edge lit led lcd panel manufacturer

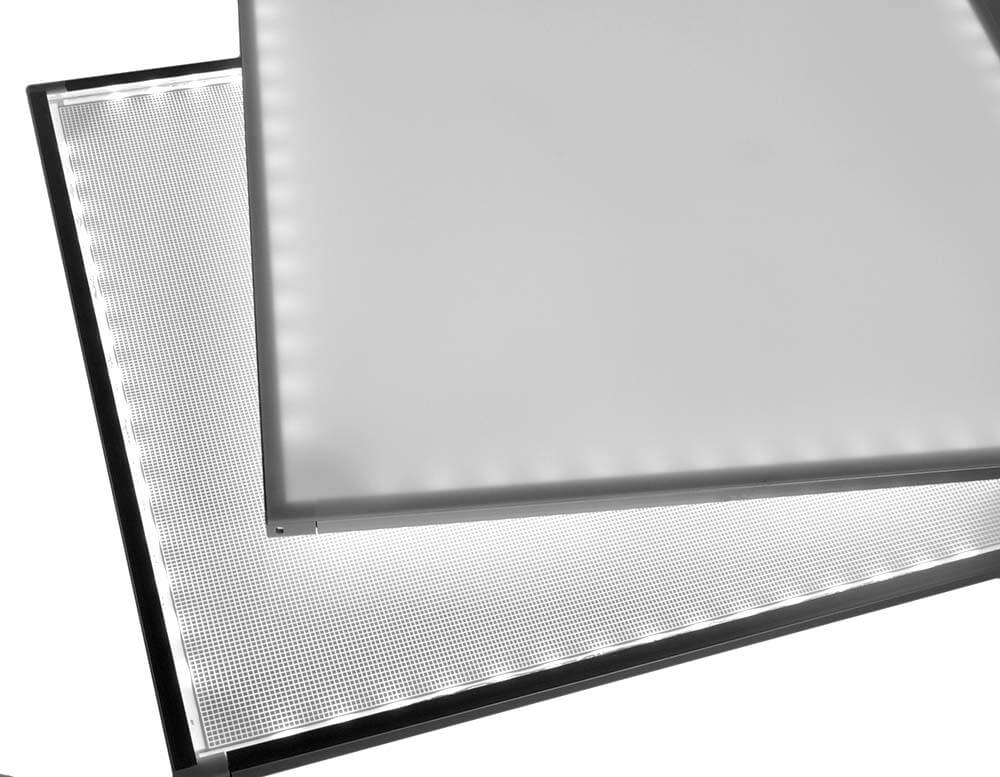

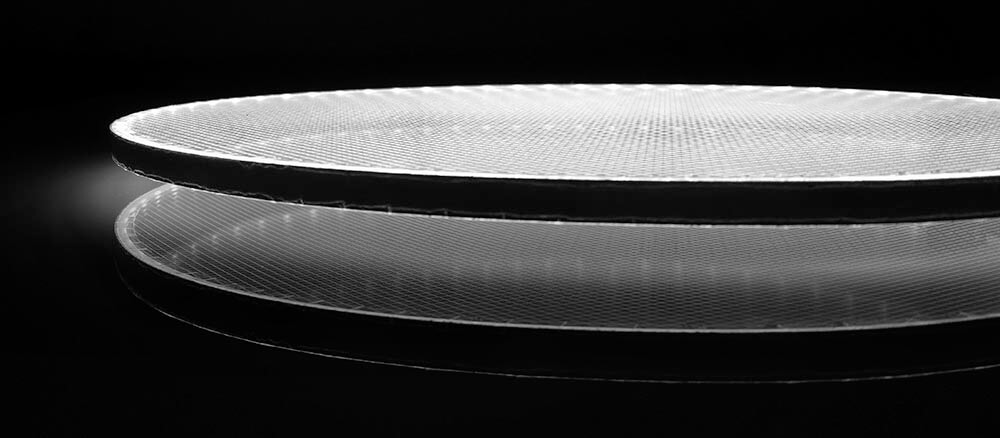

Lightboxes can be built to your specifications regarding size, color temperature, and frame color. Single and double-sided [illuminated on the front and rear face] light panels are also available. Edge-lit panels are 8mm or about 1/3-inch thick a light panel including a flip-open frame [now called a lightbox] has a thickness of 0.625 to 1.50-inches. Illumination across the LED light panel from edge-to-edge is within 10% so a dark center is not a concern. Read more

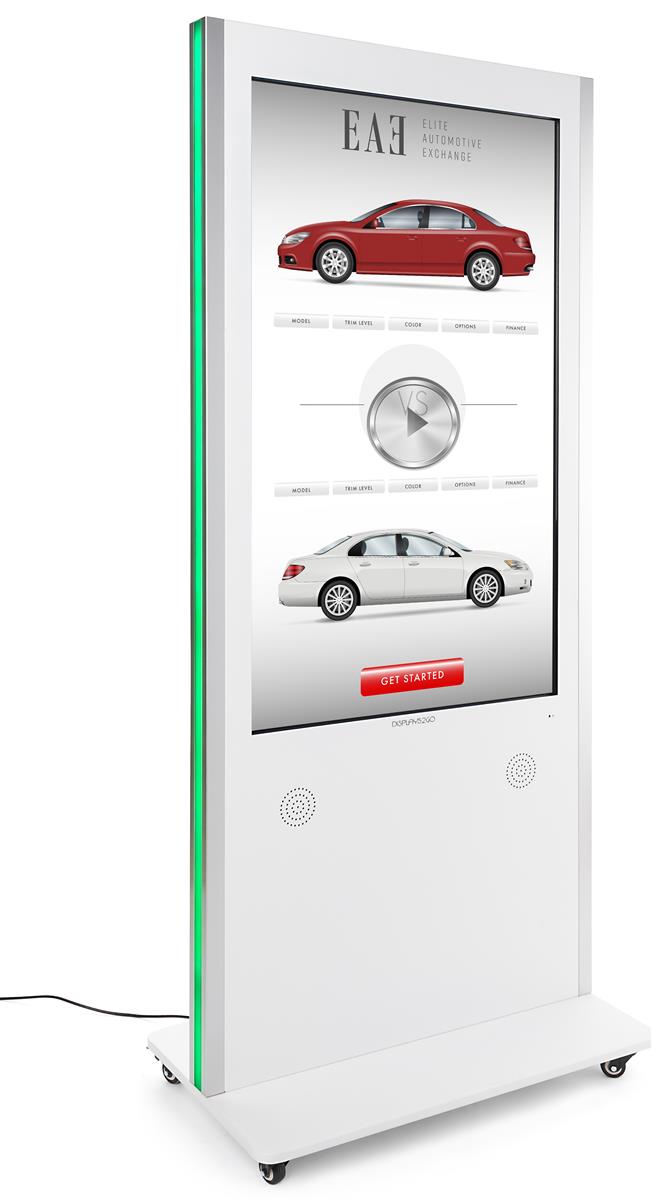

Light panels have many uses in retail environments such as lighted shelves, signs or as a lightbox for photographic transparencies, stained glass and faux windows. For interior lighting applications, the panel performs well as a ceiling troffer, lighted wall, under cabinet light and under stone such as Onyx, quartzite or translucent man-made countertops. Read more

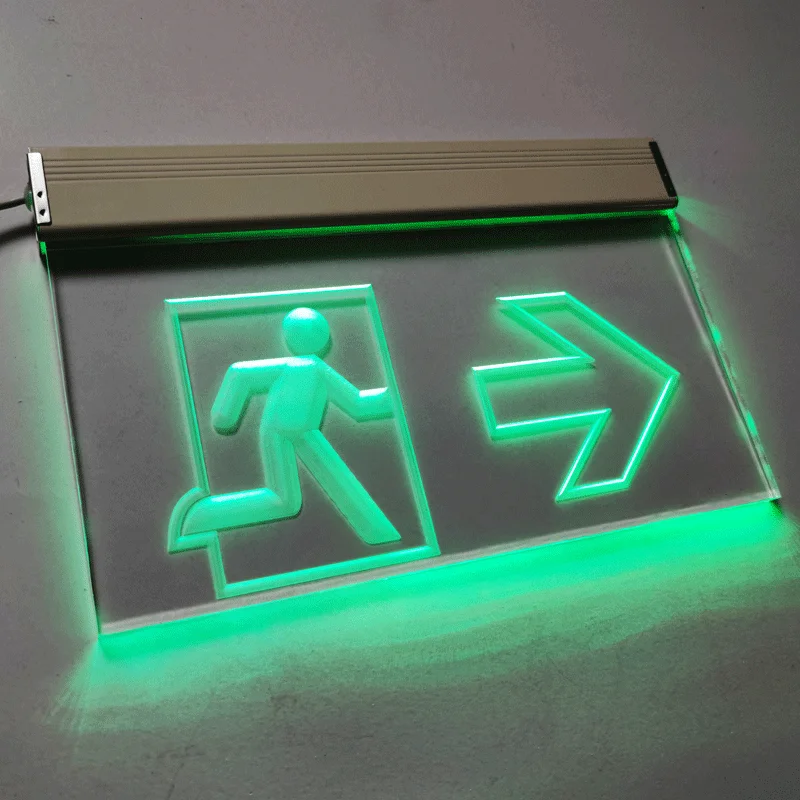

In signage, edge-lit panels can be a substitute for fluorescent tubes. Panels are thin, evenly illuminated and last for years without maintenance. Several color temperatures are available and RGB.

When displaying stained glass or some other translucent material in a window, you can use our clear edge-lit panel to let natural light through during the day and illuminate your art at night.

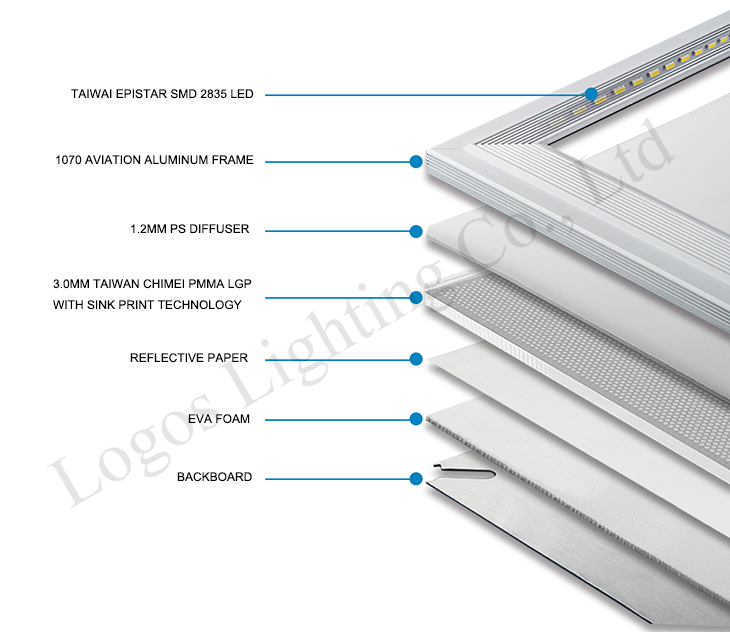

Here"s the "exploded" view of the edge-lit LED-based LCD display. In the foreground is the frame, followed by the LCD element, then the LED lighting assembly.

The heart of the beast is the LED lighting assembly. The LEDs themselves are arranged in strips on all four sides of the panel (the bottom strip was removed for this display). A series of filters, a "light guide," and a reflecting back serve to translate the LEDs" light toward the LCD display itself.

Here"s a closer look at the assembly. The rightmost, thinner three panels are the color filter, polarizing filter, and diffuser. The leftmost, notched white panel is the reflecting back, the only one of the five elements that sits behind the row of LEDs (top).

Second from the left is the clear-looking, thicker "light guide," a proprietary Samsung development that uses a series of tiny lens-like refractors to send light from the LEDs along edges toward the middle of the screen. The company claims its edge-lit LED-based LCDs have the same uniformity characteristics as its standard backlit LCD displays. If true, that would be an improvement on the only other edge-lit display we"ve reviewed so far, the Sony KLV-40ZX1M.

Here"s a closeup of the LEDs themselves, which are visible along the strip at the top. Despite their yellowish appearance, each produces white light, which is filtered and sent through the LCD panel. According to Samsung, the advantage of using white LEDs, as opposed to the multicolored "triluminous" LEDs in Sony"s XBR8 models, is purer reproduction of color-corrected primary and secondary colors at low luminance levels, as well as better energy efficiency.

Here"s where we mention that, unlike so-called local dimming LED based displays we"ve reviewed in the past, these edge-lit models can"t dim or turn off the LEDs selectively. That"s why we expect that the black-level performance of edge-lit LED-based LCD displays won"t match that of local dimming models, such as the Sony XBR8 or Samsung"s own A950 series.

When comparing different models of televisions, you might see the term "edge-lit LED." All LED TVs are a type of LCD TV; the "LED" refers only to the kind of lighting source used to illuminate the LCD pixels in the television. There is more than one way to light the pixels. The two primary technologies are edge-lit and full-array.

In an edge-lit television, the LEDs that illuminate the LCD pixels are located only along the edges of the set. These LEDs face inward toward the screen to illuminate it.

These models are thin and light at the mild expense of some picture quality—specifically in the area of black levels. Black areas of the picture, such as a dark night scene, are not truly black but more like a very dark gray since the lighting is coming from the edge and illuminating the dark areas a bit more.

In some poorer-quality edge-lit LEDs, uniform picture quality can be a problem. Because the LEDs are along the edges of the panel, quality declines as you approach the middle of the screen because a uniform amount of illumination is not reaching the pixels further from the edges. Again, this is more noticeable during scenes of darkness; the black along the sides of the screen is more gray than black (and corners can appear to have a flashlight-like quality of illumination emanating from the edges).

Full-array LED televisions use a full panel of LEDs to illuminate the pixels. Most of these sets also have local dimming, which means the LEDs can be dimmed in different regions of the panel while other areas are not. It helps improve black levels, which appear closer to black than dark gray.

In general, full-array LED is a superior technology when it comes to picture quality, but edge-lit sets have one significant advantage: depth. Edge-lit LED TVs can be much thinner than those lit with either a full LED panel or traditional fluorescent (non-LED) backlight. For that reason, most of the super-thin sets you see in stores will be edge-lit.

If you"re looking for the best possible picture quality, you are most likely to find it in a full-array LED display with local dimming. If you are primarily concerned about the appearance of the television and want an extremely thin screen, edge-lit is the style that will fit your needs.

ST. PAUL, Minn.--(BUSINESS WIRE)--In an effort to meet LCD manufacturer design flexibility demands, the 3M Optical Systems Division today announced that it has developed a unique solution called Uniformity Tape that will allow LCD manufacturers to reduce the number of LEDs required for edge-lit LED LCD panels at a low cost, without sacrificing brightness or efficiency.

"As LED technology continues to improve and becomes even brighter, some backlight designs are currently using more LEDs than needed for a brightness specification in order to avoid head lighting or thick bezels. Uniformity constraints have also prevented manufacturers from removing LEDs to save on cost"

LEDs are becoming brighter and even more efficient-requiring fewer bulbs to achieve target brightness for a given display. Until now, there have been limitations as to how far LEDs can be spaced apart at the edge of an LCD panel because of dark areas that appear between LEDs when they are too far apart. This scenario is commonly referred to as "head-lighting" because it looks like the dark space on the road between the headlights of a car.

3M"s Uniformity Tape is a clear tape, which has adhesive on one side and a micro-replicated optical pattern on the other side. It is adhered to the edge of the light guide, which faces the LED light sources. The tape is designed to increase the spreading of light in the light guide from each LED, which greatly increases the allowable LED spacing. The optical pattern is spatially uniform, meaning that no positional registration of LEDs is required along its length. The Uniformity Tape keeps the edge of the display closest to the LEDs uniform in brightness when the spacing of light sources is increased. This allows panel manufacturers to save money by removing unnecessary LEDs. Uniformity Tape can also increase LED spacing by up to three times the current spacing, while maintaining edge uniformity for a given bezel size.

"As LED technology continues to improve and becomes even brighter, some backlight designs are currently using more LEDs than needed for a brightness specification in order to avoid head lighting or thick bezels. Uniformity constraints have also prevented manufacturers from removing LEDs to save on cost," noted Gilles Georges, 3M global marketing manager. "By spacing LEDs further apart for edge-lit LED LCD panels, 3M"s Uniformity Tape allows light to travel inside the light guide at wider angles-allowing manufacturers to design wider spacing between LEDs without any dark areas."

When combined with 3M"s Dual Brightness Enhancement Film (DBEF), Uniformity Tape allows display manufacturers even more design freedom to innovate and use less LEDs to create a backlight that not only meets energy standards, but also remains competitive at a low cost. Furthermore, Uniformity Tape helps device manufacturers meet the growing number of energy efficiency standards around the world.

The local dimming on LED TVs is a key way of introducing contrast. With this technology, the intensity of lighting adapts to the image shown achieving contrast ratios.

LED-backlit LCD, which uses light-emitting diodes for backlighting is a common type of display on televisions and laptops. Unlike pure LED screens these LCDs are not self-illuminating and are reliant on the backlighting for illuminating the display. It is an advancement on the preceding cold cathode fluorescent technology and some manufacturers and retailers may advertise this type of screen as an LED TV.

Edge-lit is a type of screen backlighting that has LED lights lining either the top and bottom edges of the screen or the perimeter of the screen. This form of backlighting differs from others as the screen is not lit from behind, and often produces a more muted effect. An opaque piece of plastic called a diffuser light guide distributes the lighting across the rear of an LCD panel.

Edge-lit LEDs can be individually brightened or dimmed to provide the high degree of backlight control that screened content demands. Edge-lit screens can achieve this in one of two ways:

Direct-lit backlighting uses LED lighting across a television back panel. This form of backlighting initially used Cold Cathode Fluorescent Lamps (CCFLs) before transitioning to LED. The lighting is behind the LCD panel to provide consistent lighting across the entire screen.

The use of LEDs creates an extremely bright picture. This can lead to black and naturally dark tones appearing too bright, a phenomenon known as ‘elevated black levels’. This appearance can really affect wide-screed films, especially as there is no way to alter the backlight of specific portions of the screen. This has led to the development of alternative backlighting arrangements that minimize the greying of black sections of the screen.

Both types of backlighting provide the illumination LED screens required to produce a visible image. The main difference is that direct-lit backlights sit behind the LCD panel to provide the necessary lighting whereas edge-lit screens have LEDs sitting at the perimeter of the screen. Here are some other notable differences:

The first generation of LED backlighting was edge-lit. However, this early form of edge-lit technology caused the development of hotspots on the screen and the overall lighting was inadequate. As LED design became more efficient and effective, Samsung revisited this type of backlighting with a market-leading edge-lit LED television in 2009.

Direct-lit panels use a simple array of LEDs to provide uniform lighting across an entire LCD panel. The adoption of direct-lit screen technology in the 2000s was driven by the availability of white LEDs that could replace existing CCFL technology.

Direct-lit performs across a range of viewing angles and colors, but it is limited by not being able to increase contrast, as the entire backlight has to be dimmed to change color intensity. This affects the ability of a screen to achieve a deep black tone. Full array lighting and flexible backlight technologies have superseded direct-lit lighting. They are more advanced and can achieve more nuanced imaging effects.

Edge Lit screens can achieve full, deep blacks as they can use local dimming technology to reduce lighting in areas of the screen that display black or dark colors.

LCDs need to be supported by additional lights because they don’t produce their light. To create this light, you can either use edge-lit LEDs or backlit LEDs. The primary difference between edge-lit and backlit LEDs is in the lighting is arranged. The light sources of Edge-lit displays are placed on a diffuser (usually thin) behind the LCD to create light dispersion.

The significant advantage of using an Edge-lit flat panel lights LED display is the reduced thickness. As a result of this, the displays are placed on Edge and not directly behind the LCD. It leads to the thinness of the diffuser. Most thin diffusers are usually edge-lit and not backlit, and they transfer the majority of the components to a big stand.

Switching from fluorescent troffer lights to LED troffer lights has its benefits, but the process could prove to be daunting and not so easy. You could either use Edge-lit panels or Backlit panels. Here are the significant differences between these panels.

Concerning the location of the LEDs, Edge-lit light panels are placed on the Edge of the frame. The light that emits is guarded by a light guard panel that directs it sideways. The light board is designed for the smooth and evenly distribution of light in a given space. The sleek look of the diffusers is a result of the small depth of the panel. The installation of Edge-lit can be done in a standard grid ceiling. And the sleekness and thinness of the board make it possible to install Edge-lit LEDs on walls and ceilings using suspension box or cable installation kits.

Backlit, as the name implies, is placed at the back of the frame instead of at the Edge. This position causes the LED to shine directly out, straight through the diffuser. In backlit LED, there is no light guard. As a result of this, the light shines directly outward and does not need to be directed. The straight direct light does not cause a glare because the backlit LED also has a diffuser which smoothens the light. The risk of yellowing of light guard is absent because there is no need for one. The directness of the LED light makes backlit more efficient than edge-lit. Unlike in edge-lit, where the light travels through the diffuser panel, light only passes through the thickness of the material in backlit.

The disadvantage of Backlit is the thickness of its diffuser. You cannot install it just anywhere. It has to be installed in a drop grid ceiling. Although its panel is thicker than Edge-lit, it is still easy to operate due to its lightweight around its surface.

There are two types of LED TV - edge-lit and back-lit televisions. So what is the difference, and is it important? Find out everything you need to know.

This type of lamp has managed to produce high-quality televisions. But, there have always been disadvantages to this technology, such as poor contrast ratios and color reproduction.

Different parts of the screen can have the blocks of lights switched on or off at any time, which gives the TV a much better contrast ratio than a traditional LCD TV.

Therefore, a back-lit LED TV with local dimming produces a better picture, which helps it to create an image comparable with other TV technologies like OLED.

A downside is that the power consumption of these TVs can be greater than standard LCD or edge-lit televisions – especially those models which use RGB LEDs.

The advantage over an edge-lit TV is that the lighting will usually be more uniform across the screen – eliminating the light-pooling of edge-lit screens.

The lights in edge-lit LED televisions are placed around the perimeter of the LCD screen – and the light they emit spreads across the back of the panel using a series of ‘light guides.’

TV/Audio/Video: If you can"t get enough of your favorite sports, the latest movies, love 3D entertainment -- or just want to listen to your favorite music in stunning clarity -- our newest electronics can help you experience it all in a whole new way. Another plus? Now, you can get a one-year Disney+ subscription with participating OLED TV model purchases, or a 6-month subscription with participating NanoCell TVs.

:max_bytes(150000):strip_icc()/Untitled-8f9cd351586348eaa141a6167c8097a6.jpg)

An LED-backlit LCD is a liquid-crystal display that uses LEDs for backlighting instead of traditional cold cathode fluorescent (CCFL) backlighting.TFT LCD (thin-film-transistor liquid-crystal display) technologies as CCFL-backlit LCDs, but offer a variety of advantages over them.

While not an LED display, a television using such a combination of an LED backlight with an LCD panel is advertised as an LED TV by some manufacturers and suppliers.

A 2016 study by the University of California (Berkeley) suggests that the subjectively perceived visual enhancement with common contrast source material levels off at about 60 LCD local dimming zones.

LED-backlit LCDs are not self-illuminating (unlike pure-LED systems). There are several methods of backlighting an LCD panel using LEDs, including the use of either white or RGB (Red, Green, and Blue) LED arrays behind the panel and edge-LED lighting (which uses white LEDs around the inside frame of the TV and a light-diffusion panel to spread the light evenly behind the LCD panel). Variations in LED backlighting offer different benefits. The first commercial full-array LED-backlit LCD TV was the Sony Qualia 005 (introduced in 2004), which used RGB LED arrays to produce a color gamut about twice that of a conventional CCFL LCD television. This was possible because red, green and blue LEDs have sharp spectral peaks which (combined with the LCD panel filters) result in significantly less bleed-through to adjacent color channels. Unwanted bleed-through channels do not "whiten" the desired color as much, resulting in a larger gamut. RGB LED technology continues to be used on Sony BRAVIA LCD models. LED backlighting using white LEDs produces a broader spectrum source feeding the individual LCD panel filters (similar to CCFL sources), resulting in a more limited display gamut than RGB LEDs at lower cost.

Using PWM (pulse-width modulation), a technology where the intensity of the LEDs are kept constant but the brightness adjustment is achieved by varying a time interval of flashing these constant light intensity light sources,

A first dynamic "local dimming" LED backlight was public demonstrated by BrightSide Technologies in 2003,Sony in September 2008 on the 40-inch (1,000 mm) BRAVIA KLV-40ZX1M (known as the ZX1 in Europe). Edge-LED lighting for LCDs allows thinner housing; the Sony BRAVIA KLV-40ZX1M is 1 cm thick, and others are also extremely thin.

LED-backlit LCDs have longer life and better energy efficiency than plasma and CCFL LCD TVs.mercury, an environmental pollutant, in their manufacture. However, other elements (such as gallium and arsenic) are used in the manufacture of the LED emitters; there is debate over whether they are a better long-term solution to the problem of screen disposal.

Because LEDs can be switched on and off more quickly than CCFLs and can offer a higher light output, it is theoretically possible to offer very high contrast ratios. They can produce deep blacks (LEDs off) and high brightness (LEDs on). However, measurements made from pure-black and pure-white outputs are complicated by edge-LED lighting not allowing these outputs to be reproduced simultaneously on screen.

Quantum dots are photoluminescent; they are useful in displays because they emit light in specific, narrow normal distributions of wavelengths. To generate white light best suited as an LCD backlight, parts of the light of a blue-emitting LED are transformed by quantum dots into small-bandwidth green and red light such that the combined white light allows a nearly ideal color gamut to be generated by the RGB color filters of the LCD panel. In addition, efficiency is improved, as intermediate colors are no longer present and do not have to be filtered out by the color filters of the LCD screen. This can result in a display that more accurately renders colors in the visible spectrum. Companies developing quantum dot solutions for displays include Nanosys, 3M as a licensee of Nanosys, QD Vision of Lexington, Massachusetts, US and Avantama of Switzerland.Consumer Electronics Show 2015.quantum dot displays at CES 2017 and later formed the "QLED Alliance" with Hisense and TCL to market the technology.

Mini LED displays are LED-backlit LCDs with mini-LED–based backlighting supporting over a thousand full array local dimming (FALD) zones, providing deeper blacks and a higher contrast ratio.

LED backlights are often dimmed by applying pulse-width modulation to the supply current, switching the backlight off and on more quickly than the eye can perceive. If the dimming-pulse frequency is too low or the user is sensitive to flicker, this may cause discomfort and eyestrain similar to the flicker of CRT displays at lower refresh rates.

Novitsky, Tom; Abbott, Bill (12 November 2007). "Driving LEDs versus CCFLs for LCD backlighting". EE Times. Archived from the original on 28 November 2010. Retrieved 21 November 2020.

LED TVs: 10 things you need to know; David Carnoy, David Katzmaier; CNET.com/news; 3 June 2010; https://www.cnet.com/news/led-tvs-10-things-you-need-to-know/

LCD Television Power Draw Trends from 2003 to 2015; B. Urban and K. Roth; Fraunhofer USA Center for Sustainable Energy Systems; Final Report to the Consumer Technology Association; May 2017; http://www.cta.tech/cta/media/policyImages/policyPDFs/Fraunhofer-LCD-TV-Power-Draw-Trends-FINAL.pdf Archived 1 August 2017 at the Wayback Machine

Polarisation-sensitive beam splitter; D.J. Broer; A.J.S.M. de Vaan; J. Brambring; European patent EP0428213B1; 27 July 1994; https://worldwide.espacenet.com/publicationDetails/biblio?CC=EP&NR=0428213B1&KC=B1&FT=D#

Image at bottom left: An edge-lit LED/LCD TV light guide plate. The grid of reflective bumps help distribute light from the screen"s edges towards its center.

Edge-lit LED/LCD TVs are simpler and generally less expensive to manufacture than fullarray models. According to research firm DisplaySearch, the actual cost of materials can be 30% to 40% less. Edge-lit TVs have white LEDs implanted all around the bezel, behind the LCD panel. The LEDs are positioned so that the light beams sideways toward the screen"s center, parallel to it and perpendicular to the line between viewer and screen.

The light guide plate, a large sheet of reflective material that"s covered with tiny convex bumps, reflects the side-fired light at a 90° angle so that it passes through the LCD panel to the viewer. The bumps are taller toward the center of the screen, where light coming from the LEDs is weakest; these higher bumps have a higher reflectivity to make up for the weaker light in the center. Because the light guide plate contains many thousands of reflective bumps, most edge-lit sets need no diffuser panel. The LEDs illuminating an edge-lit LCD can be also dimmed to produce deeper blacks, but they can be dimmed only as a group, not individually.

The advantage of edge-lit LED/LCD TVs is that they can be made exceptionally slim. For example, the latest Samsung models measure 1.2 inches thick - much slimmer than the 4-inch-thick LCD TVs of just a few years ago. However, the company"s recent full-array models are almost as slim, measuring a mere 1.5 inches thick. As Jonas Tanenbaum, Samsung vice president of LED and LCD marketing, says, "Edge-lit may always enjoy an advantage in slimness, but once you get to a 1.5-inch depth [with a fullarray TV], how perceptible is that extra 0.3 inches?" Because edge-lit TVs use fewer LEDs and no diffuser screen, they also tend to be more energy-efficient than full-array TVs, despite the fact that the LEDs in an edge-lit TV can"t be dimmed locally.

The main disadvantage of edge-lit LED/ LCD TVs is that they usually can"t match the extremely high contrast ratios achieved by full-array TVs. They can also suffer image uniformity problems stemming from imperfect light plate designs that don"t evenly distribute the light from the LEDs, and from mild "hot-spotting" caused by the lack of a diffuser. However, you wouldn"t notice the latter two issues except in certain situations, such as movie scenes that fade to black.

Videophiles generally consider full-array LED/LCD TVs to offer better picture quality because of the deeper blacks created by local dimming. But the point is debatable. In many movies and TV shows, you would appreciate the potentially lower black level of fullarray TVs in only a few scenes - and in those scenes, blooming may be visible. Edge-lit TVs can actually deliver better contrast in certain situations and scenes, because while the shadow depth may be somewhat less than with a full-array model, white highlights in the picture can also be brighter due to the set"s greater efficiency.

Edge-lit displays may also offer somewhat smaller viewing angles compared with full-array models, because the light coming from the LED array through those sets" diffuser panel is more broadly distributed than the light coming off the reflector bumps on a light guide panel. Thus, an edge-lit TV"s brightness may drop off a bit if you"re viewing it from an angle. Neither technology, though, can match the broad viewing angle of a plasma TV.

(Pocket-lint) - In 2021, Apple introduced Mini LED displays to its iPad Pro and 14 and 16-inch MacBook Pro. Now, TV manufacturers are embracing the tech, too, with models launching from LG, Samsung, Sony and more. But what is Mini LED and what benefits could it bring to your next tech purchase?

Like MicroLED, the term "Mini LED" or "mini-LED" has popped up a lot in recent times. However, unlike that technology, "Mini LED" relates to the backlighting rather than a display"s pixels.

It utilises tens of thousands of miniature LED bulbs that sit behind the LCD substrate in a display. They combine with local dimming zones to provide more precise lighting in bright areas and better black levels in darker regions of a picture.

The difference between Mini LED and other direct backlighting technologies is that, because each LED is much smaller, the lighting bleeds less (ie. when light encroaches on adjacent pixels) and local dimming zones can be smaller and more accurate.

Usually, LED TVs adopt either larger LEDs behind the LCD substrate (and therefore are more prone to light bleed and less precise) or are edge-lit - where the LEDs are housed around the edge of the screen and shine across the panel. It is much harder to gain deep, involving black levels with each type of lighting - often resulting in a grey tone in darker areas. And black levels have a direct impact on accurate colour representation in standard and HDR images.

As we explain above, the Mini LED backlight sits behind the LCD substrate in a panel (and any other substrates included to enhance colours or picture quality) and houses thousands of tiny LEDs that are switched on or off depending on the image. They are generally grouped into zones for responsiveness, to sync the backlight to the main image perfectly, and the fact there are so many of them allows the TV to be more accurate in terms of which areas of the screen it lights.

The local dimming zones run at a similar refresh rate to the LCD substrate, and when a zone is off or barely lit, the area on the screen will seem darker or even completely black. When on, that area of the screen will be brighter. The brightness of the LEDs depends on the colour and what is required from the on-screen action.

LG"s 2021 QNED Mini LED TVs, for example, use up to 30,000 Mini LEDs in almost 2,500 local dimming "blocks" (on its 8K 86-inch flagship) as the backlight.

This, claims LG, provides a 1 million to 1 contrast ratio. And, while it isn"t quite as accurate as self-lighting technologies, such as OLED, which can switch each pixel on and off where desired, it is as close as you can get with LCD.

Mini LED and MicroLED are two very different TV technologies. MicroLED, used by Samsung for its The Wall TV system, is a technology that features self-illuminating pixels - much like OLED - whereby each pixel can switch on or off depending on the picture.

The main benefit of Mini LED over conventional LED TVs (which also use LED backlighting with an LCD panel) is that the LED backlights are so much smaller, and there are so many more of them. This means they can be much more precise and, therefore, ensure that pictures are bolder in colour, deeper in black levels, and brighter for HDR.

Mini LED TVs won"t be quite as accurate as OLED, but are a lot closer than existing LED sets, with the side benefit of being more affordable than the best OLED TVs.

In addition, as good as the recent OLED TVs are, the technology is still prone to image retention - even permanent screen burn in the most extreme cases. Mini LED TVs are not.

Mini LED tech has been in development for several years but has only really broken in to the mass market in the past couple of years. But that means it is out there and easily available for you to get your hands on - in various ways and through various brands.

In the TV market, TCL and Samsung were among the earliest adopters, and the tech now powers Samsung"s high-end Neo QLED range - including 2022"s flagship QN95B.

LG"s Mini LED range is called QNED, and it sits alongside its popular OLED offering. It first launched 10 Mini LED TVs in different screen sizes in 2021, but it has extended that in 2022 with both 4K and 8K options. Sony also uses the technology to power a number of its high-end sets, including the Master Series Z9K and the X95K.

Away from TVs, and as we mentioned at the start, Apple introduced Mini LED displays on its iPad Pro and 14 and 16-inch MacBook Pro, and we"re expecting more models to follow, including a rumoured Mini LED monitor in 2023.

The Samsung QN90B QLED is the best TV with an LED panel we"ve tested. It"s an impressive TV with amazing picture quality and a great selection of gaming features. It uses a Mini LED backlight, with way more dimming zones than most LED TVs, which allows for greater control over the local dimming feature for better dark room performance, with less distracting blooming around bright objects. It also gets exceptionally bright, meaning it can handle lots of glare in a bright room.

Unlike most high-end LED TVs, it"s also a good choice for a wide seating arrangement, as the image remains consistent when viewed at an angle thanks to Samsung"s "Ultra Viewing Angle" technology. It also has a great selection of extra features like a built-in Tizen smart interface that"s easy to use and has a ton of apps available to download, so you can easily find your favorite shows. It"s also excellent for gaming, as it supports 4k @ 120Hz gaming from the new-gen consoles, and it supports a variable refresh rate to reduce tearing.

The TGS ThinTek™ G2 Edge Lit LED panel affords an efficient and elegant LED replacement for fluorescent lamps and troffer fixtures in offices, schools, hospitality, healthcare and other commercial and industrial applications. It provides flicker-free, uniform lighting, with a fully-integrated internal driver that allows bypass of existing ballasts for quick, easy and safe installation. Only 1.09” thick, the TGS ThinTek™G2 flat panel is equipped with an aluminum heat sink for advanced thermal control. Designed with high-quality, durable components, the panels can be surface, or recess for a contemporary or traditional look. Engineered with robust LEDs, the ThinTek™ G2 produces high lumen output and provides superior correlation to a wide range of selected color temperatures (CCT). The comprehensive spatial illumination provides a more natural light and creates stress-free environments. It is available in 1’x4’, 2’x2’ and 2’x4’ models, in 3000K, 3500K, 4000K and 5000K CCT. The TGS ThinTek™ G2 Edge Lit LED panel is Title 24 compliant, with full dimmable functionality, and is compatible with building controls, motion sensors, timers, and daylight harvesting systems. The ThinTek™ G2 panel is UL, cUL, and RoHS certified, and suitable for damp locations. It is backed by a 5 year/50,000 hour warranty for a long life of maintenance-free service. Recommended for indoor use only.Specification Sheet+ Save Product

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey