for a long time been exclusively related to ozone generation. In this paper, a 6kW high voltage plasma power supply system was developed for LCD cleaning. The -phase input voltage is rectified and then inverter system is used to make a high frequency pulse train, which is rectified after passing through a high-power transformer. Finally, bi-directional high voltage pulse switching circuits are used to generate the high voltage plasma. Some experimental results showed the usefulness of atmospheric plasma for LCD panel cleaning.

To overcome the technological and economic obstacles of amorphous indium-gallium-zinc-oxide (a-IGZO)-based display backplane for industrial production, a clean etch-stopper (CL-ES) process is developed to fabricate a-IGZO-based thin film transistor (TFT) with improved uniformity and reproducibility on 8.5th generation glass substrates (2200 mm × 2500 mm). Compared with a-IGZO-based TFT with back-channel-etched (BCE) structure, a newly formed ES nano-layer (~ 100 nm) and a simultaneous etching of a-IGZO nano-layer (30 nm) and source-drain electrode layer are firstly introduced to a-IGZO-based TFT device with CL-ES structure to improve the uniformity and stability of device for large-area display. The saturation electron mobility of 8.05 cm 2 /V s and the V th uniformity of 0.72 V are realized on the a-IGZO-based TFT device with CL-ES structure. In the negative bias temperature illumination stress and positive bias thermal stress reliability testing under a ± 30 V bias for 3600 s, the measured V th shift of CL-ES-structured device significantly decreased to - 0.51 and + 1.94 V, which are much lower than that of BCE-structured device (- 3.88 V, + 5.58 V). The electrical performance of the a-IGZO-based TFT device with CL-ES structure implies that the economic transfer from a silicon-based TFT process to the metal oxide semiconductor-based process for LCD fabrication is highly feasible.

This study investigated nitrification performance and nitrifying community in one full-scale membrane bioreactor (MBR) treating TFT-LCD wastewater. For the A/O MBR system treating monoethanolamine (MEA) and dimethyl sulfoxide (DMSO), no nitrification was observed, due presumably to high organic loading, high colloidal COD, low DO, and low hydraulic retention time (HRT) conditions. By including additional A/O or O/A tanks, the A/O/A/O MBR and the O/A/O MBR were able to perform successful nitrification. The real-time PCR results for quantification of nitrifying populations showed a high correlation to nitrification performance, and can be a good indicator of stable nitrification. Terminal restriction fragment length polymorphism (T-RFLP) results of functional gene, amoA, suggest that Nitrosomonas oligotropha-like AOB seemed to be important to a good nitrification in the MBR system. In the MBR system, Nitrobacter- and Nitrospira-like NOB were both abundant, but the low nitrite environment is likely to promote the growth of Nitrospira-like NOB. Copyright © 2012 Elsevier Ltd. All rights reserved.

There are several electrophysiological systems available commercially. Usually, control groups are required to compare their results, due to the differences between display types. Our aim was to examine the differences between CRT and LCD/TFT stimulators used in pattern VEP responses performed according to the ISCEV standards. We also aimed to check different contrast values toward thresholds. In order to obtain more precise results, we intended to measure the intensity and temporal response characteristics of the monitors with photometric methods. To record VEP signals, a Roland RetiPort electrophysiological system was used. The pattern VEP tests were carried out according to ISCEV protocols on a CRT and a TFT monitor consecutively. Achromatic checkerboard pattern was used at three different contrast levels (maximal, 75, 25%) using 1° and 15" check sizes. Both CRT and TFT displays were luminance and contrast matched, according to the gamma functions based on measurements at several DAC values. Monitor-specific luminance parameters were measured by means of spectroradiometric instruments. Temporal differences between the displays" electronic and radiometric signals were measured with a device specifically built for the purpose. We tested six healthy control subjects with visual acuity of at least 20/20. The tests were performed on each subject three times on different days. We found significant temporal differences between the CRT and the LCD monitors at all contrast levels and spatial frequencies. In average, the latency times were 9.0 ms (±3.3 ms) longer with the TFT stimulator. This value is in accordance with the average of the measured TFT input-output temporal difference values (10.1 ± 2.2 ms). According to our findings, measuring the temporal parameters of the TFT monitor with an adequately calibrated measurement setup and correcting the VEP data with the resulting values, the VEP signals obtained with different display types can be transformed to be

Gate oxynitride structures of TFT-LCDs were investigated by SIMS, and successful solutions are demonstrated to overcome difficulties arising due to the charging effects of the multilayer systems, the matrix effect of the method, and the small pattern sizes of the samples. Because of the excellent reproducibility achieved by applying exponential relative sensitivity functions for quantitative analysis, minor differences in the barrier gate-oxynitride composition deposited on molybdenum capped aluminium-neodymium metallisation electrodes were determined between the centre and the edge of the TFT-LCD substrates. No differences were found for molybdenum-tungsten metallisations. Furthermore, at the edge of the glass substrates, aluminium, neodymium, and molybdenum SIMS depth profiles show an exponential trend. With TEM micrographs an inhomogeneous thickness of the molybdenum capping is revealed as the source of this effect, which influences the electrical behaviour of the device. The production process was improved after these results and the aging behaviour of TFT-LCDs was investigated in order to explain the change in control voltage occurring during the lifetime of the displays. SIMS and TEM show an enrichment of neodymium at the interface to the molybdenum layer, confirming good diffusion protection of the molybdenum barrier during accelerated aging. The reason for the shift of the control voltage was finally located by semi-quantitative depth profiling of the sodium diffusion originating from the glass substrate. Molybdenum-tungsten was a much better buffer for the highly-mobile charge carriers than aluminium-neodymium. Best results were achieved with PVD silicon oxynitride as diffusion barrier and gate insulator deposited on aluminium-neodymium metallisation layers.

Recent progresses in the photoresists and photolithography for LCD industry applications have been primarily driven by the following two factors: advancement in the material performances (high resolution, high contrast ratio, low dielectric constant) for higher display quality, and cost reduction in the fabrication process. Along with crucial demand for cost competitiveness by improving production efficiency, environmental consciousness has been a major priority at fabrication process design to minimize the amount of waste produced. Having said the above, integration of two or more fabrication processes into a single process by using multi-tone mask technology has been the interest of research, due to its obvious advantage of reducing fabrication processes and cost. For example, multi-tone mask technology application has been widely employed on the TFT side to reduce the different types of photomasks being used. Similar trend has been employed on the CF side as well, where application of multi-tone mask technology is being investigated to integrate fabrication of multiple CF micro-components into a single process. In this presentation, we demonstrate a new approach of fabricating photospacer and peripheral CF components (MVA protrusion, sub-photospacers) in a single integrated process through multi-tone mask technology.

Performance and relating subject for fine patterned Si TFT (Thin Film Transistor) are reviewed and discussed from a viewpoint of device and/or fabrication process based on reported results. Poly-Si TFTs fabricated on glass using low-temperature process are studied extensively for the application to LCD (Liquid Crystal Display) or OLED (Organic Light Emitting Diode) Display. Currently, the research target for the TFT application is emphasized on the highly functional system on glass or the display on flexible substrate by adopting an effective crystallizing technique of SPC (Solid Phase Crystallization) or ELC (Excimer Laser Crystallization). Improvement of device characteristics such as an enhancement of carrier mobility has been studied intensively by enlarging the grain size. Reduction of the voltage and shrinkage of the device size are the trend of Si LSI, which arise a peculiar issue of uniformity or an anisotropy problem for the device characteristics in the large grained poly-Si film. Some trial approaches for solving the issues such as nucleation control for the grain growth or lateral grain growth are proposed, so far. By overcoming the issues, coming SOP (System on Panel) era using the Si TFTs is expected.

Stereoscopic display technologies have been developed as one of advanced displays, and many TV industrials have been trying commercialization of 3D TV. We have been developing 3D TV based on LCD with LED BLU (backlight unit) since Samsung launched the world"s first 3D TV based on PDP. However, the data scanning of panel and LC"s response characteristics of LCD TV cause interference among frames (that is crosstalk), and this makes 3D video quality worse. We propose the method to reduce crosstalk by LCD driving and backlight control of FHD 3D LCD TV.

An LC-projector usually contains 3 monochrome TFT-LCDs with a 3-channel dichroic system or a single TFT-LCD with a micro color filter. The liquid crystal operation mode adopted in a TFT-LCD is TN. The optical throughput of an LC-projector is reduced by a pair of polarizers, an aperture ratio of a TFT- LCD and a color filter in a single-LCD projector. In order to eliminate absorption loss by a color filter, a single LCD projection system which consists of a monochrome LCD with a microlens array and a color splitting system using tilted dichroic mirrors or another optical element such as a holographic optical element or a blazed grating has been developed. And LC rear projection TVs have started to challenge CRT-based rear projection TVs. In addition to this system, new technologies to improve optical throughput have been developed to the practical stage such as an active- matrix-addressed PDLC and a reflective type LCD on a Si-LSI chip. Merits and technical issues of newly developed systems and conventional systems including a-Si TFT-LCDs and p-Si TFT-LCDs are discussed mainly in terms of optical throughput.

Piezo drop-on-demand inkjet printing technology has attracted the attention of display industries for the production of colour filters for thin film transistor liquid crystal displays (TFT LCD) because of the opportunity of reducing manufacturing cost. Colourant ink droplets ejected from inkjet nozzles selectively fill subpixels surrounded with black matrix (BM). Surface energy differences between the glass substrate and the BM generally guide this ink filling process. This colourant ink filling process, however, results from the complex hydrodynamic interaction of ink with the substrate and the BM. Neither computationally expensive numerical methods nor time and cost expensive experiments are suitable for the derivation of optimum surface conditions at the early development stage. In this study, a more concise surface evolution technique is proposed and ways to find the optimum surface conditions for the fabrication of TFT LCD colour filters and polymer light emitting devices are discussed, which might be useful for chemists and developers of ink and BM material, as well as for process engineers in display industries.

Flexible displays fabricated using plastic substrates have a potential for being very thin, light weight, highly rugged with greatly minimized propensity for breakage, roll-to-roll manufacturing and lower cost. The emerging OLED display media offers the advantage of being a solid state and rugged structure for flexible displays in addition to the many potential advantages of an AM OLED over the currently dominant AM LCD. The current high level of interest in flexible displays is facilitating the development of the required enabling technologies which include development of plastic substrates, low temperature active matrix device and backplane fabrication, and display packaging. In the following we will first discuss our development efforts in the PEN based plastic substrates, active matrix backplane technology, low temperature (150°C) a-Si TFT devices and an AM OLED test chip used for evaluating various candidate designs. We will then describe the design, fabrication and successful evaluation and demonstration of a 64x64 pixel AM OLED test display using a-Si TFT backplane fabricated at 150°C on the flexible plastic substrate.

International Display Consortium (IDC) is the joining together of display companies to combined their buying power and obtained favorable terms with a major LCD manufacturer. Consolidating the buying power and grouping the demand enables the rugged display industry of avionics, ground vehicles, and ship based display manufacturers to have unencumbered access to high performance AMLCDs while greatly reducing risk and lowering cost. With an unrestricted supply of AMLCD displays, the consortium members have total control of their risk, cost, deliveries and added value partners. Every display manufacturer desires a very close relationship with a display vender. With IDC each consortium member achieves a close relationship. Consortium members enjoy cost effective access to high performance, industry standard sized LCD panels, and modified commercial displays with 100 degree C clearing points and portrait configurations. Consortium members also enjoy proposal support, technical support and long-term support.

Burkholderia cepacia AC1100 uses the chlorinated aromatic compound 2,4,5-trichlorophenoxyacetic acid (2,4,5-T) as a sole source of carbon and energy. The enzyme which converts the first intermediate in the pathway, 2,4,5-trichlorophenol, to 5-chlorohydroquinone has been purified and consists of two subunits of 58 and 22 kDa, encoded by the tftC and tftD genes (48). A degenerate primer was designed from the N terminus of the 58-kDa polypeptide and used to isolate a clone containing the tftC and tftD genes from a genomic library of AC1100. The derived amino acid sequences of tftC

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey