lcd module 16x2 pinout made in china

Winstar 16x2 Character LCD Display WH1602W is having two pinout interfaces on upper and bottom sides of the LCD module. This 16x2 lcd display has the outline size of 80.0 x 36.0 mm and VA size of 66.0 x 16.0 mm and the maximum thickness is 13.2 mm. WH1602W 16x2 LCD Displays are built-in controller ST7066 or equivalent. It is optional for + 5.0 V or + 3.0 V power supply. The LEDs can be driven by pin 1, pin 2, or pin 15 pin 16 or A/K. This type of module can be operating at temperatures from -20℃ to +70℃; its storage temperatures range from -30℃ to +80℃.

We come across Liquid Crystal Display (LCD) displays everywhere around us. Computers, calculators, television sets, mobile phones, and digital watches use some kind of display to display the time.

An LCD screen is an electronic display module that uses liquid crystal to produce a visible image. The 16×2 LCD display is a very basic module commonly used in DIYs and circuits. The 16×2 translates a display of 16 characters per line in 2 such lines. In this LCD, each character is displayed in a 5×7 pixel matrix.

Contrast adjustment; the best way is to use a variable resistor such as a potentiometer. The output of the potentiometer is connected to this pin. Rotate the potentiometer knob forward and backward to adjust the LCD contrast.

A 16X2 LCD has two registers, namely, command and data. The register select is used to switch from one register to other. RS=0 for the command register, whereas RS=1 for the data register.

Command Register: The command register stores the command instructions given to the LCD. A command is an instruction given to an LCD to do a predefined task. Examples like:

Data Register: The data register stores the data to be displayed on the LCD. The data is the ASCII value of the character to be displayed on the LCD. When we send data to LCD, it goes to the data register and is processed there. When RS=1, the data register is selected.

Generating custom characters on LCD is not very hard. It requires knowledge about the custom-generated random access memory (CG-RAM) of the LCD and the LCD chip controller. Most LCDs contain a Hitachi HD4478 controller.

CG-RAM address starts from 0x40 (Hexadecimal) or 64 in decimal. We can generate custom characters at these addresses. Once we generate our characters at these addresses, we can print them by just sending commands to the LCD. Character addresses and printing commands are below.

LCD modules are very important in many Arduino-based embedded system designs to improve the user interface of the system. Interfacing with Arduino gives the programmer more freedom to customize the code easily. Any cost-effective Arduino board, a 16X2 character LCD display, jumper wires, and a breadboard are sufficient enough to build the circuit. The interfacing of Arduino to LCD display is below.

The combination of an LCD and Arduino yields several projects, the most simple one being LCD to display the LED brightness. All we need for this circuit is an LCD, Arduino, breadboard, a resistor, potentiometer, LED, and some jumper cables. The circuit connections are below.

FormikeGroup was founded in 1999, which engaged in R&D, design, manufactureand sales of LCD display solution, Wi-Fi / Bluetooth Module, Smart Watch as well asaccessories of cell phone.

Ourexperienced technical on OEM and ODM and managerial personnel, strict qualitymanagement system, competitive prices ensure that we always be at the forefrontof LCD, Wifi Module, Smart Watch and accessories of cell phone industry.

With the two rows in this module, there are sixteen columns. The VA dimension of these modules are (66 x 16) millimetres and thickness is 13.2 millimetre. Its operating voltage is plus five or plus three volts. In today"s post we will have a look at working, applications, circuit, features, advantage and disadvantages. So let"s get started with Introduction to 16x2 LCD Module.

In this module there are 2 main types of register first one is data register and the second one is command register. The RS pinout is used for the change the register.

16×2 LCD is named so because; it has 16 Columns and 2 Rows. There are a lot of combinations available like, 8×1, 8×2, 10×2, 16×1, etc. But the most used one is the 16*2 LCD, hence we are using it here.

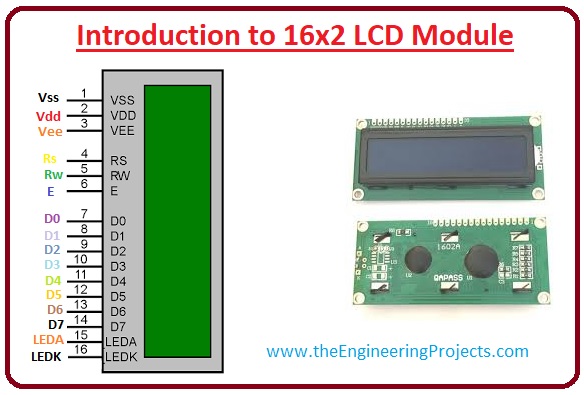

All the above mentioned LCD display will have 16 Pins and the programming approach is also the same and hence the choice is left to you. Below is the Pinout and Pin Description of 16x2 LCD Module:

These black circles consist of an interface IC and its associated components to help us use this LCD with the MCU. Because our LCD is a 16*2 Dot matrix LCD and so it will have (16*2=32) 32 characters in total and each character will be made of 5*8 Pixel Dots. A Single character with all its Pixels enabled is shown in the below picture.

So Now, we know that each character has (5*8=40) 40 Pixels and for 32 Characters we will have (32*40) 1280 Pixels. Further, the LCD should also be instructed about the Position of the Pixels.

It will be a hectic task to handle everything with the help of MCU, hence an Interface IC like HD44780 is used, which is mounted on LCD Module itself. The function of this IC is to get the Commands and Data from the MCU and process them to display meaningful information onto our LCD Screen.

The LCD can work in two different modes, namely the 4-bit mode and the 8-bit mode. In 4 bit mode we send the data nibble by nibble, first upper nibble and then lower nibble. For those of you who don’t know what a nibble is: a nibble is a group of four bits, so the lower four bits (D0-D3) of a byte form the lower nibble while the upper four bits (D4-D7) of a byte form the higher nibble. This enables us to send 8 bit data.

As said, the LCD itself consists of an Interface IC. The MCU can either read or write to this interface IC. Most of the times we will be just writing to the IC, since reading will make it more complex and such scenarios are very rare. Information like position of cursor, status completion interrupts etc. can be read if required, but it is out of the scope of this tutorial.

The Interface IC present in most of the LCD is HD44780U,in order to program our LCD we should learn the complete datasheet of the IC. The datasheet is given here.

There are some preset commands instructions in LCD, which we need to send to LCD through some microcontroller. Some important command instructions are given below:

Q; Could you provide the product drawings and the factory inspection report9 A We could provide the product drawings and the factory inspection report. Q; Can we customize products9 How many charges9 A; The LCD screen can be customized, customized products have the minimum purchase quantity constraint. Q: How do you make QC control9 Internal or third party9 A: Internal control,all products have to pass strict inspection before they go out.

Monochrome lcd panel is low cost LCD screen, monochrome lcd display is the mainstream in custom lcd screen because its custom tooling fee is very cheap.Monochrome LCD display included standard graphic monochrome lcd display, character lcd module, monochrome segment lcd display, monochrome tft lcd module and custom lcd screen.The monochrome lcd screen structures have COG LCD (chip on lcd glass), COB (chip on board), COF (chip on film).

An seven segment lcd display is like the below picture, it can display numbers from 0 to 9 and several letters such as C, A, b E, L, and F by control some segments "on" and "off". it is the cheapest lcd display panel.

The segment lcd also could be in Icon lcd display, that is the display content are the custom segments based on customer"s application.each segment means one icon, we could design the icon on our application.

The familiar Characters lcd modules have 16x1, 16x2, 16x4 characters, 20x1, 20x2, 20x4 characters, and 40x2, 40x4 etc, characters lcd display module. An 16x2 lcd display means 16 characters x 2 lines character on the lcd. normally, one characters is made by 5x8 pixels, we could display numbers 1~9, and A~Z letters and most of characters on the 5x8 pixels per characters.

The standard graphic lcd resolution have 96x64、96x96、122x32、128x64、128x128、160x128、160x160、192x64、240x64、240x128、320x240 etc.we could display all the characters and image in the graphic lcd display. of course, the higher resolution lcd, the display effect of image would be better.

(What is lcd resolution: )Lcd resolution means how many pixels of lcd screen,128x64 lcd resolution means 128 column x 64 row pixels on the lcd screen, we also call it 128x64 lcd display. monochrome lcd resolution could be 320x240 (QVGA) or 480x240 maximum, tft lcd resolution could be VGA (640X480) or HD (1366x768, FHD(1920x1080) or 4k2k lcd resolution.

Yes, if you only need the low quantity monochrome lcd display for your project, you could choose Maclight standard monochrome lcd, Maclight have wide range standard Characters lcd and Graphic lcd module, including COB type and COG type for your choosing. please find the standard monochrome list in the end of article, welcome to contact Maclight at [email protected]

The tooling fee of monochrome lcd panel would be around 300~500 USD, if only the simple segment lcd panel, such as TN display mode, then tooling fee would be cheaper, but if the custom lcd screen is monochrome graphic lcd panel, such as STN display panel, the tooling fee would be little higher than TN lcd panel. because the tooling mask for stn lcd would be higher than TN lcd panel. but it is only the tooling fee for monochrome lcd panel.

If for custom monochrome lcd module that with IC chip on glass, we call it COG LCD module, the tooling fee would be more higher, because if for custom TN or STN lcd display panel, the tooling mask can be made by PI film, while for custom monochrome COG LCD module, the custom COG LCD tooling mask would be used the metal mask, the tooling fee would be more higher to around 1500~2000 USD.

Besides the custom lcds panel, for some custom lcd mode that in transmissive lcd or transflective lcd display mode, because lcd panel is passive display, instead of oled display, lcd panel can not emit light by itself, it have to use the backlight, the backlight tooling fee would be upper than 1000 USD or more, the more complicating structure on the backlight, the tooling fee would be higher. for saving the cost of tooling fee on lcd backlight, the simple structure would be cheaper.

The MOQ of custom lcd display for monochrome lcd is calculated based on the mother-glass of LCD panel, some person may ask, what is mother-glass of lcd panel? is it the mother of lcd panel? no, no,no..., it is just a joke, the mother-glass of lcd is the primary glass of lcd, we also call it ITO glass, because it have an ITO layer on the glass. the lcd panels are array on the mother glass in manufacturing lcd panel, and cutting it one by one after lcd cell production finished. the main mother glass sizes if 14"x16", as in lcd manufacturing, for stable running in the full-auto machine line, it is at least 50 set of 14"x16" for an production running, that is the smaller sizes of lcd, the bigger MOQ of lcd quantity is necessary.

1. Confirm the sizes what you would like to custom making? the custom mono lcd displays would be mainly less than 10", the custom sizes is up to the mother glass of lcd panels that is less than 14"x16". the custom mono lcd can be custom made the random sizes below 10".

If you would not like to custom lcd display, you could choose the standard lcd from the following list, it is no MOQ requirement for the standard lcd.

Monochrome lcd display have TN, STN LCD, monochrome tft lcd types. the monochrome lcd could be with or without backlight. even for monochrome lcd display, it have difference LCD colors for choosing, such as yellow-green mode, blue mode, gray mode, black-white mode, negative display mode and positive display available. the backlight color could be white, green, orange, yellow-green colors.

I was trying to integrate this display with my arduino uno. But nothing is visible in the LCD screen. I have used http://arduino.cc/en/Tutorial/LiquidCrystal connection diagram. How can I check that the LCD itself is okey?

Sorry. Coding is totally user"s concern. We have many tutorials using both LCD and Sonar sensor but we did not do any tutorial exactly on what you said. Google it, we are sure you will find many.

I have bought two of these lcds and the qualities of the products were not conforming to the prior ones i.e. poor pcb edges. I hope you will look into this matter.

Hello, this one is always without pin as shown in the picture. This one is with pins: https://www.techshopbd.com/product-categories/lcd/2797/lcd-display-16x2-with-header-techshop-bangladesh

.jpg)

Do you want your Arduino projects to display status messages or sensor readings? Then these LCD displays can be a perfect fit. They are extremely common and fast way to add a readable interface to your project.

This tutorial will help you get up and running with not only 16×2 Character LCD, but any Character LCD (16×4, 16×1, 20×4 etc.) that is based on Hitachi’s LCD Controller Chip – HD44780.

True to their name, these LCDs are ideal for displaying only text/characters. A 16×2 character LCD, for example, has an LED backlight and can display 32 ASCII characters in two rows of 16 characters each.

The good news is that all of these displays are ‘swappable’, which means if you build your project with one you can just unplug it and use another size/color LCD of your choice. Your code will have to change a bit but at least the wiring remains the same!

Vo (LCD Contrast) controls the contrast and brightness of the LCD. Using a simple voltage divider with a potentiometer, we can make fine adjustments to the contrast.

RS (Register Select) pin is set to LOW when sending commands to the LCD (such as setting the cursor to a specific location, clearing the display, etc.) and HIGH when sending data to the LCD. Basically this pin is used to separate the command from the data.

R/W (Read/Write) pin allows you to read data from the LCD or write data to the LCD. Since we are only using this LCD as an output device, we are going to set this pin LOW. This forces it into WRITE mode.

E (Enable) pin is used to enable the display. When this pin is set to LOW, the LCD does not care what is happening on the R/W, RS, and data bus lines. When this pin is set to HIGH, the LCD processes the incoming data.

Now we will power the LCD. The LCD has two separate power connections; One for the LCD (pin 1 and pin 2) and the other for the LCD backlight (pin 15 and pin 16). Connect pins 1 and 16 of the LCD to GND and 2 and 15 to 5V.

Most LCDs have a built-in series resistor for the LED backlight. You’ll find this near pin 15 on the back of the LCD. If your LCD does not include such a resistor or you are not sure if your LCD has one, you will need to add one between 5V and pin 15. It is safe to use a 220 ohm resistor, although a value this high may make the backlight a bit dim. For better results you can check the datasheet for maximum backlight current and select a suitable resistor value.

Next we will make the connection for pin 3 on the LCD which controls the contrast and brightness of the display. To adjust the contrast we will connect a 10K potentiometer between 5V and GND and connect the potentiometer’s center pin (wiper) to pin 3 on the LCD.

That’s it. Now turn on the Arduino. You will see the backlight lit up. Now as you turn the knob on the potentiometer, you will start to see the first row of rectangles. If that happens, Congratulations! Your LCD is working fine.

Let’s finish connecting the LCD to the Arduino. We have already made the connections to power the LCD, now all we have to do is make the necessary connections for communication.

We know that there are 8 data pins that carry data to the display. However, HD44780 based LCDs are designed in such a way that we can communicate with the LCD using only 4 data pins (4-bit mode) instead of 8 (8-bit mode). This saves us 4 pins!

The sketch begins by including the LiquidCrystal library. The Arduino community has a library called LiquidCrystal which makes programming of LCD modules less difficult. You can find more information about the library on Arduino’s official website.

First we create a LiquidCrystal object. This object uses 6 parameters and specifies which Arduino pins are connected to the LCD’s RS, EN, and four data pins.

In the ‘setup’ we call two functions. The first function is begin(). It is used to specify the dimensions (number of columns and rows) of the display. If you are using a 16×2 character LCD, pass the 16 and 2; If you’re using a 20×4 LCD, pass 20 and 4. You got the point!

After that we set the cursor position to the second row by calling the function setCursor(). The cursor position specifies the location where you want the new text to be displayed on the LCD. The upper left corner is assumed to be col=0, row=0.

There are some useful functions you can use with LiquidCrystal objects. Some of them are listed below:lcd.home() function is used to position the cursor in the upper-left of the LCD without clearing the display.

lcd.scrollDisplayRight() function scrolls the contents of the display one space to the right. If you want the text to scroll continuously, you have to use this function inside a for loop.

lcd.scrollDisplayLeft() function scrolls the contents of the display one space to the left. Similar to above function, use this inside a for loop for continuous scrolling.

If you find the characters on the display dull and boring, you can create your own custom characters (glyphs) and symbols for your LCD. They are extremely useful when you want to display a character that is not part of the standard ASCII character set.

CGROM is used to store all permanent fonts that are displayed using their ASCII codes. For example, if we send 0x41 to the LCD, the letter ‘A’ will be printed on the display.

CGRAM is another memory used to store user defined characters. This RAM is limited to 64 bytes. For a 5×8 pixel based LCD, only 8 user-defined characters can be stored in CGRAM. And for 5×10 pixel based LCD only 4 user-defined characters can be stored.

Connecting an LCD to your Raspberry Pi will spice up almost any project, but what if your pins are tied up with connections to other modules? No problem, just connect your LCD with I2C, it only uses two pins (well, four if you count the ground and power).

In this tutorial, I’ll show you everything you need to set up an LCD using I2C, but if you want to learn more about I2C and the details of how it works, check out our article Basics of the I2C Communication Protocol.

There are a couple ways to use I2C to connect an LCD to the Raspberry Pi. The simplest is to get an LCD with an I2C backpack. But the hardcore DIY way is to use a standard HD44780 LCD and connect it to the Pi via a chip called the PCF8574.

The PCF8574 converts the I2C signal sent from the Pi into a parallel signal that can be used by the LCD. Most I2C LCDs use the PCF8574 anyway. I’ll explain how to connect it both ways in a minute.

I’ll also show you how to program the LCD using Python, and provide examples for how to print and position the text, clear the screen, scroll text, print data from a sensor, print the date and time, and print the IP address of your Pi.

Connecting an LCD with an I2C backpack is pretty self-explanatory. Connect the SDA pin on the Pi to the SDA pin on the LCD, and the SCL pin on the Pi to the SCL pin on the LCD. The ground and Vcc pins will also need to be connected. Most LCDs can operate with 3.3V, but they’re meant to be run on 5V, so connect it to the 5V pin of the Pi if possible.

If you have an LCD without I2C and have a PCF8574 chip lying around, you can use it to connect your LCD with a little extra wiring. The PCF8574 is an 8 bit I/O expander which converts a parallel signal into I2C and vice-versa. The Raspberry Pi sends data to the PCF8574 via I2C. The PCF8574 then converts the I2C signal into a 4 bit parallel signal, which is relayed to the LCD.

Before we get into the programming, we need to make sure the I2C module is enabled on the Pi and install a couple tools that will make it easier to use I2C.

Now we need to install a program called I2C-tools, which will tell us the I2C address of the LCD when it’s connected to the Pi. So at the command prompt, enter sudo apt-get install i2c-tools.

Now reboot the Pi and log in again. With your LCD connected, enter i2cdetect -y 1 at the command prompt. This will show you a table of addresses for each I2C device connected to your Pi:

We’ll be using Python to program the LCD, so if this is your first time writing/running a Python program, you may want to check out How to Write and Run a Python Program on the Raspberry Pi before proceeding.

The function mylcd.lcd_display_string() prints text to the screen and also lets you chose where to position it. The function is used as mylcd.lcd_display_string("TEXT TO PRINT", ROW, COLUMN). For example, the following code prints “Hello World!” to row 2, column 3:

On a 16×2 LCD, the rows are numbered 1 – 2, while the columns are numbered 0 – 15. So to print “Hello World!” at the first column of the top row, you would use mylcd.lcd_display_string("Hello World!", 1, 0).

You can create any pattern you want and print it to the display as a custom character. Each character is an array of 5 x 8 pixels. Up to 8 custom characters can be defined and stored in the LCD’s memory. This custom character generator will help you create the bit array needed to define the characters in the LCD memory.

By inserting the variable from your sensor into the mylcd.lcd_display_string() function (line 22 in the code above) you can print the sensor data just like any other text string.

These programs are just basic examples of ways you can control text on your LCD. Try changing things around and combining the code to get some interesting effects. For example, you can make some fun animations by scrolling with custom characters. Don’t have enough screen space to output all of your sensor data? Just print and clear each reading for a couple seconds in a loop.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey