static lcd display quotation

Liquid Crystal Displays or more commonly known as LCDs are one of the most common electronic components which help us interact with an equipment or a device. Most personal portable equipment and even gigantic industrial equipment utilize a custom segment display to display data. For many portable consumer electronics, a segment LCD display is one of the biggest contributors to the overall cost of the device, hence designing a custom segment display can drive the cost down while also utilizing the display area in the most optimum manner. These displays have the lowest cost per piece, low power requirements, and a low tooling fee too.

At first thought, designing a custom segment LCD might look like a Herculean task, but trust me that it is easier than it seems. In this article, we have summarised and compared the display types and available technologies which are required to construct a custom segment LCD. We have also provided a flowchart that can act as a step-by-step guide while you design your own custom LCD. We have also provided the process we followed, a require gathering sheet we used for communicating our needs to the manufacturer, and a few other data and the quotation we received from the manufacturer.

Icons: A silhouette of any shape can be placed on the glass which enhances the ability to display data. For example, a symbol of a heart can be made to denote heart rate or an icon for a low battery to show that the battery needs to be charged. Icons are counted as a single pixel or segment and can give a lot more details than similar-sized text.

LCD Bias– It denotes the number of different voltage levels used in driving the segments, static drives (explained later in this article) only have 2 voltage levels or 2 bias voltage while multiplex drives have multiple voltage levels. For example, 1/3 will have 4 bias voltages.

LCDs utilizes the light modulating properties of liquid crystals which can be observed by using polarizing filters. Polarizing filters are special materials that have their molecules aligned in the same direction. If the light waves passing through polarisers have the same orientation as the filter, then the molecules of lights are absorbed by the filter, hence reducing the intensity of light passing through it, making it visible.

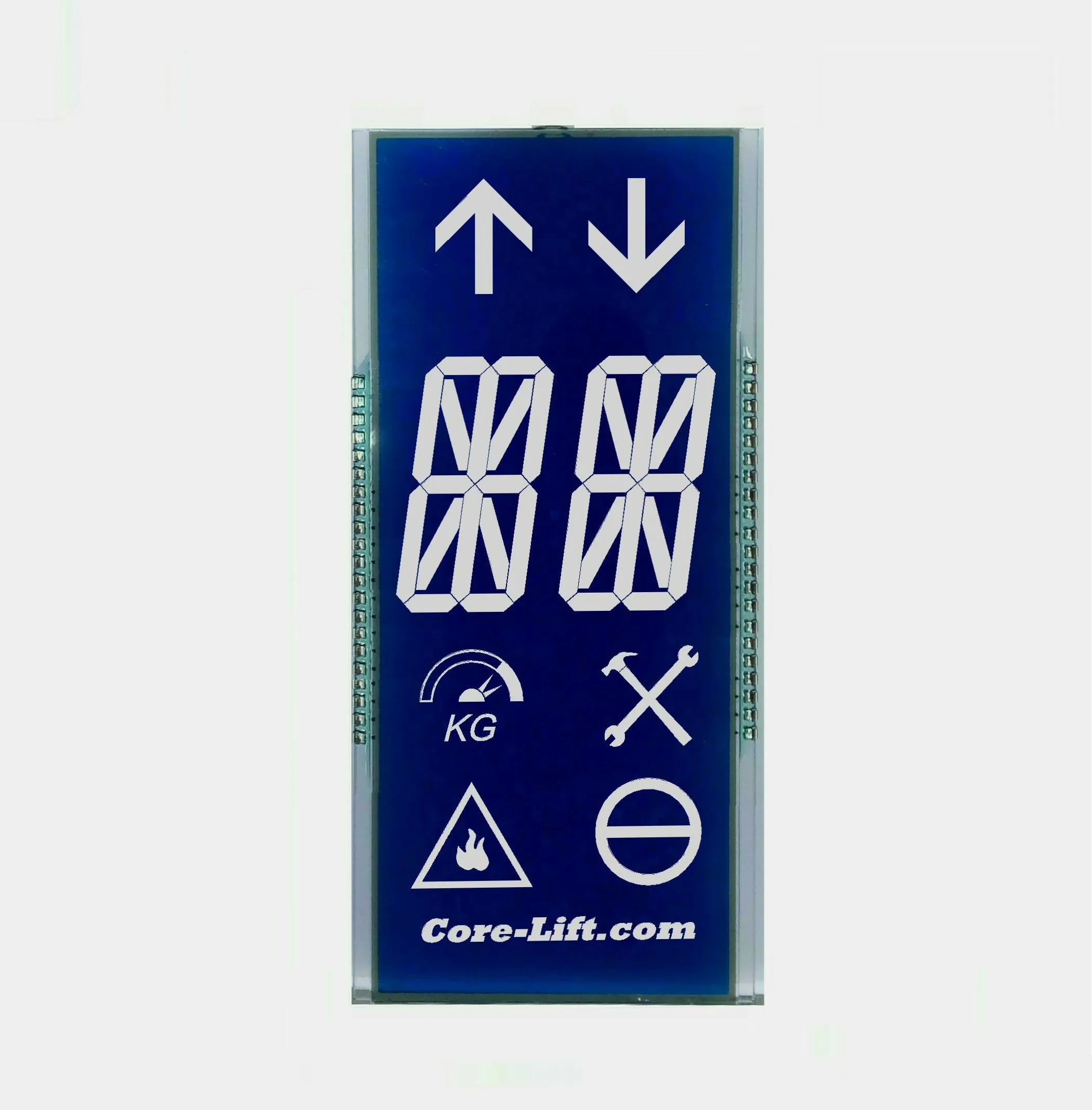

A custom LCD is important for maximizing the efficiency of the display area by adding custom symbols and characters. It also helps in reducing the cost and improving energy efficiency of the product. A higher number of custom symbols and specified placement of numerical and alphanumerical characters make the display more informative and readable for the user. This makes it look better than the plain old boring displays we get in the market. Furthermore, we can specify the viewing angle, contrast, and other specifications which can increase durability or give a better value for money for our intended usage. A typical Custom Segment display is shown below, we will also show you how to design and fabricate the same further in the article.

The LCD display doesn’t emit any light of its own, therefore it requires an external source of illumination or reflector to be readable in dark environments.

While designing a custom segment LCD display, we have the leverage of choosing a lot of parameters that affect the final product. From the color of the display to the illumination technique and color of illumination as well as the type of input pins. Some important considerations we need to take while designing a custom 7 segment display are - the type of display, i.e. positive or negative, illumination method, driving technique, polarising type, and connection method. All these design criteria are explained below:

Positive and negative displays can be easily distinguished by the colour of the background and characters. Some common differences between the positive and negative displays are:

So, which one should you choose? When the displays are to be used in areas with higher ambient light, we should select positive segment LCD display as it has better visibility than negative segment LCD displays without using a backlight.

As we know that LED displays don’t emit any light, hence to illuminate it and make it visible in a dark environment, we can use different methods of illumination. The most common LCD Illumination methods are compared below:

For displays that need to be used for budget-friendly devices that should be small and rugged, LED lights are preferred for the displays due to the high durability and low cost of operations. For high brightness, CCFL and Incandescent lights can be used.

A polarizer film is the most important component of an LCD display, which makes it possible to display characters by controlling the light. There are 3 types of polarizers that can be used in the LCD display, the properties and difference are given below:

Displays can be categorized into two types, passive displays, and active display, passive displays are simpler to construct as they have 2 connections at each segment, the conductors comprise of an Indium Tin Oxide to create an image, whereas the active displays use thin-film transistors (TFT) arranged in a grid. The name is due to its ability to control each pixel individually.

If your displays have fewer segments, then static LCD drive is preferred as it is easier to control and cheaper to construct, and has a better contrast ratio. But let’s say that if the number of segments in the display are more than 30-40 then a multiplex LCD drive should be preferred as it has multiple common pins, hence reducing the total number of pins required to drive the display.

Choosing a connector type!!! For the prototyping phase or if you need to connect your LCD display on a Microcontroller directly, a pin type connector is the best and most economical option you have. If you need to connect your LCD display in a final product with a high volume of production which also requires to be extremely durable, but at the same time should not take up a lot of space, a Flex type LCD Connector will work best for you

LCDs have limited viewing angles and when seen from an angle they lose contrast and are difficult to be observed. The viewing angle is defined by the angles perpendicular to the center of the display towards its right, left, up, and down which are denoted by the notations 3:00, 9:00, 12:00, and 6:00 respectively. The viewing angle of LCD can be defined as the angle w.r.t. to the bias angle at which the contrast of segments is legible.

To improve the viewing angle in an LCD, a Bias is incorporated in the design which shifts the nominal viewing angle with an offset. Another technique is to increase the Voltage, it affects the bias angle, making the display crisper when viewed from a direction.

For example, the viewing angle of a TN type TFT LCD is 45-65 degrees. Extra-wide polarising film (EWP) can increase the viewing angle by 10 degrees, using an O film polariser can make the viewing angles 75 degrees but these come at a cost of reduced contrast.

LCD Control chip or LCD driver chips can be mounted on the flex cable, display, or externally on a PCB. The placement of LCD control chip can affect the cost and size of the display. The 2 most common methods of chip placement are-Chip of Board (COB)and Chip on Glass(COG) which are described below:

We planned to design an air quality monitoring system for which we needed a custom segment LCD panel for an air quality monitoring device. Our product needs to display the following data: 2.5-micron and 10-micron particulate matter (PM) suspended in the air; the units should be in parts per million (PPM). CO2 in the air in PPM along with total volatile organic compounds present in the air in parts per billion (PPB). To make the product more usable, we included time in 24-hour format, Temperature in ºC, Battery status, loudspeaker status, Bluetooth status, and Wi-Fi status. And for some personal touch, we also added how good the air quality in the room is by using 3 different smileys.

We realized that it was impossible to provide all these data in a generic LCD available in the market, thus decided to build a custom LCD for our project.

A step-by-step flowchart is shown below to walk you through each and every step of selecting components and getting your custom segment LCD manufactured.

We started by listing down our requirements and drew a mock-up of the display on paper. After finalizing the placement of all the segments and icons on the prototype sketch of the display, we then decided which all icons and segments have to be kept on for the whole time and which needs to be driven. Realizing that there are too many segments, characters and icons, hence we selected a multiplex drive with 8 common pins which helped us bring down the total pins from an estimated 180 pins to less than 40 pins.

Since the device was meant to be used inside houses and offices, which are more often than not well lit and protected from environmental conditions, we opted for a positive mode display. For superior contrast ratio and better viewing angle, we chose a Film Super Twisted Nematic Display (FSTN) with a drive condition of 1/8 Duty and bias of 1/4.

Usually, the displays are mounted at a height of 4.5 feet from the ground, thus the viewing direction was selected to be 12"O clock with an operating frequency of 64Hz. We selected a Transmissive polarizer for the front glass and a reflective polarizer for the rear glass so that the natural light can pass through the front panel and the display can achieve the maximum contrast without the need for backlighting and we opted for the pin type connectors as they are easy for prototyping and are suitable for harsh environment with a lot of vibrations and shocks which best suited our purpose.

In the above image of a custom display design, we sent to the manufacturer, the red lines over multiple characters indicate that all these are considered as a single segment. For the sake of simplicity, we added test like T, S, U, B to denote Text, Symbols, Units, and Battery respectively. These characters were followed by numbers to simplify communication between us and the manufacturer. For example, if we needed any particular text or symbol to remain on, we can easily specify that to the manufacturer by using the corresponding text for that segment.

We mailed our requirements to multiple LCD manufacturers, (you will find a lot of LCD manufacturers on the Internet). Most LCD manufacturers have competitive pricing, and reply within a week. A sample requirement sheet is shown above which a customer needs to fill to specify all the details to the manufacturer.

This is a sample Custom Segment LCD quotation we got from one of the manufacturers. As you can see, the cost is based on the quantity. Higher the quantity, lower the cost. Apart from the cost per quantity, there is one more component called tooling fees. Tooling fee is a one-time fee charged by the manufacturer. It is for the technical design, support, and customization of the product. Customization of PCB or tooling of LCD can drive the tooling price higher or lower.

A custom segment LCD can help you personalize your product while also saving the overall cost of your product. The whole process will take you around 2-3 months, which will include the designing phase, prototyping phase, and getting your custom segment LCDs delivered to your doorstep. Higher ordering quantity will reduce the cost per piece of each unit, thus driving down the cost of your final product.

Golden View Display wants you to make an informed choice among our LCD products. The tech center provides you with most of the information you will need to understand liquid crystal displays.

The configuration for Liquid Crystal Display Static Drive technique is that one side of all of the Liquid Crystal Display segments are tied to a common, or backplane, and the other side of each of the segments are routed to individual connection points that are tied to the driver control circuitry. This method uses a large number of interconnects and is not feasible for complex displays, but it does produce the best looking display

LCD’s require an AC drive voltage with virtually no DC component. Segments are controlled by the magnitude of the AC voltage across the LCD segment, but there must always be AC voltage across ALL segments of the LCD. Prolonged DC operation may cause electrochemical reactions inside the displays which will cause significantly reduced life. The initial indications of display degradation because of excessive DC current is a loss of alignment along the edges of some of the characters. The visual indication will be a “fuzzy” appearance of some of the characters.

The TN LCD is an RMS voltage responsive device, that is, the contrast of a given segment is dependent upon the RMS value of the applied voltage across it, measured with respect to the common plane. This fact, which seems obvious now, is very important when discussing drive schemes.

Drive frequencies for direct drive displays are typically between 30Hz and 100Hz. Depending on the display size and design, displays can be operated at higher frequencies, but this will result in increased power consumption. LCDs portray a capacitive load, which reduces the load impedance as frequency increases. However, operation below 30Hz typically results in display flicker

LCD’s can be overdriven by a combination of voltage and frequency, which will result in cross talk or “ghosting”. Ghosting is the appearance or partial activation of an “off” segment. This condition occurs when high drive voltage and frequency are applied. Since the current is directly proportional to the frequency, there is a voltage-frequency product which must not be exceeded. These values are very dependent on the design and layout of any given part, so proper display design and choice of driving conditions is important. It is also very important that all unused segments be connected to the backplane, and not allowed to float.

The configuration for Liquid Crystal Display Multiplex Drive technique differs from a Static Drive technique is that it uses more than a single”backplane” or segment common. With this configuration, each segment control line can be connected to as many segments as there are backplanes, providing that each of the segments that it is connected to are tied to a separate backplanes. This method “Multiplexes” each of the segment control lines and minimizes the number of interconnects. This is the method used with complex displays that have limited interconnection surface area or available drive circuits. This reduction in the number of external connections enhances device reliability and increases the potential display density. The liability of a higher multiplex rate will effect display quality, operational temperature range, and the increased complexity of drive circuitry (or perhaps microprocessor software) may necessary for their operation.

The method of drive for multiplexed displays is essentially a time division multiplex with the number of time divisions equal to twice the number of common planes used in a given format. As is the case with conventional LCDs, in order to prevent irreversible electrochemical action from destroying the display, the voltage at all segment locations must be caused to reverse polarity periodically so that zero net DC voltage is applied. This is the reason for the doubling in time divisions: Each common plane must be alternately driven with a voltage pulse of opposite polarity.

As is the case with non multiplexed displays, the drive frequency should be chosen to be above the flicker-fusion rate, i.e. >30 Hz. Since increasing the drive frequency significantly above this value increases current demand by the CMOS drive electronics, and to prevent problems due to the finite conductivity of the display segment and common electrodes, an upper drive frequency limit of 60-90 Hz is recommended.

Segmented LCDs and graphic displays are a popular choice among products such as thermostats, kitchen appliances, medical devices, industrial meters, and more. A segmented LCD is an ideal solution for products that require a customizable cost-effective, low-power display option. Displaytech offers custom 7 segment displays in static or multiplex drive.

Segmented LCDs are monochrome liquid crystal displays where the elements on the panel are divided into segments which can either be visible (on) or hidden (off).

A 7-segment LCD is a cost-effective, low-power display option to use within your product design. At Displaytech, we are here to help you choose the best LCD solution for your product.

Dr Pan: Hello, Greg. Segment LCD screen can only be used for simple display content of numbers and characters at a specified position. For example, the display on clock, landline, calculator, etc.

It is supposed to be a replacement for LED segment display. If we compare it with LED segment display, it is more stylish and high class, but more expensive. If we compare it with dot matrix LCD, the display content is very simple and absence of variation, but much cheaper. It is widely used in monochrome LCD screen: TN, HTN, STN, FSTN and VA because of relatively low cost.

Researchers at the Hong Kong University of Science and Technology have developed a new type of LCD screen that only requires power when when it is refreshed. It’s based on optically rewritable liquid crystal display (ORWLCD), an LCD tech that has been batting around the research labs for the past several years.

While a regular LCD screen requires a constant supply of power so it can display an image, an ORWLCD only requires power when an image is first displayed. After that, the power can be turned off and the image will continue to be shown on the screen.

That is really quite similar in concept to an E-ink screen, but unfortunately ORWLCD tech also shares one of E-ink’s weaknesses; they’re both limited to grayscale screens, and not the 3 pigment color screen you expect to see on LCD screens.

I have much higher hopes that we will one day see JDI’s solution to the LCD power problem hit the market. For the past few years Japan Display has been working on a way to add a tiny bit of RAM to each pixel in an LCD display. The idea here is that the RAM would reduce the power requirements from the full power required to constantly refresh the screen multiple times a second to a lower level which would provide just enough power to keep the screen from going dark.

Liquid crystal display (LCD) is a flat panel display that uses the light modulating properties of liquid crystals. Liquid crystals do not produce light directly, instead using a backlight or reflector to produce images in colour or monochrome.

OK, this is the sketch that I used to try out user-defined characters on a four-row, 20 character LCD. If you have a two-row LCD, you"ll have to change the calls to "drawbar" in the main loop. You"ll need a potentiometer with the track connected to 0V and 5V, and the wiper connected to analog in 0. Turn (or slide) the pot to see the bar extend across the LCD. The crucial command to the LCD is 0x40, which is used to position the "cursor" in the CGRAM, which is where the user-defined characters are stored. A call to "home" is required after defining the characters, to put the cursor back into the main display memory. All this is documented in the HD44780 data sheet.

Spatial uniformity of displayed luminance can vary widely between different makes and models of LCD, the major determinant of uniformity being the backlight scheme [34] (some older LCDs allowed VGA input and relied on built-in analog-to-digital conversion, also a potential source of noise). Two commonplace schemes are, first, direct backlighting, wherein a spatial array of light-emitting diodes (LEDs) and a diffuser screen sit behind the liquid crystal panel, and, second, edge illumination, wherein light emitted by a linear array of diodes at one of the display’s edges is spatially distributed via lightguide. We quantified the spatial uniformity of the CG247X by presenting low-, medium-, and high-luminance static test patches at nine display positions (Fig 2, inset) and using the LS-110 spot meter to measure the luminance of each patch. At each luminance tested, we calculated the grand average over all display positions, and divisively normalized measurements by that average. As illustrated in Fig 2, at medium- and high-luminance, the CG247X showed greater spatial uniformity than our consumer-grade LCD (Dell U2415b): for the CG247X, spatial variation was 5.1% at medium and 3.5% at high luminance, whereas for the U2415b, variation was 8.1% at medium and 8.5% at high luminance. The uniformity of the two displays was comparable at low luminance (CG247X, 27% versus U2415b, 17%). Prior to normalization, there were, as expected, marked differences between low-, medium-, and high-luminance measurements. For example, at display position 5 (Fig 2, inset) on the CG247X, low-luminance measurements ranged from 0.07 to 0.10 cd/m2, medium-luminance measurements ranged from 57.70 to 57.93 cd/m2, and high-luminance measurements ranged from 113.9 to 114.2 cd/m2 (Table 1). We also quantified spatial surround effects; using a tripod at 1 m, we measured displayed luminance at position 5 comparing large (1920-by-1200 pixels) and small (384-by-384 pixels) 100%-luminance patches. For CG247X, the mean of 10 large-patch measurements was 0.56 cd/m2 greater than that of 10 small-patch measurements (two-sample t-test, p < 0.01), i.e., an increase of 0.50%. For the U2415b, the increase was 0.71 cd/m2, i.e., 0.67% (two-sample t-test, p < 0.01).

In-plane switching (IPS) LCDs, like our CG247X and U2415b, enable larger viewing angles than older LCD technology (e.g., twisted-nematic displays) [23]. To do so, IPS displays interdigitate electrodes (see 23]. For the displays we tested, vendor-issued specifications state a viewing angle of 178 deg, however, in the absence of further details, that derived measure is difficult to assimilate. We measured displayed luminance as a function of viewing angle over a range of azimuth and elevation (±60 deg). We fit a circular von Mises function (Fig 3, the CG247X and U2415b performed comparably in this regard. For the CG247X, the FW90M was 28.6 deg (fitted parameters: α = 1.45, κ = 3.37) and 32.6 deg (α = 1.65, κ = 2.62) for azimuth and elevation, respectively. For the U2415b, the FW90M was 31.2 deg (α = 1.60, κ = 2.85) and 31.0 deg (α = 1.55, κ = 2.90) for azimuth and elevation, respectively. At high-luminance we made a reduced set of measurements, assuming rotational symmetry, varying azimuth or elevation from 0 to 60 deg. These additional measurements yielded similar FW90M estimates. This descriptive model can be used to select a viewing distance with tolerable attenuation due to viewing angle. For example, if the CG247X is viewed from 1 m, a stimulus presented at the top of the display’s vertical meridian (i.e., elevation = 9.2 deg) would, due to viewing angle, undergo luminance attenuation by a factor of 0.97.

We presented a large, static test patch, measuring luminance with the LS-110 spot meter near the display’s center. We used a turntable to rotate the display (

A common misconception among vision researchers and clinicians is that LCDs do not flicker (i.e., that LCDs are temporally uniform). In fact, there are two major sources of flicker that can affect a LCD: first, backlight flicker which usually occurs at temporal frequencies (e.g., 1000 Hz) well beyond the critical flicker fusion frequency (e.g., Elze & Tanner [24], and Ghodrati, Morris, & Price [35]), and, second, the so-called frame response which occurs at the refresh rate of the display (here, 60 Hz) [23, 36]. Frame responses are largely attributable to an LCD’s inversion scheme: a feature of modern displays wherein the polarity of the video signal voltage applied to the liquid crystal material is inverted from one video frame to the next. This inversion minimises long-term degradation, or aging, of the display by minimizing the DC voltage across the liquid crystal elements. Frame inversion schemes typically have fine spatial structure, on the scale of individual pixels, making them mostly imperceptible (e.g., dot inversion schemes [36]). We quantified the temporal uniformity of the CG247X by presenting (nominally) static test patches at display position 5 (Fig 2, inset) and using the linearized photodiode device to measure displayed luminance over time. At each of 11 luminances (0, 10, 20 … 100%) we made 10 one-second recordings, averaging the Fourier amplitude spectra of those 10 recordings. Fig 4 shows the average spectrum at each luminance. The spectra of the CG247X revealed a frame response comprising a 60 Hz component as well as harmonic components at integer multiples of 60 Hz. The response at 60 Hz varied non-monotonically in amplitude with the luminance of the static test patch, peaking at a luminance of 50%. However, the CG247X appeared free of backlight modulations. This absence of backlight modulations freed us of the consequences of said modulations (often desynchronized with the frame refresh signal) on increment/decrement transitions between luminances (see Fig 5 in [24]). The spectra of our consumer-grade LCD also revealed a frame response, as well as 1.2 kHz flicker, likely associated with the back light. This latter temporal nonuniformity increased linearly with the luminance of the static test patch.

We presented nominally static test patches at display position 5 (Fig 2, inset), measuring luminance with a linearized photodiode device. At each luminance (0, 10, 20 … 100%) we made ten 1-second recordings, deriving the Fourier amplitude spectrum for each. Each spectrum illustrated is the average of 10 spectra. For each display, we normalized spectra such that 1000 corresponds to the DC component at 50% luminance; therefore, a value of 5.0 corresponds to approximately 0.15 cd/m2. The spectra of the CG247X (upper) revealed a frame response, comprising a 60 Hz component and harmonic components at integer multiples of 60 Hz. This frame response varied non-monotonically in amplitude with the luminance of the static test patch, peaking between 40 and 50% luminance. The spectra of the U2415b (lower) also revealed a frame response, as well as 1.2 kHz flicker, the amplitude of which increased linearly with the luminance of the static test patch (amplitudes above 5.0 are not shown, arrowheads). For the U2415b, mains noise (50 Hz) was apparent at high-luminance. lum., luminance.

For each display, we verified that the frame response was optical and not related to any radiated electromagnetic noise: We used the oscilloscope to visualize the Fourier amplitude spectrum online. We then interposed opaque cardboard between the photodiode and display which caused the disappearance of the frame response. For the U2415b, we similarly verified that the 1.2 kHz response was optical.

In general, LCD response times—the duration of the rise or fall of a step from one luminance level to another—vary as a function of both step source and destination luminance. This nonlinear behaviour is owing largely to mechanisms of response time compensation (RTC) (e.g., the work of McCartney [25]), a feature of many modern LCDs designed to enhance video. RTC mechanisms speed luminance transitions by transiently altering the voltage applied to the liquid crystal associated with individual pixels (e.g., Fig 1 in [27]; Fig 5 in [24]). We measured the CG247X’s response times by presenting luminance steps—both increments and decrements—to the linearized photodiode device. Step source and destination took values 0, 25, 50, 75, or 100%. As illustrated in Fig 5, response times varied as a function of both luminance step source and destination. For example, stepping from 0% luminance to 25% luminance took 24.5 ms, stepping from 75% to 100% took 12.9 ms, and stepping from 25% to 0% took 8.1 ms. All of these steps are the same height, but response times differ markedly. Overall, the response times of our consumer-grade LCD were less than the CG247X response times. However, as we will illustrate below, faster is not better; although RTC mechanisms reduced the response times of our consumer-grade LCD, they contaminated displayed luminance with overshoot and undershoot artifacts which are problematic for many applications in clinical and experimental vision research, including the presentation of mean-modulated flicker. RTC mechanisms lower “black-white-black” and “grey-to-grey” response times, which are used to promote displays to the gaming community and other consumer markets.

(A) CG247X response times. The leftmost gray box (labelled “0%”) encompasses four points showing mean response times for transitions from source luminance = 0% to destination luminances = 25, 50, 75, and 100% (x axis). These rise times (upward triangles) decreased with increasing destination luminance. The gray box labelled “25%” shows mean response times of transitions from source luminance = 25% to destination luminances = 0, 50, 75, and 100%. The fall time (downward triangle), from 25% to 0% luminance, was less than the rise times. Overall, response times varied as a function of both source and destination luminance, as is generally expected of LCDs. We made 10 measurements at each source/destination luminance pair; error bars, where not obscured by symbols, mark the full range (from minimum to maximum) of these 10 measurements. (B) U2415b response times. Graphical conventions are as in A. Overall, U2415b response times were less than CG247X response times.

At the outset of this study, we made preliminary measurements similar to those illustrated in Fig 5. We noticed that rise and fall times straddling 50% luminance were approximately equal (e.g., rise time from 25% to 75% = 16.3 ms; fall time from 75% to 25% = 17.1 ms) which led us to wonder whether the CG247X could be used to display achromatic, mean-modulated flicker without the introduction of unworkable artifacts. To better determine the CG247X’s potential suitability for presenting mean-modulated flicker, and its susceptibility, or otherwise, to overshoot and undershoot artifacts typical of LCDs implementing RTC mechanisms, we presented mean-modulated flicker on both the CG247X and our consumer-grade display, using the linearized photodiode device to measure luminance over time. We used a flicker period of 20 frames (333.3 ms), and contrast ranging from 20 to 100%. As illustrated in Fig 6, the consumer-grade display’s luminance traces revealed overshoot and undershoot artifacts symptomatic of RTC. The CG247X’s luminance traces, however, appeared free of RTC artifacts. We used these traces to estimate response times specific to mean-modulated flicker, illustrated in Fig 7. Overall, CG247X rise and fall times were greater than those of our consumer-grade LCD. However, with the exception of 100% contrast, CG247X rise and fall times were approximately equal, indicating its potential suitability for presenting mean-modulated flicker.

Flicker period = 20 frames (333.3 ms), and contrast = 20 to 100% in increments of 20 as marked. At 40% contrast, the arrowheads show examples of luminance step source and destination as used in the computation of response times (Fig 7). For each display, we normalized traces to the luminance step destination at 100% contrast. For the U2415b, over- and undershoot are readily apparent at low and moderate contrast. The CG247X, however, shows exponential rise and fall, regardless of contrast.

To further determine whether the CG247X could be used to display achromatic, mean-modulated flicker without the introduction of unworkable artifacts, we presented flicker at frequencies ranging from 0.94 to 30 Hz and contrasts ranging from 20 to 100%. We used recorded traces (similar to those in Fig 6) to derive cycle-averaged luminance. In Fig 8, we illustrate how cycle-averaged luminance was approximately constant for all flicker frequencies, and for contrasts up to 80%. At 100% contrast, cycle-averaged luminance decreased with flicker frequency, indicating that, at full contrast, the monitor is not suitable for presenting mean-modulated flicker. Cycle-averaged luminance recorded from our consumer-grade LCD (Dell U2415b) varied as a function of flicker frequency at all contrasts tested; this variation is problematic for presenting achromatic, mean-modulated flicker. We also used CG247X traces to derive cycle-averaged r.m.s. luminance. In Fig 8, we illustrate how cycle-averaged r.m.s. luminance decreased with flicker frequency, indicative of loss of contrast. The consumer-grade LCD was affected by both changes in cycle-averaged luminance and loss of contrast.

We presented mean-modulated flicker at a range of flicker frequencies (0.94 to 30 Hz) and contrasts (20 to 100%). We used waveforms (e.g., Fig 6) recorded from the CG247X (A) to derive cycle-averaged luminance; we divisively normalized that derived measure using the cycle-averaged luminance of a “reference” waveform, that is, the response to contrast = 20% and flicker frequency = 0.94 Hz. This relatively low-contrast, low-frequency waveform was chosen as reference because it should be easily realized by both displays. For clarity, cycle-averaged responses for contrast = 40, 60, 80, and 100% are offset by -0.1, -0.2, -0.3, and -0.4 log units, respectively (arrowheads). As shown, cycle-averaged luminance was approximately constant for contrast = 20 to 80% at all flicker frequencies tested (0.94 to 30 Hz). At contrast = 100%, cycle-averaged luminance decreased with flicker frequency. Cycle-averaged luminance recorded from the consumer-grade U2415b (B) increased with flicker frequency at all contrasts tested. Graphical conventions are as in A. We used waveforms recorded from the CG247X (C) to derive cycle-averaged r.m.s. luminance; we divisively normalized that derived measure using cycle-averaged r.m.s. luminance of the reference waveform (20%, 0.94 Hz). As shown, at all contrasts tested (20 to 100%), cycle-averaged r.m.s. luminance decreased with flicker frequency, indicative of a loss of effective contrast. Cycle-averaged r.m.s. luminance recorded from the U2415b (D) revealed both increases and decreases to effective contrast with flicker frequency. Each symbol is the average of 10 measurements. (None of the data in panels C and D is offset.) We modeled cycle-average luminance and r.m.s. luminance on the CG247X as a causal exponential decay (Methods). This model comprised one free parameter, τ. For the illustrated fit (blue), τ = 6.6 ms. The red symbols in panel C (slightly offset rightward for clarity) show the result of a validation experiment (see

Taken together, Fig 8, and the traces used to derive the measures plotted there, indicated a simple relationship between nominal and displayed luminance on the CG247X, namely, that the latter was, simply, a low-pass-filtered version of the former. To test this hypothesis, we modeled the function transferring nominal luminance to displayed luminance as a causal, exponential decay (Methods). We optimized the single free parameter in this model, the time constant of the exponential decay (τ), by minimizing the sum of the squared error between the model-derived cycle-averaged mean luminance and cycle-averaged r.m.s. luminance, and those derived from the photodiode traces. For the CG247X, the fit is illustrated in Fig 8 (blue). There, the fitted parameter, τ, was 6.6 ms. To assess the fit to cycle-averaged luminance, we computed the root-mean-square error (RMSE) separately at each flicker contrast. For the CG247X, the RMSE was negligibly small for contrasts from 20 to 80% (ranging from 6.0e-4 to 6.3e-3 normalized units). At 100% contrast, RMSE was highest at 0.093. This simple model was a poor fit to the U2415b, not illustrated in Fig 8. For the U2415b, RMSEs were high, ranging from 0.04 at 20% contrast to 0.15 at 60% contrast. To assess the fit to cycle-averaged r.m.s. luminance, we calculated the square of Pearson’s correlation coefficient, R2, separately at each flicker contrast. For the CG247X, R2 was high, ranging from 0.9965 to 0.9999. As expected, the same calculation for the U2415b was consistent with a poor fit; at its worst, R2 = 0.03.

To quantify the nonlinearities associated with high-contrast, mean-modulated flicker, and to quantify temporal dependence between frames, we used a paired-pulse paradigm [37, 38]. We presented paired biphasic luminance pulses at position 5 (Fig 2, inset), systematically varying the inter-pulse interval, T (Methods). We used the measured responses to individual pulses to predict paired-pulse responses, and to model the display’s nonlinearities we subtracted each paired-pulse response from its prediction. Fig 9 shows the nonlinear behaviour of the CG247X and, for comparison, that of our consumer-grade LCD. In our CG247X, a nonlinear mechanism appeared to speed the transition between white and black (100% and 0% luminance, respectively; leftmost upper panel in Fig 9B). When paired pulses were separated by 16.67 ms or more (the three rightmost upper panels in Fig 9B where predicted and displayed luminance are approximately equal), the CG247X behaved linearly, that is, we saw no evidence of temporal dependence between frames. In our consumer-grade LCD, a nonlinear mechanism appeared to attenuate the transition to white (100% luminance; leftmost lower panel in Fig 9B). This attenuation reconciles with Fig 6 (lower), which shows marked overshoot at moderate contrast (e.g., 60% contrast, middlemost panel of Fig 6), but a near absence of overshoot at high-contrast (rightmost panel of Fig 6). Compared to the CG247X, the U2415b’s nonlinearities were large in magnitude and long-lasting. Paired pulses separated by as much as 33.33 ms (the third lower panel in Fig 9B, where predicted and displayed luminance are unequal) evoked nonlinear behaviour in the U2415b, that is, we saw clear evidence of temporal dependence between frames.

(A) Illustration of the paired-pulse paradigm. We presented a single biphasic luminance pulse (e.g., left panel), parametrically varying its latency relative to a trigger (cf. left and middle panels). We then presented a pair of biphasic luminance pulses (right panel), parametrically varying the offset between pulses comprising the pair, T = 0, 1, 2, and 3 times the frame period (frame period = 16.67 ms). Single-pulse responses can be used to predict the paired-pulse response; differences between this prediction and the displayed luminance model the display’s nonlinearities. (B) Nonlinear behaviour of the CG247X (upper). The four panels show responses to paired pulses with various offsets, T; we normalized responses (0, 0.5 and 1 corresponded to 0, 50 and 100% luminance, respectively) and then subtracted the baseline. For each offset, the predicted displayed luminance derived from single-pulse responses is shown in blue, and the measured displayed luminance in response to paired pulses is shown in black. The measured responses are an average of 16 recordings. The difference, that is, the nonlinearity, is shown in red. For the CG247X, superposition (T = 0 ms) of pulses evoked a nonlinearity which accelerated the transition from 100% luminance to 0% luminance. There was negligible nonlinearity of displayed lumiance for T > = 16.67 ms. Compared to the CG247X’s nonlinearity, the U2415b’s nonlinearity (lower panels) was large in magnitude and long-lasting, affecting subsequent frames (to T = 33.33 ms). Graphical conventions are as in B.

The DC content of your drive waveform should not exceed some tens of mV or you will damage the display permanently. If you are driving your (static) display with single ended port pins you will get less contrast and will damage the display eventually. To minimize the DC content you want the out-of-phase waveform to be very close to 50% on off ratio. You can work out the permissible error in time from the frequency (which should be in the range 32-100Hz for this display).

5V is required for Lumex displays that operate up to 80°C, 3V is okay for 60°C. With your 3V supply (and properly driving the common) you will be driving the display with 6V RMS so it should be fine.

It"s quite possible to source LCD displays that fit your requirement, in fact custom displays are more common than standard ones. There is an NRE cost and usually a minimum order quantity. You get to specify the type of drive (static or the more common multiplexed), pick a fluid temperature range, a viewing angle, glass size, type of termination (zebra strip, FPC or pins) and so on. Figure on a starting cost in the low thousands of dollars for an ordinary display.

Newhaven 20x2 character Liquid Crystal Display shows characters with white pixels on a black background when powered on. This transmissive LCD Display requires a backlight for visibility while offering a wide operating temperature range from -20 to 70 degrees Celsius. This NHD-0220DZ-NSW-FBW display has an optimal view of 6:00. This display operates at 5V supply voltage and is RoHS compliant.

Easily modify any connectors on your display to meet your application’s requirements. Our engineers are able to perform soldering for pin headers, boxed headers, right angle headers, and any other connectors your display may require.

Choose from a wide selection of interface options or talk to our experts to select the best one for your project. We can incorporate HDMI, USB, SPI, VGA and more into your display to achieve your design goals.

I was working with the tft_eSPI library & esp_now. Everything was working fine, then I reuploaded the sketch and started getting this weird noise at the top of the LCD. Additionally when I use tft.fillScreen(TFT_BLACK); the screen remains white. I"ve tried other colors like TFT_BLUE, which seems to work fine (maybe a little washed out). I"m thinking the screen it"s self is just broken, but I"m also noticing that every sketch displayed on the screen is cropped and offset about the same amount of space that is distorted. Again I"m not sure if this is an actual "Issue" or just a broken display. Any insight would be helpful and greatly appreciated.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey