lcd panel backlighting quotation

Liquid crystal display (LCD) is a flat panel display that uses the light modulating properties of liquid crystals. Liquid crystals do not produce light directly, instead using a backlight or reflector to produce images in colour or monochrome.

LED backlighting is the most commonly used backlight for small, LCD panels. Light-emitting diodes, or LEDs, are practical components for a light source because of their small size. LED backlighting is popular due to its overall low cost, long life, variety of colors and high brightness.

LED backlights are housed in a light box that has a diffuser to evenly distribute the LED light. The light box is then mounted behind the LCD’s viewing area. The LED backlight comes in two configurations: array and edge lit. The array configuration has the LEDs mounted in a uniform, grid layout within the light box. This configuration gives off a very bright, even light. The disadvantage of an array configuration is that it requires a thick light box design to accommodate the number of LEDs required. The high number of LEDs in this configuration also means it consumes more power.

Another type of backlight options is the use of fiber optic technology. Fiber optic backlights use sheets of fiber optic woven cloth and are bundled by a ferrule (metal cap) to an LED or halogen light source. Advantages for the fiber optic technology includes low voltage, low power, and a very uniform brightness. This type of backlighting is ideal for custom display shapes or sizes however it is priced at a higher cost compared to other technologies available.

A third type of backlight option available uses an electroluminescent (EL) panel. The EL backlight is constructed of a series of different material layers that work together to create the light. The EL panel generates light when an electric current (AC power) is applied to its conductive surfaces. The advantage with EL backlighting is its low power consumption, no heat emission, and overall thin composition. EL backlighting is limiting in that it requires an invertor to generate the VAC needed to emit the light.

The last common backlight option available are cold cathode fluorescent lamps (CCFLs). CCFL backlights are a cost effective option typically found in graphic displays. The CCFL backlight for LCDs is usually configured with the lamp on the edge of a diffuser to distribute the light. An inverter is required to supply the voltage required by the fluorescent lamp. CCFLs offer a bright white light with low power consumption. This backlight option is not ideal for cold-temperature applications (less than 15°C) as the light output decreases with decreased ambient temperature.

There are many different backlight options available for your LCD. The most common types are LED, fiber optic, EL, and CCFL backlights. Cost and application of your product will have the highest influences on which backlight technology is best for your LCD.

You can get custom made lcd backlight with an operation range that suits your specific application, choosing from a wide selection of suppliers. Source wholesale custom made lcd backlight on Alibaba.com for your business and enjoy a wide variety and great deals.

custom made lcd backlight (Liquid crystal display) are made of liquid crystals that form digital images made visible through ambient light or through LED backlight. LCDs are used in the place of other displays that are less efficient such as cathode ray tubes (CRTs) and have become the most popular display type on the market.

custom made lcd backlight enable metal and position detection without having to physically contact the metal object. They offer a wide range of applications in robotics, rail, material handling, aerospace, military, as well as heavy machinery. Choose from different custom made lcd backlight types, from the shielded versions that have electromagnetic fields concatenated in the front and unshieldated versions that allow wider sensing distances. Whether you want to use your sensors for industrial purposes or source for your brand, there is a wide selection of wholesale custom made ledcd backlights to choose from that will suit different applications.

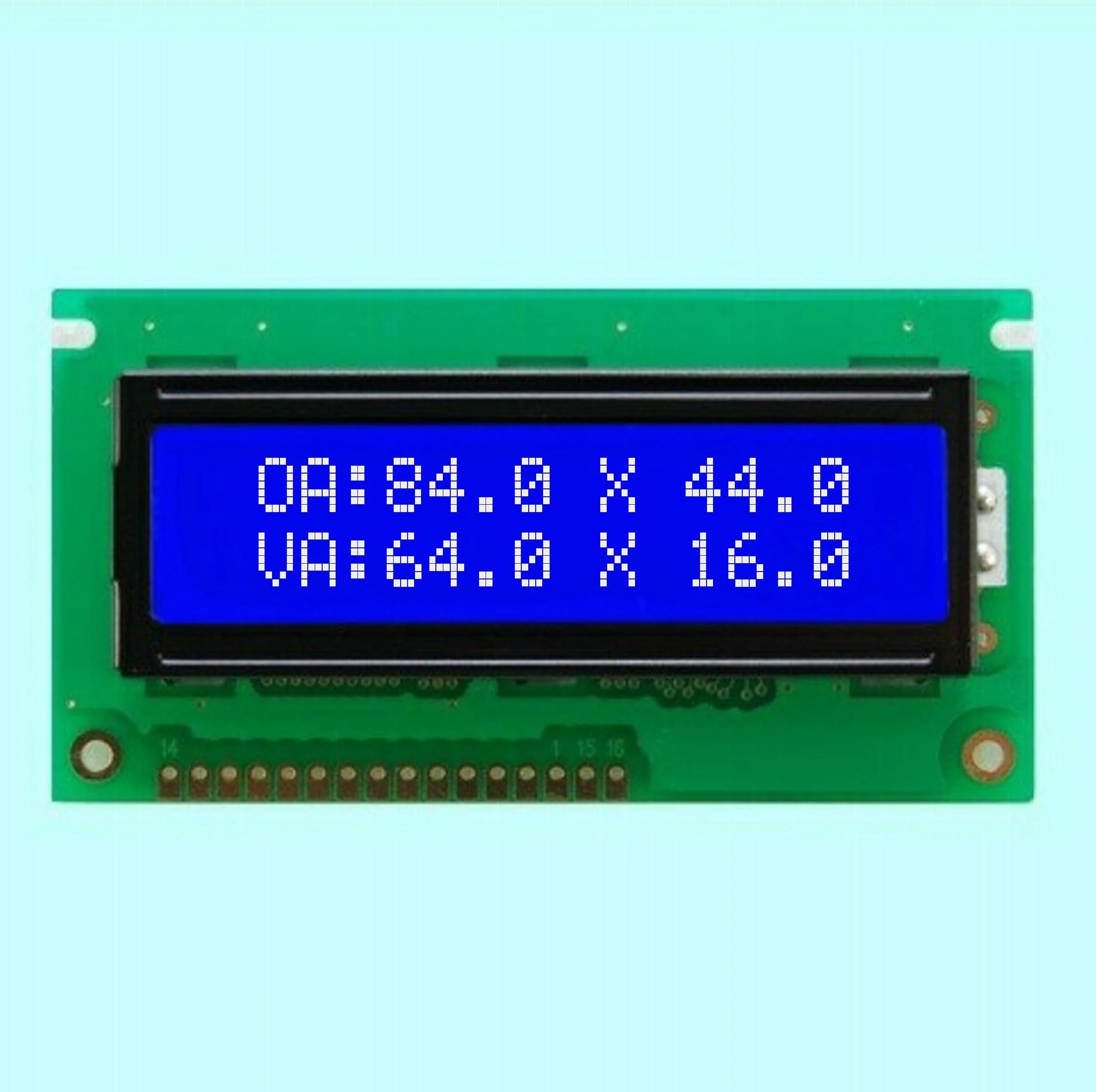

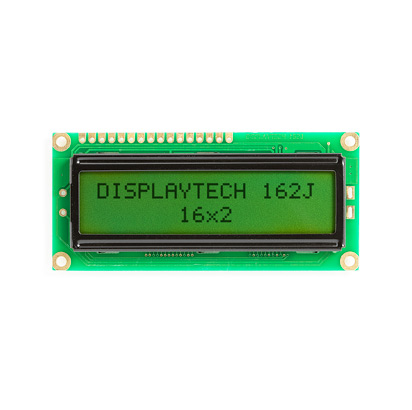

We offer character LCDs and graphic LCDs as modules or COG (Chip On Glass) displays in a wide array of character and pixel configuration sizes. From yellow/green, red, orange, green, blue, amber, white, and RGB backlight colors to displays without a backlight, we have the perfect LCD for your application.

LCD Panel are used for TV,Personal Computer, Mobile Phone, Degital Camera etc widely. LCD Panel can not emit light by itself. To emit light, it need the backlight(light source) on the back of LCD Panel. Minebea develops and manufactures the parts used for backlight and backlight using LED light source,for Mobile phone, PC application.

Broken LCD, or flickering display, or a dull dark display, we have the solution. We can repair or replace the LCD. Backlight or display card problem we have solution for all.

Liquid crystal display (LCD) is a form of electronic visual display that leverages the light-modulating power of liquid crystals. When the crystals are illuminated, it creates the colored pixel we see on televisions, computer monitors, tablets, smartphones and other LCD-based displays. In order for the liquid crystals to receive this illumination, however, the device must use some type of backlight technology.

Cold Cathode Fluorescent Lamps (CCFL) — one of the most common types of LCD backlights, CCFL involves the use of either two cold cathode fluorescent lamps, each of which is placed at the edge of the display, or parallel rows of cold cathode fluorescent lamps resting behind a larger display. The key benefit of CCFL is that it produces an even, all-white spectral output, creating higher quality colors. The downside to CCFL, however, is that it’s less energy-efficient than standard light-emitting diodes (LED), and converters tend to cost more for it.

EL-WLED — this type of LCD backlight is characterized by the use of one or more rows of LEDs, usually placed at the edge of the screen. EL-WLED features a light diffuser to spread the light across the display, resulting in a smooth, even brightness. In 2012, it became the de-facto standard for computer monitor backlights, due largely in part to its minimal use of hardware (note: this allows for thin monitors and displays). Depending on the particular display, some units with EL-WLED boast dynamic contrast, which allows the backlight to be dimmed to the display’s brightest color. Subsequently, this triggers some impressive contrast ratios, such as the scaling of a 1000:1 contrast ratio to a 30000:1 ratio.

WLED –with WLED, the rear panel of the LCD display is lit with a vast array of white-colored LEDs, all of which are placed behind a diffuser. one of the benefits of WLED is its ability to dim the brightness of the LED in certain areas. Much like EL-WLED, this boosts the contrast ratio of the display. WLED backlights are commonly use in big-screen LCD TVs and select computer monitors.

RGB LED — a fourth type of backlight display use in LCDs is RGB LED. This technology is similar to WLED but with one major defining characteristic: it uses an array of red-green-blue (RGB) LEDs instead white LEDs. This results in higher color gamuts and better overall picture quality than its counterpart.

An LED-backlit LCD is a liquid-crystal display that uses LEDs for backlighting instead of traditional cold cathode fluorescent (CCFL) backlighting.TFT LCD (thin-film-transistor liquid-crystal display) technologies as CCFL-backlit LCDs, but offer a variety of advantages over them.

While not an LED display, a television using such a combination of an LED backlight with an LCD panel is advertised as an LED TV by some manufacturers and suppliers.

The local dimming method of backlighting allows to dynamically control the level of light intensity of specific areas of darkness on the screen, resulting in much higher dynamic-contrast ratios, though at the cost of less detail in small, bright objects on a dark background, such as star fields or shadow details.

A 2016 study by the University of California (Berkeley) suggests that the subjectively perceived visual enhancement with common contrast source material levels off at about 60 LCD local dimming zones.

LED-backlit LCDs are not self-illuminating (unlike pure-LED systems). There are several methods of backlighting an LCD panel using LEDs, including the use of either white or RGB (Red, Green, and Blue) LED arrays behind the panel and edge-LED lighting (which uses white LEDs around the inside frame of the TV and a light-diffusion panel to spread the light evenly behind the LCD panel). Variations in LED backlighting offer different benefits. The first commercial full-array LED-backlit LCD TV was the Sony Qualia 005 (introduced in 2004), which used RGB LED arrays to produce a color gamut about twice that of a conventional CCFL LCD television. This was possible because red, green and blue LEDs have sharp spectral peaks which (combined with the LCD panel filters) result in significantly less bleed-through to adjacent color channels. Unwanted bleed-through channels do not "whiten" the desired color as much, resulting in a larger gamut. RGB LED technology continues to be used on Sony BRAVIA LCD models. LED backlighting using white LEDs produces a broader spectrum source feeding the individual LCD panel filters (similar to CCFL sources), resulting in a more limited display gamut than RGB LEDs at lower cost.

A first dynamic "local dimming" LED backlight was public demonstrated by BrightSide Technologies in 2003,Sony in September 2008 on the 40-inch (1,000 mm) BRAVIA KLV-40ZX1M (known as the ZX1 in Europe). Edge-LED lighting for LCDs allows thinner housing; the Sony BRAVIA KLV-40ZX1M is 1 cm thick, and others are also extremely thin.

LED-backlit LCDs have longer life and better energy efficiency than plasma and CCFL LCD TVs.mercury, an environmental pollutant, in their manufacture. However, other elements (such as gallium and arsenic) are used in the manufacture of the LED emitters; there is debate over whether they are a better long-term solution to the problem of screen disposal.

Quantum dots are photoluminescent; they are useful in displays because they emit light in specific, narrow normal distributions of wavelengths. To generate white light best suited as an LCD backlight, parts of the light of a blue-emitting LED are transformed by quantum dots into small-bandwidth green and red light such that the combined white light allows a nearly ideal color gamut to be generated by the RGB color filters of the LCD panel. In addition, efficiency is improved, as intermediate colors are no longer present and do not have to be filtered out by the color filters of the LCD screen. This can result in a display that more accurately renders colors in the visible spectrum. Companies developing quantum dot solutions for displays include Nanosys, 3M as a licensee of Nanosys, QD Vision of Lexington, Massachusetts, US and Avantama of Switzerland.Consumer Electronics Show 2015.quantum dot displays at CES 2017 and later formed the "QLED Alliance" with Hisense and TCL to market the technology.

Mini LED displays are LED-backlit LCDs with mini-LED–based backlighting supporting over a thousand full array local dimming (FALD) zones, providing deeper blacks and a higher contrast ratio.

Novitsky, Tom; Abbott, Bill (12 November 2007). "Driving LEDs versus CCFLs for LCD backlighting". EE Times. Archived from the original on 28 November 2010. Retrieved 21 November 2020.

LCD Television Power Draw Trends from 2003 to 2015; B. Urban and K. Roth; Fraunhofer USA Center for Sustainable Energy Systems; Final Report to the Consumer Technology Association; May 2017; http://www.cta.tech/cta/media/policyImages/policyPDFs/Fraunhofer-LCD-TV-Power-Draw-Trends-FINAL.pdf Archived 1 August 2017 at the Wayback Machine

![]()

This article is about backlights in liquid crystal displays. For the rear window of an automobile, see Car glass. For the lighting design practice, see Backlighting (lighting design). For other uses, see Backlight (disambiguation).

A backlight is a form of illumination used in liquid crystal displays (LCDs). As LCDs do not produce light by themselves—unlike, for example, cathode ray tube (CRT), plasma (PDP) or OLED displays—they need illumination (ambient light or a special light source) to produce a visible image. Backlights illuminate the LCD from the side or back of the display panel, unlike frontlights, which are placed in front of the LCD. Backlights are used in small displays to increase readability in low light conditions such as in wristwatches,smart phones, computer displays and LCD televisions to produce light in a manner similar to a CRT display. A review of some early backlighting schemes for LCDs is given in a report Engineering and Technology History by Peter J. Wild.

Simple types of LCDs such as in pocket calculators are built without an internal light source, requiring external light sources to convey the display image to the user. Most LCD screens, however, are built with an internal light source. Such screens consist of several layers. The backlight is usually the first layer from the back. Light valves then vary the amount of light reaching the eye, by blocking its passage in some way. Most use a fixed polarizing filter and a switching one, to block the undesired light.

Backlights come in many colors. Monochrome LCDs typically have yellow, green, blue, or white backlights, while color displays use white backlights that cover most of the color spectrum.

Colored LED backlighting is most commonly used in small, inexpensive LCD panels. White LED backlighting is becoming dominant. ELP backlighting is often used for larger displays or when even backlighting is important; it can also be either colored or white. An ELP must be driven by relatively highAC power, which is provided by an inverter circuit. CCFL backlights are used on larger displays such as computer monitors, and are typically white in color; these also require the use of an inverter and diffuser. Incandescent backlighting was used by early LCD panels to achieve high brightness, but the limited life and excess heat produced by incandescent bulbs were severe limitations. The heat generated by incandescent bulbs typically requires the bulbs to be mounted away from the display to prevent damage.

For several years (until about 2010), the preferred backlight for matrix-addressed large LCD panels such as in monitors and TVs was based on a cold-cathode fluorescent lamp (CCFL) by using two CCFLs at opposite edges of the LCD or by an array of CCFLs behind the LCD (see picture of an array with 18 CCFLs for a 40-inch LCD TV). Due to the disadvantages in comparison with LED illumination (higher voltage and power needed, thicker panel design, no high-speed switching, faster aging), LED backlighting is becoming more popular.

LED backlighting in color screens comes in two varieties: white LED backlights and RGB LED backlights.blue LED with broad spectrum yellow phosphor to result in the emission of white light. However, because the spectral curve peaks at yellow, it is a poor match to the transmission peaks of the red and green color filters of the LCD. This causes the red and green primaries to shift toward yellow, reducing the color gamut of the display.a red, a blue, and a green LED and can be controlled to produce different color temperatures of white. RGB LEDs for backlighting are found in high end color proofing displays such as the HP DreamColor LP2480zx monitor or selected HP EliteBook notebooks, as well as more recent consumer-grade displays such as Dell"s Studio series laptops which have an optional RGB LED display.

RGB LEDs can deliver an enormous color gamut to screens.additive color) the backlight can produce a color spectrum that closely matches the color filters in the LCD pixels themselves. In this way, the filter passband can be narrowed so that each color component lets only a very narrow band of spectrum through the LCD. This improves the efficiency of the display since less light is blocked when white is displayed. Also, the actual red, green, and blue points can be moved farther out so that the display is capable of reproducing more vivid colors.

A newNanosys, claims that the color output of the dots can be tuned precisely by controlling the size of the nanocrystals. Other companies pursuing this method are Nanoco Group PLC (UK), QD Vision, 3M a licensee of Nanosys and Avantama of Switzerland.Sony has adapted Quantum Dot technology from the US company QD Visionedge-lit LED backlight marketed under the term Triluminos in 2013. With a blue LED and optimized nanocrystals for green and red colors in front of it, the resulting combined white light allows for an equivalent or better color gamut than that emitted by a more expensive set of three RGB LEDs. At the Consumer Electronics Show 2015, Samsung Electronics, LG Electronics, the Chinese TCL Corporation and Sony showed QD-enhanced LED-backlighting of LCD TVs.

CCFL backlighting has also improved in this respect. Many LCD models, from cheap TN-displays to color proofing S-IPS or S-PVA panels, have wide gamut CCFLs representing more than 95% of the NTSC color specification.

The use of LED backlights in notebook computers has been growing. Sony has used LED backlights in some of its higher-end slim VAIO notebooks since 2005, and Fujitsu introduced notebooks with LED backlights in 2006. In 2007, Asus, Dell, and Apple introduced LED backlights into some of their notebook models. As of 2008Lenovo has also announced LED-backlit notebooks. In October 2008, Apple announced that it would be using LED backlights for all of its notebooks and new 24-inch Apple Cinema Display, and one year later it introduced a new LED iMac, meaning all of Apple"s new computer screens are now LED. Almost every laptop with a 16:9 display introduced since September 2009 uses LED-backlit panels. This is also the case for most LCD television sets, which are marketed in some countries under the misleading name LED TV, although the image is still generated by an LCD panel.

Most LED backlights for LCDs are edge-lit, i.e. several LEDs are placed at the edges of a lightguide (Light guide plate, LGP), which distributes the light behind the LC panel. Advantages of this technique are the very thin flat-panel construction and low cost. A more expensive version is called full-array or direct LED and consists of many LEDs placed behind the LC panel (an array of LEDs), such that large panels can be evenly illuminated. This arrangement allows for local dimming to obtain darker black pixels depending on the image displayed.

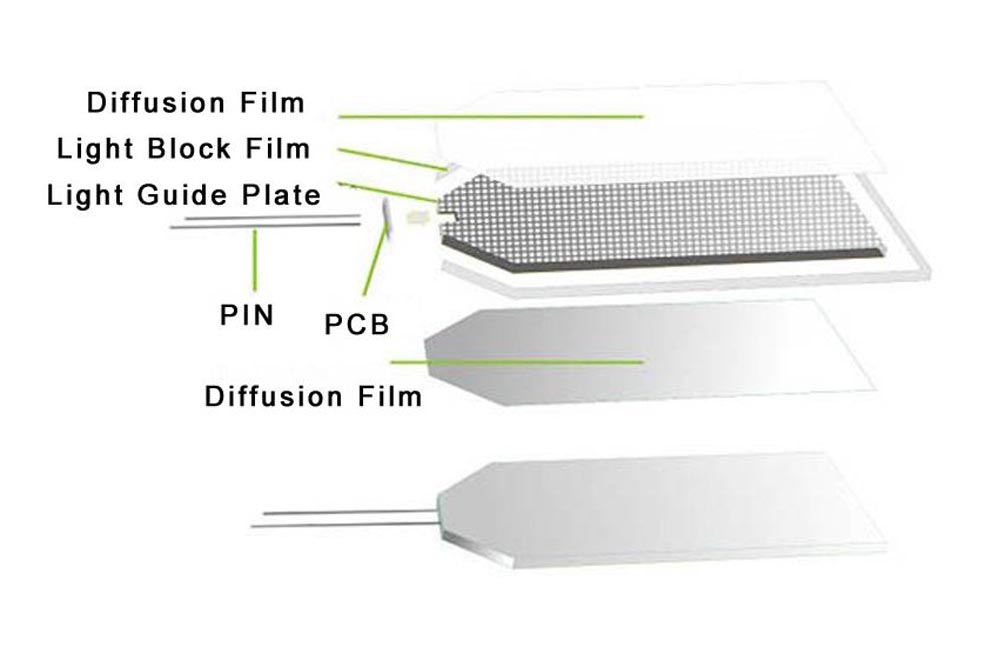

For a non-ELP backlight to produce even lighting, which is critical for displays, the light is first passed through a lightguide (Light guide plate, LGP) - a specially designed layer of plastic that diffuses the light through a series of unevenly spaced bumps. The density of bumps increases further away from the light source according to a diffusion equation. The diffused light then travels to either side of the diffuser; the front faces the actual LCD panel, the back has a reflector to guide otherwise wasted light back toward the LCD panel. The reflector is sometimes made of aluminum foil or a simple white-pigmented surface.

The LCD backlight systems are made highly efficient by applying optical films such as prismatic structure to gain the light into the desired viewer directions and reflective polarizing films that recycle the polarized light that was formerly absorbed by the first polarizer of the LCD (invented by Philips researchers Adrianus de Vaan and Paulus Schaareman),

Dimming options for LCD brightness; J. Moronski; Electronicproducts.com; 3 Januari 2004; "Dimming options for LCD brightness control". March 2004. Archived from the original on 2017-07-28. Retrieved 2017-11-20.

LCD Television Power Draw Trends from 2003 to 2015; B. Urban and K. Roth; Fraunhofer USA Center for Sustainable Energy Systems; Final Report to the Consumer Technology Association; May 2017; "Archived copy" (PDF). Archived from the original (PDF) on 2017-08-01. Retrieved 2017-11-20.link)

Traditional display panels, such as cathode ray tube (CRT) displays are being replaced by more advanced alternatives, such as liquid crystal displays (LCDs) and plasma displays. These newer display technologies offer various advantages over traditional CRT technology, including reduced weight; thinner profile; superior color, contrast and brightness in the resulting display; and reduced power consumption.

LCDs typically include an array of pixels arranged in front of a light source, lighting panel, or reflector. Each pixel includes a layer of liquid crystal material, and two filters, with one filter serving to polarize light horizontally and the other filter serving to polarize light vertically. A reflective LCD has a reflective layer (such as a minor) behind the pixels and is lit by either a frontlight or by ambient light. A transmissive LCD is lit by a backlight, in an arrangement where the pixels are arranged in front of a light source and light from the light source is transmitted through the pixels to the front of the LCD or the viewing area, resulting in a “lit” pixel. Light sources for backlighting may include electroluminescent panels/foils (ELs), cold cathode fluorescent lamps (CCFLs), hot cathode fluorescent lamps (HCFLs) External Electrode Fluorescent Lamps (EEFLs), traditional incandescent light bulbs, or light emitting diodes (LEDs). High intensity discharge lamps (HIDs) may also be used in certain backlighting applications.

When LEDs are utilized as light sources for transmissive LCD backlighting, they may be traditional or side view LEDs. Side view LEDs are also known as “side emitting LEDs” or “side looker LEDs.” A side view LED is a packaged LED that emits light parallel to the plane of the surface to which the package is mounted. Compared to traditional LED packages, side view LED packages are thinner and typically less expensive to manufacture. A typical side view LED package has dimensions of about 1.5 mm by about 0.5-0.7 mm, but such dimensions may vary. Owing at least in part to their small size, side view LED packages have limited current handling capabilities, thus limiting their emissions. As a result, a single side view LED package typically has less output capability than a traditional LED package. Whether accidentally or deliberately, practitioners often “overcurrent” side view LEDs to achieve greater output, which can lead to overheating and failure of a device incorporating such LEDs.

Current LED lighting techniques for transmissive LCDs include either direct backlighting or backlighting by edge illumination. While a backlight will light the pixels from the backside, that light may come from directly behind the center of the pixels (direct backlighting) or from behind the sides of the pixels (backlighting by edge illumination). While both techniques are recognized as backlighting, direct backlighting refers to illumination directed axially (centrally) through the backside of pixels. In contrast, edge illumination refers to an arrangement where the light source is located along an edge of a LCD system and lights the pixels from the side. Edge illumination may occur along the side edges of the LCD, the top edge, or the bottom edge. Backlighting of transmissive LCDs may utilize a waveguide to spread the light to an entire LCD panel, with such waveguide having a single entry for light and transmitting the light by internal reflection to be spread over a desired area.

A traditionally LED backlit LCD may include a layered system that includes an array of red, green and blue LEDs positioned on a panel or array of tiles. The panel or tiles include a reflective surface or layer arranged so that light is reflected in the desired direction toward a diffusion layer that diffuses the light provided from the LED backlight and reflects some of the light back toward the reflective surface or layer, thereby functioning to mix the light and improve the light uniformity (“recycling effect”). A brightness enhancement film and/or collimating layer over the reflective layer or surface and the diffusion layer provides light to the LCD panel layers in a more optimal fashion and also acts with the reflective layer or surface and the diffusion layer to enhance the recycling effect Depending on the embodiment, additional or less layers can be utilized as is understood by one of skill in the art. Such a backlight system may also include thermal layers below the LEDs for thermal management. As such, as is understood by one of skill in the art, the LED backlight system provides uniform white light to the LCD panels, which typically include a shutter layer and red, green and blue color filters.

The above-described traditionally lit screens have several inherent limitations. In the context of direct backlighting with a LED, a traditional LED package emits light directly at (i.e., through) a LCD screen. In order to light the entire screen, the LED must operate at high power and be very thick if utilized without a waveguide. Accordingly, the thickness of the resulting LCD system (television, monitor, etc.) is also increased. Modern consumers, however, desire thinner profile systems with thicknesses as small as a few inches. Accordingly, thick LCD systems are not commercially desirable. Additionally, use of high powered traditional LED package without a waveguide may create a “headlight effect” also known as a “hot spot” on the panel, causing a detrimental lack of light uniformity.

With regard to edge illumination, in which a waveguide is used to spread the light emission of a side view LED package disposed on an edge of the LCD, the resulting screen size is limited. As indicated previously, light emission characteristics of side view LED packages are reduced in comparison to traditional LED packages, with such limitation due to their size and current handling capabilities. As a result of the lower light emission, and the single entry for light in the waveguide, one or more portions (i.e., typically the center) of a side view LED-lighted LCD screen may not be lit if the screen is relatively large in size. LCD screens illuminated with side view LED packages and having acceptably uniform illumination characteristics are currently limited to screens of about 12 to 14 inches (diagonal) in size.

Accordingly, a need exists in the art for backlit LCD displays and display systems that are light in weight, have a thin profile, that enable use of large screens, and that are uniformly lit over the entire display with superior color and contrast. These and other needs are addressed with devices and systems according to embodiments of the present invention. SUMMARY

In one aspect, the invention relates to a waveguide system comprising: a) a first waveguide element comprising at least one first light entry region; b) a first light-emitting source positioned to emit light into the first waveguide element at the first light entry region; c) at least a second waveguide element comprising at least one second light entry region; and d) at least a second light-emitting source positioned to emit light into the at least a second waveguide element at the at least one second light entry region. Embodiments of the invention also provide LCD systems utilizing waveguide systems as described herein

In another aspect, the invention relates to a liquid crystal display (LCD) system comprising: a) a LCD panel having a peripheral region and an inner region; b) at least one first waveguide element comprising at least one first light entry region at an edge of said LCD panel and arranged to backlight the peripheral region of said LCD panel; c) at least one first light-emitting diode source positioned to emit light into said at least one first light entry region; and d) at least a second light-emitting diode source positioned to emit light for backlighting of the inner region of said LCD panel.

In another aspect, the invention relates to a liquid crystal display (LCD) system comprising: a) a LCD panel; b) at least one waveguide element comprising at least one light entry region, wherein the at least one light entry region comprises an extension of the at least one waveguide element that is non-coplanar with a principal plane of the at least one waveguide element; c) a first light-emitting source positioned to emit light into the at least one waveguide element at the at least one light entry region; and d) at least a second light-emitting source positioned to emit direct backlight onto the LCD panel or positioned to emit light into the at least one waveguide element along an edge thereof.

FIG. 1A is a schematic front view illustration of at least a portion of an exemplary LCD system including a waveguide element with edge illumination from two side edges, utilizing a plurality of LEDs arranged in strips as light sources according to one embodiment of the invention.

FIG. 2 is a schematic perspective view illustration of at least a portion of an exemplary LCD system including a waveguide element with angled extensions to receive light from a plurality of LEDs arranged in strips, according to one embodiment of the invention.

FIG. 3 is a schematic view illustration of at least a portion of an exemplary LCD system including a waveguide element with multiple extensions curved toward a principal plane of the waveguide element according to one embodiment of the invention.

FIG. 4 is a schematic perspective view illustration of an exemplary LCD system including a waveguide element subject to both backlighting by a plurality of LEDs arranged in strips behind the LCD screen, and side backlighting by a plurality of LEDs arranged in strips along at least one side edge of the system according to one embodiment of the invention.

FIG. 5 is a schematic illustration of a plurality of LEDs arranged in a strip for use in a light-emitting source in a LCD system according to one embodiment of the invention.

FIG. 6A is a schematic front view illustration of a lit LCD screen, lighted by a waveguide system containing two waveguides, according to one embodiment of the invention.

FIG. 6B is a cross-sectional view illustration of the LCD screen of FIG. 6A and at least a portion of an associated waveguide system arranged to light the LCD screen.

FIG. 7A is a schematic front view illustration of a lit LCD screen, lighted by a waveguide system containing three waveguides, according to one embodiment of the invention.

FIG. 7B is a cross-sectional view illustration of the LCD screen of FIG. 7A and at least a portion of an associated waveguide system arranged to light the LCD screen according to one embodiment of the invention.

FIG. 8A is a schematic front view illustration of a lit LCD screen, lighted by a waveguide system containing four waveguides, according to one embodiment of the invention.

FIGS. 8B and 8C are cross-sectional view illustrations of LCD screen of FIG. 8A and at least a portion of an associated waveguide system arranged to light the LCD screen, according to one embodiment of the invention.

FIG. 9A is a schematic front view illustration of a lit LCD screen, lighted by a waveguide system containing four waveguides, according to one embodiment of the invention.

FIG. 9B is a cross-sectional view illustration of the LCD screen of FIG. 9A and at least a portion of an associated waveguide system arranged to light the LCD screen according to one embodiment of the invention.

The present invention relates in various aspects to improved LCD systems. In one embodiment, a LCD system comprises a LCD panel or screen, at least one waveguide with multiple entry regions for light, and at least two light-emitting sources positioned to emit light into the at least one waveguide. When the light emitted by the light-emitting sources is optically coupled into the waveguide, the waveguide transmits light sufficient to light the entire LCD panel or screen of the system. Alternatively, multiple waveguides may be employed, each with at least one entry region for light and at least one associated light-emitting source positioned to emit light into the waveguides. With multiple waveguides, each waveguide may be positioned to light a portion of the LCD panel.

A conventional LCD system generally includes a LCD panel and a light source such as a LED optionally coupled to a single waveguide element having a single light entry point. Side view LED packages are desirable for use in LCD systems, due to their low current usage and small size. Due to concerns of overheating, however, the current that can be supplied to side view LED packages is limited, thus limiting their emissions. Consequently, the amount of light that can be emitted from a single side view LED package into a conventional waveguide is also limited. Therefore, side view LED packages coupled to single-input waveguides are not well-suited for use in backlighting LCD panels having viewable diagonal measurements larger than approximately 12-14 inches.

Embodiments of the present invention are not so limited, as they provide for uniform backlighting of panels of any desirable size, including panels having viewable diagonal measurements larger than about 12 inches, without problems such as overheating and creation of “hot spots.” LCD systems embodied in the present invention may include, but are not limited to televisions and computer monitors.

Embodiments of the present invention include single waveguides having multiple light entry regions for receiving light from locations other than, and/or in addition to, a single edge of the waveguide. The provision of light into at least one waveguide from multiple entry regions permits low current side view LED packages, whether alone or with other types of light sources, to uniformly light a LCD panel or screen, even if the LCD panel or screen has a viewable surface with a diagonal measurement greater than approximately 12-14 inches.

Embodiments of the present invention also include waveguide systems comprising multiple waveguides each waveguide having at least a single light entry region. Such a waveguide system may be utilized in a LCD system, where each waveguide has a transmissive surface that lights a portion of the LCD panel. The provision of light to multiple waveguides permits use of low current side view LED packages, whether alone or with other types of light sources, to uniformly light the LCD panel.

A LCD system according to the present invention may include any suitable type of conventional LCD panel or screen. Generally, a LCD panel includes LCD pixels arranged in front of a light source or reflective surface to illuminate the pixels. Furthermore, the LCD may include an LCD shutter panel and/or color filters, such as RGB color filters, as are known to those of skill in the art.

In one embodiment, a LCD system according to the present invention includes a transmissive LCD, such that the light is provided to the LCD panel or screen from behind via at least one waveguide element. Preferably the at least one waveguide element disperses the light in an even and complete manner, such that the entire panel is lit consistently and at a consistent intensity. A single waveguide element may be utilized, or multiple waveguide elements may be utilized with a single LCD panel. A waveguide element is a device utilized to guide optical waves from a light entry region to a transmissive surface or exit region of the waveguide element. A waveguide element may comprise a hollow structure with a reflective internal surface; alternatively, a waveguide may be substantially solid in nature. Glass, quartz, plexiglass, and other optically transmissive materials may be employable in the fabrication of transmissive portions of waveguides, with reflective materials such as metals further employed to fabricate reflective portions. Other materials such as glass and plastic may be employed to fabricate additional portions of the waveguide. To minimize loss of light from the waveguide element from an area other than the transmissive surface or exit region, the waveguide element may also be surrounded in whole or in part by a material such as plastic to reflect any light back into the element. In one embodiment, the waveguide includes a prism. At least a portion of a waveguide may be substantially planar or tubular in shape, or of any other configuration known to those of skill in the art. Total internal reflection is desirable, such that all of the light supplied to the waveguide element from associated light source(s) is transmitted out of the waveguide element via the transmissive surface. Internal reflection guides the optical waves to a transmissive surface of the waveguide element, which is optically coupled to provide light to the LCD screen or panel, such that the LCD panel or screen may be lit by the transmitted light. A waveguide is generally utilized in an arrangement where the LCD panel or screen is located between the waveguide element and a viewer.

When a single waveguide element is used, the waveguide preferably has multiple light entry regions. Additionally, the transmissive surface of the waveguide element and the viewable surface of the LCD panel or screen are preferably of substantially the same size. Optionally, the waveguide may contain gaps or holes to allow light from a direct backlight to the LCD panel or screen.

Waveguides utilized in LCD systems according to the invention may be utilized in combination, and when multiple waveguides are employed in a waveguide system, each may have one or more light entry regions. Light enters the one or more light entry regions of a waveguide and is transmitted to the transmissive surface thereof. A transmissive surface is preferably substantially flat to conform to a LCD panel. This transmissive surface provides backlight to the LCD panel, and is capable of lighting the viewable surface of the LCD panel or screen. In a LCD system of the invention, one or more waveguides may be utilized in lighting the LCD panel or screen.

When multiple waveguide elements are used, each waveguide preferably has at least one light entry region. The combined transmissive surface area of the waveguide elements is preferably substantially the same as that of the viewable surface area of the LCD panel or screen. Each waveguide of the group may light a different portion of the LCD panel, or the combined transmission may light substantially all of the LCD panel. In another embodiment, when multiple waveguides are utilized, the waveguides may be spaced sufficiently to allow light from a direct backlight to the LCD screen or panel or any of the individual waveguides of the group may contain gaps or holes to allow light from a direct backlight to the LCD panel or screen. When multiple waveguides are employed, they may abut one another laterally, or at least portions thereof may be disposed in a front-to-back or layered relationship if desired. In one embodiment, multiple upstream waveguides may be optically coupled to a downstream waveguide to promote easy fabrication and/or enhance uniformity of light distribution.

A light entry region of a waveguide element according to the invention may be adapted to receive light from one or more light sources. Light entry regions may be arranged along any convenient portion of a waveguide element. If a front portion of a waveguide is optically coupled to transmit light to a LCD panel or screen, then light entry regions may be disposed along any of a top edge, a first side edge, a second side edge, a bottom edge, and a back side of the waveguide element.

A waveguide element of the invention may be also adapted for use with a direct backlight source. As described above, a traditionally backlit LCD system includes a layered system which may include a direct backlight and, optionally, thermal layers under the light source, reflective layer(s), diffusion layer(s), brightness enhancement film(s) and/or collimating layer(s). In one embodiment of the invention the waveguide element of the invention is adapted for use with a direct backlight source, such that the waveguide element is included within or in addition to the layered backlight system. Where direct backlighting is provided in the LCD system of the invention, inclusion and orientation of such layers, films and elements, including one or more waveguide elements, is provided to optimize the direct backlight transmitted to the LCD panel or screen. In one embodiment a waveguide element is provided between the direct backlight source and the diffusion layer. In another embodiment, the waveguide element serves as a diffusion layer.

Multiple waveguides may form a “waveguide system” such that in one embodiment, light transmitted from each of the waveguides is coupled to provide light to the LCD panel or screen of a LCD system. A waveguide system in another embodiment may include two or more waveguides arranged in a layered configuration, where each waveguide provides light to a different portion of a LCD panel, such that the entire panel is substantially illuminated by the waveguide system. Each individual waveguide within the waveguide system includes one or more light entry regions, to which one or more light sources are optically coupled. Each waveguide also includes a transmissive surface or an exit region, where light exits the waveguide. A transmissive surface may comprise glass, quartz, or other optically transmissive materials, and may be referred to as a “prismatic” section of the waveguide. Portions of the waveguide not comprising a transmissive surface may comprise materials without prismatic or transmissive properties. The waveguide may also comprise a material or be surface treated such that a light shined directly at the waveguide will enter the waveguide or pass through the waveguide. Optionally, layered waveguides may be alternated with layers of diffusers and/or “light shaping” components.

In an exemplary LCD system according to one embodiment of the invention, a waveguide system including two layered waveguides is used, where the first waveguide may light a central or interior region of the LCD screen and the second waveguide may light a peripheral or outer region of the LCD screen. FIG. 6A illustrates a LCD screen 42 lit by a two layer waveguide system according to one embodiment of the invention. On the lighted screen 42, a first waveguide (not shown) is arranged to provide lighting to a central portion 45 of the LCD screen 42 and a second waveguide (not shown) is arranged to provide lighting to a peripheral or outer section 46 of the LCD screen 42. Each waveguide of the waveguide system preferably receives light from at least one different light source (not shown). FIG. 6B provides a cross-sectional view of an exemplary waveguide system 41 used to light a LCD screen 42 such as illustrated in FIG. 6A, taken along section lines B-B of FIG. 6A. As can be seen in FIG. 6B, in the exemplary two waveguide system 41, the waveguide layers 44A, 44B may be of similar size to one another. The waveguides 44A, 44B are positioned in a layered configuration, such that one waveguide 44A is positioned between the second waveguide 44B and the LCD screen 42. Each waveguide 44A, 44B has a transmissive or prismatic portion 49A, 49B on a major surface that emits light toward the LCD screen 42. Each waveguide 44A, 44B lights a portion of the LCD screen 42, such that the LCD screen 42 is substantially lit. A waveguide system may optionally be backed by a mirror or white light diffuser 40, and/or may contain additional diffusers or light shaping components (not shown) between the waveguide layers 44A, 44B.

In one embodiment according to the present invention, a waveguide system includes three layered waveguides, with a first waveguide lighting a central or interior region of the LCD screen, a second waveguide lighting a first portion of a peripheral or exterior region of the LCD screen, and a third waveguide lighting a second (e.g., remaining) portion of the peripheral or exterior region of the LCD screen. FIG. 7A illustrates an exemplary lit LCD screen 52 utilizing a three layer waveguide system 51. On the lighted screen 52, a first waveguide (not shown) is arranged to provide lighting to a first portion 55 along the center of the LCD screen 52, a second waveguide (not shown) is arranged to provide lighting to a second portion 56 along the exterior of the LCD screen 52 and a third waveguide (not shown) is arranged to provide lighting to a third portion 57 along a remaining exterior portion of the LCD screen 52. Each waveguide 54A-54C of the waveguide system preferably receives light from at least one different light source (not shown). FIG. 7B provides a cross-sectional view of an exemplary waveguide system 51 used to light LCD screen 52 as illustrated in FIG. 7A, taken along section lines B-B of FIG. 7A. As can be seen in FIG. 7B, each waveguide layer 54A-54C of the exemplary three waveguide system 51 may be of similar size. The waveguides 54A-54C are positioned in a layered configuration, such that one waveguide 54A is positioned closest to the LCD screen 52 and the third waveguide 54C is positioned furthest from the LCD screen 52, with the second waveguide 54B positioned between the first and third waveguides 54A, 54C. Each waveguide 54A-54C has a transmissive or prismatic portion 59A-59C on a major surface thereof that emits light toward the LCD screen 52. Each waveguide 54A-54C lights a portion of the LCD screen 52, such that the entire LCD screen 52 is substantially lit. The waveguide system 51 may optionally be backed by a minor or white light diffuser 50, and/or may contain additional diffusers or light shaping components (not shown) between the waveguide layers 54A-54C.

In another embodiment according to the present invention, four layered waveguides are provided. In such an arrangement, the waveguides may each provide light to a different portion (e.g., quadrants) of a LCD screen.

FIG. 8A illustrates such an exemplary LCD screen 62 lit by a four layer waveguide system. On the exemplary lit screen 62, a first waveguide (not shown) is arranged to provide lighting to a first portion 65 corresponding to an upper left quadrant of the LCD screen 62, a second waveguide (not shown) is arranged to provide lighting to a second portion 66 corresponding to a lower left quadrant of the LCD screen 62, a third waveguide (not shown) is arranged to provide lighting to a third portion 67 corresponding to an upper right quadrant of the LCD screen 62, and a fourth waveguide (not shown) is arranged to provide lighting to a fourth portion 68 corresponding to a lower right quadrant of the LCD screen 62. Each waveguide of the waveguide system preferably receives light from at least one different light source (not shown). FIG. 8B provides a first cross-sectional view of a waveguide system 61 useable to light the LCD screen 62 of FIG. 8A, taken along section lines B-B of FIG. 8A. FIG. 8C provides an alternative cross-sectional view of a first waveguide system useable to light the LCD screen 62 of FIG. 8A, taken along section lines C-C. As can be seen in FIGS. 8B and 8C, in the exemplary four waveguide system 61, the waveguide layers 64A-64D are of similar size to one another. The waveguides 64A-64D are positioned in a layered configuration, such that a first waveguide 64A is positioned closest to the LCD screen 61 and a fourth waveguide 64D is positioned furthest from the LCD screen 61, with a second waveguide 64B and a third waveguide 64C positioned between the first and fourth waveguides 64A, 64D. Each waveguide 64A-64D has a transmissive or prismatic portion 69A-69D on its surface that emits light toward the LCD screen 62. Each waveguide 64A-64D lights a portion of the LCD screen 62, such that the entire LCD screen 62 is substantially lit. The waveguide system 61 is optionally backed by a mirror or white light diffuser (not shown) and may contain additional diffusers or light shaping components (not shown) between the waveguide layers 64A-64D.

FIG. 9A illustrates an exemplary LCD screen 72 lit by another four layer waveguide system. On the exemplary lit screen 72, a first waveguide lights a first portion 75 of the LCD screen 72, a second waveguide lights a second portion 76 of the LCD screen 72, a third waveguide lights a third portion 77 of the LCD screen 72, and a fourth waveguide lights a fourth portion 78 of the LCD screen 72. Each waveguide 74A-74D of the waveguide system preferably receives light from at least one different light source (not shown). FIG. 9B provides a cross-sectional view of a waveguide system 71 useable to light the LCD screen 72 of FIG. 9A, taken along section lines B-B of FIG. 9A. As can be seen in FIG. 9B, in the exemplary four waveguide system 71, the waveguide layers 74A-74D are of similar size to one another. The waveguides 74A-74D are positioned in a layered configuration, such that a first waveguide 74A is positioned closest to the LCD screen 72 and a fourth waveguide 74D is positioned furthest from the LCD screen 72, with a second waveguide 74B and a third waveguide 74C positioned between the first and fourth waveguides 74A, 74D. Each waveguide 74A-74D has a transmissive or prismatic portion 79A-79D on its surface that emits light toward the LCD screen 72. Each waveguide 74A-74D lights a portion of the LCD screen 72, such that the entire LCD screen 72 is substantially lit. The waveguide system 71 is optionally backed by a mirror or white light diffuser (not shown) and may contain additional diffusers or light shaping components (not shown) between the waveguide layers 74A-74D.

It is to be understood that the exemplary waveguide systems described above are not limited to the particular transmission configurations provided herein. Any number of waveguides may be arranged in any configuration such that the transmissive sections of the waveguides illuminate various sections of a LCD screen. Transmission by the waveguides in any particular configuration does not have to be evenly distributed among individual waveguides. The exemplary waveguide systems set forth above include waveguides of approximately similar size; however, the waveguides of a waveguide system may be of any size, as long as the resulting transmissive sections of those waveguides illuminate substantially all of the LCD screen.

As described hereinabove, one or more light sources are optically coupled to a waveguide element in various embodiments of the invention. Any number of light sources may be employed to achieve uniform lighting of a LCD panel. While the light sources are optically coupled to emit light into the light entry regions of the waveguide element, the number of light entry regions does not limit the number of light sources. In one embodiment, at least one waveguide element is utilized, including a first light-emitting source positioned to emit light into a first entry region of the at least one waveguide element and a second light-emitting source positioned to emit light into a second entry region of the at least one waveguide element. Additional light-emitting sources and light entry regions may be employed.

A light-emitting source may be positioned anywhere within a LCD system that allows optical coupling of the light emitted into a light entry region. Accordingly, light-emitting sources may be located in or along a side region, a top region, a bottom region and/or a rear region of the LCD system. Light-emitting sources may be spaced apart from corresponding light entry regions, may be adjacent to corresponding light entry regions, and/or may be physically coupled to the corresponding light entry regions. In one embodiment, the light-emitting sources include side view LED packages, the light-emitting sources are arranged to not simultaneously and solely emit light into a top edge and a bottom edge of the waveguide. In such an embodiment, light sources may be arranged in locations other than both the top and bottom edges of the waveguide, or light sources arranged along both the top and bottom edge of a waveguide are supplemented with at least one additional light source arranged to emit light into the waveguide from at least one other location.

As thinner profile LCD systems may be desirable, where waveguide extensions are utilized, they may be optionally oriented in a manner such that they are angled, bent, or curved toward a primary plane of the waveguide element itself and, correspondingly, toward the LCD panel, to achieve a thinner profile system.

In one embodiment, a LCD system may further comprise a light source that is not optically coupled to emit light into the waveguide. An exemplary system includes a light source that directly backlights a LCD panel, supplemented by waveguide-directed light. Light emitted by such a backlight may pass through or around a waveguide or waveguide system disposed between the backlight and the LCD panel, in order to transmit light from the backlight to the LCD panel. In such an embodiment, the backlight provides light to the LCD panel or screen, which light is supplemented in one or more locations by light transmitted by the waveguide or waveguide system.

In another embodiment, a LCD system may further comprise a direct backlight source that is optically coupled into the waveguide as understood by one of skill in the art. An exemplary system includes a light source that provides light optically coupled into the waveguide, where the light source is positioned directly behind the LCD panel. Such direct backlighting may be coupled into the waveguide by any means known to those of skill in the art. In one embodiment the LED is provided at the end of a waveguide extension. Such a waveguide extension may be oriented in any manner as more fully described above. Preferably such an extension is short and the backlight is flush with the extension. In another embodiment the waveguide comprises such a material or is surface-treated such that a direct backlight shined on the waveguide will enter the waveguide through the surface and will be optically coupled to light provided to the waveguide through additional light entry sources. In a still further embodiment, the waveguide contains a light entry source in the form of a notch, or groove or other indentation in the surface of the waveguide, allowing for placement of a direct backlight directly against the waveguide. Light emitted from the direct backlight can therefore be optically coupled directly into the waveguide.

Light sources useful in lighting a LCD panel can include any of: a cold cathode fluorescent lamp (CCFL), a hot cathode fluorescent lamp (HCFL), an electroluminescent panel (ELP), an incandescent light bulb, a light emitting diode (LED), an organic light emitting diode (OLED), a high intensity discharge (HID) lamp, and any combination of the foregoing sources arranged to provide light in additive or spatially discrete arrangement.

A light source in a LCD system of the invention may include a LED that emits any of white light, blue light, red light, green light, or light of any desirable wavelength. In one embodiment, a light source includes one or more clusters of red-green-blue (RGB) LEDs. Such clusters may be independently controlled. In another embodiment, a light source includes a blue LED coated or otherwise covered with phosphors to upconvert blue light to white light.

Exemplary combinations of light sources of the invention may include: (1) direct backlighting utilizing one or more side view LEDs, supplemented with edge backlighting utilizing one or more side view LEDs; (2) direct backlighting utilizing one or more traditional LEDs, supplemented with edge backlighting utilizing one or more side view LEDs; (3) direct backlighting utilizing one or more side view LEDs, supplemented with edge backlighting utilizing one or more traditional LEDs; (4) direct backlighting utilizing one or more traditional LEDs, supplemented with edge backlighting utilizing one or more traditional LEDs; and (5) edge backlighting from more than one edge, utilizing one or more side view LEDs or traditional LEDs, or any combinations thereof. Such combinations may include, but are not limited to, single light sources including both traditional and side view LEDs. The foregoing combinations represent mere examples of possible configurations; other configurations may be employed within the scope of the present invention.

FIG. 5 illustrates of an exemplary light source for use in a LCD system, including a plurality of LED packages arranged in a strip 100. In a preferred embodiment, the strip 100 has dimensions of 20 mm×2.5 mm and contains five or more LED packages 101A-101E, which may be disposed in series. Optionally, such a strip 100 comprises a circuit board 105 including a 2.5 mil thickness FR4 substrate and 1 oz. copper, electroless Nickel Immersion Gold plating, and does not contain soldermask on the back surface. The strip 100 includes a common ESD diode 102 in electrical communication with the LEDs 101A-101E. Contacts 103, 104 may be provided to serve as common electrical inputs for the strip 100.

It is understood that when a single light source comprises a plurality of LED packages, any desirable number of LED packages may be provided. Factors affecting the makeup of a single light source may include: the size of the panel being lit, the desired viewing angle, the entry angle of the light into the light entry region of the waveguide element, the spacing of the individual LED packages, the brightness of the individual LED packages, and the size of the LED packages. In combination, plural light sources coupled to at least one waveguide utilized in a system as described herein are adapted to uniformly light a LCD panel of any desired size.

FIG. 1A is a schematic front view illustration of at least a portion of an exemplary LCD system 1 including a LCD panel 2 and multiple light sources 3A, 3B. FIG. 1B is a schematic side view illustration of the system of FIG. 1A, depicting the LCD panel 2, light sources 3A, 3B and waveguide element 4. FIG. 1C is a schematic side view illustration of an exemplary light source 3B, comprising a plurality of side view LED packages, 6A-6E arranged as a strip on base 7 and emitting light 8, parallel to the plane of base 7, into waveguide 4. FIG. 1D is a perspective view of a television or computer monitor 100 including a LCD system according to FIG. 1B, with the LCD panel 2 arranged in the foreground.

FIG. 2 is a schematic perspective view illustration of at least a portion of an exemplary LCD system 11 according to an embodiment of the present invention, including a LCD panel 12, waveguide element 14, first light source 13, and additional light sources 15A-15D, each coupled to the waveguide element 14 at the end of waveguide extensions 16A-16D, respectively. In FIG. 2, the first light source 13 provides light to a light entry region located along a lateral edge of the waveguide element 14 and additional strips of LED packages 15A-15D are optically coupled to the waveguide element 14 along light entry regions on extensions 16A-16D of the waveguide element 14.

FIG. 3 is a schematic perspective view illustration of at least a portion of an exemplary LCD system 21 according to one embodiment of the invention, the system including a LCD panel 22, waveguide element 24, and light sources 23, 25A, 25B coupled to the waveguide element 24 along an edge 27 of a primary waveguide surface and at the ends of waveguide extensions 26A, 26B, respectively. Additional light sources (not shown) are contemplated to be coupled to the waveguide element 24 at the end of waveguide extensions 26C and 26D, and along edge 28. Waveguide extensions 26A-26D are curved toward a primary plane of the waveguide element 24, such that the side profile of the resulting system 21 is thinner than it would otherwise be if the extensions 26A-26D were straight.

FIG. 4 is a schematic perspective view illustration view of an exemplary LCD system 31 according to one embodiment of the invention. The system 31 includes a LCD panel 32, a waveguide element 34, a first light source 33 optically coupled to an edge 37 of the waveguide element 34, and additional light sources 34A-34I optically coupled to the back side 35 of the waveguide element 34.

Various embodiments of the invention also provide methods of lighting a LCD panel utilizing light sources as described above. A LED panel may be lit by any combination of light sources that provides complete and uniform illumination of the panel. Light may be provided to the panel from light sources located along edge or back regions of the waveguide element, by direct backlighting, or use of any combination of light sources arranged to emit light directly to a LED panel and/or to emit light into one or more interposing waveguide elements.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey