custom lcd display xyzprinting brands

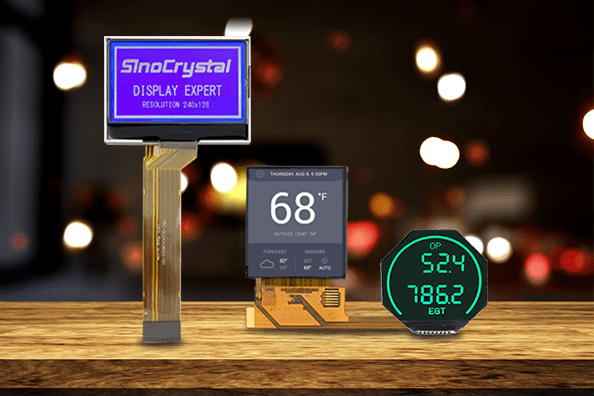

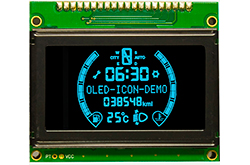

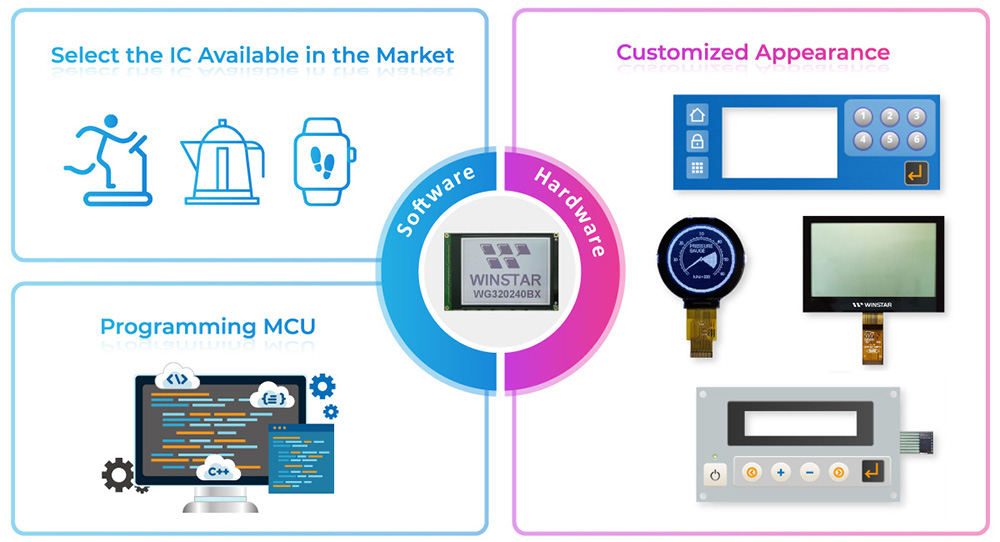

New Vision Display is a custom LCD display manufacturer serving OEMs across diverse markets. One of the things that sets us apart from other LCD screen manufacturers is the diversity of products and customizations we offer. Our LCD portfolio ranges from low-cost monochrome LCDs to high-resolution, high-brightness color TFT LCDs – and pretty much everything in between. We also have extensive experience integrating LCD screen displays into complete assemblies with touch and cover lens.

Sunlight readable, ultra-low power, bistable (“paper-like”) LCDs. Automotive grade, wide operating/storage temperatures, and wide viewing angles. Low tooling costs.

Among the many advantages of working with NVD as your LCD screen manufacturer is the extensive technical expertise of our engineering team. From concept to product, our sales and technical staff provide expert recommendations and attentive support to ensure the right solution for your project.

In addition, our extensive technology portfolio and manufacturing capabilities enable us to deliver high-quality products that meet the unique specifications of any application. To learn more about what makes us the display manufacturer for your needs, get in touch with us today.

As a leading LCD panel manufacturer, NVD manufactures custom LCD display solutions for a variety of end-user applications: Medical devices, industrial equipment, household appliances, consumer electronics, and many others. Our state-of-the-art LCD factories are equipped to build custom LCDs for optimal performance in even the most challenging environments. Whether your product will be used in the great outdoors or a hospital operating room, we can build the right custom LCD solution for your needs. Learn more about the markets we serve below.

It’s not uncommon for OEMs to have unique requirements to meet their products specifications. Because PDI focuses exclusively with OEMs to supply mid-volume standard, custom and semi-custom LCD displays, we are able work directly with select customers to provide LCD product solutions.

AGDisplays offers this screen print and glass service to give your display a finished and professional look. Add a hardened glass/touchscreen configuration with various ink options for logo customizations. Our custom branding allows for a unique finish to your product.Typically, screen print applications include display and touch panels;icons, lettering and logos;gauges and instrumentation and more. Screen printed images are printed by applying ink through a mesh screen to achieve a precise and crisp custom image or border.There are different cover glass thicknesses that range from ultra-thin for lightweight applications to thick and heavy for rugged applications. AGDisplays works with various types of glass and substrate options for which ever suites the display’s environment.

We offer a clean and efficient printing process with a high level of printing precision.Our screen printing is performed on a semi-automatic printer or an automated printer in a Class 1000 or 10,000 clean room, depending on project specification requirements. We offer customized color matching to meet your exact specification requirements.

For the screen printing process, we apply ink through a mesh screen to create the desired image. The ink is then cured to bond it to the substrate. This is a low-cost printing method which allows a durable and vibrant print. Screen printing allows more flexibility in terms of ink colors and thicknesses and is usually used to print on products like cover glass, display glass and EMI shielding.AGDisplays offers frit or epoxy/polyester inks for printing.

The epoxy/polyester ink type is offered in black and silver as standard but customizable colors are available. The ink is able to print as fine as 0.127 mm minimum resolution.Epoxy is a cost effective ink that may be cured at low temperatures and it shows good opacity. This ink can be used on thin glass, as it does not need tempering to adhere to the glass substrate.

Using ceramic frit ink is highly durable and ideal for marine display/cluster gauge applications. The ink is resistant to an environment where corrosive salt spray and fog are a constant threat. The frit ink is offered in black and silver as standard but customizable colors are available. This ink has a higher durability than the epoxy/polyester option. The resolution may print as fine as 0.305 mm.

The frit ink is configured of three parts, giving the ink a high adhesion to the LCD’s glass substrate. Once applied, the glass is placed into a tempering oven to fuse the ceramic ink to the substrate. Overall, the three-part combination creates a permanent and rigorous print.

Optionally integrate a touchscreen so your display performance jumps immediately to intuitive usability and ease of access. AGDisplays offers a complete touchscreen solution for integration into your LCD. A durable PCAP touchscreen OCA bonded with a cover lens and a finished border.This touch sensor is embedded behind the glass and we carefully selected OCA bonding to increase LCD/component ruggedization when installed into your LCD stack up. The increased durability does not compromise on the integrity of the display itself. The ruggedized touch sensors and cover lens combo fit panels in the range of 3.5 to 32 inches. We add a touch sensor embedded behind a glass substrate for protection. Our designs increase durability without compromising integrity of the technology.

Before we dive into the software, there are a few final hardware checks you should perform before using your da Vinci 1.0. If you’re confident your printer is ready to go, you can jump directly to the software setup. The da Vinci 1.0 comes with several additional pieces you will need to remove before performing your first print. These are also described in XYZprinting’s documentation as mentioned above. You will want to remove the plastic clips near the extruder or print head that hold onto the rods and secure the printer when being shipped. You will also want to remove the orange clip securing the build plate, this can be done by removing the thumb screw holding down the orange clip.

Premier Mounts, now a subsidiary of Gamber Johnson Inc., has been a leading manufacturer of reliable display mounting solutions that serve the diverse needs of the professional audiovisual industry since 1977.

We have over 300 heavy-duty mounting solutions engineered for compatibility with major display and projector providers, cart and stand applications, and custom solutions to meet your project needs.

We lead the industry in responsive production at scale and designing products with enhanced durability that are easy to install, reducing overall cost. From our group of talented engineers to our dedicated team of customer service and sales professionals, we offer heavy-duty solutions to ensure the best fit, every time.

Settings saved in EEPROM persist across reboots and still remain after flashing new firmware, so always send M502, M500 (or “Reset EEPROM” from the LCD) after flashing.

#define CUSTOM_STATUS_SCREEN_IMAGE STRING_CONFIG_H_AUTHOR is shown in the Marlin startup message to identify the author (and optional variant) of the firmware. Use this setting as a way to uniquely identify your custom configurations. The startup message is printed whenever the board (re)boots.

This is the name of your printer as displayed on the LCD and by M115. For example, if you set this to “My Delta” the LCD will display “My Delta ready” when the printer starts up.

Enable PID_AUTOTUNE_MENU to add an option on the LCD to run an Autotune cycle and automatically apply the result. Enable PID_PARAMS_PER_HOTEND if you have more than one extruder and they are different models.

M301 can be used to set Hotend PID and is also accessible through the LCD. M304 can be used to set bed PID. M303 should be used to tune PID values before using any new hotend components.

Use this option if you’ve connected the probe to a pin other than the Z MIN endstop pin. With this option enabled, by default Marlin will use the Z_MIN_PROBE_PIN specified in your board’s pins file (usually the X or Z MAX endstop pin since these are the most likely to be unused). If you need to use a different pin, define your custom pin number for Z_MIN_PROBE_PIN in Configuration.h.

Even if you have no bed probe you can still use any of the core AUTO_BED_LEVELING_* options below by selecting this option. With PROBE_MANUALLY the G29 command only moves the nozzle to the next probe point where it pauses. You adjust the Z height with a piece of paper or feeler gauge, then send G29 again to continue to the next point. You can also enable LCD_BED_LEVELING to add a “Level Bed” Menu item to the LCD for a fully interactive leveling process. MANUAL_PROBE_START_Z sets the Z-height the printer initially moves to at each mesh point during manual probing. With this disabled, the printer will move to Z0 for the first probe point. Then each consecutive probe point uses the Z position of the probe point preceding it.

The ANTCLABS BLTouch probe uses custom circuitry and a magnet to raise and lower a metal pin which acts as a touch probe. The BLTouch uses the servo connector and is controlled using specific servo angles. With this option enabled the other required settings are automatically configured (so there’s no need to enter servo angles, for example).

These offsets specify the distance from the tip of the nozzle to the probe — or more precisely, to the point at which the probe triggers. The X and Y offsets are specified as integers. The Z offset should be specified as exactly as possible using a decimal value. The Z offset can be overridden with M851 Z or the LCD controller. The M851 offset is saved to EEPROM with M500.

Use these settings to specify the distance (mm) to raise the probe (or lower the bed). The values set here apply over and above any (negative) probe Z Offset set with Z_PROBE_OFFSET_FROM_EXTRUDER, M851, or the LCD. Only integer values >= 1 are valid for these settings. Example: M851 Z-5 with a CLEARANCE of 4 => 9 mm from bed to nozzle.

These settings reverse the motor direction for each axis. Be careful when first setting these. Axes moving the wrong direction can cause damage. Get these right without belts attached first, if possible. Before testing, move the carriage and bed to the middle. Test each axis for proper movement using the host or LCD “Move Axis” menu. If an axis is inverted, either flip the plug around or change its invert setting.

AUTO_BED_LEVELING_UBL (recommended) combines the features of 3-point, linear, bilinear, and mesh leveling. As with bilinear leveling, the mesh data generated by UBL is used to adjust Z height across the bed using bilinear interpolation. An LCD controller is currently required.

MESH_BED_LEVELING provides a custom G29 command to measure the bed height at several grid points using a piece of paper or feeler gauge. See G29 for MBL for the full procedure. This type of leveling is only compatible with PROBE_MANUALLY.

#if ENABLED(LCD_BED_LEVELING) #define MESH_EDIT_Z_STEP 0.025 // (mm) Step size while manually probing Z axis. #define LCD_PROBE_Z_RANGE 4 // (mm) Z Range centered on Z_MIN_POS for LCD Z adjustment //#define MESH_EDIT_MENU // Add a menu to edit mesh points

Enable this option if a probe (not an endstop) is being used for Z homing. Z Safe Homing isn’t needed if a Z endstop is used for homing, but it may also be enabled just to have XY always move to some custom position after homing.

These are the default values for the Prepare > Preheat LCD menu options. These values can be overridden using the M145 command or the Control > Temperature > Preheat Material X conf submenus.

Choose your preferred language for the LCD controller here. Supported languages include: Code Language Code Language Code Language en English (Default) an Aragonese bg Bulgarian

This option applies only to character-based displays. Character-based displays (based on the Hitachi HD44780) provide an ASCII character set plus one of the following language extensions: JAPANESE … the most common

The SDSUPPORT option must be enabled or SD printing will not be supported. It is no longer enabled automatically for LCD controllers with built-in SDCard slot.

Disable all menus and only display the Status Screen with NO_LCD_MENUS, or just remove some extraneous menu items to recover space with SLIM_LCD_MENUS.

This option reverses the encoder direction for navigating LCD menus. If CLOCKWISE normally moves DOWN this makes it go UP. If CLOCKWISE normally moves UP this makes it go DOWN.

The duration and frequency for the UI feedback sound. Set these to 0 to disable audio feedback in the LCD menus. Test audio output with the G-code M300 S

Marlin includes support for several controllers. The two most popular controllers supported by Marlin are: REPRAP_DISCOUNT_SMART_CONTROLLER A 20 x 4 character-based LCD controller with click-wheel.

REPRAP_DISCOUNT_FULL_GRAPHIC_SMART_CONTROLLER A monochrome 128 x 64 pixel-based LCD controller with click-wheel. Able to display simple bitmap graphics and up to 5 lines of text.

LCD_I2C_PANELOLU2 PANELOLU2 LCD with status LEDs, separate encoder and click inputs. The click input can either be directly connected to a pin (if BTN_ENC is defined) or read through I2C (with BTN_ENC undefined). Requires LiquidTWI2 library v1.2.3 or later.

Temperature status LEDs that display the hotend and bed temperature. If all hotend and bed temperature set-point are < 54C then the BLUE led is on. Otherwise the RED led is on. There is 1C hysteresis.

#define NEOPIXEL_PIXELS 30 // Number of LEDs in the strip, larger of 2 strips if 2 NeoPixel strips are used #define NEOPIXEL_IS_SEQUENTIAL // Sequential display for temperature change - LED by LED. Disable to change all LEDs at once. #define NEOPIXEL_BRIGHTNESS 127 // Initial brightness (0-255) //#define NEOPIXEL_STARTUP_TEST // Cycle through colors at startup

With Dual X-Carriage the HOTEND_OFFSET_X setting for T1 overrides X2_HOME_POS. Use M218 T1 X[homepos] to set a custom X2 home position, and M218 T1 X0 to use X2_HOME_POS. This offset can be saved to EEPROM with M500.

#if EITHER(ULTIPANEL, EXTENSIBLE_UI) #define MANUAL_FEEDRATE { 50*60, 50*60, 4*60, 60 } // Feedrates for manual moves along X, Y, Z, E from panel #define SHORT_MANUAL_Z_MOVE 0.025 // (mm) Smallest manual Z move (< 0.1mm) #if ENABLED(ULTIPANEL) #define MANUAL_E_MOVES_RELATIVE // Display extruder move distance rather than "position" #define ULTIPANEL_FEEDMULTIPLY // Encoder sets the feedrate multiplier on the Status Screen #endif

#if ENABLED(LED_CONTROL_MENU) #define LED_COLOR_PRESETS // Enable the Preset Color menu option #if ENABLED(LED_COLOR_PRESETS) #define LED_USER_PRESET_RED 255 // User defined RED value #define LED_USER_PRESET_GREEN 128 // User defined GREEN value #define LED_USER_PRESET_BLUE 0 // User defined BLUE value #define LED_USER_PRESET_WHITE 255 // User defined WHITE value #define LED_USER_PRESET_BRIGHTNESS 255 // User defined intensity //#define LED_USER_PRESET_STARTUP // Have the printer display the user preset color on startup

#if ENABLED(LCD_PROGRESS_BAR) #define PROGRESS_BAR_BAR_TIME 2000 // (ms) Amount of time to show the bar #define PROGRESS_BAR_MSG_TIME 3000 // (ms) Amount of time to show the status message #define PROGRESS_MSG_EXPIRE 0 // (ms) Amount of time to retain the status message (0=forever) //#define PROGRESS_MSG_ONCE // Show the message for MSG_TIME then clear it

Show a progress bar on HD44780 LCDs for SD printing. Sub-options determine how long to show the progress bar and status message, how long to retain the status message, and whether to include a progress bar test in the Debug menu.

Add an option for the firmware to abort SD printing if any endstop is triggered. Turn on with M540 S1 (or from the LCD menu) and make sure endstops are enabled (M120) during SD printing.

This option makes it easier to print the same SD Card file again. Whenever an SD print completes the LCD Menu will open with the same file selected. From there you can click to start a new print, or you can navigate elsewhere.

Use the optimizations here to improve printing performance, which can be adversely affected by graphical display drawing, especially when doing several short moves, and when printing on DELTA and SCARA machines.

Some of these options may result in the display lagging behind controller events, as there is a trade-off between reliable printing performance versus fast display updates.

#define DGUS_UPDATE_INTERVAL_MS 500 #if EITHER(DGUS_LCD_UI_FYSETC, DGUS_LCD_UI_HIPRECY) #define DGUS_PRINT_FILENAME #define DGUS_PREHEAT_UI #if ENABLED(DGUS_LCD_UI_FYSETC) //#define DGUS_UI_MOVE_DIS_OPTION

#if ENABLED(CLCD_USE_SOFT_SPI) #define CLCD_SOFT_SPI_MOSI 11 #define CLCD_SOFT_SPI_MISO 12 #define CLCD_SOFT_SPI_SCLK 13 #endif #endif //#define TOUCH_UI_INVERTED

Babystepping enables M290 and LCD menu items to move the axes by tiny increments without changing the current position values. This feature is used primarily to adjust the Z axis in the first layer of a print in real-time. Warning: Does not respect endstops!

Experimental feature for filament change support and parking the nozzle when paused. Adds the M600 command to perform a filament change. With PARK_HEAD_ON_PAUSE enabled also adds the M115 command to pause printing and park the nozzle. Requires an LCD display. Note that M600 is required for the default FILAMENT_RUNOUT_SCRIPT. Requires LCD display and NOZZLE_PARK_FEATURE.

#define CUSTOM_MENU_MAIN_SCRIPT_DONE "M117 User Script Done" #define CUSTOM_MENU_MAIN_SCRIPT_AUDIBLE_FEEDBACK //#define CUSTOM_MENU_MAIN_SCRIPT_RETURN // Return to status screen after a script

#define CUSTOM_MENU_CONFIG_SCRIPT_DONE "M117 Wireless Script Done" #define CUSTOM_MENU_CONFIG_SCRIPT_AUDIBLE_FEEDBACK //#define CUSTOM_MENU_CONFIG_SCRIPT_RETURN // Return to status screen after a script

#if PIN_EXISTS(BUTTON1) #define BUTTON1_HIT_STATE LOW // State of the triggered button. NC=LOW. NO=HIGH. #define BUTTON1_WHEN_PRINTING false // Button allowed to trigger during printing? #define BUTTON1_GCODE "G28" #define BUTTON1_DESC "Homing" // Optional string to set the LCD status #endif

#define MAX7219_INIT_TEST 2 // Test pattern at startup: 0=none, 1=sweep, 2=spiral #define MAX7219_NUMBER_UNITS 1 // Number of Max7219 units in chain. #define MAX7219_ROTATE 0 // Rotate the display clockwise (in multiples of +/- 90°) // connector at: right=0 bottom=-90 top=90 left=180

The MMU2 LCD menu allows you to load filament to the nozzle. The MMU2 will transport the filament all the way to the extruder gears. The required extruder steps to load it into the hotend have to be defined in Marlin.

To unload filament using the LCD menu a generic ramming sequence will be executed before the MMU2 will retract the filament. The steps to do so are defined using

If you want to download the latest stable firmware version, go to Releases page and download the needed files. In the releases page you will find the Source Code and the SD Files needed for the LCD Display.

This repo contains the firmware and the files for the LCD Touchscreen display (for now). When a new release is done, normally is needed updating the SD files of the display. That way we can update menus, graphics and functionalities. You can find more information on how to update the LCD SD files here.

Navigating the LCD menu is done by a single control element: a rotational knob that you press to confirm a selection. In addition, you have a Reset button which will reset the printer if pushed. The main LCD screen also displays some other information about your printer"s current state.

I got a Da Vinci 1.0 pro this week and i successfully finished 2 demo prints and 1 own print. So ich still using the original yellow xyzprinting ABS filament.

I could use some help. I have a pro and needed to change the nozzle up by the filament feeder. I got it fixed. but while I was dismantling the printer to get to the nozzle, I dislodged the sticky pad sensor from the top door sensor, and now it just displays top door open, close top door on the readout. It still prints, but you can"t get an idea of what percentage is completed, time and etc. on the display panel. If anyone has a good photo of where I am supposed to attach the wired sticky pad, I would be forever in their debt.

The card supplied by XYZprinting has a thickness of 0.69mm (or 0.0275 inches) while a Lexar card I have laying around here measures 0.74mm (or 0.029 inches).

today i received the new sensor from xyzprinting and i installed it but still the same problem so i rechecked the 3 pin wires and its working too so now i can say i cant understand anything and am really pissed of this shity printer

Hi, I"m stuck and I am really hoping someone on here can help me out. I have owned my da Vinci 1.0 AiO 3d printer for about 6 months and it worked perfectly until when I was printing a model airplane propeller and it came unstuck from the printing platform and got jammed up into the long skinny belt that moves the print head left to right causing the belt"s little black plastic tensioning device to shatter ripping out the little white nylon belt return pulley leaving the belt hanging down. I contacted XYZprinting right away on their website and ended up having a very bad experience with them because I am in Canada and they told me they won"t ship warranty parts there for free and they don"t accept visa credit cards or paypal for payment and demanded I send them $50 dollars for shipping by ways of a bank wire transfer. I called my bank and they told me there was a $57.00 service charge for this. This is when I got really upset when I realized that even though my printer failed under warranty I was going to have to pay XYZprinting $107.00 for a little black plastic part the size of a sugar cube! I ended up being lucky because a machinist buddy of mine took my broken pieces and used them as a guide to make me a perfect fitting aluminum replacement and I got my printer back together.

I´m having an error on temperature readings. The display shows 67 when I´m sure it´s 37. It goes on an infinite loop of not printing because it stays forever heating.

Brian, I know you have a good relationship with XYZprinting. Do you think they would require shipping the printer back to try to fix this problem? Or do you think they could help solve it remotely? It sounds like a mainboard problem.

Because I told in public (YouTube) what I didn"t like about my printer, XYZPrinting in the Netherlands was threatening to sue me. The fun part was that while this was happening, XYZPrinting in Korea gave me a huge amount of filament and so on because the liked the way I was helping people who had bought the printer.

i"m pretty disappointed with XYZprinting support myself, the straight push fitting on the inside of the carriage broke, twisting the piece of angled PFTE plastic inside, making the feeder gears slip and pushing the filament out of the carriage from the top, So I called customer support and whoever answered was very confused but advised me to start a support ticket online, So I did but now they take too long to respond and are generally not helpful, you"re usually better off buying aftermarket parts from a third party, now in the case of a faulty motherboard, let"s just wait and see, please keep us posted @Midncoco.

Thanks Brian, but I"ve actually order them already, I just kept going with the support ticket because we are supposed to have a warranty and customer support, fortunately in my case I can buy the parts, but, what if it was the mainboard or some other critical component only they have like the cartridge PCB? I"ll follow up on my request as I think everyone should, otherwise they should tell you the printers are sold AS IS too keep the cost down.

I do not know which model of da Vinci printer you have, but I suggest you familiarize yourself with the options available via the printer"s LCD display. If your printer is similar to my da Vinci 1.0 Pro there should be a UTILITIES menu with a JOG MODE option that will allow you to move the X, Y or Z axis using the arrow buttons on the printer. The printer may refuse to move one or more of the axes if you have not first used the HOME AXES utility -- this is because if the printer has not recently homed the axes then it doesn"t know how far it can move without exceeding its limits.

I just got my da vinci 1.0 pro yesterday. It came with xyzprinting kapton tape. No uhu glue. I ran the sample part and it stuck like crazy just to the kapton. And idea what I can try? I heard purple aqua net hairspray. But does that go on the aluminum or on the tape. I"m brand new to this. This was that best thread online. Hope you guys have some suggestions.

Guys, On request of XYZPrinting, I made them a few video"s on the problems described in this thread. As an answer, they made and uploaded a few video"s on their channel to answer what we can do to solve the problems.

I currently have a Cube3D 2nd Gen that I replaced the motherboard with a RAMPS board; the extruder with a hexagon extruder; and modified marlin software to run on it. It wa quite successful, albeit with PLA only due to no heated bed (I did do some ABS prints, but I could not control the warping... so I bought a Da Vinci. I toyed with getting the 1.0 or the 2.0, and flashing with repetier, but this Pro caught my eye. I have only had it a few days, and so my comments may have been premature. As I was used to using Simplify3D, the XYZPrinting software was a bit of a shock to me. Now that the new iMac version is out, it seems more usable. I am currently testing gcode created in Simplify3D, at 50mm/s, so much faster that std. I will post my results.

Yes. Unfortunately the printer I am wrangling has the LCD screen showing the two solid black bars permanently. The lights are on on the motherboard but there does not appear to be anyone home. I am keen to hear if anyone else has any suggestions for fixing this. Here is what i have done so far.

Okay, I just managed to slice a hollow 20mm calibration cube stl I found on here with slic3r and changed the heading to the above. It"s printing now and seems to be making the cube as expected, but the LCD never changes from the "Initializing" screen. Am I missing a code that tells the printer to switch over to that monitor mode? Also, it doesn"t print the two strips on the side of the bed to get the nozzle flow started. Are those also lines of gcode that the XYZ slicer adds to the start of the job?

If you work with Slic3r, you won"t get normal info on your printer LCD. Also, the stripes on the side of your print bed are generated bij de XYZWare slicer and will therefore not be available in any other slicer.

The header that displays the temperature and time information is in nobber"s post from the 29th. From what I gather, the "time left" portion is still not correct. I suspect that the printer is using the layers information (layer height, number of layers) from the header to figure out the time left, so I think a possible solution might be to figure out a way (if possible) to get slic3r to provide the number of layers so that calculation can correctly be made.

I never did but I did have a tall print stop n say it was done before, this is a hack job, so weird stuff will happen, I changed the height way higher and it worked fine so yeah give it a try n see what happens... also doing this you loose the display on the printer so u don"t know how long till its done and you cant cancel, you have to flip the power switch

Yea. My design is going to be bolt in. No firmware changes or rigging it to work. Just drill two 4mm holes and bolt it all back together and plug it in. Then when simplified3d releases support for the xyz pro in their next update (I already use simplified3d on my prusa i3) it will be the XYZPrinting DaVinci PRO 2.0 Baker Edition. And with all the extra room and weight loss on the X&Y carriage print speeds will be doubled with the addition of a print cooling fan.

Well i called the webshop i used and they said i need to contact XYZprinting in the Netherlands(country i live). I called them and they did see i already made a support ticket and they will look into it. They will call me back today. I hope it is easy to fix.

I"m seriously thinking about removing the entire extruder and using an MK8 extruder with a custom carriage. I DO NOT like that the Da Vinci pushes filament into a tube. This is the first printer I"ve had that does this, and it"s not a good design at all.

That"s what I am doing, too... instead of machining a custom bracket for the filament tube. I have all of the body panels off of my machine, and I"m making several upgrades while I"ve got it opened up. On my machine, several of the small metal gripper teeth inside the push-in connector got bent (and/or broke off completely), so the tube was free to slip out of the connector when there was too much force inside the tube. (And you"re right... that can only happen when filament is jammed at the extruder end.) I also bought some new PTFE tube along with the connectors, so I"m hoping that both are of better quality than what came with the machine.

Called the support of XYZPrinting and they told me to switch off the printer and press and hold the up and down button while switching back on. The printer then starts in it"s bootloader. After that I could again update my firmware to 1.1.2

I called XYZprinting (took me about 10 tickets, and 20 calls till they finally answered). They basically said, you are under warranty still, so pack it up and send it back.

We fully own and operate our manufacturing, combining a dedicated sales and support team with board-level manufacturing, research and development under one brand. We offer services from simple customization of our existing product lines to development of completely new products.

Resin 3D printers function by using light to treat and cure liquid resin into the layers of an object. Compared to the work produced by FDM printers, the finished products of resin 3D printers are capable of much higher levels of detail and durability. Multiple types of resin printers are available, including LCD printers, DLP printers and SLA (stereolithography) printers. The three printing technologies have many similarities, but work differently and have their own advantages and considerations.

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

From cinema content to motion-based digital art, Planar® Luxe Displays offer a way to enrich distinctive spaces. These professional-grade displays provide vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior decor.

From cinema content to motion-based digital art, Planar® Luxe MicroLED Displays offer a way to enrich distinctive spaces. HDR support and superior dynamic range create vibrant, high-resolution canvases for creative expression and entertainment. Leading-edge MicroLED technology, design adaptability and the slimmest profiles ensure they seamlessly integrate with architectural elements and complement interior décor.

Planar® CarbonLight™ VX Series is comprised of carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility, available in 1.9 and 2.6mm pixel pitch (wall) and 2.6mm (floor).

Carbon fiber-framed indoor LED video wall and floor displays with exceptional on-camera visual properties and deployment versatility for various installations including virtual production and extended reality.

a line of extreme and ultra-narrow bezel LCD displays that provides a video wall solution for demanding requirements of 24x7 mission-critical applications and high ambient light environments

Since 1983, Planar display solutions have benefitted countless organizations in every application. Planar displays are usually front and center, dutifully delivering the visual experiences and critical information customers need, with proven technology that is built to withstand the rigors of constant use.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey