arduino uno lcd touch screen free sample

In this Arduino touch screen tutorial we will learn how to use TFT LCD Touch Screen with Arduino. You can watch the following video or read the written tutorial below.

For this tutorial I composed three examples. The first example is distance measurement using ultrasonic sensor. The output from the sensor, or the distance is printed on the screen and using the touch screen we can select the units, either centimeters or inches.

The third example is a game. Actually it’s a replica of the popular Flappy Bird game for smartphones. We can play the game using the push button or even using the touch screen itself.

As an example I am using a 3.2” TFT Touch Screen in a combination with a TFT LCD Arduino Mega Shield. We need a shield because the TFT Touch screen works at 3.3V and the Arduino Mega outputs are 5 V. For the first example I have the HC-SR04 ultrasonic sensor, then for the second example an RGB LED with three resistors and a push button for the game example. Also I had to make a custom made pin header like this, by soldering pin headers and bend on of them so I could insert them in between the Arduino Board and the TFT Shield.

Here’s the circuit schematic. We will use the GND pin, the digital pins from 8 to 13, as well as the pin number 14. As the 5V pins are already used by the TFT Screen I will use the pin number 13 as VCC, by setting it right away high in the setup section of code.

I will use the UTFT and URTouch libraries made by Henning Karlsen. Here I would like to say thanks to him for the incredible work he has done. The libraries enable really easy use of the TFT Screens, and they work with many different TFT screens sizes, shields and controllers. You can download these libraries from his website, RinkyDinkElectronics.com and also find a lot of demo examples and detailed documentation of how to use them.

After we include the libraries we need to create UTFT and URTouch objects. The parameters of these objects depends on the model of the TFT Screen and Shield and these details can be also found in the documentation of the libraries.

Next we need to define the fonts that are coming with the libraries and also define some variables needed for the program. In the setup section we need to initiate the screen and the touch, define the pin modes for the connected sensor, the led and the button, and initially call the drawHomeSreen() custom function, which will draw the home screen of the program.

So now I will explain how we can make the home screen of the program. With the setBackColor() function we need to set the background color of the text, black one in our case. Then we need to set the color to white, set the big font and using the print() function, we will print the string “Arduino TFT Tutorial” at the center of the screen and 10 pixels down the Y – Axis of the screen. Next we will set the color to red and draw the red line below the text. After that we need to set the color back to white, and print the two other strings, “by HowToMechatronics.com” using the small font and “Select Example” using the big font.

Now we need to make the buttons functional so that when we press them they would send us to the appropriate example. In the setup section we set the character ‘0’ to the currentPage variable, which will indicate that we are at the home screen. So if that’s true, and if we press on the screen this if statement would become true and using these lines here we will get the X and Y coordinates where the screen has been pressed. If that’s the area that covers the first button we will call the drawDistanceSensor() custom function which will activate the distance sensor example. Also we will set the character ‘1’ to the variable currentPage which will indicate that we are at the first example. The drawFrame() custom function is used for highlighting the button when it’s pressed. The same procedure goes for the two other buttons.

So the drawDistanceSensor() custom function needs to be called only once when the button is pressed in order to draw all the graphics of this example in similar way as we described for the home screen. However, the getDistance() custom function needs to be called repeatedly in order to print the latest results of the distance measured by the sensor.

Ok next is the RGB LED Control example. If we press the second button, the drawLedControl() custom function will be called only once for drawing the graphic of that example and the setLedColor() custom function will be repeatedly called. In this function we use the touch screen to set the values of the 3 sliders from 0 to 255. With the if statements we confine the area of each slider and get the X value of the slider. So the values of the X coordinate of each slider are from 38 to 310 pixels and we need to map these values into values from 0 to 255 which will be used as a PWM signal for lighting up the LED. If you need more details how the RGB LED works you can check my particular tutorialfor that. The rest of the code in this custom function is for drawing the sliders. Back in the loop section we only have the back button which also turns off the LED when pressed.

In order the code to work and compile you will have to include an addition “.c” file in the same directory with the Arduino sketch. This file is for the third game example and it’s a bitmap of the bird. For more details how this part of the code work you can check my particular tutorial. Here you can download that file:

In this tutorial, you will learn how to use and set up 2.4″ Touch LCD Shield for Arduino. First, you’ll see some general information about this shield. And after learning how to set the shield up, you’ll see 3 practical projects.

The role of screens in electronic projects is very important. Screens can be of very simple types such as 7 Segment or character LCDs or more advanced models like OLEDs and TFT LCDs.

One of the most important features of this LCD is including a touch panel. If you are about to use the LCD, you need to know the coordinates of the point you touch. To do so, you should upload the following code on your Arduino board and open the serial monitor. Then touch your desired location and write the coordinates displayed on the serial monitor. You can use this coordination in any other project.

To display pictures on this LCD you should save the picture in 24bit BMP colored format and size of 240*320. Then move them to SD card and put the SD card in the LCD shield. we use the following function to display pictures. This function has 3 arguments; the first one stands for the pictures name, and the second and third arguments are for length and width coordinates of the top left corner of the picture.

If you want to display pictures without using an SD card, you can convert it to code and then display it. You can display even several photos sequentially without delay to create an animation. (Check this) But be aware that in this case, Arduino UNO may not be suitable (because of low processor speed). We recommend using the Arduino Mega or Arduino DUE.

Spice up your Arduino project with a beautiful large touchscreen display shield with built in microSD card connection. This TFT display is big (7" diagonal) bright (14 white-LED backlight) and colorfu 800x480 pixels with individual pixel control. As a bonus, this display has a optional resistive touch panel with controller XPT2046 attached by default.

The shield is fully assembled, tested and ready to go. No wiring, no soldering! Simply plug it in and load up our library - you"ll have it running in under 10 minutes! Works best with any classic Arduino (Due/Mega 2560). This display shield has a controller built into it with RAM buffering, so that almost no work is done by the microcontroller. You can connect more sensors, buttons and LEDs.

Of course, we wouldn"t just leave you with a datasheet and a "good luck!" - we"ve written a full open source graphics library at the bottom of this page that can draw pixels, lines, rectangles, circles and text. We also have a touch screen library that detects x,y and z (pressure) and example code to demonstrate all of it. The code is written for Arduino but can be easily ported to your favorite microcontroller!

For 7 inch screen,the high current is needed.But the current of arduino uno or arduino mega board is low, an external 5V power supply is needed. Refer to the image shows the external power supply position on shield ER-AS-SSD1963.

If you"ve had a lot of Arduino DUEs go through your hands (or if you are just unlucky), chances are you’ve come across at least one that does not start-up properly.The symptom is simple: you power up the Arduino but it doesn’t appear to “boot”. Your code simply doesn"t start running.You might have noticed that resetting the board (by pressing the reset button) causes the board to start-up normally.The fix is simple,here is the solution.

Spice up your Arduino project with a beautiful large touchscreen display shield with built in microSD card connection. This TFT display is big 4"(3.97" diagonal) bright (6 white-LED backlight) and colorful (18-bit 262,000 different shades)! 480x800 pixels with individual pixel control. As a bonus, this display has a optional resistive touch panel with controller XPT2046 and capacitive touch panel with FT6336.

The shield is fully assembled, tested and ready to go. No wiring, no soldering! Simply plug it in and load up our library - you"ll have it running in under 10 minutes! Works best with any classic Arduino (Due/Mega 2560).

Of course, we wouldn"t just leave you with a datasheet and a "good luck!" - we"ve written a full open source graphics library at the bottom of this page that can draw pixels, lines, rectangles, circles and text. We also have a touch screen library that detects x,y and z (pressure) and example code to demonstrate all of it. The code is written for Arduino but can be easily ported to your favorite microcontroller!

If you"ve had a lot of Arduino DUEs go through your hands (or if you are just unlucky), chances are you’ve come across at least one that does not start-up properly.The symptom is simple: you power up the Arduino but it doesn’t appear to “boot”. Your code simply doesn"t start running.You might have noticed that resetting the board (by pressing the reset button) causes the board to start-up normally.The fix is simple,here is the solution.

Touchscreen displays are everywhere! Phones, tablets, self-serve kiosks, bank machines and thousands of other devices we interact with make use of touchscreen displays to provide an intuitive user interface.

Today we will learn how touchscreens work, and how to use a common inexpensive resistive touchscreen shield for the Arduino. Future videos and articles will cover capacitive touchscreens, as well as a touchscreen HAT for the Raspberry Pi.

Although touchscreens seem to be everywhere these days we tend to forget that just a few decades ago these devices were just science fiction for most of us. For many people, the touchscreen concept was introduced 30 years ago in the television seriesStar Trek: The Next Generation.

Eric A Johnson, a researcher at the Royal Radar Establishment in Malvern UK is credited for describing and then prototyping the first practical touchscreen. HIs device was a capacitive touchscreen, and it’s first commercial use was on air traffic control screens. However, the touchscreens used then were not transparent, instead, they were mounted on the frame of the CRT display.

In 1972, a group at the University of Illinois filed for a patent on an optical touchscreen. This device used a 16×16 array of LEDs and phototransistors, mounted on a frame around a CRT display. Placing your finger, or another solid object, on the screen would break two of the light beams, this was used to determine the position and respond accordingly.

The first transparent touchscreen was developed atCERNin 1973. CERN is also home to the Large Hadron Collider, and this is where Tim Berners-Lee invented the World Wide Web.

The first resistive touchscreen was developed by American inventor George Samuel Hurst in 1975, although the first practical version was not produced until 1982.

In 1982 theUniversity of Toronto’sInput Research Group developed the first multi-touch touchscreen, a screen that could interpret more than one touch at the same time. The original device used a video camera behind a frosted piece of glass. Three years later the same group developed a multi-touch tablet that used a capacitive touchscreen instead.

The first commercial product to use a touchscreen was a point-of-sale terminal developed by Atari and displayed at the 1986 COMDEX expo in Las Vegas. The next year Casio launched theCasio PB-1000 pocket computerwith a touchscreen consisting of a simple 4×4 matrix.

LG created the world’s first capacitive touchscreen phone, theLG Pradaused a capacitive touchscreen and was released in early 2007. A few weeks later Apple released its first iPhone.

Most early touchscreen devices were resistive, as this technology is generally less expensive than capacitive screens. However, nowadays capacitive screens are more common, being used in the majority of smartphones and tablets.

Although they were invented after capacitive touchscreens, resistive touchscreens are probably the most common type used by hobbyists. The reason for that is the price and performance, resistive touchscreens are cheaper than capacitive ones and they are generally more accurate.

A resistive touchscreen consists of two thin layers of material, separated by a tiny gap. Spacers are used to maintain the gap and keep the two sheets apart.

In operation, the resistance between the two sheets is measured at different points. Pressing down upon the tip sheet will change that resistance, and by comparing the measurement points it can be determined where the screen was pressed. Essentially, it creates a pair of voltage dividers.

In a 4-Wire Analog touchscreen, there are two electrodes or “busbars” on each of the conductive layers. On one layer these electrodes are mounted on the two X-axis sides, the other layer has them on the two y-axes.

This is the most inexpensive method of designing a resistive touchscreen. The touchscreen display that we will be working with today uses this arrangement.

In a 5-Wire Analog touchscreen, there are four wires, one connected to a circular electrode on each corner of the bottom layer. A fifth wire is connected to a “sensing wire”, which is embedded in the top layer.

Touching any point on the screen causes current to flow to each of the bottom electrodes, measuring all four electrode currents determines the position that the screen was touched.

This 8-Wire Analog touchscreen uses an arrangement of electrodes identical to the 4-Wire variety. The difference is that there are two wires connected to each electrode, one to each end.

Capacitive touchscreens are actually older technology than resistive displays. They are commonly used in phones and tablets, so you’re probably familiar with them.

The capacitive touchscreen makes use of the conductivity of the human body. The touchscreen itself consists of a glass plate that has been treated with a conductive material.

The surface capacitive touchscreen is the most inexpensive design, so it is widely used. It consists of four electrodes placed at each corner of the touchscreen, which maintain a level voltage over the entire conductive layer.

When your finger comes in contact with any part of the screen, current flows between those electrodes and your finger. Sensors positioned under the screen sense the change in voltage and the location of that change.

This is a more advanced touchscreen technique. In a projected capacitive touchscreen transparent electrodes are placed along the protective glass coating and are arranged in a matrix.

One line of electrodes (vertical) maintain a constant level of current. Another line (horizontal) are triggered when your finger touches the screen and initiates current flow in that area of the screen. The electrostatic field created where the two lines intersect determine where it was touched.

The module we will be experimenting with today is a very common Arduino Shield, which is rebranded by many manufacturers. You can easily find these on Amazon, eBay or at your local electronics shop.

You can also just use the shield as an LCD display and ignore the two other components, however, if you intend on doing that it would be cheaper just to buy an LCD display without any touchscreen features.

You do need to be looking directly at the display for best color accuracy, as most of these inexpensive LCD displays suffer from distortion and “parallax error” when viewed from the side. But as the most common application for a device like this is as a User Interface (UI) this shouldn’t be a problem.

This shield uses a 4-wire analog resistive touchscreen, as described earlier. Two of the wires (one X and one Y) are connected to a couple of the analog inputs on the Arduino. The analog inputs are required as the voltage levels need to be measured to determine the position of the object touching the screen.

You should note that the microSD card uses the SPI interface and is wired for the Arduino Uno. While the rest of the shield will function with an Arduino Mega 2560, the SPI connections on the Mega are different, so the microSD card will not work.

The last paragraph regarding the microSD card may make you think that an Arduino Uno is the best choice for the Touchscreen Display Shield. And it you require the microSD card then it probably is a good choice.

But using an Arduino Uno with this shield does have one big disadvantage – a limited number of free I/O pins. In fact there are only three pins left over once the card has been plugged in:

If your product is self-contained and doesn’t need many (or any) I/O pins then you’ll be fine. But if you need more pins to interface with then an Arduino Mega 2560 is a much better choice. It has a lot of additional analog and digital pins.

So if you don’t require the microSD card, or are willing to hook up a separate microSD card, then the Arduino Mega 2560 is a better choice for most applications.

As there are three devices on the shield you will need libraries for each of the ones you want to use. TheSD Libraryis already installed in your Arduino IDE, so you will just need libraries for the display and touchscreen.

For the LCD you will have a lot of choices in libraries. Most of these shields come with a CD ROM with some sketches and libraries, so you can use the LCD libraries there. Bear in mind however that code on these CD ROMs tends to be a little dated, you may have better lick on the vendors website.

This useful resource contains code, libraries and datasheets for a wealth of LCD displays, both touchscreen and non-touchscreen. You’ll also find code for some common OLED displays as well.

I ran my touchscreen through all of the code samples I obtained from the LCD Wiki. It’s an interesting exercise, and by examining the sketch for each demo you can learn a lot about programming the display.

The first example is a very simple color “sweep” test. Navigate to theExample_01_Simple_testfolder and open the folder for your Arduino controller. Navigate down until you find the “ino” file and load it.

This test does not make use of any of the extra libraries, it drives the LCD directly. It is only a test of the LCD display, it does not make use of the touchscreen membrane.

You’ll find this example in theExample_02_clear_screenfolder, the sameclear_Screen.inoexample is used for both the Uno and Mega so there are no separate folders.

This example does use the custom libraries, and is a very good way to learn how to use them. You’ll note that theLCDWIKI_GUI.hlibrary is loaded, which is the graphics library for the LCD display.

Another library, LCDWIKI_KBV.h, is loaded as well. This is a hardware-specific “helper” library that provides an interface to the actual hardware for the other libraries.

When you run this example the results will be similar to the first one, a series of colors will sweep across the screen. In this case the colors are different, and they vary in speed.

A look at the loop will show how this is done. TheLCDWIKI_GUI.hlibrary has a “Fill_Screen” method that fills the screen with an RGB color. You can specify the color in both hexadecimal or decimal format, the example illustrates both ways.

This sketch uses a number of functions from theLCDWIKI_GUI.hlibrary, along with some custom functions to draw geometric shapes. It then displays a cycle of graphs, shapes, and patterns on the LCD display.

The result of running the sketch is the display screen fills with rows of hexadecimal values while the background alternates between blue and black and the orientation (or “aspect”) changes. If you stand back to see the “big picture” you’ll note that the color values form “number patterns”.

In addition to the graphics and “helper” libraries that have been used in the previous examples this sketch also uses theTouchScreenlibrary to read screen interaction. This was one of the libraries included in the original ZIP file.

Note that this demo will only work on the Arduino Uno, as the microSD card uses the SPI bus and is wired to the Arduino Uno SPI port. The Arduino Mega 2560 board uses different pins for SPI.

Another thing you will notice is the speed at which the images draw, which is not particularly impressive. The clock speed of the Arduino has a lot to do with this, as does the method used to extract each individual pixel from the image.

This example draws some small “switches” on the display. The switches are active and respond to touch. There are slide switches, a push button, some radio buttons and some text-based expandable menus to test with.

The Touch Pen example is actually a pretty decent little drawing application. You can draw whatever you want on the main screen area. A set of buttons allow you to set the stylus color and pen width.

While the sample code is a bit difficult to follow it’s worth the effort, as it shows you how to create a dynamic menu system. Touching the stylus color button, for example, will open a new menu to select colors. This is a handy technique that you’ll need to know when developing your own user interfaces.

The Calibration utility lets you calibrate the resistive touchscreen. It achieves this by placing a number of crosses on the screen. You can calibrate the screen by using the stylus to touch the center of one of the crosses as accurately as you can.

After you touch one of the cross points the sketch runs through a calibration sequence, during which time you need to continue to touch the cross point. You’ll be informed when it is finished.

After calibration, the sketch will display a number of calibration values for the resistive touchscreen. These values can be used in your future sketches to make the touchscreen more accurate.

The examples are a great way to demonstrate the capabilities of your touchscreen. But to really put your interface to work you’ll need to write your own interface code.

Writing a touchscreen interface can be challenging. I would suggest that you start by modifying one of the example codes, one that is closest to your desired interface.

For my experiment, I will be using an Arduino Mega 2560 to drive three LEDs. I used a Red, Green and Blue LED but really any colors will work – I just wanted my LED colors to match my button colors.

The digital I/O connector at the back of the Mega is still accessible even when the touchscreen display shield is installed, so I used three of those connections for the LEDs. I hooked up each LED anode through a 220-ohm dropping resistor and connected them as follows:

TheAdafruit TFTLCD Libraryis used. It uses the previous library to provide an easy method of drawing on the LCD display. It works with LCD displays that use driver chips like the ILI9325 and ILI9328.

TheTouchScreenlibrary comes in the code that you downloaded from the LCD Wiki or from the CD ROM included with your touchscreen shield. As its name implies it is used to interface with the touchscreen.

Next, we define some touchscreen parameters. You can ‘fine-tune” your code here by using parameters from your own display, which you can obtain from the Calibration Sketch we ran from the sample code. Otherwise, just use the values here and you should be fine.

Now, still in the Setup, we set up the LCD display rotation and fill the background in black. Next step is to draw our buttons. Once we are done that the Setup is finished, and our screen should be displaying the three buttons on a black background.

The loop is where we will be monitoring the screen for keypresses. If we get one, and if its position corresponds to a button location, then we need to toggle the correct LED.

We start by triggering the touchscreen, which is done by toggling pin 13 on the Arduino high. If something is touching the screen we read it and assign it to a TSPoint object named “p”.

We then need to reset the pin modes for two of the touchscreen pins back to outputs. This is done as these pins get shared with other LCD display functions and get set as inputs temporarily.

Now we check to see if the pressure on the screen was within the minimum and maximum pressure thresholds we defined earlier. If it makes the grade then we determine where exactly the screen was pressed.

Now that we know where the screen was pressed we need to see if the pressure point corresponds to one of our buttons. So we cycle through the button array and check to see if the pressure point was within 10 pixels of our button location.

Load the code into your Arduino IDE and upload it to your Arduino Mega 2560. Make sure you have the correct processor-type set in your Arduino IDE, especially if you are used to working with the Uno!

This is a pretty simple demo but it does illustrate how to create a simple IDE. You can expand upon it to add more buttons, or to change the button colors or shapes. And, of course, you don’t have to light LEDs with your buttons, they can control anything that you can connect to your Arduino.

Touchscreen interfaces are used in a number of products, and now you can design your own devices using them. They can really make for an intuitive and advanced display and will give your project a very professional “look and feel” if done correctly.

This is not the only time we will look at touchscreen displays. Next time we’ll examine a capacitive touchscreen and we’ll explore the Adafruit Graphics libraries further to create some very fancy displays with controls and indicators.

Let"s learn how to use a touchscreen with the Arduino. We will examine the different types of touchscreens and will then create a simple interface using an inexpensive Arduino touchscreen shield.

There are many tutorials on Arduino shields for 2.4 inch TFT LCD displays. In this road test I apply different tutorials to check the performance and issues of this specific shield: AZ-Delivery 2.4 inch TFT LCD display with resistive 4-wire touchscreen and an integrated SD card reader.AZ-Delivery 2.4 inch TFT LCD display.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology. That improves image quality, better contrast and addressability.

Depends on the needs of your project. Arduino UNO processor frequency is low. With the Arduino UNO full-color TFT LCDs are suitable to display simple data and commands. The TFT controller used cannot switch internal display RAM, so you can"t use the double buffer technique for animations but still you can only re-draw small sections of screen.

Given the limitations of the Arduino UNO the bigger the display the worse the performance. The size of this display is adequate to meet that compromise between number of pixels, display area and capabilities of the Arduino UNO.

This module consumes most of the resources available in Arduino UNO. This is not a limitation of the module itself. In return, using a parallel interface allows you to quickly update the image. If you want to take advantage of all its functionality (LCD + touch screen + SD card), only pins 0 and 1 (RX and TX, respectively) and pin 19 (A5) remain unused. If the SD card is not used, pins 10, 11, 12 and 13 are additionally available. With a suitable layout, some SPI devices could be connected even if the SD card is used.

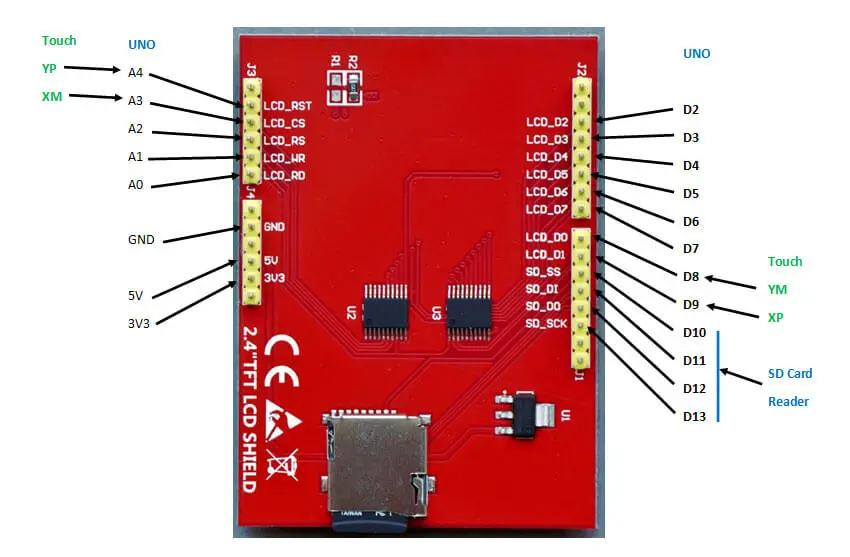

The PCB silkscreen indicates the main function of each pin, the labels are easy to read, although it does not show labels for the touch screen pins:Pin 9 - Touch X+ / LCD_D1

The SD card reader is very well located between the USB connector and the power connector, it does not touch either of them as it happens in other lcd tft shield modules and it is easily accessible to insert and remove the SD cards.

You can directly use the shield with any arduino uno. In this case we are using an Arduino UNO that exposes all the pins both on the header and on the board. In such a way that you do not need another shield to access the pins not used by the screen

ShieldCompatible with Arduino. 5V compatible, can be used with 3.3V or 5V logic. On-board 3.3 V (300mA LDO controller). The design is very well thought out and fits Arduino UNO perfectly.

2x74LVC245A Octal Bus Transceiver With 3-State outputs. This octal bus transceiver is designed for 1.65-V to 3.6-V VCC operation. The LVC245A is designed for asynchronous communication between data buses. The device transmits data from the A bus to the B bus or from the B bus to the A bus, depending on the logic level at the direction-control (DIR) input. The output-enable (OE) input can be used to disable the device so the buses effectively are isolated. Inputs can be driven from either 3.3-V or 5-V devices. This feature allows the use of this device as a translator in a mixed 3.3-V/5-V system environment. This chip solves the problem of how to interface 3.3V logic devices to a 5.0V logic chip such as the Arduino. Most 3.3V devices do not like being run with 5V signals and can be damaged or flaky. The 74LVC245 is designed so that even when it runs at 1.8V, it still happily accepts 5V signals in one pin and converts it to a lower logic level on the opposite pin. It has 8 pipes it can convert but it won"t work with bi-directional/pull-up based devices such as I2C or 1-Wire. It does work great for SPI, Serial, Parallel bus, and other logic interfaces.

If you want to take advantage of all its functionality (LCD + touch screen + SD card), only pins 0 and 1 (RX and TX, respectively) and pin 19 (A5) remain unused. If the SD card is not used, pins 10, 11, 12 and 13 are additionally available. With a suitable layout, some SPI devices could be connected even if the SD card is used.

The ILI9341 which can control each pixel with a small number of pins. The shield connects ILI9341"s data pins 0-7 to Arduino digital pins 2-8 (allowing parallel communication, not SPI). ILI"s RESET goes to pin to Arduino analog pin A4.CS (chip select) to A3. RS (CD command/data) to A2. WR and RD to A1 and A0.

Includes a resistive 4-wire touchscreen (touchpad). The touch screen is attached on the surface of the display. Touch screen needs two analog inputs and two digital outputs. It connects through 4 wires, which share arduino pins 8, 9, A2, A3 with the ILI9341 driver. So you can"t write to LCD display and read the touch screen in the same time. I. Driver chip is XPT2046.

The optical characteristics are good, with a wide color gamut and good sharpness. The viewing angle is quite wide and there is no color inversion or other flaws. The screen is brilliant. Colors are bright enough to read the screen well even in daylight.

The resistive touch screen does not appear to appreciably affect the optical characteristics. Works properly, It takes a little pressure with the stylus for it to respond like in old mobile phones. You notice how it sinks into the screen when you press with the stylus. The stylus that comes with the module makes it easy to use if your interface design uses small controls. Some touch screen libraries offer better accuracy by specifying the resistance of the touch screen in the X direction. Resistance can be easily measured with a multimeter by connecting the test leads to the LCD_D1 - X + and LCD_DS X- terminals. Touch is sensitive to pressure.

Arduino has always helped to build projects easily and make them look more attractive. Programming an LCD screen with touch screen option might sound as a complicated task, but the Arduino libraries and shields had made it really easy. In this project we will use a 2.4” Arduino TFT LCD screen to build our own Arduino Touch Screen calculator that could perform all basic calculations like Addition, Subtraction, Division and Multiplication.

Before we actually dive into the project it is important to know, how this 2.4” TFT LCD Module works and what are the types present in it. Let us take a look at the pinouts of this 2.4” TFT LCD screen module.

As you can see there are 28 pins which will perfectly fit into any Arduino Uno / Arduino Mega Board. A small classification of these pins is given in the table below.

As you can see the pins can be classified in to four main classifications such as LCD Command Pins, LCD Data Pins, SD Card Pins and Power Pins, We need not know much about the detailed working of these pins since they will be take care by our Arduino Library.

You can also find an SD card slot at the bottom of the module shown above, which can be used to load an SD card with bmp image files, and these images can be displayed in our TFT LCD screen using the Arduino Program.

Another important thing to note is your Interface IC. There are many types of TFT modules available in the market starting from the original Adafruit TFT LCD module to cheap Chinese clones. A program which works perfectly for your Adafruit shield might not work the same for Chinese breakout boards. So, it is very important to know which types of LCD display your are holding in hand. This detail has to be obtained from the vendor. If you are having a cheap clone like mine then it is most probably using the ili9341 driver IC.You can follow this TFT LCD interfacing with Arduino tutorial to try out some basic example programs and get comfortable with the LCD screen. Also check out our other TFT LCD projects with Arduino here:

If you planning to use the touch screen function of your TFT LCD module, then you have to calibrate it to make it work properly. A LCD screen without calibration might work unlikely, for instance you might touch at one place and the TFT might respond for a touch at some other place. These calibrations results will not be similar for all boards and hence you are left on your own to do this.

The best way to calibrate is to use the calibration example program (comes with library) or use the serial monitor to detect your error. However for this project since the size of buttons is large calibration should not be a big problem and I will also explain how you can calibrate your screen under the programming section below.

The 2.4” TFT LCD screen is a perfect Arduino Shield. You can directly push the LCD screen on top of the Arduino Uno and it will perfectly match with the pins and slid in through. However, as matters of safety cover the Programming terminal of your Arduino UNO with a small insulation tape, just in case if the terminal comes in contact with your TFT LCD screen. The LCD assembled on UNO will look something like this below.

We are using the SPFD5408 Library to get this arduino calculator code working. This is a modified library of Adafruit and can work seamlessly with our LCD TFT Module. You can check the complete program at the end of this Article.

Now, open Arduino IDE and select Sketch -> Include Librarey -> Add .ZIP library. A browser window will open navigate to the ZIP file and click “OK”. You should notice “Library added to your Libraries” on the bottom-left corner of Arduino, if successful. A detailed guide to do the same is given in the Interfacing Tutorial.

Now, you can use the code below in your Arduino IDE and upload it to your Arduino UNO for the Touch Screen Calculator to work. Further down, I have explained the code into small segments.

As said earlier we need to calibrate the LCD screen to make it work as expected, but don’t worry the values given here are almost universal. The variables TS_MINX, TS_MINY, TS_MAXX, and TS_MAXY decide the calibration of the Screen. You can toy around them if you feel the calibration is not satisfactory.

As we know the TFT LCD screen can display a lot of colours, all these colours have to be entered in hex value. To make it more human readable we assign these values to a variable as shown below.

Okay now, we can get into the programming part. There are three sections involved in this program. One is creating a UI of a calculator with buttons and display. Then, detecting the buttons based on the users touch and finally calculating the results and display them. Let us get through them one by one.

Another challenging task is detecting the user touch. Every time the user touches somewhere we will able to how where the X and Y position of the pixel he touched. This value can be displayed on the serial monitor using the println as shown below.

Now, since we know the position of all the boxes. When a user touches anywhere we can predict where he has touched by comparing his (X,Y) values with the value for each box as shown below.

The final step is to calculate the result and display them on TFT LCD Screen. This arduino calculator can perform operation with 2 numbers only. These two numbers are named as variables “Num1” and “Num2”. The variable “Number” gives and takes value from Num1 and Num2 and also bears the result.

The working of this Arduino Touch Screen Calculator is simple. You have to upload the below given code on your Arduino and fire it up. You get the calculator displayed on your LCD screen.

You have to press the “C” to clear the value on screen each time after performing a calculation. Hope you understood the project and enjoyed building something similar. If you have any doubts feel free to post them on forums or on the comment section below. See you next time with another interesting project until then happy computing!!

The AZ-Delivery 2.4” TFT LCD Touch Display boasts 320x 240 pixels with 16-bit color. It has Touch capabilities, a built-in SD card drive, and plugs straight onto the top of an Arduino UNO or Mega. Amazon charges less than £11 for this device. It offers a major step up from the tiny SSD1306 128×64 monochrome display.

The TFT screen is much larger than the SSD1306 128×64 and much more colourful. The package includes an SD card reader on the underside and a stylus for accurate touch-screen control.

The underside of the board has labels on the pins. As the board is an Arduino shield, it will only fit on a UNO in one position. The SD card reader sits between USB and the power socket. It will also plug into and Arduino MEGA 2560. J1 and J2 fit into the digital pins, covering D0 to D13, while J3 and J4 fit into the analog and power pins.

I searched the Web for drivers and examples and found a great deal of praise for the TFT graphics, reports of problems with the Touch control and nothing about the SD card reader on this board.

In the end I installed several libraries (with all dependencies): Adafruit GFX, Adafruit TFTLCD, Adafruit TouchScreen, Adafruit ILI9341, MCUFRIEND_kbv and SPFD5408-master. (The last 2 are not essential but include some interesting examples). The SD library is included in the basic Arduino set.

I’ve used GFX with mono displays such as SSD1306 and soon got the TFT display working. The following script gives some idea about what it can do. I’ve included pixels, text (of varying sizes), lines, rectangles, triangles, squares, graphs, screen rotation, and text on a path. I was very impressed with the clarity, speed, brightness, and colors produced.

Normally, when setting the colour of an RGB LED you have a range of 0-255 (0-FF hex) for each RGB component which gives white = FFFFFF, red = FF000, green FF00 and blue = FF. This is 24-bit colour and takes 3 bytes. 224 gives 16,777,216 different colours. The TFT screen is a 16-bit colour device which can display 65,536 different colours – more than enough. Here the range is limited to 5 bits each for red and blue and 6 bits for green. (Our eyes are more sensitive to green so It gets the extra bit of accuracy.)

The following sketch gives an indication of the colours available by converting an array of 24-bit colour values into their 16-bit equivalent and displaying them on the screen with the data. There are not enough pixels on the screen to display all the colours at once so the last part of the sketch takes out the least significant green bit and displays half the available colours six ways.

Most Arduino users seldom use string manipulation. The documentation and a few simple examples of how to use strings are well scattered over the Web and difficult to find. The first sketch demonstrates how to create a file of 5 records/lines, each made up from an integer, a string, and a floating-point variable. The file is called datalog6.txt.

This is the part that often causes the most trouble with many owners giving up at this point. It may be because there are several different configurations of the pins used to connect to the touch layers of the screen on the many varied breakout boards and shields using this display. In this case four of the pins are used, at different times, to control both the graphics or the touch elements of the screen.

This is a resistive touch screen, rather than a capacitive one. Above the graphics, layers are two transparent resistive layers held apart by tiny dimples. One is connected at the top and bottom and the other at the sides. A potential difference is applied across them and when the stylus or a finger presses on the screen an electrical connection is made between the resistive layers.

The Analog pins are used to measure the voltages at that point on the two resistive layers, one at a time, in the same manner as we read the voltage from the wiper of a potentiometer – a potential divider. Using these values, it is possible to calculate, quite accurately, the coordinates of the point on the screen where the pressure has been applied. Calibration is often needed to improve accuracy. Adafruit suggests reading the resistance across the X plate (XP = D8 and XM = A2). On my board, I got 341 Ohms. Use this value as SENSITIVITY.

Try running the sketch to draw on the screen. The BLACK palette ‘button’ clears the screen and the others change the ‘ink’ colour. If the dot drawn is not directly under the stylus you can adjust the ‘fudge factors’ in the scaling section.

As a final example here is a sketch which shows off the Touch screen with buttons, bar graphs and colours. The buttons allow the user to adjust the RGB mix to display all the possible colours available. If you find one you particularly like it displays the hex value of the 16-bit colour.

There is a small amount of jitter as the bar graph re-draws but overall, the shield works quickly and very well. After the screen has updated and waiting for a touch the image is steady, sharp, and bright. Once you have calibrated the touch device it is very accurate as demonstrated with the small (30×30 pixel buttons) and provides excellent, colorful graphics on a usefully large display.

I was very pleased with the quality of the display and the accuracy of the Touch device. It sits neatly and securely on a UNO or a MEGA 2560. With an SD card reader included it was excellent value and I will be making good use of it in the future.

In this article, you will learn how to use TFT LCDs by Arduino boards. From basic commands to professional designs and technics are all explained here.

There are several components to achieve this. LEDs, 7-segments, Character and Graphic displays, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, type of user interaction, and processor capacity.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments.

In Arduino-based projects, the processor frequency is low. So it is not possible to display complex, high definition images and high-speed motions. Therefore, full-color TFT LCDs can only be used to display simple data and commands.

There are several components to achieve this. LEDs, 7-segments, Character and Graphic displays, and full-color TFT LCDs. The right component for your projects depends on the amount of data to be displayed, type of user interaction, and processor capacity.

TFT LCD is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image qualities such as addressability and contrast. A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments.

In Arduino-based projects, the processor frequency is low. So it is not possible to display complex, high definition images and high-speed motions. Therefore, full-color TFT LCDs can only be used to display simple data and commands.

After choosing the right display, It’s time to choose the right controller. If you want to display characters, tests, numbers and static images and the speed of display is not important, the Atmega328 Arduino boards (such as Arduino UNO) are a proper choice. If the size of your code is big, The UNO board may not be enough. You can use Arduino Mega2560 instead. And if you want to show high resolution images and motions with high speed, you should use the ARM core Arduino boards such as Arduino DUE.

In electronics/computer hardware a display driver is usually a semiconductor integrated circuit (but may alternatively comprise a state machine made of discrete logic and other components) which provides an interface function between a microprocessor, microcontroller, ASIC or general-purpose peripheral interface and a particular type of display device, e.g. LCD, LED, OLED, ePaper, CRT, Vacuum fluorescent or Nixie.

The LCDs manufacturers use different drivers in their products. Some of them are more popular and some of them are very unknown. To run your display easily, you should use Arduino LCDs libraries and add them to your code. Otherwise running the display may be very difficult. There are many free libraries you can find on the internet but the important point about the libraries is their compatibility with the LCD’s driver. The driver of your LCD must be known by your library. In this article, we use the Adafruit GFX library and MCUFRIEND KBV library and example codes. You can download them from the following links.

You must add the library and then upload the code. If it is the first time you run an Arduino board, don’t worry. Just follow these steps:Go to www.arduino.cc/en/Main/Software and download the software of your OS. Install the IDE software as instructed.

First you should convert your image to hex code. Download the software from the following link. if you don’t want to change the settings of the software, you must invert the color of the image and make the image horizontally mirrored and rotate it 90 degrees counterclockwise. Now add it to the software and convert it. Open the exported file and copy the hex code to Arduino IDE. x and y are locations of the image. sx and sy are sizes of image. you can change the color of the image in the last input.

Upload your image and download the converted file that the UTFT libraries can process. Now copy the hex code to Arduino IDE. x and y are locations of the image. sx and sy are size of the image.

In this template, We converted a .jpg image to .c file and added to the code, wrote a string and used the fade code to display. Then we used scroll code to move the screen left. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We used sin(); and cos(); functions to draw Arcs with our desired thickness and displayed number by text printing function. Then we converted an image to hex code and added them to the code and displayed the image by bitmap function. Then we used draw lines function to change the style of the image. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We added a converted image to code and then used two black and white arcs to create the pointer of volumes. Download the .h file and add it to the folder of the Arduino sketch.

In this template, We added a converted image and use the arc and print function to create this gauge. Download the .h file and add it to folder of the Arduino sketch.

In this template, We display simple images one after each other very fast by bitmap function. So you can make your animation by this trick. Download the .h file and add it to folder of the Arduino sketch.

In this template, We just display some images by RGBbitmap and bitmap functions. Just make a code for touchscreen and use this template. Download the .h file and add it to folder of the Arduino sketch.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey