arduino and dht11 output to lcd module factory

Here is the simple code that will make it work correctly. I had the same issue and just figured it out. I put some comments about the changes I made and stuff I figured out…. Make sure you have the 3 libraries that are noted “#include”

Want to keep a log of the climate in your greenhouse, build a humidor control system, or track temperature and humidity data for a weather station project? AOSONG’s DHT11 or DHT22 Temperature and Humidity Sensor could be the perfect fit for you!

These sensors are factory-calibrated and do not require any external components to function. With just a few connections and a bit of Arduino code, you can begin measuring relative humidity and temperature right away.

They provide temperature and humidity readings accurate to within one decimal place, which is a plus. The only drawback is that they only provide new data every second or two, but for the price and performance, it’s hard to complain.

The DHT11 and the DHT22 are the two most widely used sensors in the DHTxx series. They look kind of the same and have the same pinout, but their specs are different.

Of the two, the DHT22 is more expensive and, undoubtedly, has better specifications. The DHT22 can measure temperatures from -40°C to +125°C with an accuracy of ±0.5°C, while the DHT11 can measure temperatures from 0°C to 50°C with an accuracy of ±2°C. In addition, the DHT22 sensor can measure relative humidity from 0 to 100% with an accuracy of 2-5%, while the DHT11 sensor can only measure relative humidity from 20 to 80% with an accuracy of 5%.

Despite the fact that the DHT22 is more accurate, precise, and capable of operating in a wider range of temperature and humidity, there are three areas where the DHT11 completely outperforms the DHT22 – It is more affordable, more compact, and has a higher sampling rate. DHT11 takes a reading once per second (or 1Hz sampling rate), while DHT22 takes a reading once every two seconds (or 0.5Hz sampling rate).

Despite these differences, the operating voltage of both sensors ranges from 3 to 5 volts, with a maximum current of 2.5mA (during conversion). The best part is that DHT11 and DHT22 sensors are swappable, which means that if you build your project with one, you can simply unplug it and replace it with another. Your code may need to be tweaked slightly, but the wiring remains the same!

The humidity sensing component has two electrodes with a moisture-holding substrate (usually a salt or conductive plastic polymer) in between. As the humidity rises, the substrate absorbs water vapor, resulting in the release of ions and a decrease in the resistance between the two electrodes. This change in resistance is proportional to the humidity, which can be measured to estimate relative humidity.

Technically, all resistors are thermistors in the sense that their resistance changes slightly with temperature, but the change is typically very small and difficult to measure.

Thermistors are designed so that their resistance changes dramatically with temperature (by 100 ohms or more per degree). The term “NTC” stands for “Negative Temperature Coefficient,” which means that resistance decreases as temperature rises.

The sensor also includes an 8-bit SOIC-14 packaged IC. This IC measures and processes the analog signal using stored calibration coefficients, converts the analog signal to digital, and outputs a digital signal containing the temperature and humidity.

VCC pin provides power to the sensor. Despite the fact that the supply voltage ranges from 3.3V to 5.5V, a 5V supply is recommended. With a 5V power supply, the sensor can be placed up to 20 meters away. With 3.3V supply voltage, the sensor can be placed up to 1 meter away; otherwise, the line voltage drop will cause measurement errors.

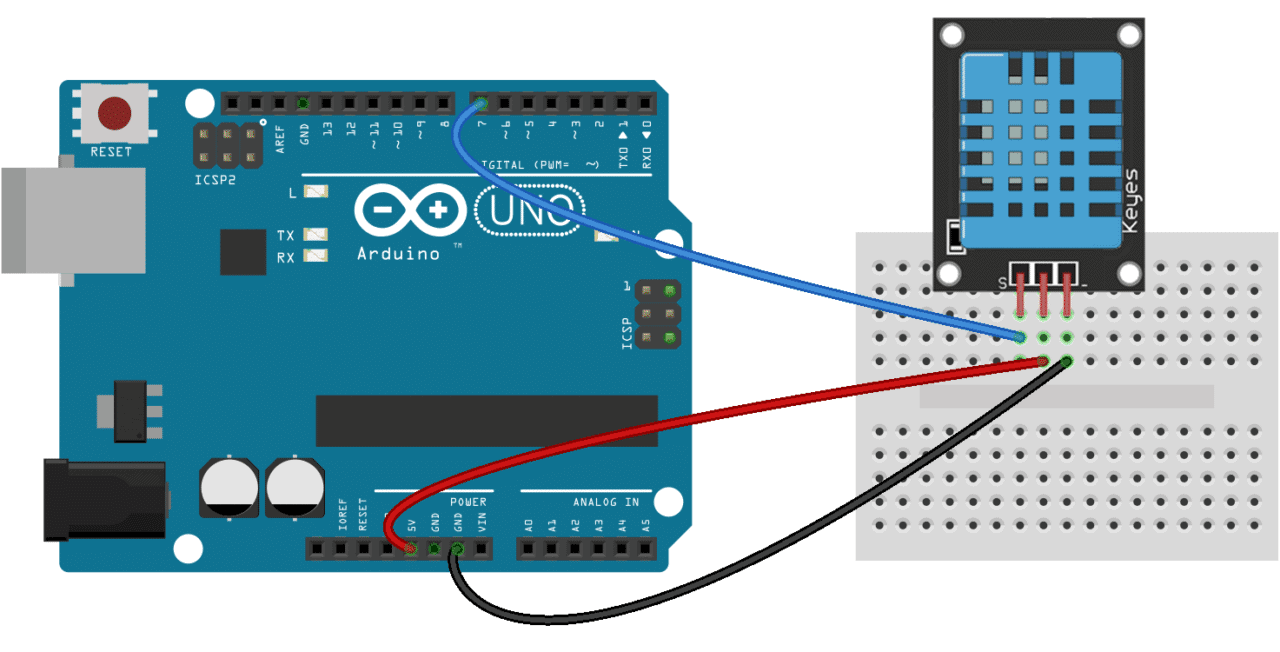

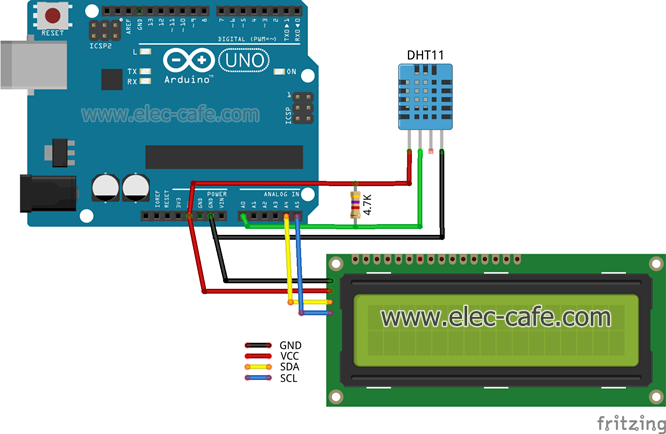

Connecting DHT sensors to Arduino is straightforward. They have fairly long 0.1′′-pitch pins, allowing them to be easily plugged into any breadboard. Connect the VCC pin to the Arduino’s 5V and the GND pin to ground. Finally, connect the Data pin to digital pin #8.

To ensure proper communication between the sensor and MCU, you must also add a 10K pull-up resistor between the Data line and VCC (to keep the signal HIGH). If you have a breakout board for the sensor, you do not need to add an external pull-up resistor, as it already contains one.

The DHTxx sensors have their own proprietary single-wire data transfer protocol. This protocol requires precise timing. We don’t have to worry too much about this, though, because we’ll be using the DHTlib library, which handles almost everything.

To install the library, navigate to Sketch > Include Library > Manage Libraries… Wait for the Library Manager to download the libraries index and update the list of installed libraries.

After installing the library, copy and paste this sketch into the Arduino IDE. The following test sketch will print the temperature and relative humidity values to the serial monitor. Try out the sketch, and then we’ll go over it in more detail.

The sketch begins by including the DHT library. Following that, we specify the Arduino pin number to which our sensor’s Data pin is connected and create a DHT object.

In the loop, we use the read22(dataPin) function to read the DHT22. This function takes as a parameter the sensor’s Data pin number. When working with DHT11, you must use the read11() function; to do so, you just need to uncomment the second line.

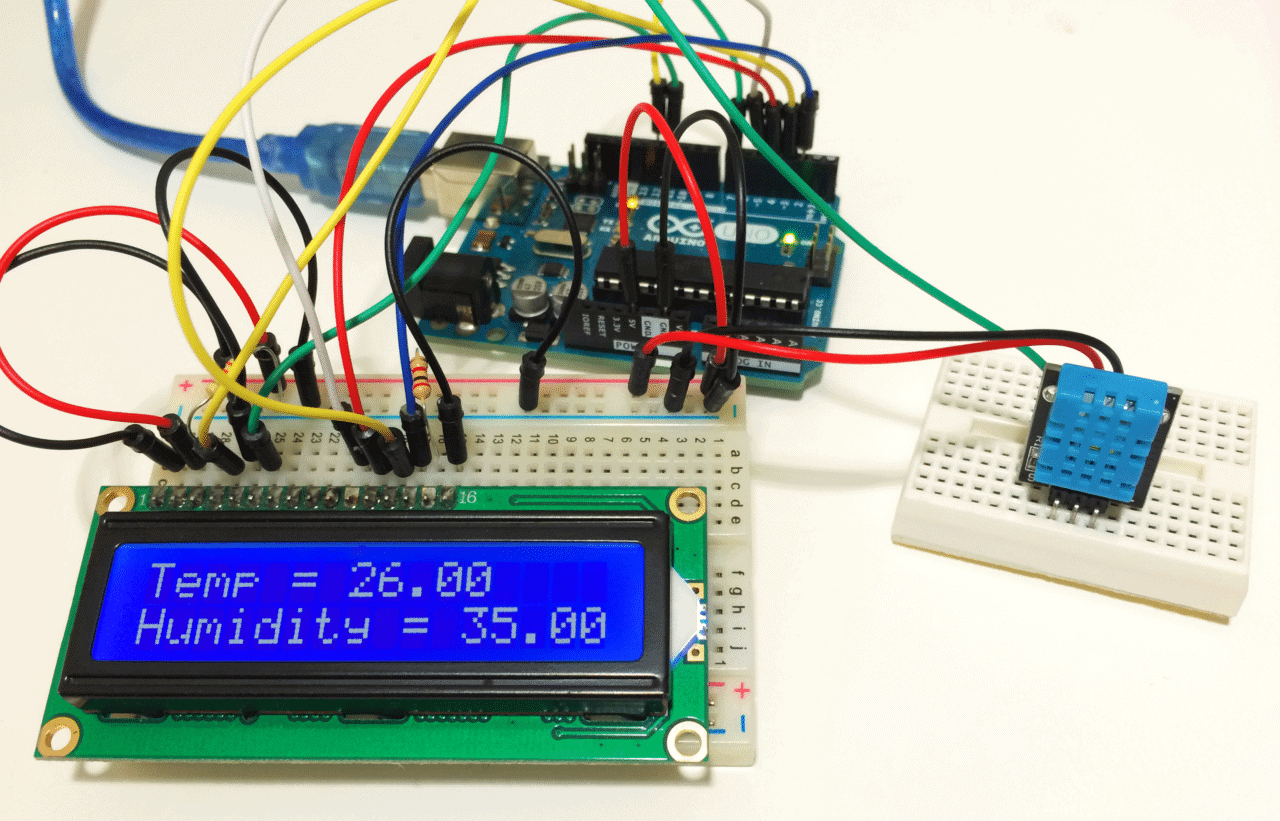

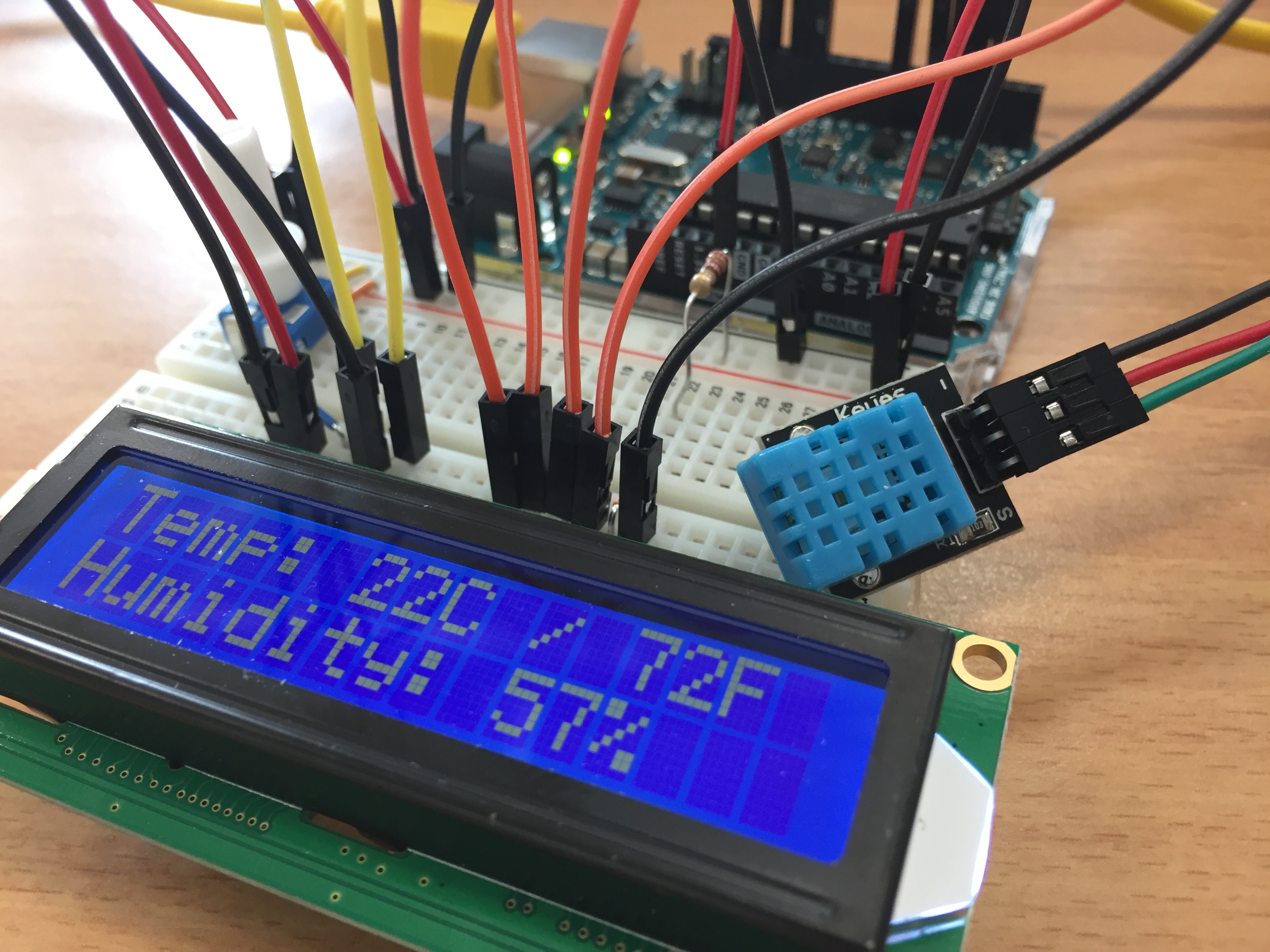

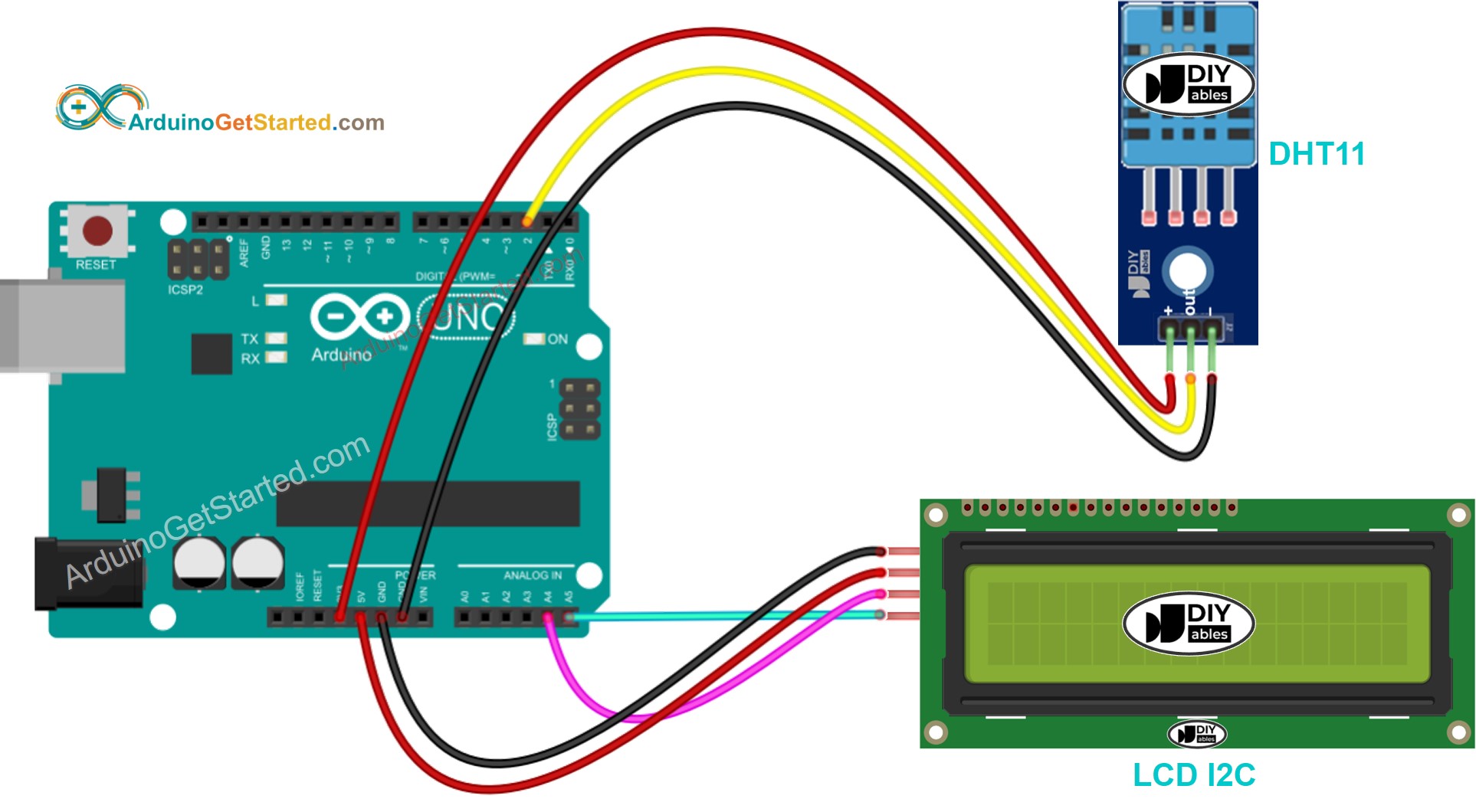

If you’re constructing your own incubator or a similar project, you’ll need a 16×2 character LCD rather than a serial monitor to display the current temperature and humidity levels. So, in this example, we’ll also connect the LCD to the Arduino in addition to the DHT11 and DHT22 sensors.

The sketch below will display the temperature and relative humidity values on the 16×2 character LCD. This sketch is similar to the previous one, except that the values are printed on the LCD.

I have the dht11 reading and printing to lcd and serial monitor.I have the dht11 controlling two relays one for temp and one for humidity.When the relay turns on the dht11 stops sending readings and freezes and stops reading? Any way I can fix that ?thanks

From what I’ve read from the datasheet it can’t be read from more than once every 2 seconds. Changing the delay to 2000 cleared the issue up right away for me

The output is to the serial monitor, unless you have connected an LCD. The video will show you how to open the serial monitor if you don’t already know how to.

A quick question tho, do you have a tutorial on how to connect this to a wireless transceiver?? also in theory could i connect more then one humidity detector to an arduino in order to detect humidity from more then one spot? Thank you again and i’ve subscribed!

Hi Jose, you can definitely connect more than one sensor to a single Arduino. You would basically duplicate the code, and have a separate pins read the data from each sensor. As for connecting them to a wireless tranceiver, I’m sure it’s possible, but you would probably need to use another microcontroller as a hub to transmit the data. I haven’t tried it yet though, so don’t take my word for it!

Hello, I built my first arduino project (measuring the room temperature and humidity with the DHT11) during Christmas holidays. The readings of the values were shown on the screen of my laptop. The measured room temperature was correct, but the measured humidity was much too low (about 20%RH). What can be the reason for ithe low humidity? And how can the sensor (if needed) be recalibrated?

I haven’t tried connecting multiple sensors, but it should be fairly easy. You would just duplicate the code and use a separate pin to read the data for each sensor

Probably not, since the signal is at the same voltage as Vcc. If you swap the Vcc and signal pins, the output will just read -999.00 for temp and humidity.

vcc is the left one, signal the middle one and ground is the round one, in case of a 3 pin DHT11. the diagram above is not right. i was getting the same problem here.

IN MY CASE IN THE DHT-11 BOARD WRONG RESISTOR WAS SOLDERED, WITHOUT KNOWING TAT I HAD TRIED ALL STUFF, GIVEN 10K PULL UP ADDITIONALLY.. DIDN’T WORKED FINALLY TRACED THE RESISTANCE BETWEEN PINS IT WAS 5 OHMS.. THEN BACK TRACED & REMOVED TAT & PULLED UP WITH 10k SOLVED MY ISSUE.. GUESS U TOO HAVE THE SAME ISSUE.. JUST CHK OUT..

The diagram is correct for most three pin DHT11 modules. Depending on the manufacturer, the pins on the PCB might be different though. The pins should be labelled with S for signal and “-” or “GND” ground.

Then i understood, that the breadboard has not 2 power circuits (top and bottom), but four (top left, top right, bottom left, bottom right). This is the thing which was never said on youtube)

See the section “Output Humidity and Temperature Readings to an LCD Display” on a desktop… If you are viewing it on mobile, the full code might not display. Hope this helps

Can you guys help me in this. All I want is to design a circuit that could predict a rainfall or water and send a message to the user to his phone.Also keeping in mind about the humidity and temperature factors.

It sounds like you want to control the heater with the DHT11 and have the readings output to an LCD too… You can use the DHT11 to control the signal to a 5V relay, similar to what’s done in this article: https://www.circuitbasics.com/build-an-arduino-controlled-power-outlet/

Then you just need to add the code to initialize the LCD, include the LiquidCrystal library, and change the “serialprint()” functions to “lcd.print(). We have another article on setting up an LCD on the Arduino if you need help with it: https://www.circuitbasics.com/how-to-set-up-an-lcd-display-on-an-arduino/

i didnt have any trouble interfacing the arduino, lcd and the dht11 sensor and my codes were quite right since when i run it, nothing’s odd in the output. but when i connect the relay,in which an ac device is connected, as an output that turns on after a couple of minutes, the temperature and humidity dislayed on the lcd becomes odd, like chinese and numbers, after some time. i checked my codes but i cant figure out whats wrong with it.

please help me.. i won’t get Alarm temperature and humidity..and show in lcd display 16×2.. and changeing temperature, humidity alarm set point HOW IS DO… PLEASE HELP ME.

So curiously, I had already downloaded and installed the latest version of DHTLib (v0.1.21) versus the older version (v0.1.14) that is provided here. And I kept getting 0.00 values for the temp and humidity readings as Alex reported on April 20, 2016 in a posting above. I scratched my head for a while until I remembered I had the newer version of the library installed. So I removed that, installed the older v0.1.14 version, and bam, lo and behold, I started getting real values back. So this may be the same problem that Alex had, too.

I’ve looked at the brief changelog history in dht.cpp file, and I’m seeing no obvious reason that might allow v0.1.14 to work, but not the newer v0.1.21. Anyone have thoughts about this?

Any comments about DHTLib v0.1.14 vs. v0.1.21, and why this simple Arduino sketch works in the former, but not the latter? The brief history in the cpp file header for v0.1.21 looks like it took care of a few issues so my first instinct is to use that, but again, it results in all zero readings. Anyway, if no comments, well, I’ll have to take a look through the diffs between the two versions to see what might be causing the issue.

vcc is the left one, signal the middle one and ground is the right one, in case of a 3 pin DHT11. the diagram above is not right. i was getting the same problem here.

The diagram is correct, but your particular DHT11 could have a different pinout depending on the manufacturer. The DHT11 I used is from Keyes, what type do you have?

Are you using the four pin DHT11? If so you’ll need to put a 10K Ohm resistor between the Signal line and Vcc. I just added another diagram to the post to make it a bit clearer. That may be causing your issue.

Thanks a lot, may you please help me out, I am using a Mega 2560 with a DHT11 sensor, my problem is that both temperature and humidity reading is just being reed as 0.00 and they are not changing. What might i be doing wrongly, I have even tried the code that accompanies these tutorials

This seems like a really simple setup, but I’ve been having a lot of trouble setting this up. Have there been changes to this library? I have downloaded it, but arduino still refuses to recognize dht or any of the related functions, like temperature/humidity. It had a lot of trouble with line 3, dht DHT;. Any advice?

Yes, the library was updated recently (v. 0.1.21) and doesn’t seem to work. If you download the zip file I put in the post, it should work. It’s the older version 0.1.14.

Hi, you mentioned you added a piece of code to show the “degree” symbol,” lcd.print((char)223)”, can you tell me if the number 223 is from the ASCII table.

vcc is the left one, signal the middle one and ground is the right one, in case of a 3 pin DHT11. the diagram above is not right. i was getting the same problem here.

i am doing fire alarm system using dht and lcd and GSM sim800l how can i make argument to send message from gsm if the sensor reading is higher that the set temp and how to declare it thanks for your response

After uploading a code my dht-11 keeps reading zero ‘0’ for both humidity and temperature as the output on my serial monitor. please what could be the problem?

I am very happy to inform you that I fixed successfully the temp and humidity project with LCD display. I would like to subscribe but cannot find the link.Many thanks

C:\Users\mhine\AppData\Local\Arduino15\packages\esp8266\hardware\esp8266\2.2.0\cores\esp8266/Arduino.h:227:63: error: cannot convert ‘volatile uint32_t* {aka volatile unsigned int*}’ to ‘volatile uint8_t* {aka volatile unsigned char*}’ in initialization

Hi. I have the same issue with the same board. Did you get it to succeed in the end? I would be interested, but I feel that it may be a compatibility issue with a 3rd-party board. I have tried the exact code with other Arduinos that I have and it works just fine.

I get this same error when I try to use the Arduino 101 instead of the Uno. I think the library doesn’t support the board. I would try finding a different DHT library, there are several others out there.

I Have issues with the Arduino recognizing the file dht.h. Was told no such file exist, meanwhile I have uploaded the zip file into the Arduino IDE, which showed in the file directory.

Did you use the library in the zip file from the post, or did you download it from the Arduino.cc page? Version 0.1.21 has some issues and doesn’t appear to work. The zip file in the post is version 0.1.14, and it does work. Also, are you using the Uno, or another board? I couldn’t get the library to work on my Arduino 101…

In this language, does declaring an object variable (as in “dht DHT;”) automatically instantiate it? I am more used to other languages that would need to follow the declaration with something along the lines of “DHT = new dht(params, for, constructor);” Does this normally go without saying in C++, or is this something the Arduino environment automatically adds at the preprocessing** stage?

**: If not “preprocessing,” then whatever else Arduino parlance calls the process of converting/expanding the “Processing” (??) or “Wiring” (???) code into standard C/C++ ????

hey can you pls help me how to use rf module with the above project. i am using two arduino uno, DHT11, LCD, RF transmitter and receiver. please can u give me a code to display temperature and humidity on the receiver side lcd…

to start the cummunication the ardduino will give LOW to the data line,after the dht finished the transmition of data,the line will return to HIGH,IS THAT CORRECT???

Thanks for the mod, skyfox66. Being in America among the holdouts, I am of course still using degrees F. After days of struggling and searching I finally got this combination of parts and code to work right. (After I found this website).

I connected the LCD and the DHT11 and copied and pasted the code. It uploaded and then I look at my LCD and all I see are white boxes on the top of the display. Can anyone help me?

I copied this exactly and got it to display temperature and humidity, but it flashes -999 for temp and -999 for humidity every other second. For example, it will display correct readings for one second, then the -999 for both readings the next second.. Flashing between the two. Any ideas why it might be doing this. I have been playing with the code, rechecking pins, etc, but I cant seem to pinpoint the problem. Any input is appreciated.

hello, i need some help, i want code for, if i m sending message from mobile (e.g. ABC) to arduino via gsm module then the values of temperature and humidity receiving specific number

I have arn Arduino y module that I am using to trgger an extractor fan in a shower. I was wondering whether this humidity sensor could be used to simply close the 5v circuit so teh fan runs on until teh humidity is below a set vaue. Is that possible simply?

Hi.recently i conduct sensor circuitry.in source code,i notice that it use \xF8 to display temperature in degree celcius.what is the function of that?

I followed the instructions exactly, wiring was good, code was an exact replica of that given. Everything was correct, but I got -999 error message every time. I was using a three pin sensor, triple checked my wiring against the diagram. I increased the delay time to 3000ms. I was definitely using the correct older version of the library. After throwing out the sensor thinking it faulty, I have since discovered that the diagram above is does not apply to every dht11, that there are some where the pins are in a different order.

What does this mean? in every other arduino program I can find that uses additional libraries, the library is called first, then the code goes straight on to initialising the variables and describing the setup. I have not been able to find any other mention of the library name mentioned twice like this. A few people have asked about this, with no answers given. I cant even search for it because I dont know what to search by.

Awesome website – every content is superb – We have a huge collection of branded Electronics product please have a look here https://webearnorg.blogspot.com/2018/05/electronics-supply-stores-near-me.html

Clear, informative and knowledgeable. Moisture from the air collects on the film and causes changes in the voltage levels between the two plates. This change is then converted into a digital measurement of the air’s relative humidity after taking the air temperature into account.

You will get 100% humidity if you put the sensor in water and it works. Use an SHT31-D breakout board to detect humidity and temperature. I’m sure you didn’t mean you are going to submerge the sensor. The SHT31-D is more accurate and easier to install and costs about the same as the DHT11 /22 both of which really aren’t accurate at all.

i have changed the sensor, checked voltages at each junction,switched pull up resistor, included the exact library available here but couldn’t get the accurate result,

Ine is set up exactly as you show. I get -999.00 for both humidity and temperature. I have 2 different sensors (both DHT11) and I get the same readings. I even set this up on an RPI 3B+ and the readings were similar. 1.0 temp and humidity. What am I doing wrong?

I’m a bit new to audrino and i started my first project. I found that this tutorial was the most comprehensive out there, which is awesome. One thing that i’m running into a bit of issue on is that im an “400 invalid_request” while attempting to import the DTH library. I was wondering if you could provide a little assistance to get pass this issue. Please see the full error message below.

I’m wondering if there’s a way to have this working intermittently? I want to moderate the humidity levels in food containers to prevent mould. If this was running off a battery would it last long enough?

I can not keep my display from blinking the temp and humidity values. It displays the value but blinks back and forth to -999.00. Thanks for the help I’m new

Your so awesome dude. I owe you a lot! Thanks for the tutorial dude. you’d help many people. keep going! God bless more power. Im from philippines ^_^

Still getting -999.00 on both temperature and humidity with LCD. If I connects ONLY DTH11 to Arduino with serial monitor it works fine, BUT if I connect it to LCD as described above it shows -999.00 In both LCD and serial monitor. It looks like it disables the DTH11 when connected to LCD. It does not work with dely(2000); or any other value.

i don’t know why but the LCD shows me white circles and within them the text is written also the temp and humidity are a constant 0 even with the serial monitor

It’s good idea for projects. I am thinking of building my own weather unit soon. Please can someone help me with a simulation circuit that will show the response graphs of dht11 for temperature and humidity

How would you configure Celsius to Fahrenheit when doing the LCD version? I read others commenting how with out the LCD but not with the code for using the LCD.

I’m looking to couple this humidity sensor with a 5V relay to actuate a small on/off valve depending on the humidity level. Essentially, I’d like valve to open when the humidity reading from the sensor goes above, say, 75%, and closes when the reading goes below 60%. Do you have any recommendations?

I am a hobbyist and has certain experience in electronics and wish to adopt programming. So kindly some one can help me to achieve the above goal with codes and probable sketches for the connections.Hope to receive a reply in this respect from your side.

HELLO, thank you for the big assistance. I’d like to share to u the screenshoot of my serial monitor output… Atleast let me show how it looks like & help me to debug. Big thanks to you

You have to adjust the wait time to less to count for the fact that the sensor Only gives an output for a small amount of time so play around with that to get it to work

DHT11 Humidity Sensor Module is designed by using DHT11 which is able to detect the temperature and humidity of the surrounding environment. This module is compatible with Arduino, PIC, Raspberry pi and etc.

I would like to calibrate the Humiduty in the sensor if this is possible. As I am a bit new to programming in C, If an example could be provided would me much appreciated.

Arduino Community I highly appreciate your time and the time you take to read this. I love and enjoy the partaking of this project and would love to learn and grow my knowledge with Arduino.

When autocomplete results are available use up and down arrows to review and enter to select. Touch device users, explore by touch or with swipe gestures.

This module integrates DHT11 sensor and other required components on a small PCB. The DHT11 sensor includes a resistive-type humidity measurement component, an NTC temperature measurement component and a high-performance 8-bit microcontroller inside, and provides calibrated digital signal output. It has high reliability and excellent long-term stability, thanks to the exclusive digital signal acquisition technique and temperature & humidity sensing technology.

The DHT11 sensors usually require external pull-up resistor of 10KΩ between VCC and Out pin for proper communication between sensor and the Arduino. However, the module has a built-in pull-up resistor, so you need not add it.

+ (VCC) pin supplies power for the sensor. 5V supply is recommended, although the supply voltage ranges from 3.3V to 5.5V. In case of 5V power supply, you can keep the sensor as long as 20 meters. However, with 3.3V supply voltage, cable length shall not be greater than 1 meter. Otherwise, the line voltage drop will lead to errors in measurement.

The DHT11 sensor can either be purchased as a sensor or as a module. Either way, the performance of the sensor is same. The sensor will come as a 4-pin package out of which only three pins will be used whereas the module will come with three pins as shown above.

The only difference between the sensor and module is that the module will have a filtering capacitor and pull-up resistor inbuilt, and for the sensor, you have to use them externally if required.

The DHT11is a commonly used Temperature and humidity sensor. The sensor comes with a dedicated NTC to measure temperature and an 8-bit microcontroller to output the values of temperature and humidity as serial data. The sensor is also factory calibrated and hence easy to interface with other microcontrollers.

The sensor can measure temperature from 0°C to 50°C and humidity from 20% to 90% with an accuracy of ±1°C and ±1%. So if you are looking to measure in this range then this sensor might be the right choice for you.

The change in resistance between the two electrodes is proportional to the relative humidity. Higher relative humidity decreases the resistance between the electrodes, while lower relative humidity increases the resistance between the electrodes.

DHt11 also contains a NTC/Thermistor to measure temperature. A thermistor is a thermal resistor whose resistance changes drastically with temperature. The term “NTC” means “Negative Temperature Coefficient”, which means that the resistance decreases with increase of the temperature.

On the other side, there is a small PCB with an 8-bit SOIC-14 packaged IC. This IC measures and processes the analog signal with stored calibration coefficients, does analog to digital conversion and spits out a digital signal with the temperature and humidity.

Connections are fairly simple. Start by connecting + (VCC) pin to the 5V output on the Arduino and connect – (GND) to ground. Finally, connect the Out pin to the digital pin #8.

DHT11 sensors have their own single wire protocol for transferring the data. This protocol requires precise timing. Fortunately, DHT Library was written to hide away all the complexities so that we can issue simple commands to read the temperature and humidity data.

The following test sketch will print the temperature and relative humidity values on the serial monitor. Try the sketch out; and then we will explain it in some detail.

#include

The sketch starts by including DHT library and defining the Arduino pin number to which our sensor’s Out pin is connected. Then we create a DHT object to access special functions related to the library.

Sometimes you come up with an idea where you want to monitor temperature and humidity levels in your DIY incubator. Then you’ll probably need 16×2 character LCD to display prevailing conditions in your incubator, instead of a serial monitor. So, in this example, we’ll hook the LCD up to the Arduino along with the DHT11 module.

Want your Arduino projects to display status messages or sensor readings? Then these LCD displays might be the perfect fit. They are extremely common and...

The following sketch will print the temperature and relative humidity values on the 16×2 character LCD. It uses the same code except we print values on LCD.

DHT11 is a Humidity and Temperature Sensor, which generates calibrated digital output. DHT11 can be interface with any microcontroller like Arduino, Raspberry Pi, etc. and get instantaneous results. DHT11 is a low cost humidity and temperature sensor which provides high reliability and long term stability.

In this project, we will build a small circuit to interface Arduino with DHT11 Temperature and Humidity Sensor. One of the main applications of connecting DTH11 sensor with Arduino is weather monitoring.

We will see the circuit design of DHT11 interfacing with Arduino. The DHT11 Humidity and Temperature sensor comes in two variants: just the sensor or a module.

The main difference is that the module consists of the pull – up resistor and may also include a power on LED. We have used a module in this project and if you wish to use the sensor itself, you need to connect a 5K Ω pull – up resistor additionally.

Coming to the design, the data pin of the DHT11 Sensor is connected to the Pin 11 of Arduino. A 16 x 2 LCD display is used to display the results. The control pins of LCD i.e. RS and E (Pins 4 and 6 on LCD) are connected to pins 4 and 5 of Arduino. The data pins of LCD i.e. D4 to D7 (pins 11 to 14 on LCD) are connected to pins 0 to 3 on LCD.

NOTE: For ease of connection, we have connected the DHT11 Sensor Module at the ICSP pins of the Arduino as it provides adjacent VCC, DATA and GND pins. This type of connection is not necessary and you can connect the data pin of sensor to normal Digital I/O pins.

DHT11 is a part of DHTXX series of Humidity sensors. The other sensor in this series is DHT22. Both these sensors are Relative Humidity (RH) Sensor. As a result, they will measure both the humidity and temperature. Although DHT11 Humidity Sensors are cheap and slow, they are very popular among hobbyists and beginners.

The DHT11 Humidity and Temperature Sensor consists of 3 main components. A resistive type humidity sensor, an NTC (negative temperature coefficient) thermistor (to measure the temperature) and an 8-bit microcontroller, which converts the analog signals from both the sensors and sends out single digital signal.

DHT11 Humidity Sensor consists of 4 pins: VCC, Data Out, Not Connected (NC) and GND. The range of voltage for VCC pin is 3.5V to 5.5V. A 5V supply would do fine. The data from the Data Out pin is a serial digital data.

The following image shows a typical application circuit for DHT11 Humidity and Temperature Sensor. DHT11 Sensor can measure a humidity value in the range of 20 – 90% of Relative Humidity (RH) and a temperature in the range of 0 – 500C. The sampling period of the sensor is 1 second i.e.

Also, the length of the cable can be as long as 20 meters. The data from the sensor consists of integral and decimal parts for both Relative Humidity (RH) and temperature.

8 – Bit data for integral RH value, 8 – Bit data for decimal RH value, 8 – Bit data for integral Temperature value, 8 – Bit data for integral Temperature value and 8 – Bit data for checksum.

In order to check whether the received data is correct or not, we need to perform a small calculation. Add all the integral and decimals values of RH and Temperature and check whether the sum is equal to the checksum value i.e. the last 8 – bit data.

This value is same as checksum and hence the received data is valid. Now to get the RH and Temperature values, just convert the binary data to decimal data.

A simple project is built using Arduino UNO and DHT11 Humidity and Temperature Sensor, where the Humidity and Temperature of the surroundings are displayed on an LCD display.

After making the connections, we need not do anything as the program will take care of everything. Although there is a special library for the DHT11 module called “DHT”, we didn’t use it. If you want to use this library, you need to download this library separately and add it to the existing libraries of Arduino.

The program written is based on the data timing diagrams provided in the datasheet. The program will make the Arduino to automatically read the data from the sensor and display it as Humidity and Temperature on the LCD Display.

Let"s get started with this innovative Arduino tutorial where you will learn about the DHT11 Temperature and Humidity Sensor Module and how to use it with our Arduino Board to create our own weather station project at home.

The DHT11 module is a temperature and humidity sensing module that uses Digital Signal Acquisition to translate temperature and humidity to a digital reading that a microcontroller can easily read. The DHT11 has a temperature range of 0°C to 50°C, which is ideal for home or hobby use.

The DHT11 Humidity and Temperature Sensor is made up of three main parts. A resistive type humidity sensor, an NTC thermistor (to calculate temperature), and an 8-bit microcontroller that transforms the analog signals from both sensors into a single digital signal.

The DHT11 Sensor can detect humidity levels ranging from 20% to 90% relative humidity (RH) and temperatures ranging from 0 to 50°C. The sensor"s sampling time is one second.

8-bit data for integral RH value, 8-bit data for decimal RH value, 8-bit data for integral Temperature value, 8-bit data for decimal Temperature value, and 8-bit data for checksum.

In order to check whether the received data is correct or not, we must perform a small calculation. Check if the sum of the integral and decimal values of RH and Temperature equals the checksum value, i.e. the last 8-bit data.

This value is the same as the checksum, indicating that the data obtained is right. Simply convert the binary data to decimal data to obtain the RH and Temperature values.

Initially Arduino sends a high to low start signal to DHT11 with 18µs delay to ensure DHT’s detection. The Arduino then pulls up the data line and waits 20-40µs for DHT to respond. When DHT detects a start signal, it sends a low voltage level response signal to the Arduino with an 80µs delay. The DHT controller then pulls up the data line and holds it for 80µs for DHT’s arrangement of sending data.

When the data bus voltage is low, the DHT11 is sending a response signal. After that, DHT performs another data line pull-up for 80µs to prepare data transmission.

Data format that is sent by DHT to the Arduino for every bit starts with 50µs low voltage level and length of high voltage level signal decides whether data bit is0or1.

LCD modules are a critical component in many Arduino-based embedded systems. As a result, understanding how to attach an LCD module to an Arduino is crucial when designing embedded systems. Here you will learn how to connect an Arduino to a 16x2 LCD display.

The JHD162A is a 16x2 LCD module based on Hitachi"s HD44780 driver. The JHD162A has 16 pins and can be used in 4-bit or 8-bit mode (using only four data lines) or (using all 8 data lines) respectively. In this case, the LCD module is set to 4-bit mode.

Pin3(VEE): Contrast adjustment pin. This is done by connecting the ends of a 10K potentiometer to +5V and ground and then connecting the slider pin to the VEE pin. The voltage at the VEE pin defines the contrast. The normal setting is between 0.4 and 0.9V.

Pin4(RS): Register select pin.The JHD162A has two registers namely command register and data register. Logic HIGH at RS pin selects data register and logic LOW at RS pin selects command register. If we make the RS pin HIGH and feed an input to the data lines (DB0 to DB7), this input will be treated as data to display on the LCD screen. If we make the RS pin LOW and feed an input to the data lines, then this will be treated as a command ( a command to be written to LCD controller – like positioning cursor or clear screen or scroll).

Pin5(R/W): Read/Write modes. This pin is used for selecting between read and write modes. Logic HIGH at this pin activates read mode and logic LOW at this pin activates write mode.

Pin15(Backlight +): Anode of the back light LED. When operated on 5V, a 560 ohm resistor should be connected in series to this pin. In arduino based projects the back light LED can be powered from the 3.3V source on the arduino board.

LCD module enable pin to the Arduino"s digital pin 11. The LCD module and the Arduino are connected in 4-bit mode in this project. This means that only four of the LCD"s digital input lines (DB4 to DB7) are used.

This method is very simple and needs fewer connections, and allows you to almost fully leverage the LCD module"s capabilities. The digital lines DB4, DB5, DB6, and DB7 are connected to the Arduino"s digital pins 5, 4, 3, and 2. The 10K potentiometer is used for controlling the contrast of the light. The current through the back light LED is limited by the 560 ohm resistor R1.

A built-in library in Arduino called LiquidCrystal.h> to enable communication between the Arduino and the LCD module is used here. This library is written for LCD modules that use the Hitachi HD44780 chipset (or a compatible chipset). This library can accommodate LCD wiring in both 4 bit and 8 bit modes.

LiquidCrystal lcd()– is a constructor used to declare a variable of its kind. Here ‘lcd’ is the variable declared using the constructor and is used to call methods defined inside the library LiquidCrystal.h

We imported the DHT and LiquidCrystal libraries in the first two lines of this code. Then we created a variable DPIN to hold the PIN to which the DHT11 data pin is attached. Next, we created a new variable DTYPE, which contains the name of the sensor"s type (DHT11 or DHT22)

Similarly, rs, en, d4, d5, d6, and d7 are the pins of the LCD whose values are assigned to the number of the pins they are attached to respectively. To set up our LCD and sensor, we now use two functions called LCD and DHT.

The setup() function is then used to start our LCD display and DHT11 sensor. Since the setup() function only runs once after the project is powered on, the syntax in it starts the LCD and sensor at the beginning.

After that, we"ll look at the loop() feature. Since we need a time interval to display the results, we added a delay of 0.5 seconds or 5000 milliseconds. Following that, we declared two float variables, ‘h" and ‘t." The letters ‘h" and ‘t" represent the percentage value of humidity and the centigrade value of temperature, respectively.

The loop() function"s if statement tests if we"re getting both humidity and temperature; otherwise, the LCD will show "Failed to read from DHT sensor!" The following lines of code simply provide the syntax for printing our result on the LCD.

The DHT11 is an all-in-one temperature and humidity digital sensor that includes an internal resistive moisture measurement element and an NTC temperature measurement element and is connected to a high performance 8-bit micro-controller.

A simple external circuit connection is all that is needed to collect local temperature and humidity in real time. the DHT11 communicates with controllers such as micro-controllers using a simple single bus, requiring only one I/O port.

The sensor internal temperature and humidity data 40Bit is transmitted to the micro-controller at once, and the data is checked by means of checksum, which effectively ensures the accuracy of data transmission.

One of the most common sensors, photosensitive sensors come in a wide variety of types: phototubes, photomultiplier tubes, photo resistors, phototransistors, solar cells, infrared sensors, ultraviolet sensors, fiber optic photoelectric sensors, color sensors, CCD and CMOS image sensors, etc.

The Arduino Uno is an ATmega328P based micro-controller board. It has 14 digital input/output pins (6 of which can be used as PWM outputs), 6 analog inputs, a 16MHz ceramic resonator (CSTCE16M0V53-R0), a USB connection, a power socket, an ICSP header, and a reset button.

It contains everything you need to support your micro-controller; just connect it to your computer with a USB cable or power it with an AC adapter or battery to get started.

You can tinker with your Uno without worrying too much about doing anything wrong, and at worst you can spend a few dollars to replace the chip and start over.

We just need to add the designed UI images through menu bar options for buttons, text boxes, background images, and page logic through the host computer, then generate the configuration file, and finally download it into the display and it is ready to run.

To develop based on our STONE TFT LCD, you first need to use to an upper computer development software STONE designer, in this upper computer, all screen-related settings are carried out in this upper computer, so how to download it, click the link below to go to the official website:https://www.stoneitech.com/support/download

Select New Project, set the screen size to 1024*600, set the project name to weather, and finally select the path where the project needs to be saved, then click OK.

After the completion of the previous step, the default blue background image will be deleted first, and then you need to add the images that need to be used for this application, which are made in advance. The size of the background image needs to be the same as the actual size of the screen, that is, 1024 * 600.

First add a button control to the temperature, select “button” control, and draw the corresponding area; then in the right feature settings, set the button effect, here select page 2, that is, when the button is pressed, the corresponding area to display the effect of page 2; then select the page switch function, here select the No. 4 page, that is, when this button is pressed, the page will immediately switch to page 4, that is, the temperature display interface.

Under the temperature display interface, a text display control is needed to display the real-time temperature data passed by the Arduino, so it is necessary to add a data variable control, as shown in the following figure.

First of all, you need to set the variable address of the control, this address is very important, the data of the micro-controller can only be displayed by sending data to this address, and then set the format of the display, here choose 2 integers and 1 decimal.

If you feel that the font size of the display is too small to see clearly, you can also adjust the font size, and finally the alignment, I generally choose the center alignment, of course, there are also left-aligned, right-aligned to choose.

The STONE TFT LCD sometimes needs to control the micro-controller to achieve a two-way interaction, which is also the case here, and needs to implement the start and stop acquisition function, using the START button as an example.

Select the “return pressed key value” control, which is different from “button” and can send key values to the micro-controller so that the micro-controller can respond.

First set the key effect, here select page 2, when the key is pressed it will display the effect of page 2, here there is no need to switch pages, so select null, it should be noted that it is also necessary to set a variable address.

This variable address can not be repeated, otherwise it may appear invalid, here the variable address is set to 0x000A, also need a key value, set to 0x0002 This value will also be sent down as the key is pressed.

After setting, click compile, then insert the U disk, wait for the recognition to finish and click download to copy the project into the U disk, and plug in the display to upgrade. In this way, the whole project is finished.

Just a simple reminder, if you run into problems with your development, Stone has an official forum where you can ask technology-related questions https://forum.stoneitech.com/

Each DHT11 sensors features extremely accurate calibration of humidity calibration chamber. The calibration coefficients stored in the OTP program memory. Internal sensors detect signals in the process in accordance with their calibration coefficients. The single-wire serial interface system is integrated to become quick and easy to use. The small size, low power, and signal transmission distance up to 20 meters makes it useful in a variety of applications and even the most demanding applications. The product is 4-pin single row pin package. Convenient connections and special packages can be provided according to users need.

DHT11 is a Temperature and humidity sensor which as the name implies is used to measure the atmospheric temperature and humidity in a particular environment or in a confined closed space. The sensor is commonly used in monitoring environmental parameters in many applications like Agriculture, Food Industries, Hospitals, Automobile, Weather Stations etc.

The sensor could measure the temperature from 0°C to 50°C with an accuracy of 1°C. It is commonly used in controlled environments such as Heat ventilation systems, temperature chambers etc to monitor temperature and take corrective measures. The measuring range of humidity is from 20% to 90% with an accuracy of 1%. Humidity indicates the amount of water vapor present in the air. The value of humidity has to be kept within a controlled range in many scenarios like in manufacturing and storing of tea powders the correct humidity must be maintained in the room or the tea will lose its taste and smell. The level of humidity in living rooms should also be maintained within a comfortable range. The ideal value of humidity for maximum comfort is between 50% to 65%.

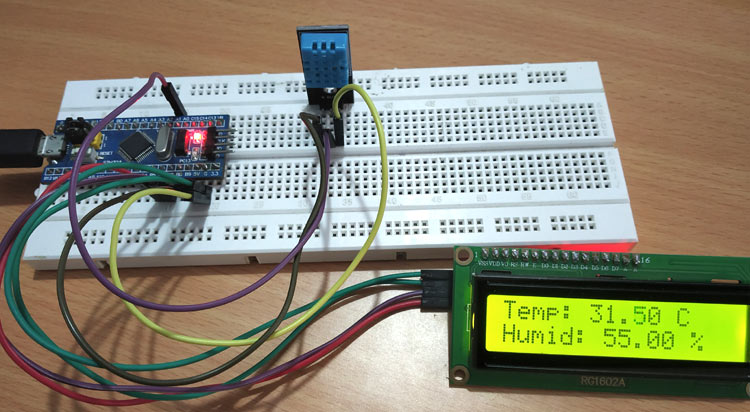

Today in this tutorial we will learn how to interface the popular DHT11 Temperature and Humidity sensor with STM32 microcontroller. We have already learnt the basics of STM32 board and how to use it Arduino IDE. For those who are new, the STM32 a.k.a BluePill development board,consists of the STM32F103C8T6microcontroller from ST Microelectronics. It is a 32-bit ARM Cortex M3 controller with high clock frequency suitable for high speed and power constraint application. Check all the STM32 related Tutorials here.

Before proceeding with the interface procedure lets learn few things about the DHT11 sensor. As discussed earlier, the Temperature and humidity. The sensor comes with a dedicated in-built NTC to measure temperature. It has an 8-bit microcontroller on-board to output the values of temperature and humidity as serial data through one-wire protocol. Meaning, the sensor has only one data pin through which both the temperature and humidity values can be read, thus saving pins on the microcontroller side. The sensor is also factory calibrated and hence easy to interface with other microcontrollers.

As you can see, we have used an I2C interface module to connect the LCD module to STM32. This makes the connections simple and further reduces the number of pins used on the controller side. However if you do not have this module you can also interface LCD directly STM32 by following the link.

If you have an interface module, then the circuit Connections between I2C Serial Interface Module (Fixed with 16X2 LCD Display) & STM32F103C8 is tabulated below:

We have to write a program to read the temperature and humidity value from the DHT11 senor and display it on the LCD module. Here the LCD display is connected through I2C adapter, hence we have first find the I2C address of this adapter to communicate with LCD.

From circuit diagram we can notice that the STM32F103C8 I2C pins PB6 and PB7 are connected with the SCL and SDA pins of I2C Serial Interface Module. To find the address of the I2C Serial Interface module we have to scan for available addresses.

3.Program for scanning the I2C device connected is present in the examples (In Arduino IDE: Files->Examples->Wire->I2C scanner wire). Before that select the board in Tools->Board->Generic STM32F103C8 Series as shown below.

Now that we know the I2C address we need to download a library for communicating to the LCD display through I2C. The I2C LCD display library can be downloaded from this link. After downloading the zip file install I2C LCD library in the Arduino IDE by sketch->import library.This library can also be used with Arduino boards for communicating with I2C LCD display modules.

Similarly in order to read the serial data from DHT11 sensor we will use the DHT11 library. Download the library as a ZIP file using the link provided and after downloading, install DHT library in the Arduino IDE by using sketch->import library. Again the same library can also be used with Arduino boards.

The complete code for this article can be found at the bottom of this page, the explanation for the same is as follows. Initially include the required libraries. Include Wire.h library for using I2C in STM32F103C8, LiquidCrystal_I2C.h for using I2C type LCD display and DHT.h for using DHT sensor functions

The value is received from the DHT11 sensor continuously. In order to get the separate values of temperature and humidity and store it in a variable following statement is used.

Once your hardware and code is ready, just the code to your hardware and you should notice your LCD displaying the welcome screen followed by the real time Temperature and Humidity values as shown below

If your displays shows nothing you can check adjusting the contrast potentiometer at the back of the I2C module. I tried varying my room temperature using an Air conditioner and found the sensor value to also vary accordingly. The AC also has an option to measure room temperature and as you can see in below image my remote displays the room temperature to be 27°C and our sensors also displays 27.3°C on the LCD which is pretty much close.

The complete working of the project can be found in the video linked at the bottom of this page. Hope you understood the project and enjoyed building it. If you have any problem in getting it to work, leave a comment below or use the forums for other technical quires.

This post is an introduction to the Nextion display with the Arduino. We’re going to show you how to configure the display for the first time, download the needed resources, and how to integrate it with the Arduino UNO board. We’ll also make a simple graphical user interface to control the Arduino pins.

Nextion is a Human Machine Interface (HMI) solution. Nextion displays are resistive touchscreens that makes it easy to build a Graphical User Interface (GUI). It is a great solution to monitor and control processes, being mainly applied to IoT applications.

The Nextion has a built-in ARM microcontroller that controls the display, for example it takes care of generating the buttons, creating text, store images or change the background. The Nextion communicates with any microcontroller using serial communication at a 9600 baud rate.

To design the GUI, you use the Nextion Editor, in which you can add buttons, gauges, progress bars, text labels, and more to the user interface in an easy way. We have the 2.8” Nextion display basic model, that is shown in the following figure.

The best model for you, will depend on your needs. If you’re just getting started with Nextion, we recommend getting the 3.2” size which is the one used in the Nextion Editor examples (the examples also work with other sizes, but you need to make some changes). Additionally, this is the most used size, which means more open-source examples and resources for this size.

To get started with Nextion, first you need to install Nextion Editor. Go to https://nextion.itead.cc/, select the Resources tab, Download > Nextion Editor and install Nextion Editor. You can either download the .zip file or the .exe file.

Connecting the Nextion display to the Arduino is very straightforward. You just need to make four connections: GND, RX, TX, and +5V. These pins are labeled at the back of your display, as shown in the figure below.

You can power up the Nextion display directly from the Arduino 5V pin, but it is not recommended. Working with insufficient power supply may damage the display. So, you should use an external power source. You should use a 5V/1A power adaptor with a micro USB cable. Along with your Nextion display, you’ll also receive a USB to 2 pin connector, useful to connect the power adaptor to the display.

The best way to get familiar with a new software and a new device is to make a project example. Here we’re going to create a user interface in the Nextion display to control the Arduino pins, and display data.

The user interface has two pages: one controls two LEDs connected to the Arduino pins, and the other shows data gathered from the DHT11 temperature and humidity sensor;

We won’t cover step-by-step how to build the GUI in the Nextion display. But we’ll show you how to build the most important parts, so that you can learn how to actually build the user interface. After following the instructions, you should be able to complete the user interface yourself.

Additionally, we provide all the resources you need to complete this project. Here’s all the resources you need (be aware that you may need to change some settings on the user interface to match your display size):

Toolbox – this is where you have a wide variety of components you can add to the user interface, like pictures, progress bar, buttons, sliders, and much more.

Open Nextion Editor and go to File > New to create a new file. Give it a name and save it. Then, a window pops up to chose your Nextion model, as show in the figure below.

We’ll start by adding a background image. To use an image as a background, it should have the exact same dimensions as your Nextion display. We’re using the 2.8” display, so the background image needs to be 240×320 pixels. Check your display dimensions and edit your background image accordingly. As an example, we’re using the following image:

2. Click the (+) button and select your background image. The image will be added to the pictures list and it will be given an id. In this case it is 0.

4. Having that component selected, you should see its attribute in the attribute area. You can double click on the attributes to edit them. Double-click on the pic attribute to select the picture you want. You must write “0” which is the index of the picture you want, or select the image on the new window that pops up. After writing “0”, you actually need to hit ENTER to save the changes.

Here you can select the font height, type, spacing and if you want it to be bold or not. Give it a name and click the Generate font button. After that, save the .zi file and add the generator font by clicking yes.

The font will be added to the Fonts library at the left bottom corner and it will be given an index. As this is your first font, it will have the index 0.

Note: At the time of writing this instructions there is an issue with font types. Whatever font type you chose, it will always look the same.Still, you can edit the font size and if it is bold or not.

At this moment, you can start adding components to the display area. For our project, drag three buttons, two labels and one slider, as shown in the figure below. Edit their looks as you like.

All components have an attribute called objname. This is the name of the component. Give good names to your components because you’ll need them later for the Arduino code. Also note that each component has one id number that is unique to that component in that page. The figure below shows the objname and id for the slider.

You should trigger an event for the touchable components (the buttons and the slider) so that the Arduino knows that a component was touched. You can trigger events when you press or when you release a component.

To do that, select one of the buttons, and in the event window, select the Touch Release Event tab, and put a tick on the Send Component ID option. Repeat this process for the other button, and the slider.

Adding more pages to your GUI is really simple. On the top right corner, in the Page area, select the Add button to add a new page. A new page will be created. In this case, page1.

Our second page will display data from the DHT11 temperature and humidity sensor. We have several labels to hold the temperature in Celsius, the temperature in Fahrenheit, and the humidity. We also added a progress bar to display the humidity and an UPDATE button to refresh the readings. The bBack button redirects to page0.

Notice that we have labels to hold the units like “ºC”, “ºF” and “%”, and empty labels that will be filled with the readings when we have our Arduino code running.

In that window you can click on the buttons and see what happens. You should be able to swap between pages by clicking the corresponding buttons. You should also see the data returned when you click each button as highlighted in red in the figure above.

Once the GUI is ready, you need to write the Arduino code so that the Nextion can interact with the Arduino and vice-versa. Writing code to interact with the Nextion display is not straightforward for beginners, but it also isn’t as complicated as it may seem.

A good way to learn how to write code for the Arduino to interact with the Nextion display is to go to the examples folder in the Nextion library folder and explore. You should be able to copy and paste code to make the Arduino do what you want.

The first thing you should do is to take note of your components in the GUI that will interact with the Arduino and take note of their ID, names and page. Here’s a table of all the components the code will interact to (your components may have a different ID depending on the order you’ve added them to the GUI).

After that, you define led1 and led2. These variables refer to the digital pins 8 and 9 respectively. (led 1 will be controlled with the ON and OFF buttons of the user interface, and led2 brightness will be controlled using the slider).

Here you use the page ID, the component ID and their name – just check the table above with all the components. To define a text you use NexText, to define a button you use NexButton, for a slider you use NexSlider and for the progress bar you use NexProgressBar.

This function will set the led1 to HIGH, as well as update the tState label with the text “State: on”. Updating text labels is as simple as using setText().

For the slider (h0), you have the following function that writes the current slider position on the tSlider label and sets led2 brightness accordingly:

Finally, you need a function for the bUpdate (the update button). When you click this button the DHT temperature and humidity sensor reads temperature and humidity and displays them on the corresponding labels, as well as the humidity on the progress bar. That is the bUpdatePopCallback() function.

In the setup(), you need to attach the functions created to the corresponding events. For example, when you click on the bOn button, the bOnPopCallback function will be triggered.

In this post we’ve introduced you to the Nextion display. We’ve also created a simple application user interface in the Nextion display to control the Arduino pins. The application built is just an example for you to understand how to interface different components with the Arduino – we hope you’ve found the instructions as well as the example provided useful.

In our opinion, Nextion is a great display that makes the process of creating user interfaces simple and easy. Although the Nextion Editor has some issues and limitations it is a great choice for building interfaces for your electronics projects. We have a project on how to create a Node-RED physical interface with the Nextion display and an ESP8266 to control outputs. Feel free to take a look.

I’ve been working on a new remote controlled tank in my spare time. My goal with this project is to make a cheap, printable RC tank kit. This post goes back and forth between talking about the tank, and a basic tutorial on how the components and code work together.

Currently it’s a working prototype. The tank uses an Arduino Nano clone (ATmega328) as the primary board. An L298n H-Bridge is used to control the left and right motors independently, allowing it to quickly turn or revese. It uses the HC-06 Bluetooth module to receive commands. The power comes from two 18650 batteries that are connected in series.

I purchased the majority of the hardware from Aliexpress, because it’s so cheap. The links below are to the stores that I used, but you can find the same parts on many websites other than Aliexpress.Arduino Nano V3 Clone ( AtMega328p ) – Link

The frame of the tank was printed as a solid piece. There are four mounting spots for wheels. The two at the front are designed so that small bearings will slot into them, so that the front wheels spin freely. The other two of the mounts are designed to hold the gearbox motors. I made a T-shape in the center of the frame so that I can mount a breadboard on top of the frame. The frame design leaves much to be desired, it’s much too thin and flexible.

The Arduino and L298N are powered using two 18650 batteries. These are fairly common rechargeable batteries, with an output around 3.7V. I wired my batteries in seri

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey