lcd display comparison factory

Asia has long dominated the display module TFT LCD manufacturers’ scene. After all, most major display module manufacturers can be found in countries like China, South Korea, Japan, and India.

However, the United States doesn’t fall short of its display module manufacturers. Most American module companies may not be as well-known as their Asian counterparts, but they still produce high-quality display products for both consumers and industrial clients.

In this post, we’ll list down 7 best display module TFT LCD manufacturers in the USA. We’ll see why these companies deserve recognition as top players in the American display module industry.

STONE Technologies is a leading display module TFT LCD manufacturer in the world. The company is based in Beijing, China, and has been in operations since 2010. STONE quickly grew to become one of the most trusted display module manufacturers in 14 years.

Now, let’s move on to the list of the best display module manufacturers in the USA. These companies are your best picks if you need to find a display module TFT LCD manufacturer based in the United States:

Planar Systems is a digital display company headquartered in Hillsboro, Oregon. It specializes in providing digital display solutions such as LCD video walls and large format LCD displays.

Planar’s manufacturing facilities are located in Finland, France, and North America. Specifically, large-format displays are manufactured and assembled in Albi, France.

Another thing that makes Planar successful is its relentless focus on its customers. The company listens to what each customer requires so that they can come up with effective display solutions to address these needs.

Microtips Technology is a global electronics manufacturer based in Orlando, Florida. The company was established in 1990 and has grown into a strong fixture in the LCD industry.

What makes Microtips a great display module TFT LCD manufacturer in the USA lies in its close ties with all its customers. It does so by establishing a good rapport with its clients starting from the initial product discussions. Microtips manages to keep this exceptional rapport throughout the entire client relationship by:

Displaytech is an American display module TFT LCD manufacturer headquartered in Carlsbad, California. It was founded in 1989 and is part of several companies under the Seacomp group. The company specializes in manufacturing small to medium-sized LCD modules for various devices across all possible industries.

The company also manufactures embedded TFT devices, interface boards, and LCD development boards. Also, Displaytech offers design services for embedded products, display-based PCB assemblies, and turnkey products.

Displaytech makes it easy for clients to create their own customized LCD modules. There is a feature called Design Your Custom LCD Panel found on their site. Clients simply need to input their specifications such as their desired dimensions, LCD configuration, attributes, connector type, operating and storage temperature, and other pertinent information. Clients can then submit this form to Displaytech to get feedback, suggestions, and quotes.

Clients are assured of high-quality products from Displaytech. This is because of the numerous ISO certifications that the company holds for medical devices, automotive, and quality management. Displaytech also holds RoHS and REACH certifications.

A vast product range, good customization options, and responsive customer service – all these factors make Displaytech among the leading LCD manufacturers in the USA.

Products that Phoenix Display offers include standard, semi-custom, and fully-customized LCD modules. Specifically, these products comprise Phoenix Display’s offerings:

Phoenix Display also integrates the display design to all existing peripheral components, thereby lowering manufacturing costs, improving overall system reliability, and removes unnecessary interconnects.

Clients flock to Phoenix Display because of their decades-long experience in the display manufacturing field. The company also combines its technical expertise with its competitive manufacturing capabilities to produce the best possible LCD products for its clients.

True Vision Displays is an American display module TFT LCD manufacturing company located at Cerritos, California. It specializes in LCD display solutions for special applications in modern industries. Most of their clients come from highly-demanding fields such as aerospace, defense, medical, and financial industries.

The company produces several types of TFT LCD products. Most of them are industrial-grade and comes in various resolution types such as VGA, QVGA, XGA, and SXGA. Clients may also select product enclosures for these modules.

All products feature high-bright LCD systems that come from the company’s proprietary low-power LED backlight technology. The modules and screens also come in ruggedized forms perfect for highly-demanding outdoor industrial use.

Slow but steady growth has always been True Vision Display’s business strategy. And the company continues to be known globally through its excellent quality display products, robust research and development team, top-of-the-line manufacturing facilities, and straightforward client communication.

LXD Incorporated is among the earliest LCD manufacturers in the world. The company was founded in 1968 by James Fergason under the name International Liquid Xtal Company (ILIXCO). Its first headquarters was in Kent, Ohio. At present, LXD is based in Raleigh, North Carolina.

All of their display modules can be customized to fit any kind of specifications their clients may require. Display modules also pass through a series of reliability tests before leaving the manufacturing line. As such, LXD’s products can withstand extreme outdoor environments and operates on a wide range of temperature conditions.

Cystalfontz America is a leading supplier and manufacturer of HMI display solutions. The company is located in Spokane Valley, Washington. It has been in the display solutions business since 1998.

Crystalfontz takes pride in its ISO 9001 certification, meaning the company has effective quality control measures in place for all of its products. After all, providing high-quality products to all customers remains the company’s topmost priority. Hence, many clients from small hobbyists to large top-tier American companies partner with Crystalfontz for their display solution needs.

We’ve listed the top 7 display module TFT LCD manufacturers in the USA. All these companies may not be as well-known as other Asian manufacturers are, but they are equally competent and can deliver high-quality display products according to the client’s specifications. Contact any of them if you need a US-based manufacturer to service your display solutions needs.

We also briefly touched on STONE Technologies, another excellent LCD module manufacturer based in China. Consider partnering with STONE if you want top-of-the-line smart LCD products and you’re not necessarily looking for a US-based manufacturer. STONE will surely provide the right display solution for your needs anywhere you are on the globe.

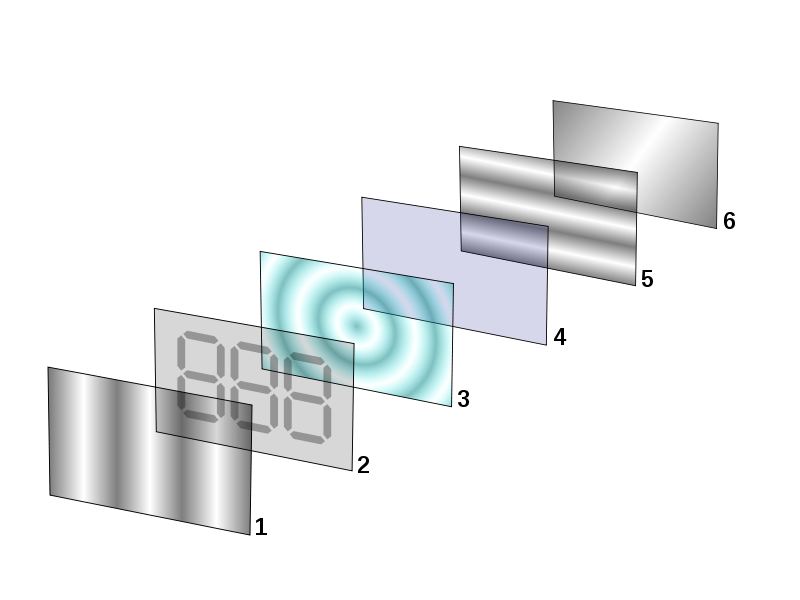

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

Sony produces and sells commercial MicroLED displays called CLEDIS (Crystal-LED Integrated Displays, also called Canvas-LED) in small quantities.video walls.

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Business Place Information – Global Operation | SAMSUNG DISPLAY". www.samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

Byeonghwa, Yeon. "Business Place Information – Global Operation – SAMSUNG DISPLAY". Samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

www.etnews.com (30 June 2017). "Samsung Display to Construct World"s Biggest OLED Plant". Archived from the original on 2019-06-09. Retrieved 2019-06-09.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Screen technology, quality, and visibility are just some of the most important factors to consider when choosing between AMOLED and LCD displays. Average consumers might not necessarily know the difference between these two types of devices or why one is preferable to the other. In this article, we’ll draw comparisons between LCD vs. AMOLED displays so you can decide which type of screen is the right choice for your personal or professional applications.

First, it’s important to note that AMOLED and Super AMOLEDs are both types of OLED display technology. OLED stands for Organic Light Emitting Diode. This is a type of thin-film display technology that’s built directly into the screen. The electroluminescent materials, also known as the light emitting diodes, immediately light up when they contact electricity.

AMOLED is an acronym that stands for active-matrix light-emitting diodes. This is a step up from traditional OLEDs. The basic concept of lighting up crystal diodes using electricity is the same, but the execution is slightly different. Each pixel inside of AMOLED displays consists of individual thin-film transistor strips that light up when an electrical current runs through them.

Super AMOLED devices are also descendants of the OLED technological display family. Commonly used for smartphones, AMOLEDs feature innovative touch technology integrated directly into the screen rather than including a separate thin film on top of the screen.

If you frequently use electronic devices, chances are very high that you’ve most likely come across an LCD (liquid crystal display) in some capacity. Common applications for LCDs include electronic billboards, computer and laptop monitors, digital cameras, portable electronic games, and the list goes on. LCDs are flat-panel displays. They consist of liquid crystal films that are sandwiched between two thin polarized glass layers. Backlighting is used to activate the crystals and illuminate the screen to present the desired image to the user.

– No backlighting means the display powers off pixels when showing the black portions of an image– Brighter overall picture quality, colours are true to life

Screen size and technology– AMOLEDs eliminate the need for a backlighting layer, so the screens can be made thinner– LCDs feature a backlighting layer, they require a thicker design, and will always be bulkier than AMOLEDs

Display prices– Higher price point because they cost more to design and manufacture– Require more layers, but they use a slightly more affordable technology and have been around for years, which means all of the kinks have already been ironed out of the design and manufacturing process

That depends on what you need the device for and how much you are willing or able to spend. For basic and everyday applications, you’re probably better off purchasing a standard LCD device. But if you’re looking for enhanced picture quality with excellent colour contrast and have an expansive budget, then AMOLED is probably the right device for you.

At Nauticomp Inc., we’re always at the forefront of state-of-the-art commercial and industrial display design and manufacturing. Our devices are customizable and suitable for a wide range of applications from military ops to retail POS, and so much more. Contact us today to learn more.

In the LCD display screen industry, LCD has been called two ways, one is the assembly LCD module, the other is the original LCD screen. Do you know the difference between them? To sum up, there are three main obvious differences.

LCD module is generally produced by LCD module manufacturers, while the original LCD screen is generally produced by the brand"s own LCD panel factory. Different manufacturers mean different services.

The price of the original LCD screen is higher than that of the assembled LCD module. Due to the original lcd screen from the manufacturer to the agent, the cost of different levels of agents is also different. And assembly lcd module manufacturers are generally ex-factory price, so the price is lower.

TFT LCD is a mature technology. OLED is a relatively new display technology, being used in more and more applications. As for Micro LED, it is a new generation technology with very promising future. Followings are the pros and cons of each display technology.

TFT Liquid Crystal Display is widely used these days. Since LCD itself doesn"t emit light. TFT LCD relies on white LED backlight to show content. This is an explanation of how TFT LCD works.

Relatively lower contrast:Light needs to pass through LCD glasses, liquid crystal layer, polarizers and color filters. Over 90% is lost. Also, LCD can not display pure black.

Organic Light-Emitting Diode is built from an electro-luminescent layer that contains organic compounds, which emit light in response to an electric current. There are two types of OLED, Passive Matrix OLED (PMOLED) and Active Matrix OLED (AMOLED). These driving methods are similar to LCD"s. PMOLED is controlled sequentially using a matrix addressing scheme, m + n control signals are required to address a m x n display. AMOLED uses a TFT backplane that can switch individual pixels on and off.

In market, LCD means passive matrix LCDs which increase TN (Twisted Nematic), STN (Super Twisted Nematic), or FSTN (Film Compensated STN) LCD Displays. It is a kind of earliest and lowest cost display technology.

LCD screens are still found in the market of low cost watches, calculators, clocks, utility meters etc. because of its advantages of low cost, fast response time (speed), wide temperature range, low power consumption, sunlight readable with transflective or reflective polarizers etc. Most of them are monochrome LCD display and belong to passive-matrix LCDs.

TFT LCDs have capacitors and transistors. These are the two elements that play a key part in ensuring that the TFT display monitor functions by using a very small amount of energy without running out of operation.

Normally, we say TFT LCD panels or TFT screens, we mean they are TN (Twisted Nematic) Type TFT displays or TN panels, or TN screen technology. TFT is active-matrix LCDs, it is a kind of LCD technologies.

TFT has wider viewing angles, better contrast ratio than TN displays. TFT display technologies have been widely used for computer monitors, laptops, medical monitors, industrial monitors, ATM, point of sales etc.

Actually, IPS technology is a kind of TFT display with thin film transistors for individual pixels. But IPS displays have superior high contrast, wide viewing angle, color reproduction, image quality etc. IPS screens have been found in high-end applications, like Apple iPhones, iPads, Samsung mobile phones, more expensive LCD monitors etc.

Both TFT LCD displays and IPS LCD displays are active matrix displays, neither of them can produce color, there is a layer of RGB (red, green, blue) color filter in each LCD pixels to make LCD showing colors. If you use a magnifier to see your monitor, you will see RGB color. With switch on/off and different level of brightness RGB, we can get many colors.

Neither of them can’t release color themselves, they have relied on extra light source in order to display. LED backlights are usually be together with them in the display modules as the light sources. Besides, both TFT screens and IPS screens are transmissive, it will need more power or more expensive than passive matrix LCD screens to be seen under sunlight. IPS screens transmittance is lower than TFT screens, more power is needed for IPS LCD display.

There is a constant debate on Amoled vs LCD, which is a better display? Where Amoled display offers some remarkable colors with deep black eye-soothing contrast ratio, LCD displays offer much more subtle colors with better off-axis angles for viewing & offers a much brighter picture quality.

While purchasing a new smartphone we consider various specifications like software, camera, processor, battery, display type etc. Among all the specifications display is something that most people are concerned about. 2 of the major competitors of smartphone display are AMOLED and LCD. Often in the LCD vs Amoled comparison, people get confused about which one to choose. In this article, we have explained a clear comparison of the Amoled vs LCD screen to find out which is actually better.

Amoled display is nothing but a part of OLED display which comes with some extra features. The first component is Light Emitting Diode (LED) and the second component is "O", here "O" stands for organic & together they make OLED. The real meaning derived from it is organic material placed with 2 conductors in every LED. And this is how light is produced.

The OLED display can generate light out of individual pixels. AMOLED displays contain Thin Film Translator (TLT) which makes the overall procedure of sourcing current to the correct pixel much quicker and smoother. The TXT further helps grab control for operating different pixels at a time. For example, some pixels could be absolutely switched off though others remain on in Amoled displays. This produces a deep black color.

Speaking about LCDs, it is relatively pretty much commonly found in today"s smartphones. LCD (Liquid Crystal Display) offers a devoted black light that is white or rather slightly blueish in color. Mostly here we get a blue light that is passed through some yellowish phosphor filter which brings out the white light. The white light is subsequently passed through multiple filters and thereafter the crystal elements are again passed through blue, red & green filters. Note that LCD displays have both passive and active matrix which depends on the cost and requirement involved.

Since the process involved in LCDs is much more complex than Amoled & requires extra steps, when compared to AMOLED displays, LCDs are less battery friendly. In the technological era where energy efficiency is the first priority, Amoled displays are certainly going to be the future of display technology. But both of them come with a separate set of pros and cons and it is only by knowing the pros and cons you will be able to choose the right one.

Amoled display technology is mostly used in smartphones, media players & digital cameras. Amoled is mostly used in low power, cost-effective & large application sizes.

Cost is one of the major factors that act as a differentiator between the two display types. Amoled displays are comparatively more expensive than LCD displays because LCD displays are much cheaper to manufacture. So while buying a low-budget smartphone, the probability to get a Amoled display is pretty less.

The quality of a display is mainly measured according to the colors and sharpness it offers. Also while comparing two displays, only technology comparison won"t work because often displays behave inversely even if a manufacturer is using the very same technology. If you consider colors especially contrasting colors such as blue, red or green, Amoled will serve better throughout the day. This happens mainly because in the case of AMOLED displays, as mentioned above, every pixel present in it emit its own light whereas in LCD light comes out of the backlight. Therefore Amoled displays offer high-end saturation and vibrant colors compared to LCD displays.

As Amoled displays put out vibrant colors, you will find Amoled displays to be warmer in nature compared to LCD displays which has a more neutral whitish tint. In short, the pictures seen on Amoled displays are more eye-soothing compared to LCD displays where the pictures appear more natural.

In the Amoled vs LCD screen display comparison, another thing to consider is the brightness offered by both of them. Compared to LCD displays, Amoled displays have lesser brightness levels. This is mainly because of the backlight in LCD displays which emits a higher brightness level. Therefore if you are a person who spends most of the time outdoors and mostly uses your smartphone under the sun, then LCD is the right choice for you. Although certain leading brands are working on the brightness level in Amoled displays.

The display is one such thing that sucks your phone"s battery to a great extent. In Amoled displays, the pixels can get absolutely switched off thereby saving a lot of battery. Whereas LCD displays remain dependent on the back light, as a result even if your screen is completely black, the backlight remain switched on throughout. This is why even though Amoled displays are more expensive than LCD displays as they consume much less battery than LCD displays.

In the battle between LCD display vs Amoled display both come with separate pros and cons. Well if battery consumption and color contrast or saturation is a concern then the Amoled display is going to win over LCD display anyway. While purchasing a smartphone, customers today mainly focus on two features- lesser battery consumption and a high-quality display. Amoled display offers both the benefits- high-end vibrant display and less battery consumption. The only criteria where LCD displays win over Amoled is the brightness level. But with brands coming with the latest technologies, Amoled is certainly going to catch up with the brightness level with LCD displays. Also, the brightness difference in current Amoled display smartphones that are available in the market is hardly noticeable.

OLED displays have higher contrast ratios (1 million : 1 static compared with 1,000 : 1 for LCD screens), deeper blacks and lower power consumption compared with LCD displays. They also have greater color accuracy. However, they are more expensive, and blue OLEDs have a shorter lifetime.

OLED displays offer a much better viewing angle. In contrast, viewing angle is limited with LCD displays. And even inside the supported viewing angle, the quality of the picture on an LCD screen is not consistent; it varies in brightness, contrast, saturation and hue by variations in posture of the viewer.

There are no geographical constraints with OLED screens. LCD screens, on the other hand, lose contrast in high temperature environments, and lose brightness and speed in low temperature environments.

Blue OLEDs degrade more rapidly than the materials that produce other colors. Because of this, the manufacturers of these displays often compensate by calibrating the colors in a way that oversaturates the them and adds a bluish tint to the screen.

With current technology, OLED displays use more energy than backlit LCDs when displaying light colors. While OLED displays have deeper blacks compared with backlit LCD displays, they have dimmer whites.

LCDs use liquid crystals that twist and untwist in response to an electric charge and are lit by a backlight. When a current runs through them, they untwist to let through a specific amount of light. They are then paired with color filters to create the display.

In theIn-cell vs On-cell process comparison article, the formation process of the On-cell process is described in detail. The On-cell process comes from the touch screen production process developed by panel manufacturers. In the On-cell process, the TP layer is embedded in the OLED module. The TP layer is embedded in the OLED surface using the On-cell process, and the TP layer embedded inside the LCD screen is the In-cell process.

In the Apple after-sales market, there is more demand in the iPhone Incell LCD market. On-cell products provided by mobile phone display manufacturers are scarce, and the number of manufacturers to choose from is also small. Coupled with the low process technology of On-cell external processing, the quality of the On-cell screen is not high. On-cell Hard OLED is gradually moving towards the development trend of low quality and low price. The advantages of the On-cell screen are similar to those of the In-cell. The touch sensing layer is integrated into the display module to make the screen thinner.

Both screens are made up of Pixels. A pixel is made up of 3 sections called sub-pixels. The three sections are red, green and blue (primary colors for display tech).

The light is generated from a “backlight”. A series of thin films, transparent mirrors and an array of white LED Lights that shine and distribute light across the back of the display.

On some lower quality LCD screens, you can see bright spots in the middle or on the perimeters of screens. This is caused by uneven light distribution. The downside to using backlights, is that black is never true black, because no matter what, light has to be coming through, so it will never have as dark of a screen as an AMOLED screen. Its comparable to being able to slow a car down to 2 mph versus coming to a complete stop.

Each pixel is its own light source, meaning that no backlight is necessary. This allows the screen assembly to be thinner, and have more consistent lighting across the whole display.

Long-time display manufacturer Samsung Display will likely stop the production of LCD displays this year. A recent report says several factors have influenced the South Korean firm’s decision.

Samsung has been a reputed LCD display manufacturer since 1991. It manufactures panels for its own devices and also works as a supplier for several other Big Tech firms, such as Apple. Its displays are used in virtually all products, ranging from foldable smartphones to televisions and tablets.

Despite the company’s successful business, a recent report from The Korea Times suggests Apple is exiting the LCD production business for good. One of the biggest reasons cited for the decision is the increased competition from Chinese and Taiwanese display manufacturers in the recent past.

Samsung wanted to shut its LCD production late in 2020 and its move was on the cards for a while now. Samsung probably kept its LCD manufacturing facilities operational during the pandemic due to the sudden and unprecedented spike in demand. However, LCD technology has been eclipsed by OLED and QD-OLED technologies on most mainstream devices in the last few years. This is another reason why Samsung will probably shutter the business later this year.

Moreover, research firm Display Supply Chain Consultants (DSCC) believes the average price index of LCD panels measured as 100 in January 2014 will drop down to just 36.6 in September 2022. The figure is indicative of the demand for LCD panels and it plummeted to a record low of 41.5 in April this year. The April figure is a whopping 58 percent lower than the record-high index value of 87 in June 2021 when the pandemic was raging. This reduction in demand and price could also be detrimental to the company’s plans to soldier on producing LCDs.

The report says that in the future, Samsung will remain focused on manufacturing OLED panels and more advanced quantum dot OLED displays. LCD division staffers will likely be transferred to the QD-OLED division. Meanwhile, Samsung Display did not respond to the Korea Times’ request for comment.

Tech observers and investors revel in lively discussions about the latest, greatest gadget and whose bottom line will get the greatest bounce. They enjoy debating the intricacies and details of materials that contribute to these devices, and the related trends and developments. For us at Corning, materials innovators for 165 years, it’s been great to see a recent uptick in discussions about OLED versus LCD display panel technology - a genuine #GlassAge debate.

Corning.com staff sat down with Mike Kunigonis, business director for Corning’s High Performance Displays Group, to understand key differences between OLED and LCD display technology.

Corning.com: Thanks for your time today, Mike. Let’s start with a key question: In the context of display panels, how does OLED technology work and what are the main differences between it and LCD technology?

MK: OLED stands for Organic Light-Emitting Diode, or Organic LED. It’s an alternative to LCDs for consumer electronic devices that range in size from wearable to TVs. Like LCD, OLED is a type of panel that enables the displays on device screens. An OLED display picture is generated by turning on and off millions of tiny individual LEDs, each forming the individual pixels of a display. Compare this to LCD, where an always-on backlight projects light through a liquid crystal, sandwiched between two pieces of glass. When the liquid crystal is excited by an electrical current, it lets the light of an individual pixel pass through like a shutter. LCD and OLED display panels both excel at delivering vibrant consumer displays, each in its own unique way.

Corning.com: We’ve heard industry analysts with varying opinions on the benefits an OLED device offers. So why would a consumer prefer a device with an OLED display over an LCD display?

MK: Adoption of OLED displays on smaller, mobile devices is the driver behind most of today’s OLED industry growth, so let me focus on that. A handheld OLED display is attractive to consumers because of the industrial design and display attributes that this technology can support. For example, OLED displays can be curved, or be thinner, or have narrower bezels – or no bezels at all – or flex and bend. Plus, an OLED display will be a great solution for virtual reality applications because it can provide high resolution and superior response time and latency.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey