lcd screen pressure marks free sample

• Perform highly diversified duties to install and maintain electrical apparatus on production machines and any other facility equipment (Screen Print, Punch Press, Steel Rule Die, Automated Machines, Turret, Laser Cutting Machines, etc.).

The most annoying thing about laptop damage is having a problem with its screen. It is not enough to have the laptop in good working condition. Rather, it is best if the laptop looks perfect on the outside too.

Some laptop problems do not need an expert to fix, you can do it as a DIY project. Find out how to remove pressure marks on LCD screens as explained in this article.

Pressure marks, despite how nasty they can be, unfortunately, have no specific fixing techniques. You might be lucky if you manage to remove the damage without interfering with your laptop’s part.

Liquid crystal displayis a technology used in making many electronics’ screens. Mostly found on monitors, TV screens, and even phone screens, the technology creates images by illuminating light through multiple liquid crystals.

Pressure application is the major cause of damage to these screens. This is because these screens are very sensitive. The liquid crystal, in the LCD screen, is fixed between two glass sheets.

After purchasing a good LCD screen, usually, you feel so contented; not knowing with time some problems may arise. The most common issues experienced are:

The mark does not damage your screen, although it can be frustrating seeing it there. There is software to solve this. They work by forcing the area with the dead pixel to experience a rapid change of colors.

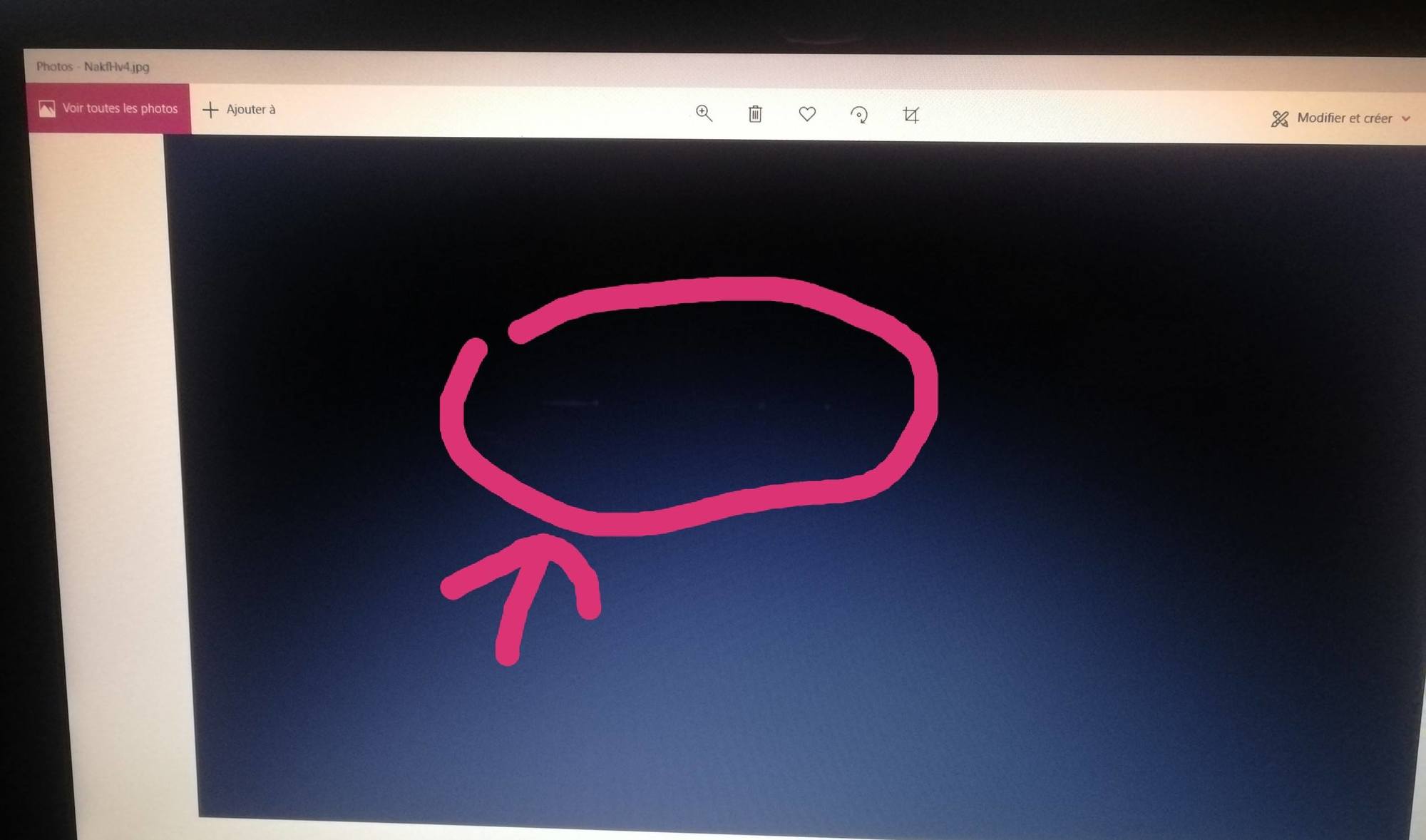

This is a layer of a crushed crystal, found between two glasses that makes the screen. They form due to physical pressure exerted on the screen. The pressure forces the crystal to lose its solid properties.

To prevent it, you will require less pressing of the screen. Avoid unnecessary holding of the screen, not unless it’s a touch screen that is designed to withstand pressure.

This should also apply when you are wiping the screen or other sensitive laptop parts like the touchpad. Ensure you do it lightly and gently. While traveling, ensure your laptop is closed properly without having any object that will exert pressure between the keyboard and screen.

Pressure marks are a result of physical force that occurs when a laptop is mishandled, example when you bring the laptop to a plane. Therefore it will require physical fixing attention.

Physically fixing the screen also is not a 100 percent guarantee of solving the problem. It may even result in worse damages since it will require opening the laptop parts.

The LCD liquid crystal display screen brought a massive change in the latest technology because we left the TV and monitor screens and got a sleek design screen.

The main problem with LCD screens and LCD pressure marks is that they get pressure spots; here in this article, we will explain what the pressure spots and black dots are and how to get rid of them.

It is not easy to remove pressure marks from the LCD screen, as you think that if your screen got damaged, you could easily replace it by changing your hardware or software spare parts.

So there is no permanent method to get rid of these pressure spots; you only need to change your screen; however, you can follow some things to free your screen from the pressure spot.

If you try to fix your screen pressure, your screen gets harmed, so be careful while selecting your pressure spots on your screen. The only way to fix this issue is to ask a professional repairer to change the screen.

Some people say that their screen automatically after a long time, but what can you wait for a long time? If you do not change it otherwise, it will also increase the pressure spot area.

Some common problems with LCD screens appear on your screen due to negligence and careless use. Here we discuss some of these problems and proven ways how to remove pressure marks from your LCD screen.

Some people also said that applying pressure on the dotted area can solve this issue, but this is not working for all the screens; maybe your screen gets more damage, so don’t use these tricks.

The crack is also a common issue that we face because of the physical damage; the screen is falling from the table, and you’re accidentally through the liquid on your screen.

Sometimes the child hits a sharp thing on the screen, so you need to change your screen in these situations because there is no way to fix this issue.

Did you notice you are working on your computer or laptop and hear some sounds from the screen’s backside? This problem mostly happens with the old computers because they used fluorescent lighting tubes and caused the sounds.

There is also a big reason for these white dots: when the micromirrors are stuck in between the screen and stop the signals from reflecting, sometimes they become permanent if you did not repair this issue in time.

Sometimes the stains are also a hurdle between you and the TV screen. But this problem is not as serious as the others. You can get rid of this problem by cleaning your screen. You can use a soft cloth and chemical cleaner to clean laptops, mobiles, and computer screens.

You can only prevent your screen from getting pressure, white dots, or vertical lines is care because many of us use the laptop without any attention and keep heavy things on the computer screen.

Yes, you can fix and remove pressure marks from LCD screen, laptop and phone screen by using wipes and chemical cleaners which are available in market.

You can also use the same method and treatment which you use for LCD, laptop and phone screen. Use wipes and chemical cleaners available in market to get rid of marks and spots on your TV.

If you are facing pressure marks on phone screen, you don’t need worry. Use wipes and chemical cleaners to remove pressure marks on phone screen as well.

Bruising screen of phone, laptop and LCD may happen when glass of screen is cracked and there are spots of different colors. This is difficult to fix bruising screen as the damage may be permanent and difficult to repair.

If you have pressure marks on monitor and want to remove spots, You can also use wipes with dry and anti-static LCD cleaning cloth to remove the dust and the stain. You can also use wipes and chemical cleaner as well.

Getting pressure marks, and white and black dots on your screen is a ubiquitous thing nowadays, and this is the only reason for our use. Some laptops getheat when we overuse them, and heat-affected screens in different ways.

Here in this article, we discuss some of the common problems of screen issues and ways how to remove pressure marks from LCD screens. We also highlight some methods and techniques that you can follow to prevent these issues.These methods will help you out to get pressure marks from the screen.

Your monitor is made up of millions of pixels. Each pixel is a group of red, green and blue subpixels that combine to create the images you see on your computer screen. When a few are dead or stuck, it can be super distracting.

To see what’s going on, you can enlist software to help. Try a third-party download like InjuredPixels for Windows. If you’re on a Mac or don’t want to download anything, go with a browser-based solution like LCD DeadPixel Test.

You can go the web browser application route with a site called JScreenFix. The free service claims to fix most stuck pixels within 10 minutes by using an HTML5 “PixelFixer” tool.

First, take note of the location of the stuck or dead pixel. Then turn off your monitor and try applying gentle pressure on the affected area to “massage” it back to life. Use something with a narrow but flat edge like a pencil eraser or a pen cap. To avoid damaging your screen, wrap it with a soft, damp microfiber cloth.

Dead and stuck pixels can appear on LCD screens of all kinds. This includes monitors, phones, and camera displays. It’s easier to spot them on larger displays, though.

If you’re using a camera, carefully look at your LCD display as you take photos. Are there any spots that stay in the same place no matter how much you move your camera? Those spots are dead or stuck pixels.

There’s a distinct difference between stuck and dead pixels. If you’re completely sure that the pixels on your screen aren’t dust, you need to identify them.

Stuck pixels are usually red, green, blue, or yellow. Dead pixels are black. No matter how much your screen changes, those pixels will remain fixed in one spot and won’t change their color.

Stuck pixels are much easier to remove than dead pixels. If you’re sure that there’s a dead pixel on your screen, you’ll probably have to hire a specialist or replace your display.

You need to be in full-screen mode. Make sure you wipe your screen beforehand so that you don’t accidentally mistake a speck of dust for a dead pixel!

Click on each color. If you don’t notice any unusual spots (black or any other color) on your screen, it’s likely that you don’t have an issue with dead or stuck pixels.

Too much rubbing can damage even more pixels on your screen and lead to serious problems. If none of the solutions work, the best way out is to contact a specialist.

This is a very simple and seemingly straightforward method. But it might be the best solution to your problem. If your screen appears glitchy, it might simply need to be refreshed.

Use a screen-cleaning spray and a cloth to wipe your display. Make sure you don’t apply too much pressure or else you might damage your screen. A few gentle swipes might get rid of the problem.

If the options above don’t work, JScreenFix might be your best solution. This is a website that anyone can use for free. You don’t need to download any programs or extensions to use it. Best of all, it promises to remove stuck pixels in less than 10 minutes.

What JScreenFix does is fix stuck pixels. If you think you have a dead pixel, you can try this method as well. For this to work effectively, you need to know where exactly your stuck pixels are located.

Dead pixels usually don’t spread. They’re usually a small fault in a display. If they do spread, you might need to hire a specialist or replace your screen.

Make sure you clean your display, take a dead pixel test, and use JScreenFix to get rid of the pixels. It’s likely that this will fix the problem and prevent you from consulting a specialist.

Before you give into your impulses and wipe your screen with whatever you have at hand, let us stop you right there. Your display is way more delicate than you think, and if you want it to last a long time in optimal conditions, you’ll need to treat it with proper love and care.

The good news is that cleaning a computer screen is more simple than you think. You only need a soft cloth, a tiny bit of water, and the most delicate of touches.

As you would expect, not all screens are created equal, and some are more delicate than others. The safest way to figure out the proper care for your screen is to search for the make and model of your device, find out if it has an LCD, LED, or some other type of display, and search for the manufacturer’s instructions on how to care for it.

If you want to skip all that, there’s an easy way to avoid making a mistake that might not only result in irreparable damage to your screen but to your entire device. According to Joe Silverman, owner of New York Computer Help, a tech repair center in New York City, no matter how much money you spent on your computer or tablet, it probably has an LED or an LCD screen if you bought it within the last three years—and neither type benefits from window cleaner or highly concentrated alcohol.

That’s the uppermost layer of your screen, which is extremely sensitive to the acidity in alcohol and in compounds like ammonia or propylene glycol. These are often present in cleaning agents such as window cleaners and degreasers. Using these liquids will corrode the surface of your screen, resulting in scratches or even smudges you won’t be able to get rid of.

Things get even trickier when you’re dealing with touchscreens. On models like the Microsoft Surface, the display is the main input—as opposed to your mouse or trackpad on a regular laptop—so it’s ultra-sensitive, Silverman says. Using a strong liquid cleaner like a degreaser or a bleach-based disinfectant can obliterate the top layer on the screen. Combine that with high pressure, and you can kiss your fancy touchscreen computer goodbye.

Another downside to newer computers is their size and weight. If you decided to splurge on a new laptop, for example, you probably found one that has top-notch components, but also a slick, lightweight design. This format is only possible if everything in your laptop is smaller and thinner. In the case of your display, a thinner screen means a weaker barrier between your computer’s guts and the elements in the outside world.

Caring for your screen is simple—it only takes a little bit of water and a dust-free cloth, such as a microfiber wipe or the piece of fabric that came with your glasses.

First, turn off your computer and disconnect the charger. This might sound paranoid, but the benefit is twofold—you avoid any chance of triggering an electrical surge, and your screen will remain black, which will make it easier to see any dirt and grime.

Pour a couple drops of water on your cloth. Forget paper towels or the sleeve of that soft cotton t-shirt you love—microfiber is your best bet. Still, no matter how soft it is, a dry wipe could always leave micro-abrasions on your screen. The moisture will also help gather dust and particles while lifting grease from your display.

Use circular motions starting in the center of your screen and moving outward, so you don’t leave any streaks. If you can see any droplets or water traces on the glass while you clean, you’ve used way too much water. Gently dab the residual H2O with an absorbent cloth or tissue paper and start again.

If you’re dealing with next-level gunk, you can use isopropyl alcohol at 70 percent or lower, Silverman says. “That percentage is very important,” he explains. “We’d only use 90 percent or higher on dummy parts that don’t have sensors, like top cases and keyboards.” In these extreme cases, spray the alcohol on the cloth, never directly on the screen, and wipe it gently.

Just like solar damage, screen damage is cumulative. The more pressure you apply, the more abrasive a product you use, and the more often you use it, the greater the damage you’re inflicting on the protective layer of your display and the delicate sensors underneath it.

Maybe you can get away with using a high percentage of alcohol or even a window cleaner on your computer screen once or twice. But if you keep at it, eventually you’ll see the deleterious effects.

“You’ll see discoloration, lines (vertical and horizontal); sometimes it looks pretty and rainbow-like,” Silverman says. “Sometimes it’ll blink and sometimes you’ll see droplets of water or liquid in the back of the screen. There’s a lot of ways in which damage appears.”

The best way to avoid damaging your screen while cleaning it is to simply keep it from getting dirty in the first place. If you have a laptop, cover the keyboard with a thin microfiber cloth before closing it to prevent finger grease from transferring to the screen. If you have a touchscreen, wash your hands often before you use it, but make sure you let your hands dry completely before you start tapping—the soapy water or liquid hand cleanser from your fingers can easily end up on the screen and corrode it.

Your phone was designed to be carried, dropped, tapped, swiped, smashed against your face for long periods of time, and stowed in the deepest corners of your bag. In other words, its screen is way more resilient than your computer’s.

Silverman explains that most iPhones and Samsung phones, for example, have screens made out of one thick piece of glass. These, as opposed to computer screens, have all the LCD layers fused together, making them much more difficult to damage. Still, if you’re using alcohol, he recommends keeping the concentration at 70 percent or lower, using a soft cloth, and applying only low pressure to get rid of any accumulated gunk there.

Replacing the screen of your computer or smartphone can be expensive, and even if that’s not an issue for you, no one wants their devices to fail when they need them the most. So remember these tips well—we hope you never have to read this article again.

Are you looking for how to get rid of those irritating spots on your phone screen? This article shows you everything you need to know on how to fix pressure spots on LCD screens and how to prevent them in the future.

One of the deadliest and most frustrating issues you could have with your mobile phone is screen damages. And for pressure spots on LCD screens, it"s somewhat annoying than breaking the whole screen itself, as it requires going for replacement in most cases.

As its name implies, pressure spots on phone screens can render the display useless (or irritating, based on how you see it) by creating spots of different shapes and styles on the screen. These spots show continually, and most times, permanently on the display and can obstruct your viewing or cause other problems such as dead pixels, flickering, or blurriness.

When you apply too much pressure on your phone’s display – whether accidentally, intentionally, or carelessly, it damaged the LCD components, hence creating different spots on the display.

Pressure spots on LCD screens can come in different forms and shapes depending on the density of pressure applied. Sometimes, the spots can be whitish, deep black, or come in various colors depending on what’s currently showing on the screen.

Unfortunately, learning how to fix pressure spots on LCD screens isn"t the same as learning how to fix simple hardware and software issues. Simply put, there is no way to repair a phone screen that was damaged by pressure.

Attempting to get rid of pressure spots on LCD screens can cause more harm than good. Hence, you had better find a professional phone repairer to help you with screen replacement.

Meanwhile, some users reported that the pressure spots on their phone screen got healed after a few years. But do you want to keep seeing the same issue on your screen for years? So, a screen replacement is the only way out.

Fortunately, if you use a TECNO, Infinix, or itel smartphone, Carlcare Service is the best bet for you when it comes to replacing your damaged screen and fixing other issues on the device. We"re the official after-sales service provider to render professional repair and customer services for these brands.

And if you’ve bought our extra Screen Protection Plan for your TECNO, Infinix, or itel device earlier, you might be able to replace your screen for free, or better still, get huge discounts on-screen replacement at Carlcare.

Also, if you notice pressure spots on your Syinix TV, the best thing to do is bring it down to our service centre for proper screen replacement with genuine stock parts.

Paying for screen replacement from your own pocket (especially when you don’t have any form of screen insurance or protection plan), can be a pain in the ass. However, there’s probably nothing you could have done better than learning how to protect your phone screen from pressure spots in the future.

Pressure spots on LCD screens (or any screen in general) occur accidentally or carelessly. The only way to avoid such damage in the future is to handle your phone carefully. Try as much to shun applying much pressure on the screen while playing games and performing other tasks.

Overall, the only way to prevent your phone screen from getting pressure spots in the feature is to handle it carefully whenever and wherever possible. If you ever come across the need to drop your phone somewhere, ensure you don’t place anything on it.

Taking these few things into consideration would help you protect your phone screen from pressure spots in the future, rather than looking for how to fix pressure spots on LCD screen when it happens.

Now, if you’ve accidentally applied much pressure on your phone’s screen and some spots are showing on it when you turn it on, the best thing you can do is to visit the official service provider for your device for a screen replacement. Trying to shift the spots away or performing some DIY tricks may cause more harm than good.

That annoying dead pixel on your TFT, OLED, or LCD screen might just be stuck and easy to fix. We"ll show you how to do it. You can still return your monitor if this doesn"t work; nothing we recommend here will void your warranty.

Yes, you should test any new monitor for bad pixels. You can simply run your screen through a palette of basic colors, as well as black and white in full-screen mode using a tool like EIZO Monitor Test.

To test your screen, check all the boxes you want to include in your test. We recommend the default setting of having all boxes checked. If you"re testing multiple monitors, you can open the test on an additional monitor. When you"re ready, click Start test to launch the full-screen test window.

Below you see the first test pattern. Each screen has an explainer in the bottom right detailing what you should look for. Next, you"ll see a menu that lets you go from one test to the next on the left. Move through the black and white screens and all the solid colors (green, blue, and red) and check our screen. To exit, press the ESC key or the exit symbol in the top right.

The tool will load a black browser window with a square of flashing pixels. Press the green button in the bottom right to go full-screen. Drag the flashing square to where you found the stuck pixel and leave it there for at least 10 minutes.

Let it run through all colors in Auto mode to spot whether you have any weird pixels on your screen. If you do, start the fix, which will rapidly flash your entire screen with black, white, and basic color pixels.

This works because, in a stuck pixel, the liquid in one or more of its sub-pixels has not spread equally. When your screen"s backlight turns on, different amounts of liquid pass through the pixel to create different colors. When you apply pressure, you"re forcing the liquid out, and when you release the pressure, chances are the liquid will push in, spreading around evenly as it should.

When all attempts to revive your bad pixel fail, the next best thing you can do is to make peace with it. One ugly pixel won"t break your screen, and eventually, you"ll forget about it. If the defect affects more than a single pixel, however, or just bothers you a lot, you can always replace your monitor.

Bright or dark sub-pixels can occur during the production of the LCD Monitor panel but does not affect the LCD Monitor functionality. The customer may notice the bright or dark spots if the film of the liquid crystal does not perform as expected while customers uses the LCD monitor. However, this is not considered a defect unless the number of bright and dark subpixels exceeds the maximum allowable threshold (...)

Should all of these approaches fail to fix your dead pixel warrior, at least you"ll now know it"s not simple to fix, and, you might actually have to replace the screen.

Before you start, power-off and unplug your monitor. Spray the cleaning solution on a soft cloth (for example an old T-shirt), lint-free microfiber cloth, or some other very soft cloth. A large cloth is best, since it will help reducing the risk of leaving streaks across the display from finger pressure.

Starting from the top, wipe the screen in one direction until you have cleaned the entire screen. Apply light, but distributed pressure. Repeat if necessary. Let it air dry.

The use of liquid crystal displays (LCDs) in user interface assemblies is widespread across nearly all industries, locations, and operating environments. Over the last 20 years, the cost of LCD displays has significantly dropped, allowing for this technology to be incorporated into many of the everyday devices we rely on.

The odds are high you are reading this blog post on a laptop or tablet, and it’s likely the actual screen uses LCD technology to render the image onto a low-profile pane of glass. Reach into your pocket. Yes, that smartphone likely uses LCD technology for the screen. As you enter your car, does your dashboard come alive with a complex user interface? What about the menu at your favorite local drive-thru restaurant? These are some everyday examples of the widespread use of LCD technology.

But did you know that the U.S. military is using LCD displays to improve the ability of our warfighters to interact with their equipment? In hospitals around the world, lifesaving medical devices are monitored and controlled by an LCD touchscreen interface. Maritime GPS and navigation systems provide real-time location, heading, and speed information to captains while on the high seas. It’s clear that people’s lives depend on these devices operating in a range of environments.

As the use of LCDs continues to expand, and larger screen sizes become even less expensive, one inherent flaw of LCDs remains: LCD pixels behave poorly at low temperatures. For some applications, LCD displays will not operate whatsoever at low temperatures. This is important because for mil-aero applications, outdoor consumer products, automobiles, or anywhere the temperature is below freezing, the LCD crystal’s performance will begin to deteriorate. If the LCD display exhibits poor color viewing, sluggish resolution, or even worse, permanently damaged pixels, this will limit the ability to use LCD technologies in frigid environments. To address this, there are several design measures that can be explored to minimize the impact of low temperatures on LCDs.

Most LCD displays utilize pixels known as TFT (Thin-Film-Transistor) Color Liquid Crystals, which are the backbone to the billions of LCD screens in use today. Since the individual pixels utilize a fluid-like crystal material as the ambient temperature is reduced, this fluid will become more viscous compromising performance. For many LCD displays, temperatures below 0°C represent the point where performance degrades.

Have you tried to use your smartphone while skiing or ice fishing? What about those of you living in the northern latitudes - have you accidently left your phone in your car overnight where the temperatures drop well below freezing? You may have noticed a sluggish screen response, poor contrast with certain colors, or even worse permanent damage to your screen. While this is normal, it’s certainly a nuisance. As a design engineer, the goal is to select an LCD technology that offers the best performance at the desired temperature range. If your LCD display is required to operate at temperatures below freezing, review the manufacturer’s data sheets for both the operating and storage temperature ranges. Listed below are two different off-the-shelf LCD displays, each with different temperature ratings. It should be noted that there are limited options for off-the-shelf displays with resilience to extreme low temperatures.

For many military applications, in order to comply with the various mil standards a product must be rated for -30°C operational temperature and -51°C storage temperature. The question remains: how can you operate an LCD display at -30°C if the product is only rated for -20°C operating temperature? The answer is to use a heat source to raise the display temperature to an acceptable range. If there is an adjacent motor or another device that generates heat, this alone may be enough to warm the display. If not, a dedicated low-profile heater is an excellent option to consider.

Made of an etched layer of steel and enveloped in an electrically insulating material, a flat flexible polyimide heater is an excellent option where space and power are limited. These devices behave as resistive heaters and can operate off a wide range of voltages all the way up to 120V. These heaters can also function with both AC and DC power sources. Their heat output is typically characterized by watts per unit area and must be sized to the product specifications. These heaters can also be affixed with a pressure sensitive adhesive on the rear, allowing them to be “glued” to any surface. The flying leads off the heater can be further customized to support any type of custom interconnect. A full-service manufacturing partner like Epec can help develop a custom solution for any LCD application that requires a custom low-profile heater.

With no thermal mass to dissipate the heat, polyimide heaters can reach temperatures in excess of 100°C in less than a few minutes of operation. Incorporating a heater by itself is not enough to manage the low temperature effects on an LCD display. What if the heater is improperly sized and damages the LCD display? What happens if the heater remains on too long and damages other components in your system? Just like the thermostat in your home, it’s important to incorporate a real-temp temperature sensing feedback loop to control the on/off function of the heater.

Another important consideration when selecting a temperature sensor is how to mount the individual sensors onto the display. Most LCD displays are designed with a sheet metal backer that serves as an ideal surface to mount the temperature sensors. There are several types of thermally conductive epoxies that provide a robust and cost-effective way to affix the delicate items onto the display. Since there are several types of epoxies to choose from, it’s important to use a compound with the appropriate working life and cure time.

For example, if you are kitting 20 LCD displays and the working life of the thermal epoxy is 8 minutes, you may find yourself struggling to complete the project before the epoxy begins to harden.

Before building any type of prototype LCD heater assembly, it’s important to carefully study the heat transfer of the system. Heat will be generated by the flexible polyimide heater and then will transfer to the LCD display and other parts of the system. Although heat will radiate, convect, and be conducted away from the heater, the primary type of heat transfer will be through conduction. This is important because if your heater is touching a large heat sink (ex. aluminum chassis), this will impact the ability of the heater to warm your LCD display as heat will be drawn toward the heat sink.

Before freezing the design (no pun intended) on any project that requires an LCD display to operate at low temperatures, it’s critical to perform low temperature first. This type of testing usually involves a thermal chamber, a way to operate the system, and a means to measure the temperature vs time. Most thermal chambers provide an access port or other means to snake wires into the chamber without compromising performance. This way, power can be supplied to the heater and display, while data can be captured from the temperature sensors.

The first objective of the low-temperature testing is to determine the actual effects of cold exposure on the LCD display itself. Does the LCD display function at cold? Are certain colors more impacted by the cold than others? How sluggish is the screen? Does the LCD display performance improve once the system is returned to ambient conditions? These are all significant and appropriate questions and nearly impossible to answer without actual testing.

As LCD displays continue to be a critical part of our society, their use will become even more widespread. Costs will continue to decrease with larger and larger screens being launched into production every year. This means there will be more applications that require their operation in extreme environments, including the low-temperature regions of the world. By incorporating design measures to mitigate the effects of cold on LCD displays, they can be used virtually anywhere. But this doesn’t come easy. Engineers must understand the design limitations and ways to address the overarching design challenges.

A full-service manufacturing partner like Epec offers a high-value solution to be able to design, develop, and manufacture systems that push the limits of off-the-shelf hardware like LCD displays. This fact helps lower the effective program cost and decreases the time to market for any high-risk development project.

We"ve all had that moment: You"re sitting at your computer or laptop and the light hits your screen in a way to reveal an unsightly accumulation of streaks, fingerprints, and dust.

To help, we round up the most important things to know about cleaning your computer screen, whether it"s a Mac or PC. While it"s a simple process, there are a few important rules to keep in mind to make sure you"re doing it safely.

Computer screens are not all made the same, and thus can"t all be cleaned the same way. You"ll want to be careful no matter your screen type, but it"s helpful to know that displays come in two categories:Glass-coated screens: The screens on newer iMac displays and MacBooks have a glass overlay. Glass displays are a little less delicate than LCD or LED screens, and mild cleaning solutions, like rubbing alcohol, are generally safe to use on them.

LCD or LED screens:Windows computers and most touchscreens and matte displays are typically not coated in glass. Extra care should be taken with these screens so not to damage the pixels that make up the display.

To clean a computer screen, you really just need two things: A microfiber cloth and filtered or distilled water. That"s to say you don"t need a special store-bought cleaning solution.

If you"d like some extra sanitation power, an equal parts mixture of water and vinegar is safe no matter your screen type. If you know that your display is glass-coated, you can also use an equal parts mixture of water and 70% rubbing alcohol.What you needTwo lint-free microfiber cloths

d3sign/Getty ImagesTurn the computer or laptop off.For safety reasons, begin by letting the device cool down completely. Dust, fingerprints, and smudges are also easier to spot on a black screen.

Wipe off dust with a dry cloth. Use a dry, lint-free microfiber cloth to gently wipe away any visible dust and dirt. If necessary, apply gentle pressure to remove surface-level smudges.

If any marks remain, wipe with a lightly moistened cloth.For glass-coated screens, you can use a mixture of equal parts water and vinegar or rubbing alcohol. For LED or LCD screens, use only water. Spray or lightly dab the solution directly onto the cloth and carefully wipe the screen from left to right.

Buff with a dry cloth and air-dry.If any streaks remain once the screen dries, gently buff them with the dry cloth. Before you turn your computer or laptop back on, allow the screen to dry completely.Note:Apple claims that you can use 70% isopropyl disinfecting wipes to clean any Apple product. Just remember not to get any liquid into the device"s ports or openings — to avoid this, you might want to wring out the wipe to remove any excess liquid before using it.

For the best advice for cleaning your screen, it"s a smart idea to check your owner"s manual, which provides the manufacturer"s specific recommendations. But since screens are especially susceptible to damage, there are a few general guidelines that apply, no matter the type of screen you own.

Turn off your computer before cleaning the screen. This is just safe practice where any amount of liquid is involved, but more specifically, any static on the screen could create a shock and damage the internal components.

Do not use abrasive cleaning solutions. This includes bleach (or any products containing bleach), hydrogen peroxide, or all-purpose spray cleaners. Using an abrasive cleaner can ruin the finish of your screen.

Use filtered or distilled water. Especially in areas with hard water, water containing minerals like calcium and magnesium can damage your screen or leave even more streaks.

Use only soft microfiber cloths.Even a fabric as soft as a cotton shirt has snags and uneven particles that can scratch a computer screen. For this reason, avoid T-shirts, towels, and paper towels. The exception is the Apple Pro Display XDR or iMac, which requires a special polishing cloth.

Never spray cleaning solution directly onto the screen. To avoid any risk of damage from excess moisture, mist the solution directly onto the microfiber cloth instead.

Do not wipe in circles. Wiping in circles can create uneven pressure and ultimately lead to screen damage. It"s also more likely to create streaking. Wipe in tight, Z-shaped motions, or in broad strokes from side to side.

Do not scrub.Apply gentle pressure only. Hard scrubbing can damage the internal components of the screen and could leave scratches or spots of discoloration or dead pixels that won"t go away.Melanie Weir

Melanie Weir is a freelance author for Insider, mainly focusing on the Tech Reference section, but occasionally contributing to Lifestyle and Entertainment topics as well. She is also a freelance writer for ScreenRant, and is the Lead Weekend News Editor at TheThings.com. In her spare time she writes plays for both stage and screen. She can be reached at melanie.weir1008@gmail.com, or through LinkedIn.

As the weather warms, it"s time for everyone"s "favorite" pastime: spring cleaning. While you"re dusting off the shelves and shoveling out a winter"s worth of detritus, spare a moment to check your TV. Dust and grime can accumulate there, and over time it can become more and more noticeable. And if you have children, there may be an array of fingerprints and other smears on the screen.

Want the longer version? Here"s what the top TV manufacturers say about cleaning their screens:Cleaning your 4K, OLED, or LED TV screen with a soft, dry cloth is recommended. The goal here is to avoid scratching the screen. Gentle, circular motions tend to give better results, since the circular motion hits each area from several angles in a single swipe.

To clean the frame and screen, gently wipe it with a microfiber cleaning cloth. Make sure to wipe the TV frame and screen as gently as possible. TV screens are fragile and can be damaged when pressed too hard.

Important: Never use any type of window cleaner, soap, scouring powder, wax, or any cleanser with solvents such as alcohol, benzene, ammonia, or acetone. Never use abrasive pads or paper towels. If you do, you can scratch the screen or strip the anti-glare coating off the screen and cause permanent damage. Never spray water directly onto the TV. Make sure to wipe the TV as gently as possible. TV screens are fragile and can be damaged when pressed too hard.Gently wipe the screen or the exterior with a dry, soft cloth, such as an eyeglass cleaner.

For inks from oil markers on the screen, soak a cloth in a non-soap synthetic cleanser diluted (by less than 1% ) with water. Squeeze the cloth tightly to eliminate excess liquid, then wipe gently to remove the ink. Use non-soap cleansers cautiously because it may cause environmental problems when disposed improperly.

So why not Windex? Regular Windex is formulated for glass windows, plus a few other surfaces. It contains ammonia and alcohol, not the friendliest of chemicals. S. C. Johnson doesn"t explicitly say not to use Windex on TVs, but it offers Windex Electronics wipes and cleaners, so infer what you will. The better screen cleaners will clearly state that they do not contain alcohol or ammonia.

At last count, I found a billion companies making TV screen cleaners. Almost all of these are something like 99 percent water, 1 percent other stuff. Years ago I tested a handful and found them, on average, to work well enough. If you don"t have luck with a simple cloth and possibly distilled water, a screen cleaner is worth a try, and as a bonus you can also use it for your laptop, tablet and cell phone screens. Plus, they come with a microfiber cloth. If they don"t clearly state they don"t contain alcohol and ammonia, however, I would skip them.

So yeah, cleaning your TV is a good idea. But just remember that they"re exceptionally fragile. Why risk marring their surface by using cleaning methods the companies themselves don"t advise? If you damage your screen with cleaners, you won"t be able to fix it.

Screen cleaning kits are fine, though most people won"t need them. Remember, like all TV accessories, the store is selling them because they probably make more profit on that $20 kit than on a $500 TV.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey